Spring gun tuning: Part 1

Spring gun tuning: Part 2 – Building a mainspring compressor

Spring gun tuning: Part 3 – Mainspring compressor continued

Spring gun tuning: Part 4 – Let’s disassemble a gun!

Spring gun tuning: Part 5 – Powerplant disassembly

Spring gun tuning: Part 6 – Disassembly completed

Spring gun tuning: Part 7 – Disassembly of other spring guns

Spring gun tuning: Part 8 – Disassembly of other spring guns, continued

Spring gun tuning: Part 9 – Cleaning and deburring

by B.B. Pelletier

Lube the parts just before you reassemble them so they won’t attract dirt. Use another paper towel-wrapped screwdriver blade or dowel to spread a thin coat of moly grease on the walls of the clean spring cylinder/compression chamber. You’ll be able to see the metal through this coat because it is so thin.

The piston and seal

Spread a thin even coat of moly grease around the piston seal and about a seal’s width back on the body of the piston. Also, coat the rear piston skirt where it flares out wider. Coating the entire HW piston is pointless, because it doesn’t contact the cylinder except where it is larger in the rear. I lube the front of the piston, behind the seal, in case the seal ever melts and there is metal-to-metal contact. Also lube the piston’s cocking slot and the spring guide rod inside the piston. (Note: some guns don’t have guide rods inside the piston) Next, insert the piston into the spring tube, keeping the cocking slot in the piston aligned with the one in the spring tube. Be careful not to cut the seal as it goes into the tube, and don’t worry about the lube that’s scraped off as it goes in. That’s why you lubed the inside of the cylinder, as well.

The piston seal is coated uniformly with a thin layer of moly grease. Note that I also coated the front part of the piston body, as well as the cocking slot.

When the sliding cocking link is installed, it keeps the piston from rotating. It’s also lubed with moly.

The mainspring must fit inside the piston with a little room to move, but not much. The closer the fit, the less vibration the gun will have.

If there is too much room, a thin piece of strong metal plate such as stainless steel can be bent to line the inside of the piston, taking up space. This plate needs to be as long as the inside of the piston, and it should line the entire inside without overlapping. The mainspring has to fit inside this liner, so measure carefully before cutting. I don’t care for this method, so I search for the tightest-fitting mainspring I can find.

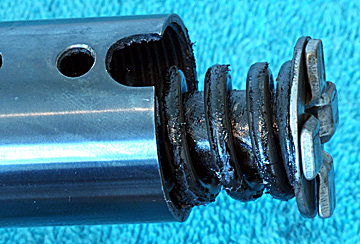

Now lube the mainspring with what Jim Maccari calls velocity tar. It’s an extremely viscous grease that clings to the coils of the spring and dampens vibration. And, to answer a reader’s question from several weeks ago, it doesn’t slow the velocity much at all. The difference in smoothness is worth the 10 f.p.s. you may lose. No other lube works as well as velocity tar. Look at the picture for how much to use.

Beeman used to sell Mainspring Dampening Compound, which was a thick silicone grease, but it did cut velocity significantly. Regular petroleum and lithium greases are simply not up to the task for this application, though they do work well in lower-powered spring rifles such as Diana 27s and IZH 61s.

Slide the mainspring as far into the cylinder as it will go. The spring that sticks out is what the mainspring compressor has to compress before the threads on the end cap start to engage.

This is what a low-powered spring looks like when it’s pushed in as far as it will go. More powerful springs are longer and stick out farther. Note how much velocity tar was used on the spring. The spring guide is installed and also has tar on it.

B.B.

Thanks for this great set of articles.

Jimmy

B.B.,

Some recommend lubricating only the outside coils of the mainspring. What are your thoughts on this?

Ehrich

Excellent detail in this series, B.B. If you had chosen cars instead of airguns 50 years ago, I’m sure you could easily have been a writer for the Haynes DIY mechanic books. Thanks !

Ehrich,

I lube the inside of the coils, as well as the outside, but I’m not fanatical about it. I believe the grease migrates as the gun is fired. At least evey gun I have disassembled that has velocity tar, has grease all around the coils. Also I put tar on the mainspring guide. I don’t know whether I mentioned that in the posting, but I smear a very thin coat around the outside of the spring guide, which contacts the inside of the spring coils.

B.B.

B.B.,

Thank you for the clarification of where to apply velocity tar. This is exactly what I wanted to know.

Ehrich

Apparently the Eun Jin Sumatra will soon be available in .177 and .25.

Two questions:

1) will PA carry these?

and 2) what is your preliminary opinion on a sumatra in .25 cal?

Seems like the perfect caliber for this rifle to me, but I have been wrong before =D

Sumatra,

I don’t know what Pyramyd plans to carry, but I will ask.

The .25 would be a nice caliber for this rifle, as is .22

B.B.

I have a .22 Career 707. I have a Leupold 3-9 EFR scope on it. It is great! Powerful, accurate, wonderful hunting gun. Either a 707 or Sumatra in .25 would be a wonderful gun.

I would personally be much less interested in a .177 as it would not be able to take advantage of the power. On the other hand, a .177 version adjusted to a low power level would exhibit many shots between refills.

It will be fun to learn B.B.’s thoughts.

Ehrich

Ooops! B.B. is a much speedier at a keyboard than I.

Ehrich

B.B. would you consider doing a review of some of the newer Chinese guns like the B-26 or B-40? I know you have not had good experiences with past chinese guns, but this recent crop is made to a noticeably higher standard, with decent quality control. I have a B26-2 that, at $160 I could reasonably afford. The gun is accurate, has a very pleasant trigger, an attractive wood thumbhole stock that handles beautifully, and very nice bluing. You will be hard pressed to find negative comments on this model by anyone, other than it was designed with a rather high comb. I think you would be doing readers a great favor by pointing this gun, or it’s recent peers, out to them.

I think, too, that it may well merit your attention, at least as much as the many Crosman and Daisy guns you have reviewed.

I’m a little confused – I know in previous posts on lubricating springers you say very occasional use of silicone chamber oil. But won’t this mix with the molly you just lubed the chamber and piston with? I think I remember from a prior post that bad things happen if molly contacts other types of oil. Could you clarify?

Now I’m REALLY confused. I just went back and checked your March 2005 blog “How, Why, & When to Lube Your Spring Gun’s Piston Seals” and you say “Use oil – and nothing else! Don’t use anything but oil in spring guns. Don’t use Molly, regardless of what you read.” And now I see a picture of your piston seal coated with Molly grease. I am not tryibg to make trouble – I am actually right in the middle of my first tune attempt, and I’m wondering what to do! Please post an answer.

b.b.

i am the guy who keeps asking about mendoza rifles. i finally got the rifle (rm-600 .22) and its cool as crap. with a bug buster its about 9 lbs. weight doesn’t bother me but the trigger is almost too light to me (2.5 lbs, two stage non adjustable). it might be just me since all i have owned is pump pneumatics but this thing is LOUD! the first time i shot it, i thought i bought a firearm and it scared the crap out of me(non anticipation). left a ringing in my ears.

i only shot it 3 times before i thought the whole block was hearing it(i can only screw around with it when my girl isn’t around since she hates guns, which is only like once a week). looking down the inside of the stock by the cocking lever i can see about a third of the mainspring and it looks in good shape. its not vibrating oddly to me so i don’t think the spring is bad. it does diesel real bad. like when i exhale cigarette smoke.

yet to be more off subject. i bought some lead balls for it (H&N Graphitized). are lead balls supposed to roll down the barrel before firing? i know they are the right caliber, .22. unless i am shooting at a slight abgle up they roll right out. should i not be using them then? i have seen tests on penetration with lead balls but no advice on what rifles to use them with. i have gamo hunters and crosman premier wadcutters to use as well.

sorry for the lengthy questions but mendoza still hasn’t responded to my questions about the rifle and you seem to give good advice which is awesome!!

B26,

I happen to have a B26, so why don’t I look at that?

B.B.

Confused,

You haven’t read everything. In the very next sentence of that post I said, “Moly that is suspended in solvents will diesel and may damage your gun!” I will now change that from MAY to WILL.

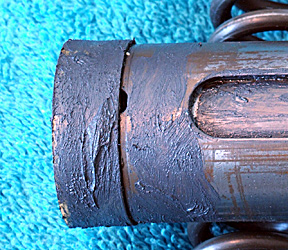

Whewn I wrote that posting, I never thought I would be showing you readers the insides of spring gun powerplants. If you look closely at the piston in Friday’s post, you’ll see rust on the steel where I put the moly. That rust was caused by Beeman Pena-Dry, a moly application suspended in solvent. Dri Slide is the same thig. Those products were used by airgunners who didn’t want to disassemble their powerplants, the way we have. They squirted the liquid through the air transfer port and the moly particles were supposed to embed in the chamber walls and on the piston body. The solvent carrier was supposed to evaporate harmlessly.

What it actually did was rust the inside of the gun and the piston. Beeman actually sold their product with that exact application in mind, and the directions came with the bottle.

The tuneup I am doing now isa real tune. I’m applying moly grease to the exact locations it needs to be to do its thing. There is a big difference between what I am doing and just dumping a miracle product down the transfer port. – like blueprinting a V8 engine versus pouring mothballs in the gas tank!

Because I never imagined showing you readers the inside of a spring gun powerplant, I told you to use chamber oil sparingly. It’s the only product that can be applied safely without disassembling the gun.

B.B.

Mendoza,

STOP!

Your gun is detonating, not just the dieseling that all powerful spring guns do. If you continue, you will break your mainspring.

DO NOT use a round ball if it rolls down the barrel! That would be like dry-firing.

It sounds like iyour rifle’s bore is too large.

What you need to do is find the LARGEST, tightest-fitting pellets you can for your gun. It would also help if they are heavy, as well. I will tell you now that all Crosman pellets are going to be too small for your gun. The one possible exception MIGHT be the real Crosman Premier that still comes in the cardboard box, but with a bore as large as the one on your rifle, there is no guarantee.

The Beeman Crow Magnum is pretty large, as is the Silver Arrow. The Gamo heavier pellets are also larger.

B.B.

I did read everything in your article, many times over, but being inexperienced I did not know the difference between Molly suspended in oil and the type of Molly you show on your piston seal. Thank you for clearing things up.

-much less confused

b.b.

thanks

thats good advice.

i haven’t tried firing the premier wadcutters but i tried fitting one in the rifle and they seem to be tighter than the gamo hunters i have. i had to remove it with the cleaning rod i have. there is also a gun shop that sells diana’s and i assume they have pellets so i will go down there when i get paid again and try to find some heavier bigger pellets to try. when i first shot the gun it was fairly dark outside and i don’t remember seeing a flash coming from the barrel indicating a detonation. like i said it might be just me. a better way to describe the noise it is making is more like a high power pneumatic nail gun.

also the owner’s manual said i should have got some pellets, oil and a carry strap with the rifle. i emailed pyramid air about it. maybe the mendoza pellets work a lot better in it.

much less confused,

Thanks for getting back with me. I just wanted to set the record straight on moly. By itself, molybdenum disulfide is a wonderful friction reducer, but the rust on my piston was caused by the solvent vehicle. I guess it works on brass lockworks, but it should never be put on steel.

If you follow the link I gave to velocity tar, you’ll find the right sort of lubricants for this work.

B.B.

Brian,

If your Crosman wadcutters are really tight in the gun then they are okay to use. Don’t confuse tight with hard to seat, though. Crosman uses lead with antimony in it, That hardens the lead, so the tight feel could be the resistance of the pellet to the rifling. Once the pellet is fully engraved, this resistance goes away. and a loose p-ellet will cause detonation.

A detonation is a pop that you can hear. The way you described the sound of the gun, you had detonations.

I’m very surprised that Gamo Hunters were a problem. I would have guessed otherwise.

B.B.

WHICH IS THE BEST GUN FOR HUNTING AND LONG LIFE.THE WEBLEY SCOTT STINGRAY OR THE RWS350?

Either of the two guns mentioned will last for hundreds of years with proper maintenance. Both have the power needed for hunting. I would recommend .22 caliber.

B.B.

Of topic, but….

I’m considering a new springer in .22 and like the idea of the Diana 48/52 as it is one of the guns you refer to most in your blog. BUT……there is no review of this gun to be found on your blog. Could you do an in depth review so I can know all the ins and outs of this gun? Is there anything better for the money? I have a .177 Crossman RM577 for plinking so the .22 would be for hunting and some plinking. Thanks.

Bob,

I am flabbegasted that I have never reported on either of these rifles, but several searches failed to turn up a posting. I refer to them all the time, and I guess that has clouded my memory.

I am way overdue on this assignment, so look for it on Monday.

B.B.

THANKS!!! I have the money in my pocket burning a hole!

If you can look at the .22’s that’d be great although I would assume that the similaritys between the two calibers would be pretty large.

Make sure and do an ammo test so I can get the best while I’m at it.

Pending your review I’m looking at the 48/52, a bugbuster 4×32, case, ammo, sling clip, etc.

Thanks again…….now will you move the calender faster!! : )

Bob,

I understand your need! I can tell you right now to just get one. It’s a very good airgun. The ONLY difference between the 48 and 52 is the stock.

Get JSB Exact 15.9-grain pellets, and Crosman Premiers. A tin of Beeman Kodiaks would also be nice.

To mount the Bug Buster you need 2-piece rings, because 1-piece rings are set too far apart to couple with the close tube mounting areas on this compact scope.

B.B.

Thanks, BB.

Odd thing tonight with the Crosman RM577, which I guess is a fairly lame gun made by Mendoza. Still on the shelves at Cabela’s but when I inquired at Crosman about a new rear sight they said it was a discontinued model.

Anyway, I’ve had this for about two weeks and its my first intro into modern springers. I’ve been reading all you tips about holding the gun lightly. My groups improved but were still eratic.

Tonight, after a bit of frustration, I held the gun tighter than a banker with a promisary note. Spot on the bullseye. I kept holding tight and got about a 1/2″ group at 15 yards….as good or better than most groups I’ve had. This with a 0 magnification red dot sight.

I continued to shoot this way and had much better success the rest of the evening. I’ve got about 450 pellets out of this gun, mostly RWS 8.2gr wadcutters. I tried some heavier pellets and the drop is huge…..aim about 6″ high at 20 yards.

Anyway, moral of the story: It pays to try different techniques, even some that don’t seem to make sense.

Bob,

You’re absolutely right. I, too, have found a few spring guns that needed a death grip to shoot well. The Beeman Kodiak seems to like it rough, for one.

Good for you for experimenting!

B.B.

hello can you please tell me a website ( usa or u.k) where i can order spare parts for my spring guns ? ( for example a spring for my bsa scorpion pistol). there is this site called ” tw chambers ” but they are unreachable…

thanks

benoit

Ben,

I would start right here with Pyramyd AIR.

B.B.

BB

I followed the link you provided, for velocity tar, they asked for a password. Do you know of any other source?

Ed

Ed,

When I gave the link, it was good. I seems that site has become a little strange since then.

I know of no other source. You might try an extremely viscous grease, like that used for packing long-term joints.

B.B.

BB,

Is it worthwhile to do a tune on a gun without a new piston seal and spring? I’ve got a B26 I bought as a project gun to learn how to do some maintenance with, and I guess I’m curious if it’s worthwile to go through the tune without those new pieces.

-Josh

Josh,

Yes, it can be worthwhile to tune a gun with the existing parts if you have some lubricants. Velocity tar is the most important and moly grease is second. You won’t get greater velocity but you can make the firing cycle smoother.

You can also get rid of all the burrs and sharp edges that make your rifle rougher right now. And this is a good time to clean the excess grease from the gun and lube it correctly.

B.B.

Hi B.B.

So I got the trigger out of my B26, and it’s so oily! Actually the whole gun is, so it’s going to be fun to tune it and see how it changes.

Anyway – how do you recommend cleaning the oil out of the trigger assembly? Would you just douse it in the whole thing in denatured alcohol? I don’t think I could get any type of cleaning utensils like a q-tip into the case so that’s about the only thing I could think of.

-Josh

Josh,

I would immerse the trigger in mineral spirits or alcohol. It may take several immersions.

Then lube the sear contact with moly grease. You can lube the pivot points with oil, but be very sparing.

B.B.

Hi BB., I’ve been reading your Blog on tunning and lubrication etc., went to the site where you say we can get the lube, well I have gamo rifles and evidendly these folks and gamo must not get along because they have nothing for gamo, where do you recommend we go if we wanted a tune kit, spring or any other parts for the gamo rifles? I don’t need anything right now, but just in case I deceide to go in there and hone the chamber and polish everything up, where can I get my replacement parts? Thanks a lot and have a really nice Christmas and Happy New Year. Marvin One other thing, how thick is the chamber wall in the gamo rifles , shadow sport, 890s and so fourth. Thanks again. Marvin

Marvin,

Many people don’t consider Gamo rifles worth the effort to tune, so they don’t mention them. The same products will work on Gamos, but you may have to correspond with these people to find things like new mainsprings and seals.

Of course the gas spring conversion will take care of everything in one shot.

Gamo spring tubes are too thin to think about honing. Maybe a light polish is all you want to do. But they are pretty well finished to begin with.

You need to find a good Gamo forum and make some friends there. Google it, or just go here:

http://www.network54.com/Forum/479035/

B.B.

BB,

A couple of questions…when you mentioned the method of using thin metal plate to line the inside of the piston to take up space:

1. Should the plate be fit snugly enough that there is continuous contact between the outside coils of the spring and the inside of the piston wall?

2. When fitting the plate to the piston, do you line the entire inner circumference or do you need to leave a gap to keep the cocking slot in the piston clear?

3. Is it ok to just use a sleeve of metal like you described- wouldn't it tend to creep out the back of the piston over time?

I agree with you in that this seems like a crude method for tuning, but a bunch of folks on the forums seem to have had great success with it and I've been thinking about giving it a shot… I've already done your recommended lubrication&deburring procedures- just trying to get the last bit of performance out of my gun (rws 34 panther).

Thanks for the great blog & info,

newtooner

Newtooner,

The plate will be pushed tight against the inner piston walls by the mainspring. Your concern is to roll the plate and fit it into the piston with the mainspring. There isn’t a lot of room in there, so the plate has to be thin.

Yes, wrap enough metal so the ends touch if possible. The plate will be inside the piston so no worries about the cocking slot.

You can make fold-over tabs at the front of the plate, so the end of the spring bears on them and keeps them inside the piston. I’ve see a couple made that way. But when the gun is cocked, almost the entire spring will be inside the piston anyway, so the plate tends to get pushed back inside if it wanders.

B.B.

“Spread a thin even coat of moly grease around the piston seal and about a seal’s width back on the body of the piston. Also, coat the rear piston skirt where it flares out wider.”

This is a part of what you ve wrote about lubricating the powerplant. What do you mean by rear piston skirt where it flares out wider. What is the piston skirt and where it gets wider?

thnx

Piston skirt,

B.B. is still out of town, but I got this answer from him by phone:

The Weihrauch pistons and some others are wider in the rear. Other pistons may not be, so just lubricate the last have inch of the skirt.

Edith (Mrs. B.B.)

The piston skirt is the open end of the piston, opposite the end that holds the piston seal.

I’ve worked on quite a few springers, and on every one that I remember the piston skirt was expanded out a little larger than the rest of the piston body. This helps keep the piston centered in the bore at the rear (the piston seal does it at the front). If the entire piston were that larger diameter it would also accomplish the same thing, but that would greatly increase the surface area – and thus friction area – between the piston and the compression tube wall. It would also make it harder to keep the entire friction area lubricated.