by B.B. Pelletier

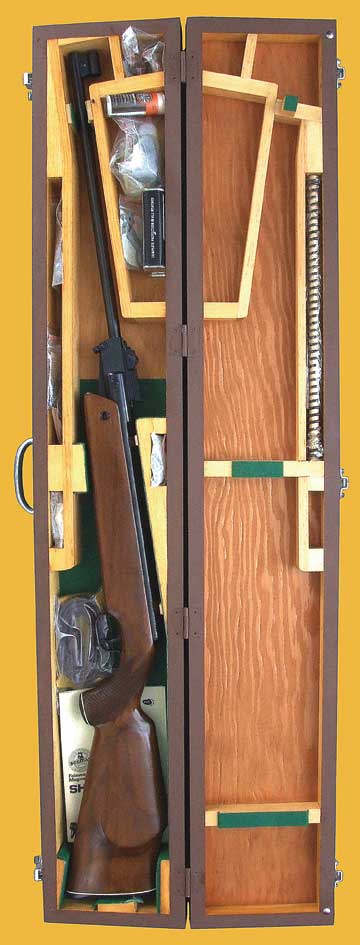

My enshrined 124.

Today, I’ll complete the tune on the FWB 124. A couple people have asked about this gun. What makes it so special? Well, it’s lightweight, accurate, easy to cock and shoots like a dream. It’s the very rifle AlanL has been searching for but doesn’t realize it.

Back in the 1970s, when the FWB first came to the attention of airunners, it was considered one of the most powerful springers available. Together with the BSF S55/60/70 and the Diana 45, it was one of those rare air rifles that would sometimes shoot faster than 800 f.p.s. Today, we wouldn’t give it a second look with numbers like that and here is what we would miss. We would miss owning a Mercedes SSK convertible, just because it doesn’t go as fast as a Mustang SVO. Nobody would give any thought to the fine coachwork, the burled wood dash or the exotic leather seats. No, they would all be focused on the speedometer and miss one of the finest examples of its kind ever to have been built.

What to expect

With a modern tuneup, like the one I’ve done here, the 124 should top 840 f.p.s. with Crosman 7.9-grain Premiers. I showed you the tuneup kit yesterday. Today I’ll install it along with some lubrication that I always do on a 124. Of course, this is one more reason for owning a chronograph.

Cutting up the old seal

Before I begin, I had some comments that I will now address. First, someone asked me how I cut the thick piston seal to remove it. I mentioned a special knife that I’d like to show you. This tanto-shaped blade comes on a Gerber Crucial multitool that Edith gave me for Christmas. I keep it in my desk drawer and it is one of the handiest multitools I’ve ever seen. The knife blade is very stout, so it handled this job like a breeze and a few passes over the Warthog got the blade sharp in moments.

A Gerber Crucial multitool has a tanto-shaped blade that was ideal for cutting the old seal into pieces, as shown previously.

Removal of old seal material

The second tip is for Derrick38, who says it can be tough to remove old seal material from a compression chamber. Yes, it can! But I found that the patch removal tool that goes on my Thompson/Center Hawken ramrod is very good at scraping in those tight corners.

The patch removal tool on a Thompson/Center Hawken ramrod is great for picking old seal material out of the crevices of the compression chamber.

Sizing the new seal

The first thing to address is the piston seal. This one fit pretty tight in the spring tube of the rifle, so I decided to remove some material from the edges. There are a lot of ways to do this, and I chose the easiest one because I’m a guy who likes simple. I held the piston with seal in my right hand and a piece of 220-grain sandpaper in my left hand and proceeded to scrub off a tiny bit of the edge of the seal.

This is the way to make the new piston seal a trifle smaller.

You have to know when to stop. I just wanted the new seal to fit in the spring tube with slightly less resistance, which it did after a few minutes of work. Next, I cleaned the inside of the piston with denatured alcohol and Q-tips. It was caked with dried moly or tar that had to be removed. The 124 piston is very heavy for the power the gun develops, so heavy pellets should work pretty well.

Lube the compression chamber walls

I had cleaned out the compression chamber earlier, so now it was time to smear moly grease on the inside walls of the chamber. For that, I use a dowel with a paper towel folded over the end and held on with a rubber band. It allows me to accurately coat the inside of the cylinder.

Moly grease on a paper towel on the end of a dowel is the way to lube the inside of the compression chamber.

Lube the piston

Next, I lubricated the piston before putting it back in the gun. I put a stripe of moly grease around the front with the seal and another around the rear where the piston flares out.

A stripe of moly grease around the piston seal and another one at the rear of the steel piston will keep things slipping along.

The piston can now be inserted back into the spring tube, keeping the cocking slot aligned with the slot in the spring tube. When the front of the piston is in the tube, that’s the best time to lubricate the rear of the piston and the piston rod. Shove the piston into the tube with the new mainspring.

A stripe of moly grease around the rear of the steel piston keeps the metal-to-metal contact lubricated.

Install the sliding shoe/cocking link

Once the piston is inside the spring tube, the sliding “shoe” that connects the cocking link to the piston can be lubricated and installed. A wide spot in the spring tube slot accepts this shoe.

The shoe is lubricated with moly grease on both sides and dropped through the wide spot in the spring tube. It rides on a special bearing surface on the piston, so that was also moly-ed before installation.

Lube and install the mainspring

Next it was time to install the new mainspring. Before I did that, the spring got a liberal coating of black tar, the open gear lubricant that deadens vibration. I smear the front half of the spring first, then insert it into the piston and use it to hold the spring so I can lube the rear half.

Caution–here is where I screwed up!

What the picture shows is too much black tar being put on the mainspring. I didn’t know that until the job was finished and the gun back together, of course, but I now have a rifle shooting 7.9-grain Premiers at 670 f.p.s. instead of the approximately 840 f.p.s. I expected. I used too much because Jim Maccari said the Mongoose kit I selected was a loose fit and needed tar to calm the vibrations. I hate vibrations, so I went overboard. The fix will be to take the gun apart and remove a lot of the tar I applied.

This is too much black tar. I will have to remove a lot of it.

One thing about fitting a mainspring to a rifle. The tightest end of the spring always goes over the spring guide in the rear.

Lube the baseblock and pivot bolt

The FWB 124 has a baseblock bearing on just the right side. The left side is plain. I smeared moly grease on both sides and also on the pivot bolt before it was inserted.

Moly on both sides of the baseblock and on the pivot bolt will reduce the cocking effort to the minimum.

The trigger unit is now pushed back into the spring tube, keeping tension on the safety spring as you go. When the bolt hole lines up, the bolt is screwed in and the job is just about finished. Just put the action back in the stock and you’re done.

Mainspring compressor make this an easy job.

The tuned rifle cocks easily at just 23 lbs. Beeman used to advertise the cocking effort at 18 lbs., but all the 124s (about a dozen) I have tested were around 21-23 lbs. So, we’re in the ballpark. Of course, the velocity is low, but I’ll take care of that in the next report. I’ll also shoot the rifle for accuracy with open sights.

The trigger

The trigger is one thing I never learned to adjust on a 124 and I used to think it was impossible, but I once owned Mrs. Beeman’s 124, which I named the Queen B. That trigger broke at less than a pound, so someone knows how to do the job. Just not me.

Irony at work

Of course, the new pliable breech seal was installed and the petrified “new” breech seal I had tried went back into the box with all the other ruined new parts. I find it incredibly ironic that the owner of this fine rifle had wanted to preserve it for all time and it didn’t last as well as a similar rifle used every day. I guess man plans and God laughs.

Good Morning All, it looks like I might get the first comment of the day.

My 124 from the 80's is shooting the old silver jets at about 750. The gun is all stock as far as the internal parts go.

Last weekend three squirrels found out the hard way that this combo still works.

Mike

Good morning B.B.,

Guess I should have tried the refresh button first!

Again, Happy St Patricks Day to all!

Mr B.

Good morning B.B.,

Guess I should have tried the refresh button first!

Again, Happy St Patricks Day to all!

Mr B.

BB, I'm surprised that you'd lose that much from an overabundance of tar. Especially if you're using Maccarri's tar, which isn't quite as viscous as that used by some others.

I'll be curious to find out if you're cleaning the spring off really gets you back all that power.

Incidentally, a while ago I reported on a Mendoza RM200 in which the velocity took a major poop after converting it to a parachute seal. I ordered a new Mendoza seal for the gun, and it was significantly different from the one that came out. It's ALMOST a parachute design with a taper to a larger diameter towards the front of the seal. And it's much softer.

It was a much tighter fit and I was tempted to trim it down a bit, but I decided to try it as it was. Velocity increased by about 80-90fps and the gun is now much quieter while firing. This tells me that the big problem with the other seal was leakage, despite the fact that it seemed to fit well.

No doubt that the drag of this new tight-fitting seal is still bringing things down somewhat, but for indoor shooting it won't really matter.

To one and all,

You need to click on the link for the Queen B. Be sure and put on a bib to catch the drool.

Mr B.

Chuck,

That is a good looking table. I have no doubt when you least expect it you will see it in service as a bar table, sewing table, and picnic table for the grandkids. Don't turn your back! She'll swipe it!

Now I will make myself unpopular: If you were going to build something that big, why not just buy a 4' tubular folding plastic table?

-AlanL

Hi BB,

The piston seal on my chinese side lever springer is a nylon type material, secured to the piston by a screw through its centre,it also looks a bit thicker than the new seal shown for the 124.

Good after market tune up parts for this rifle may be hard to come by.

The seal itself is in good condition.could it be improved?

I know I'm trying to make a silk purse out of a pigs ear, but I love that little gun.

Cheers.

Dave.

Vince,

Re RWS 350: Thanks for your thoughts on this. You've made me wonder. I'm sure I got a brand new gun and not a refurb. Is it at all likely that it might have piston damage? I wouldn't want to just return it to Pyramyd, especially now that I've dinged the muzzle. It's not fair to them. Still, do you think they will break it down for me under warranty and look inside? I don't have a spring compressor or I might even venture this myself.

What I really need is for somebody with experience with this rifle to cock it and shoot it and hear it. I just don't have enough experience to tell normal from abnormal. I've GOT to get that chrony, and an accurate spring tension gauge to measure the cocking effort. My bathroom scale is a good one, but cocking the rifle by pushing against it is an unnatural motion and angle on the gun. Also, with the front sight in place my hand grasps the muzzle at least two inches from the end and I lose leverage that way, increasing the cocking effort. I need to find a truly reliable way to measure this from the natural position and distance.

-AlanL

Dave, which Chinese sidelever are you talking about? The only Chinese gun I can think of that uses a synthetic seal retained by a single screw are the Norica clones made my Shanghai, and I don't remember any of them being sidelevers.

Hi Vince,

The rifle is more a carbine AK47 lookalike with a collapsing stock.

The stamp on the rear is a large X with what looks like three small A's across the middle,BB knows the rifle but I can't remember the name he told me,sorry.

I have only taken the gun apart once and then, nearly knocked my wifes head off when the spring…sprung.

My workshop assistant(Wife)has now resigned and I have not had it apart since.

My memory is bad and you are probably right that the seal was in fact not synthetic.

It does have a centre screw though.

Dave.

BB,

I hate to copy Vince, but he's right: the tar can't be the whole story. Perhaps the seal is too tight or too loose:). I would hope it is too tight and will wear in with a couple of hundred shots.

Also, did JM say anything about spacing the spring? He seems to like to give you the option of mild/easy cocking or powering up with spacers.

Dave,

The leather seals have a plastic center holder with a screw in the middle. Someone could have changed to a synthetic seal, also. Assuming its leather, you need an adapter to change over to an Apex type seal. The adapter can be as simple as a stack of washers (varying diameters) or a beautiful work of art turned from exotic materials or anything in between — your choice. There is a synthetic seal in the Industry QF-2 "cleaning kit", but if I understand correctly, that seal goes over a "button" and needs a different adapter, so I don't think you would have seen a screw unless you removed the seal. At this point, that's all I know — use it as vague background and do whatever Vince says.

A spring compressor is fairly simple to make with a C clamp and a piece of plywood. Still, the 350 has a lot of precompressed spring that would make disassembly a bit dangerous. You wouldn't want to do it for your first spring rifle tear down.

Dave,

One more thing. You say the piston seal is in good shape. Have you checked the breech seal (on the sliding cylinder)? They get squished to the point where they are leaky. I replaced one on my QB36-2 with 5/16" ID black fuel line and it made a world of difference — the rifle had been trying to diesel, and it lost accuracy. New breech seal made it shoot better than new. Cheap to try, and you can always put the old one back in.

Vince and BG_Farmer,

You are both right. I cleaned out all the lube and the velocity only advanced to 710-720. However, as I recall the Maccari seal has a raised central crown, which will lose pressure but provide an anti-jarring effect. He mentions that in the writeup (however the kit is no longer on the website, so I may have gotten the last one.

I'm tired of this gun at present, so I'll go back to it later. I have other 124 seals left over from a big tuneup test I did for The Airgun letter. They aren't as good as the Old School tuneup, but they ought to boost this rifle up over 800. at least.

B.B.

AlanL, if the gun has a manufacturing defect making it elegible for exchange, a ding on the muzzle shouldn't be an issue. I would think that pyramydair would just send it back to Umarex. I've bought dozens of 'return/refurb' guns from Umarex, and believe me – a ding here and there is no big deal.

With regards to cocking effort, I believe you had 3 guys all tell you that their 350's cock in the low 40's. I'm thinking it's a fair bet that you've got something wrong. If for some strange reason yours has an ultra-stiff spring installed, that'll definitely show up at the chrony.

Vince,

You've convinced me. I'm going to call them now. I'll keep you abreast of developments. Thanks again.

-AlanL

BB, thanks for the tune blog. I have had a JM kit for my 124D for a while but have never gotten around to installing it. This will help when I do it.

David Enoch

Dear B.B,

In my Mongoose Kit i did not resize the piston seal, just plug and pray. But instead of using Moly, i use Silicone grease on piston (also have high flashpoint, no detonation). I wonder which is better? Because i also have Maccari Moly Paste. Right now, after plenty of shooting, my 124 can get 870fps using Silver Bear.

Best regards,

omnislash

I know it’s been six years but the silicone made me cringe. Do NOT use the silicone on the piston! Without proper lube the piston skirt will gall the receiver to the point the gun will lock up. It may take a while to happen but it can and does happen. Use good ol’ bearing grease or moly paste. The rest of the gun can survive silicone abuse better than the piston, but best to not use it at all. Moly paste is probably the best common retail lube for the gun, and since you already have it you might as well use it. If your gun has or started to seize you can clean up the damage by sanding the area smooth. The problem area will be the inside top of the receiver tube a couple inches fwd of the trigger and a couple inches long, maybe 1/2″ wide.

ToddFilo,

Todd,

I am about the only person who will read this. Thanks for your comment, but if you want it to be read, post it to the current page, where there are over 30,000 registered readers ever day, and probably twice that are unregistered readers.

/blog//

B.B.

BB

Thanks for the link to the Queen B. That stock looks like its chiseled out of tigers eye.

It just serves to remind me of what an incredible resource the archives are, and that I have not been mining them to their full advantage lately.

There's GOLD in them thar hills!

BB,

Did removing the excess tar from the spring then make it noticeably vibrate more or were you still happy with that result?

A.J.T.,

That was a very interesting link you provided yesterday on the fire starter. I would really like to see how the Malaysians did it and what they used for the tube and the tinder.

AlanL.

I appreciate your last question (cough, cough). However, I'd like to quickly point out that the CJr-1000 is fully adjustable for placing targets at bench rest height up to standing, offhand shooting height, whereas "just buy a 4' tubular folding plastic table" as you so aptly put it, would be just that – 4 foot, and without the "me want to play" factor! Now, if I can just make it explode!

-Chuck

Chuck

You want to make your table explode? That could definitely be arranged. Email me, we can talk;^)

BB –

Thanks for the tip on the Mach 2 ammo from yesterday. I'll definately give the Eley's a try and hope they are accurate in my gun, that is the best price I've seen!

Thanks again,

Aaron

FWB124 counter point,

Bought one off GB in 98% condition with a Beeman Blue Ribbon scope – lasted for about 6 shots until the seal exploded – as expected. After soliciting the guys on the yellow, I picked the JM old school arctic kit for it and shipped the action and kit to Rich in Mich. In retrospect, I think I should of sent the entire rifle as he would have been able to test shoot it a little more after the install. But the stock was so pristine, I feared damage in shipment. After all, this was God’s gift to airgunning.

He e-mailed that it was a real pain getting all the little pieces out of the receiver, but all was well and it was on the way back. Once reassembled, I was getting in the 750-800 fps range with average to light pellets, which was the same as a MM tuned QB78 was hitting.

The biggest disappointment however was the trigger. At the time it was competing with three HW’s tuned by Paul Watts. Just no comparison, though no fault of Rich I believe either.

The HW’s rekord triggers kicked the 124’s butt stock. I think the HW50S is as good or better all around rifle, it just needs tamed with a little tar and it is also in a handier package. Even with the PW tune I had less money than in the FWB124 Deluxe. Another plus is the cocking lever only needs a short slit unlike the 124. If you are looking for a bit of history, by all means get the FWB 124. But if you just want an excellent 12 ft lb rifle, you don’t have to beat yourself up that the 124’s are no longer made. Just keep this tidbit to yourself, or you will suffer great flaming on the forums.

Also that old Beeman scope and rings could not compare to the more modern equipment I had on hand. Model 66 I think?

/product/hw50s-breakbarrel-rifle?m=1988

Having no emotional ties to the 124, it was the first tuned rifle I kicked to the curb.

Happy St Paddy’s Day:

May you fight, steal, lie and drink. When you fight, may you fight for your country. When you steal, may you steal away from bad company. When you lie, may you lie at the side of your sweetheart.

And when you drink, may you drink with me.

AlanL,

Buy the chrony . . . . your ever growing collection is clearly worthy of it, and you'll learn so much more with it. If it is a budget issue, just delay the purchase of gun #12 for a while 🙂

I only have the one springer (plus a few pumpers), and I regret not getting it sooner for the srpinger. Among other things, it helps me to know that my shooting problems are me and not the gun. For example, my shooting went south very suddenly and I couldn't get it back – must be the gun, right?. Put a few over the chrony, and nothing has changed – must be me or the scope. Doubled up on getting the hold right, figured out what I was doing wrong, and shots came back on POA . . . .

Alan in MI

Good morning All.

I've been very busy in the garden bed business, and playing "cowboy" with the .45 long colt marlin 1894 carbine, and ruger blackhawk revolver.

I believe that no firearm could be nicer to shoot than these two with the "cowboy loads".

These 200- 250gr rounds are loaded light for the cowboy action shooting guys… they come out of the blackhawk revolver about 750fps.

I really can't think about getting into another hobby/sport like competitive cowboy shooting, but I'm having way too much fun playing "walk the can" even shooting from the hip!… I surprised myself with hitting the can from the hip about twice out of the ten shot magazine marlin carbine…

I felt like the "rifleman" quickly emptying the carbine, kicking up dirt all around the can, finally knocking it for a loop!.. It's really not as hard as one might think… or I was a cowboy in my prior life!

It helps to have a seemingly endless supply of ammo.. making a trade with a reloader for garden beds really made me a "happy camper"!… I can blast away with abandon! (saving my empties of course)

So, if you want lots of foot pounds for up close action, with out beating yourself up, .45 long colt is for you… I've also got some 300gr hunting loads too for the marlin carbine… and they also shoot so easy… It's really a nice round to shoot.

Now, my problem is when will I be shooting my air guns and running the field target games? 🙂

Wacky Wayne, Match Director, Ashland Air Rifle Range

Wayne,

That is a real problem, you've got it rough 🙂

Aaron

Chuck and everyone,

I will give you a complete blow-by-blow in the next report.

B.B.

B.B.

Does all this tuning, hurt the collector's value of this rifle? I suppose it improves it survival value.

All, I see your point that the recipe line could leave you vulnerable. The logic is that the women would be restricted to one recipe to cook or eat, but there's no reason for them to follow the rules. "Power is the one element of the human condition that cannot be faked…."

Wayne, sounds like the only thing between you and cowboy action competition is the outfits. I take it you have viewed the YouTube videos on cowboy action shooting. Some of those guys are pretty good. I like the one where the guy is sitting on the fake horse with his shotgun.

Matt61

omnislash,

This kit is never going to go that fast in this gun. However, I am working on some things that should make it better.

B.B.

Wayne, here's a Cowboy load for you for the .45 Colt. A 160 gr, flat point with 4.0 grains of Bullseye. After you charge the case, fill the case to the top with Corn Meal and seat the bullet. This keeps the light load near the primer. It's a neat plinking load.

As always, use of this load is at your risk but it's worked for me.

Mike

B.B.,

Finally got time to read todays article. I'm shocked and stunned. You mention 3 of the vintage magnum springers but left out the fourth, R1?!!

Volvo,

Hope you saw my comments to you on the vintage with regards to scoping the diana 27 and receipt of the diana 23. Thank you again. After PW worked on my first fwb 124 the trigger would break at 18 ounces. Not a rekord but a vast improvement.

AlanL,

My vote, if I have one, is to send the gun back. In the future when (not if) you need to touch up your blueing I like the birchwood casey blueing pen (like a sharpie but blends better IMHO).

kevin

Just heard that they're going to have 2 shooting lanes open at the Arkansas airgun show to allow shooting before buying.

I've got to reconsider this 1,000 mile trip.

kevin

Birchwood casey blueing pen, I need one of those…my wife is asking for her sharpies back…. also she wants her fingernail polish, art paint and shoe polish back too. Then again I should just get some wonder blue and get it over with.

Alan in MI,

Yes, I'm going to buy a chrony. Knowing me, I will immediately shoot the screens out of the thing.

Vince, Kevin,

I did it! I called Pyramyd and after 13 minutes on hold I gave up and left a message. They got back to me within 5 mins!

I talked to Ms. Stacy (I'm told she's a master gunsmith and is the A-Team in Pyramyd's tech department) and she agreed that 50+ pounds is too much. I told her all you guys out there were seeing 40+ and she's going to fix the 33 lb published cocking effort info. Turns out Pyramyd is out of stock of the 350 in wood for the next few days and she didn't have one to test in house, so I suggested she grab a 350 Panther to test instead. She was going to do that and let me know. I'll let you know what she reports.

Thanks for all your feedback.

Kevin,

I'm going to buy that pen you mentioned. Instead of returning the cocking lever of the 54 to Umarex, I'll just fix the bad patches myself. Now that I've got that pull rod adjusted just right, the last thing I want to do is remove it.

-AlanL

Kevin,

The R1 came along in the early 1980s. These three were from the '70s.

B.B.

Aaron,

I'm busy, but having lots of fun.

Matt,

I haven't checked out any of the rules or videos on cowboy shooting… no time to get involved… I just grab the guns and ammo and head up to the national forest or rifle range if I have to go for supplies too… I only get an hour or two, but it's great for letting out the days hassles..

But, thanks.. I'll check out some of the utubes on cowboy shooting and get some ideas for more fun.

Mike,

I'm not reloading yet, I made a deal with a small ammo guy… who will reload for me when I get enough empties..(I'm workin on it:-))… and the 200gr is plenty light and easy to shoot accurate. Both the blackhawk revolver and the marlin 1894 carbine group real well with them.. but thanks for that advise, I might try it someday..

Wacky Wayne, MD. Ashland Air Rifle Range

Should you use moly paste on a rws 34 panther when installing an air venturi pro guide?

Kevin,

Yes I saw your post on the vintage forum, I did not reply as that pops it back to the top of the page and my topic was pretty well covered. I hope you are able to get the Diana 23 past its current wall hanger condition. If not, I suspect the HW25 would make a nice modern day version. Unless it has changed, PA was offering them for $100 less than the Competition.

The R1 you mention was undoubtedly the death blow to the FWB124. In fact it could be that the first owner ordered an R1 and was so amazed that he was inspired to build the coffin and give the FWB124D a proper burial. I know, but after all my adventures and misadventures it seems HW’s are destined to still be my favorites.

My last chance for real Competition is the Diana 27, which I hope will go head to head with the R7. About 3 more days and I’ll find out.

Random capitalization may be what I have needed all along.

Volvo

Wayne; Here's another load at the other end of the power level in .45 Colt. It shows you what a real Cowboy load is yet is still very safe. It uses a 250 Grain Lead Bullet and 8.0 grs. of Unique.

Rock and Roll!

Mike

ir Venturi Pro Guide,

You can use moly if you want to, but it really isn't necessary. The guide comes with some lube on it and that is all it ever needs.

B.B.

Wayne,

Had the urge to feel recoil and smell burning powder yesterday. I must admit you have me thinking about a 45 LC, you are a very bad man.

Went to the shooting range and was saddened to see they had gone out of business. Not a huge surprise based on how they ran it, but disappointing none the less. The other range is about another 5 miles so I made the drive.

Good time, but it certainly brings to mind the economy of shooting pellets. Doesn’t take much to burn up a C-note with ammo, range fee, and gas.

Now SA's slow things down with the loading, so that would SAVE me $$$…

Volvo

Chuck,

I don't know what the original fire piston was made out of but you can buy one made out of hardwood or water buffalo horn. They are a bit pricey though. You can find lots of info just by googling for "fire piston". It was mentioned in the latest Popular Science which is where I first saw it.

AR

Slinging Lead,

Thanks for the info on the Remington 870 Express. We have Gun Shows down here I live about 20 miles south of Albany not sure if they are Eastman or not. Guess I should check out the next one.

BB

I'm considering buying the Walther Colt 1911 Co2 pistol. I know you have written previously and gave it high marks?

Before I leap, I already have the S&W Revolver from Walther and it is excellent. Would you rate the 1911 pistol as on-par with the S&W? How about the rear sight on the 1911, is it screw adjustable or drift adjustable and… there is a video on You Tube of the Walther 1911 showing a nickel plate version that has a caption "target adjustable sights". I don't expect you to comment on someone else video but, would you consider the sights to be "target adjustable" type?

Last… (sorry for the run-on here) how would you rate the Walther CP55 versus the 1911?

Thanks for the usual fine advice…

Brian in Idaho

Volvo,

You think single actions slow you down? You ought to try a front-stuffer! Ten rounds is a half hour's work if you are a careful shooter.

B.B.

Rikib,

You live just 20 miles from Albany Georgia? Have you seen the movies Flywheel, Facing the Giants and Fireproof? They were made by Sherwood Baptist Church in Albany, and the last two flabbergasted Hollywood with their attendance numbers.

B.B.

Brian,

I like the Umarex 1911 a lot, but no, it isn't quite the gun the S&W is. No CO2 repeater is as nice as the S&W, in my opinion.

I have the black model and the sights are drift-adjustable, only. The pistol on You Tube must has replacement sights.

I'm not familiar with the Walther CP55, unless you mean a sport pistol of the Olympic class, and only then from FWB, not Walther.

B.B.

B.B.,

Have not seen Flywheel, but have both Facing the Giants (familiar with the actual schools) and Fireproof, both are excellent movies in my opinion. Don't know what others think. From what I have heard they are planning another movie. Not sure what it is going to be about though. Sure seems strange seeing streets you drive down really in movies, I mean we sure ain't Hollywood!

BG-Farmer.

Nice one mate,plenty to think on.

It may seem strange to you good folk On here why I persist with this hunk of junk rifle.

Not having a lot of money to buy a better one is a reason,but,I just love the way it looks,its shootability and the carefree manner in which it can be used.

Just like a real AK47 really.

When you hit a Dollar coin size target with my rifle at 50ft using wonky open sites.

Damn, it feels good.

B.B.,

"You think single actions slow you down? You ought to try a front-stuffer! Ten rounds is a half hour's work if you are a careful shooter." Oh yeah, especially if you get a ball stuck in your gun!

Sorry, that was mean. Couldn't resist!

:-))

-AlanL

Fred,

Since Neal is a 3rd degree, I was wondering if you guys have seen the film "MARTIAL ARTS: The Real Story-

Beyond The Myths and Facades" by Pacific Street Films.

http://www.psfp.com/martial.htm

Best documentary I ever saw on this topic. Some truly Amazing stuff there.

-AlanL

AlanL and Kevin,

I decided to apply duct seal to the front edge of the table top. I cut 2 pugs into 4 equal strips each and stuck them on the front edge. I was surprised that they held there pretty good even by their own adhesion. The plywood has a very porous edge. I then put a strip of transparent packaging tape over the edge of each strip to tape them to the table. I think the next step is to cut a 2 foot by 4 foot strip of the carpet you see in the background and set it up on edge in front of the PVC pipes to suppress ricochet there. That pretty much does it except for actually gluing the PVC pipe. However, it seems to be holding up so good I think I'll procrastinate on that. Love to procrastinate!

Look at the last two photos.

http://picasaweb.google.com/cjrley/CJr1000TargetStand#

Make that the last three photos. Not sure how that third one got in there.

-Chuck

B.B.

I have considered some of the BP replica pistols, but I didn’t think you could shoot them at an indoor range?

I had thought that a DA wheel gun was a nice compromise between a high capacity semi-auto and the SA, but with ammo prices I am not so sure. My trigger finger still gets a little too happy.

I have been keeping an eye out for a Crosman 600 but they are going for crazy prices on GB. Any other multi shot CO2 pellet pistols that you would recommend?

cool beans chuck…..cool beans!!!!!!

This comment has been removed by the author.

Can anyone summerize in short what the differences are between the Beeman RSx triggers and also the RWS TOx triggers. I'm guessing the higher number x is, the newer and better the trigger set is?

poor octopus

http://www.bing.com/airgun-videos/watch/airgun-video/octopus-vs-shark-in-underwater-battle/26pv995m

Cheap fairly effective backstop. I looked in the local paper under free stuff. Found and old sofa free to carry away. Took the 4" cushions hauled the rest to the dump. Stapleguned the cushions to separate pieces of 1/2" plywood. Attached some PVC pipe with pipe clamps to the wood. I just lean them against a tree and tape a pre-printed target on them. When I'm done I just put it back in the shed. Okay I'm cheap, but it serves my purpose for now.

Whoa! Wait a minute! PVC, 1/2" plywood, pipe clamps, Couch cushions?..I think you just gave me an idea…thanks rikib.

-Chuck

rikib;

I you are looking for an 870 Express you will probably do better at WalMart than the Gun Shows. The last few years, Gun Shows seem to have the highest prices, at least the dealers that attend the shows. If you are going to a Gun Show, you will have better luck watching for a private person attending the show with an 870 for sale.

Mike

Kevin,

You mentioned a .22 caliber pistol loaded with bird shot. I've been searching the net for .22 pistols hard to find, any ideas where to start? Found site with .22 Glocks but they are about twice as much as a 870 shotgun 12ga.

http://www.network54.com/Forum/79574/message/1268838565/New+Marauder+Stocks

a whole new world!!!

CJr,

Hope I gave you and idea you could use as you give us a lot. I only shoot a 2240 but since using this backstop have not had any ricochets. May not work for more powerful guns.

Mike,

Thanks does Wal-Mart actually sell the 870 express or are you saying I could get a decent shotgun there rather than a gun show?

Volvo,

If your hands are not small the Desert Eagle is a fine repeating pellet pistol. It uses too much CO2, but that is it's only vice. Accuracy is phenomenal.

B.B.

ajvenom,

I will be testing and comparing the T01 trigger with the T01 trigger in the near future.

B.B.

Rikib,

Flywheel was the first film Sherwood Baptist Church made. They made it with a single digital camcorder and it was way more popular that anyone had thought possible.

The next film is Courageous. It's about fatherhood. They are working on the script right now.

B.B.

B.B.,

Seems like the comparison test of a TO1 trigger to a TO1 trigger will probably be pretty short?

😉

kevin

Sorry,

Make that a T01 to a T05. That should be more interesting.

B.B.

rikib,

Look at gunbroker for your .22 pistol shopping and shotgun shopping. Don't know your state laws about shotguns but pretty sure you'll have to have your pistol shipped to a local licensed dealer (FFL holder). Mine charges me $15.00 per transaction. Here's a link:

http://www.gunbroker.com/

kevin

B.B.,

The new TO6 is getting rave reviews.

kevin

Kevin,

Shotguns can be picked up at Wal-Mart, K-Mart etc. Pistols, there are a lot of dealers and pawnbrokers selling them. Do you have any particular recommendations? Thanks

Kevin,

Correction, again, a T01 to a T06.

Why don't you handle all my answer for awhile? You seem to know what I should be saying better than I do. ; )

Been tuning a 124 all day and I'm punchy.

B.B.

Rikib,

870 express goes for around $240 if you watch the sales & rebates. Mossberg 500 likewise, maybe in the $220 range. There's a couple of cheaper options, but 870 and 500 are safe bets. Big sporting goods stores and Walmart. Gun shows and gun stores…I better not state my opinion of either:).

This comment has been removed by the author.

Chuck,

Your stand is getting heavier and more immobile by the minute. Better use lots of glue.

Jealous in Miami,

-AlanL

Rikb, if you don't mind SA revolvers…

http://www.heritagemfg.com/site/index.cfm?CFID=13257559&CFTOKEN=e2d863c5e32de4e8-6E844FC1-0906-0411-B0069BB777469AFD

B.B.,

Why are you going to compare the T01 to a T06 trigger? Why not the T05 versus the T06?

Well, did some research on the T06. It's die-cast zinc, not plastic. It now lets you adjust first stage travel and weight and it can be replaced as a modular unit including the piston in all Diana rifles. It is delivered standard in all models starting with the Diana 280 in 2010.

All my RWS Dianas ordered in 2010 from Pyramyd came with the T05 trigger. 🙁

-AlanL

B.B.

Any chance the drop in performance on your 124 is due to the sandpaper on the seal? When we overhaul engines, we "sand" the cylinder walls, (actually we hone them), and it takes some running for the rings to polish all those scratches off and get a high-pressure seal.

Anyway…will Pyramyd AIR be selling the new Evanix BLACK LEOPARD? Am I reading their description correctly? 700cc air capacity? "Autoloading action". Does this mean semi-automatic??

This is my next gun…

Ed Pikor

BG_Farmer,

Why don't you want to state your opinion if it might help me. So far looking on the net I've found a Mossberg 500 pump action cruiser 20ga 6 shot pistol grip for just under $300. I don't know if I can find it locally, but it sure sounds nice.

B.B.,

I think we all knew what you meant. Pretty pointless in comparing a TO1 to a TO5. Anxious to hear your take on the TO6. Some folks are so impressed by the adjustability in the new TO6 that they're rating it higher than a rekord. Pretty high praise if that's true.

kevin

Vince,

Thanks for the website. I've already saved it to my favorites. Some nice revolvers there. Decent prices too. Thanks again.

G'day BB and Co.

I just noticed in the latest Australian Shooter a number of air rifles you and some of your readers may be interested.

Falke Mod 80 $190Au 1950

Webley Service MK11 $600Au pre 1928

Cheers Bob

On the fire piston: The magazine "Backwoodsman" has had a lot of articles on the use of these, and places of where to buy them advertize there. Also, for ribkid, they had an article in the jan/feb issue, about a single shot .410/45 colt pistol, which the author uses for shooting pests like snakes. It sells for around $200 new , and is called the Comanche. The article had some very good information on modifying it to enhance it's use. Also , on shotguns ,don't overlook the single shots and bolt actions for cheap pest guns. I saw a pistine Mossberg bolt action at a shop near me that was going for only $75.Robert

rikib,

Once upon a time I used to buy a lot of firearms. This was in the day when you could open the newspaper and they had 200-250 guns for sale in the classified section here in Colorado. I bought a lot of firearms used since it's pretty easy to tell how much they've been used and whether they've been abused.

Later, I attended gun shows and during the winter I would rent a space usually 3 tables long on two sides. Although I did sell some guns I was usually there to trade and/or buy.

I've also bought a few new guns. The common denominator was that I saw the guns in person. This was pre-internet.

In the past year I've been selling. I've used gunbroker exclusively and can assure you that there are some good deals on gunbroker for new and used guns.

I'd suggest doing some research and narrow down what you're looking for then visit your sporting goods stores including walmart and handle the gun. Once you have your hands on it you may learn it doesn't fit or you don't like the fit. This especially applies to shotguns if you decide to go that route for snakes. Shoulder the shotgun several times. Bring it up and see how well it fits.

After you become convinced about what you want to buy I would include gunbroker, sporting goods stores, gun shows, pawnshops, etc. in my shopping for best price.

Good luck.

kevin

rikib: forgot to add. When I was on the Williams gunsight site the other day, I looked through their used gun lists. They had a few shotguns that you might find interesting. Good prices too. Robert

B.B.,

What's the price today for that pain in the neck FWB 124?

kevin

Rikib,

Briefly and inoffensively as possible, I prefer to know what I want and buy that rather than be sold what the dealer/peddler can get or will make the most money on. There are good gun stores (I do know of one excellent one and another that is at least honest), and good sellers at shows, but finding either is exceptional luck, at least for me. These are my opinions only, yours may vary:).

BB,

The patch removal tool is interesting. Thanks for showing us what it looks like. Removing small pieces of seal that are waxy and stuck in the corners of the compression tube isn't my idea of a good time.

BG_Farmer,

I understand and appreciate your honest opinion. You are right I do want to hold the gun feel the balance and not feel pressured into something that I may not want. Thanks!

I guess I need to also think about shooting that 4-5ft long snake my wife seen on the side of the shed. Don't want to blow a hole clean through the shed, haha. Can't go with more than a 20ga and even then have to stay way back. Maybe I should scale it down and just get close with an IHZ Drozd BB gun and shred it up. Oh decisions decisions so many guns so little money!

rikib,

You're pulling my leg. You're not thinking about shooting a snake on the side of your shed with a .20 gauge? You're not even thinking about shooting it with a .28 ga or even a .410 are you?

Did I take the bait?

kevin

rikib,

Your getting great advice here.. let me add on a similar note, the "judge" by Taurus. It's a revolver that can shoot 410 shot gun shells or 45. long colt.. my favorite ammo at this time… I have one and it's nice.. not a S&W 27 frame or Ruger Black Hawk.. but darn close in my wacky opinion.

And then again.. consider what my favorite firearm and all should consider for an all around short to mid range firearm….. the marlin 336 or 1894 carbine in .45LC or .357 mag. or even .44 mag. but I like to have a revolver on my hip that shoots the same ammo as the rifle.. at least for now:-).. and I don't think I'm up to the .44 mag in a revolver.

Heck the "rifleman" could clean up them snakes with real easy..

me and 1894 in .45lc will be right over:-)

Wacky Wayne

Kevin,

Hey, I just want to kill the damn thing if when I see it. Pitbull, dingo, husky and great dane not doing it and it's too big for the cats. Maybe I'll look around for a 28ga. I wish they made the Mossberg 500 pump action cruiser pistol grip in a 28, just a a home protect deterrent. Not that I think we really need it, even someone walking down the street and all my dogs are out the backdoor dogflap (within the fence of course) barking their heads off. Pitbull can be over the fence in one leap when she wants too, but she's really just wimpy if you pet her.

What's wrong with a few holes in the shed anyway..

but first we must identify the snake and it's mission.. could be on our side cleaning up the rats!

Wacky Wayne

Wacky Wayne,

Yeah, getting a lot of good info here and you've given me more. Now I got more guns to look into. But that's why I come here, for the best info.

Wacky Wayne,

Don't have any rats out here in the country. Do have voles but my cats pretty much take of them (even bringing them in the house as prizes).

rikib,

http://www.taurususa.com/airgun-video-theJudge.cfm

rikib,

Snakes on the shed and home defense are two different weapons in my opinion.

If you've got all those fine canine and feline companions roaming the yard I understand your need to eradicate poisonous snakes.

I like a pistol for primary home defense since you're in close quarters.

If you could only have one gun to do both jobs I would vote for a… .357 magnum pistol. I'm fond of the colt python. This is a compromise.

The .357 could be loaded with hollowpoints for home defense and loaded with bird shot for snake killing.

kevin

Wayne,

You're having more fun than a grown man should be allowed.

We need to get together.

kevin

Kevin,

Thanks for the info on the .357 mag never thought of it being loaded with birdshot. Yeah the dogs and cats are a big part of our life all are recuses or just not wanted by previous owners. We love them all 4 dogs, 11 cats. Seems whenever someone hears about a unwanted or stranded animal on the highway they call us can't help it guess we're just suckers but at least the vet gives us good discounts.

AlanL,

You've given me an idea. Maybe I'll weigh it just for kicks. I'll bet it weighs more that 50 lbs. I think the 2'x4' 3/4" plywood alone weighs 40lb.

-Chuck

AlanL,

Also, no need to be jealous. For a nominal fee plus shipping and handling I can send you a CJr-1000 kit. But wait there's more. For two nominal fees plus shipping and handling I'll send you not one but two CJr-1000s. I'm thinking of going into business with it and if it doesn't work out maybe I can partner with Wayne and use all the parts as an irrigation system for his raised garden beds.

Whoooo! I hope I'm feeling this good tomorrow. Happy St.Pats!

-Chuck

Kevin,

Either I'm looking up the wrong .357 mags or you think I'm rich $1000-1500. Way out of my league to kill a snake. Think I may have wandered across what maybe a happy medium, gotta see it i can find one locally to actually check it out, a Mossberg HS 410. Ever heard of it? Both home security and shouldn't tear down my shed.

AlanL,

I don't know the difference between the T05 and T06 triggers, myself. Gotta research it.

B.B.

Ed,

I will explain about the seal on Friday.

Don't know about the Black Leopard yet. I do know that the Koreans can't discriminate between a revolver and a semiautomatic action, so we'll have to wait and see.

B.B.

Bob from Oz,

Thanks for the leads. I;ll check it out.

B.B.

Bob from Oz,

That Falke rifle sounds interesting. Is there a description? I might be interested.

How can I contact the seller?

B.B.

G'day BB,

The ad says "Falke Mod 80 .22 air rifle #0021, made in Germany in 1950, adj sights, good condition $190AU.

Contact Ray 07 3263 2543. The 07 means he is in Queensland I am in NSW. I can do any ground work here if needed.

Is the Webley Service Air Rifle the one Poms used for practise been WW1 and WW2?

Cheers Bob

Bob,

I guess I should call him if I am interested.

As for the Mark II Service, that was Webley's intention, to use it as a training rifle. It may have been used for that purpose, but I don't have any information about it.

B.B.