by B.B. Pelletier

This is part 3 of Vince’s disassembly and repair of the Falke model 90 I sent him several weeks ago. After this, we’ll start a new series with the range testing of the Falke, as Mac now has the gun.

If you’d like to write a guest post for this blog, please email us.

Bloggers must be proficient in the simple html that Blogger software uses, know how to take clear photos and size them for the internet (if their post requires them), and they must use proper English. We’ll edit each submission, but we won’t work on any submission that contains gross misspellings and/or grammatical errors.

by Vince

Now that this mystery was solved (.177 pellets stuck in this .22 cal. rifle), I had to tend to the more mundane issue of that putrid piston seal. Even though the original seal was leather, I’ve got the idea that — like the Hakim — a modern Diana seal can be made to fit this gun. Measuring the bore confirms this, so I have to figure out how to adapt one to this piston.

First things first, though. I’ve got to remove that old leather seal, which means I have to remove that center screw. It doesn’t want to cooperate, and the beat-up screw head is only getting worse. There’s not much of a slot to engage a screwdriver, and I don’t want to mess up what little there is. I decided to remove the leather first — by destroying it. That way, I can grab the sides of the screwhead with something and loosen it.

Well, the screw still doesn’t want to come out. I suspect that it’s being retained by the pin circled in the following picture. Quite obviously has to be drilled. Once that’s done the screw spins out rather easily:

Even with a screw loose, it wouldn’t come out.

After some “coaxing,” the screw gave it up.

Next, I made a button adapter for the Diana seal. I’ve got some 1-inch nylon bar stock laying around (doesn’t everyone?), so I drilled a hole into one end (it doesn’t have to be perfectly centered or straight).

I drilled a hole in some spare 1-inch nylon bar stock and sliced off a section that’s the same thickness as the seal.

I installed a machine screw and nut through it and chucked it up in a drill.

I sliced an old seal in half to give me an angle guide and used a bench grinder to shape the plastic button while spinning it in the drill. I fine tuned it until it’s just about a perfect fit.

Remember that pin I drilled out of the piston? Turns out that it was also securing the piston rod into the piston — after I removed it, the rod loosened up. Since it looks like we can’t do without it, I replaced it with a roll pin.

I used threadlocker on the center screw, so I’m NOT relying on the roll pin to secure it. I don’t want the pin interfering with its installation or removal. I threaded a 5mm bolt into the head of the piston as far as possible and then pressed in the roll pin until it bottomed on that bolt.

I ground down the head of the pin so it’s flush with the piston and forcibly removed the 5mm bolt (which was binding against that pin). I ran a tap down that hole to cut through any interference. The front of the piston is now ready to go.

I installed the new button and seal onto the piston and found out that the installed height of the new seal is less than the original. This would allow the piston to move forward more than before and interfere with the cocking linkage. So, I made a spacer out of a belt.

With a new button and seal installed, I needed a spacer…so I cut up one out of an old belt.

Almost perfect, but I eventually added a little more using material from a coffee can lid.

I cleaned the compression tube and reinserted the piston and spring. Another look at the rear spring retainer, and I see a problem — no rear spring guide! When I took the gun apart, there was a metal tube inside the spring up near the piston end. I didn’t think much of it at the time, but now it dawns on me (duhhhh) that it’s the actual guide pulled out of the rear retainer. Nothing seemed to be broken — just a press fit that wasn’t quite tight enough. Wood chisel to the rescue! I expanded the diameter of the tube by spreading the seam.

The guide had to be inserted back into the spring retainer, but the fit was too loose. A wood chisel helped tighten things up by spreading the the seam with my handy wood chisel.

I asked B.B. about pinning it (which involves drilling holes into precious and rare parts), but he assured me that this gun won’t be getting a lot of use. So, this repair stays as it is.

The retainer/guide assembly is all gooped up and ready to go!

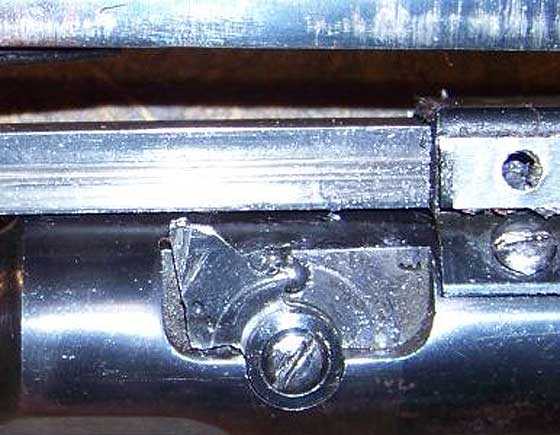

The rear guide/retainer went back in as did the cocking linkage. Now, I’m back to where I started — the taploader assembly.

First thing I did was fish around for a skinny little spring and a 3mm ball to replace the missing detent.

The detent.

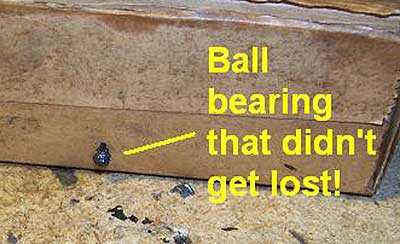

Of course, when working on something like this, it’s EXTREMELY important to heavily grease all parts BEFORE assembly, ESPECIALLY that little ball bearing which, incidentally, happens to be the only one I have. Why grease it now? Because when it goes sproing during one of several reassembly attempts, that itty bitty ball bearing HARDLY BOUNCES and DOESN’T ROLL! It sticks to things, making it infinitely easier to recover:

A greasy ball bearing does not bounce, not even an ounce, but if it did…I would trounce — it!

Back together and ready to work on the stock.

Everything went back together, and I’m getting psyched. I even put a couple of rounds through it before putting it back into the stock, and it seems to function just fine. So, I grabbed the admittedly beat-up wood. Just as I was putting the guts back into it, I noticed a crack in the stock.

Finished with the action…on to the stock.

Great. Didn’t notice that before. Oh, well, shouldn’t be that hard to fix. Unexpected, but I’m awful glad I caught it. It’s a lot easier to fix a crack, even a bad one, than it is to fix a total break.

I’m hardly a woodworking expert, but I don’t really see a good way of pinning this. Shouldn’t be necessary, a friend of mine assured me. Today’s wood glues are so strong that I shouldn’t need anything else. Not much choice.

Starting on the starboard side, I spread the crack as much as I dared with a small screwdriver and used my finger to force the glue deeply into the crack.

Glue is enough to keep this crack together without risking a complete break.

Actually, I made out pretty well and was able to get glue to ooze out of the other side of the crack

Close it, clamp it, wipe off the excess and let it sit. Hopefully, it’ll be as solid as it’s gonna get. Repeat for the port side, and I’m done.

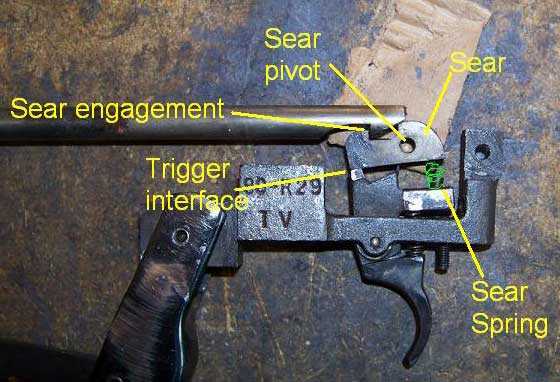

One more thing. B.B. wanted me to do a quick write-up on the trigger so you can see how it works…which I remembered after getting the gun back together. So, it comes apart again, I pulled the trigger parts out and arranged them on the workbench in their approximate working positions. Since the rest of the gun is still assembled, I’m using an old piston rod just for illustration.

This picture shows the mechanism in the cocked position:

As the piston rod comes rearward, it pushes on the sear, rotating it clockwise so the sear engagement catches the hooked end of the rod. As the front of the sear lifts upward, the trigger rotates clockwise and the trigger interface slides under the sear to keep it in position.

When the trigger is pulled, the trigger interface moves forward, allowing the sear to drop down and release the piston:

While it’s a step up from a direct-sear, it’s not a particularly elegant mechanism, similar in concept to the trigger on the (shudder) Industry B3.

So, that’s about it for working on the Falke. I did shoot it some, and found that the velocity averages almost 500 fps with Gamo Match pellets. Accuracy? I had trouble getting under .50 inches at 10 meters with the open sights. Perhaps Mac will do better.

My overall impressions of the quality of the gun? Generally, it’s not as bad as my overall impressions of the quality of the rear triggerguard scew.

Rear triggerguard screw.

In all honesty, I was a little disappointed. This is only the third type of taploader I’ve worked on, the previous being the aforementioned Hakim while the first was a pre-WWI BSA underlever. That BSA sort of ruined it for me. It was such a beautiful example of 100-year-old metalwork. I’m still half-sick that I ever let Wayne have that gun back! The Hakim was somewhere on the better side of the middle, as is this rifle. But, it’s certainly solid enough, and there’s no reason why this gun shouldn’t still be working well after all of us are pushing up daisies. Or Crosmans, or whatever we prefer to be buried with!

B.B., Could you somehow get in touch with Paul Capello and have him test out the Ruger Air Magnum?

Conor

I’m new here so i don’t know for sure but i don’t think Paul takes requests. If you need a review now, google airgunweb ( I’d give a link but I’m not sure if I’m allowed to do so). Rick Eutsler runs the site. He takes requests and is a Ruger fan.

B.B. and Mac already did a test and review. Are you looking for a second opinion?

twotalon

Twotalon, yes kind-of. I kinda like seeing a review by P.C. before I make a purchase.(Not saying that I don’t like B.B.’s review, I just want to see P.C.’s review)

Thanks,

Conor

Conor

I left you a reply on how to convert your 2240 to .177 on yesterdays blog about 2/3 of the way through.

Slinging Lead, Okay thanks!

Conor

Morning Vince,

Nice finish to the Falke series. Loved the picture along with your comment on the rear trigger guard screw.

Whose wood glue did you use?

Thanks,

Bruce

Used Elmer’s wood glue, nothing special. On the advice of a woodworking buddy this stuff is pretty good.

Vince,

I’m proud of the job you did! You got past a lot of difficulties that might have stumped a lesser airgunsmith. Me too. What wood glue did you use? Commercial “Gorilla Glue” or something a good bit better?

pz

Excellent improvising on the adaptation of the leather seal to nylon. I love these articles on “fixing” spring powered guns. Also, this just shows me how challenging my new hobby can be, and how far a person can take it. I have only been into airguns for a year and a half now, and I am just psyching myself up to working on my Weihrauch HW85 in .177 cal. It shoots a crosman 7.9 grain at 425 fps. Before you spill your coffee, I must mention that I am Canadian. Anything over 500 fps., and I have a genuine firearm according to our boys and girls in Ottawa. However, 425 fps. seems to be a tad low to me. Any fellow Canucks similar problems? I wish our esteemed law makers would have looked at Great Britain and the use of “foot pounds” to define the difference (firearm vs. airgun). Obviously, I think they should have left well enough alone in the first place. Personally, I believe age should be the defining factor in who should be able to obtain a gun. Air or powder. Also, if a license is needed, then there should be a “airgun license”. I am using the drivers licensing as an example. If I drive a car, I need a class 5 license. If I want to drive a semi, well that’s another higher class. Also I am only tested on the vehicle I am going to drive. And, I throw this out to my fellow Canadians who have taken a Possession And Acquisition (PAL) exam. Exactly how many questions on the PAL exam, were about airguns?

Woo boy, I will exit off my soap box now. And this is only my third submission to this blog and I do not want to come across as long winded . Hey, nice to see some fellow archers out there too. That is how I cut my competition teeth.

Cheers and goodnight Titus Groan

I’m a fellow Canadian airgunner and I can barely support our airgunning laws.

I think that 425fps is pretty much the best you can hope to get from a 500fps rated rifle. Remember they have to test the rifle with lighter pellets so 425fps with “normal” pellets seems pretty good to me.

Your idea of airguns license seems decent to me. I would get my PAL and RPAL (for Restricted PAL which means pretty much anything that isn’t a hunting rifle) BUT I think they should rethink the way it’s done. Right now in order to get my PAL I would have to wait a few months for the course to be given “close” to me and that would be my second point, I don’t want to have to drive 45min to an hour to get to a course and THEN if pass I have to wait a minimum of a month but I’ve seen reports of up to 4 months !!! That is unacceptable to me.

I don’t want to turn Canada into farwest country but I think the law makers have gone way too far and sadly there isn’t much we can do as guns get SO much bad press that trying to ease a gun law would mean a ticket out of Ottawa for the politician trying to do so.

Titus are you a member of the CAF (Canadian Airgun Forum) ? If not you should join us. Lots of nice people there (some bully like every other forum but still pretty decent).

J-F

As to my question, “Any fellow Canucks with similar problems?”. I change it to read “I will graciously accept advice from any airguner of any nationality”.

Titus Groan

Titus,first off let me say that it really is unfortunate and just plain ignorant that your country’s airgun laws are so logic-free.I wish I could have you visit me….you would suffer a massive stroke trying to figure out what to shoot first! You put forth a very sound idea,proposing an airgun license. I now

fully realise how lucky I was to acquire a HW 54el Barakuda from a collector in the “Great White North”. Good luck with the HW85.If the only limit set forth is 500fps…..maybe look in to getting a

9mm airpistol! 475 fps in 9mm is a blast!!

Tutus, the only thing that comes to my mind is talking to your elected official(s) and sound them out about changing this law. Obviously won’t be easy unless there are votes in it for them. Good Luck.

Fred PRoNJ

Titus, ya hoser,

Just kidding. You are so close to your max fps limit that I can’t advise what else to do for the 425 fps issue. A few tweaks as we would do down here will put you above 500 with 7.9gr pellets.

BGF has good advice for you, if you need more energy/impact, go larger cal. at <500 fps. The actual muzzle velocity rule in Canada is stupid on many levels not least of which is, I can build a .500" caliber gun that goes at 490 fps and you would not want to step in front of that projectile!

Speed / mass, energy etc, your parliament members must have missed that day at engineering school?

kinetic energy = 0.5*(mass*velocity^2)

Vince,

Very nice! It’s great to see someone’s work. And thanks for those trigger pics.

There’s something I’d like to mention – I’m not sure completely if you need this – but still.

In my experience, partly proven by some research made by enthusiasts, that kind of rounded piston head steals some performance. Under extreme conditions in the end (some thousandths of a second if not less) of the piston cycle air and piston seal behave almost like two liquids, albeit of very different density. And unsupported seal will bend back and bleed air.

That effect was studied on Gamo pistons, they have their heads a tad smaller than needed, so they do not support the back of the seal completely. And that leads to worse compression and even air escaping through.

This is cured by installing a very thin turned brass or hard “black” Caprolon washer, a sort of bandage, like a very shallow twin cup, H-like in cross-section with horizontal line equal to the piston diameter. That bandage gives a good support for the seal and eliminates seal bending. This results in increased performance and softer cycle. Seeing this piston’s rounded head and your solution – I think that’ll help you to kill two birds with one stone.

Hope this info was of some interest to you.

duskwight

Duskwight I think I need your help again.

If I remember correctly a few weeks ago you posted a link to a guy who made a competition rifle out of an IZH-60 and I can’t find it here and since I don’t know russian I’m not able to find it with google.

Do you think you could post that link again ?

When using the blog search engine it should search the comments too as invaluable info is often given in here.

I got in an argument on the Canadian forum with a guy saying it can’t be done and that the IZH is a POS.

I know the IZH isn’t a target rifle but I think IZH-Baikal has proven with big sellers like the 46M that they know how to make very good barrels so there no reason it couldn’t be done with an IZH-60/61…

J-F

Try google translate first, type in your English search words, translate to Russian, copy & paste into your browser and add .ru after the terms

J-F

Honestly, everybody gets what he deserves, so if that guy thinks his way – let him think his way. There’s nothing more stupid than trying to talk round some stubborn guy. And every time I hear “It’s impossible to make” I ask “Did YOU ever make something with your own hands to say such words?”

Old metal Izh-60s were constructed to be used as an entry-level competition rifles for youth. They were made thoroughly and precisely, their barrel is good, their trigger action and adjustment system allowed a very fine tuning – not to mention trigger positioning, simplistic yet available.

New plastic ones are made cheaper and worse. You know my usual sermon 🙂

And after all, Izh-60 is not a simple rifle to master. It requires some time skill and hands growing from the right place.

So if I were you – I would just let the guy talk and talk and talk.

Here’s your link:

http://i2.guns.ru/forums/icons/forum_pictures/001118/1118143.jpg

http://i2.guns.ru/forums/icons/forum_pictures/001118/1118132.jpg

And now you’ll have to proove that celles barbares Russes could do that 🙂

duskwight

DW those rifles are Beasts!

I think even the latest Izzy’s have darn good barrels and fair actions? Probably not worth that level of retrofit, stock work and talent as shown on the old Izzy.

Anyway, how are things with you? What are the latest airgun exploits for Duskwight?

Brian,

It seems I began to understand and like words “Slow and steady wins the race”, albeit it takes almost the same energy to make things move. Slow and steady – that’s the way things are going these days.

I began drawing some stock sketches for my project. Frankly I’m torn between classics, preferrably fullstock, and modular design, I’m taking inspiration from WA-2000.

The problem is that the whole thing seems to be a bit uneasy to fit into wood. So I’ve got to invent something about it. Crazy part of me whispers for some 7075 alloy chassis, machined from a single piece with some neoprene inserst. Really expensive, however it might be even lighter than wood. Let’s first produce a working metal part, then think about wood – that’s what I say to me every time.

Last Saturday went to the range, punched some usual holes in paper. Not sure, but my Leapers seems to start some funny business – there were some strange repeated flyers, straight rightwise, or maybe that’s just my imagination and mistakes in holding the rifle. Don’t know yet, need to test.

duskwight

duskwight,

Don’t overlook the fact that the scope may be adjusted too high, causing the erector tube to move.

B.B.

B.B.

I didn’t think in that direction yet, so thank you for your advice.

Still it’s strange, as just a week before I shot @ 50 m and pulled POI 32 clicks up for that and it was OK, no repeatable flyers. Then, on Saturday I pushed POI 32 clicks down, back to its usual zero for shooting 25 m and they appeared.

Well, strange things happen, so I’ll also check it from erector tube point of view and see what’ll happen then. I still hope it’s just my mistakes in holding rifle, as it seemed to appear closer to the end of 2nd hundred of shots. After all the scope is a real veteran, it survived for I guess close to 9000 shots, so it has the right for some oddities and aging.

duskwight

Thanks a million Duskwight, once again you came to my help. I can’t help it, guess I’m still too young to let go of some issues.

J-F

Great conclusion to this one. Thoroughly enjoyable.

Edith – couple of things…

1) Picture #2 is out of place. It does not show the old screw coming out. What it shows is how I seated the new roll pin with a bolt in place (so it didn’t protrude into the inside thread in the piston head)

2) I DID resuse that funky rear triggerguard screw… there was nothing wrong with it other than the slot being off-center.

Sorry if there was some confusion with how I wrote the original article…

I’ve just put the correct image in place and corrected the caption for the triggerguard screw. Sorry for the mixup.

Thanks,

Edith

Vince………..

Another great salvage job for sure. You are the ‘mad scientist’ of airgun repair (Frankenvince) !

Now you got me thinking (again) about what I don’t have to work with. I used to buy tools because some day I might need them. Some eventually got used for the intended purpose, and some got used for other purposes. Some never have been used (yet).

So what to put on my list?

Metric tap and die set. Metric drill set. Sized drill set. Tapered reamer. Thread guages (SAE and metric). New set of punches and drifts.

twotalon

Twotalon,

I know what you mean about the tool collecting. I think it runs parallel with the airgun affliction.

If you only want the metric tap and die set for occasional work and thread repair, I can vouch for this $11.99 set from Harbor Freight http://www.harborfreight.com/40-piece-metric-carbon-steel-tap-and-die-set-39384.html

It has taps and dies for M3 through M12, plus 1/8 pipe. It has a thread pitch gage, too. I know what you are thinking, and honestly, I am amazed at how well it has held up. I’d have to check the box that says “greatly exceeds expectations.” (I HAVE had my share of losers from HF, too!) It works fine for re-threading, and on aluminum and soft steel. I did ruin one of the dies trying to thread a piece of 17-4PH stainless rod. I bought a “real” replacement for the ruined one, but it cost me as much as the whole set from HF.

For something you are going to use once in a blue moon, this might do the trick. They have an SAE set too.

Lloyd

It’s not just for airguns. There are so many more things that are imported that are metric any more. Even “American made” stuff ends up with a mixture of SAE and metrics. You have to have two different tool sets to work on anything with nuts and bolts. Measuring instruments have to read in SAE and metric too.

We are slowly being forced into the metric system.

Then there are gun screws. Often strange sizes and superfine threads. It’s a real SOB.

I don’t know how many sets of driver bits I have bought, because everytime I turn around I see something that I don’t have and may need….or have needed before and did not have. There are a bunch of bungholes out there that keep inventing new kinds of screw heads that nobody has bits for. They want you to throw things away and buy a new item rather than fixing the old one. More planned obsolesence.

twotalon

On the very funny show “King of Queens”,one of my favorite episodes is the one where Arthur contemplates how much money Phillip made off the “Phillip’s head screwdriver”.He goes on to spend a fortune producing his own take……that has an “A” on the tip! He cannot imagine why nobody wants

to market it…LOL

Now they even have an “improved” Torx, called Torx Plus (example old T8 vs new IP8) . The new Torx plus drivers won’t fit the old torx screws, but the old torx drivers fit the new torx plus screws just well enough to bougger them up if you have to crank down on them.

When I was in elementary school 50 years ago the push was on to change to the metric system…Sputnick, science, all that good stuff.

I wish the US had made the change back then and all the pain would now be a distant memory.

Lloyd

More odd Torx bits. Now that really brightens up my day. I am now in the process of inventing some new profanity.

twotalon

How about those one-way only fasteners in the restroom stalls!?

Amen! We should metricate now. A lot of stuff made here (esp. for export) is already metric. And as the Canadians on this blog can testify, if you do it and do it quickly, there’s not much pain involved. Don’t want to be like Ireland where until a few years ago “mileage markers” were in miles, but speed limits in km/hr.

Ultimate metric give-in, Harleys with mixed SAE and metric bolts!

Same for me, the HB sets aren’t bad for re-tapping or on softer metals.

17-4!? Now that’s pushing the limit of those Chi-Com tap and die sets!

Brian,

Yes, I knew the die was going to be a goner, but I was desperate. We are lucky enough to have a great little independent place in town that sells all kinds of fasteners and cutting tools and drills. Like a mini industrial tool supply. The Harbor Freight sets hold me over until I am forced to buy the real pieces individually. But that way I have to buy one very couple of months. Works for me. LOL.

Lloyd

Vince,

I like the way you work. That screw head is a fine example of handcrafting…by someone who needs glasses :).

Chuck,Victor,

It is a good idea to stick with lead bullets in .22, but I don’t think the copper wash does any real harm (I avoid it in my Savage when possible). If the Thunderbolts (which are lead) hold up at 50 yards (don’t hold your breath) you are one lucky man. There are many complaints about them, especially that they “lead up” barrels, but I don’t know how seriously that should be taken in a .22, even with a high-velocity round. You’ll be using the ammo you ordered at 50 yards and beyond, most likely, so don’t regret doing it.

Vince,

What a terrific job! Your improvising skills are commendable.

If I sent you a roll pin, 1″ nylon bar stock, a coffee can lid, an old leather belt and some loctite I’m convinced you could build me a nice airgun from scratch.

I’ve had good luck using jet glues for stock cracks. The various viscosities, their optional micro tips for application and the ability to vary drying times using their accelerator gives me enormous latitude for almost any stock fix.

http://www.jetglues.com/images/products/super-jet.shtml

kevin

Kevin,

Do you have a local source for those, or do you order online?

I’ve never had much luck with super glues. Maybe I’m doing something wrong or don’t really understand their limitations or am using the wrong kind???

Lloyd

Lloyd, never had any problems with Superglue or Crazy glue. Always worked well on my fingers.

Fred PRoNJ

LOL!

lloyd,

I ordered mine online years ago. Since a little goes a long ways I probably have a lifetime supply. I’ve had very good luck using jet glues for small cracks and hard to reach places. Works well on metal if you get the right kind too.

kevin

Kevin,

I will have to check it out, but will avoid fingers and toilet seats.

Lloyd

Kevin,

Don’t underestimate the power of simple wood glue. It will hold until the wood around it breaks if its applied right. One trick I heard lately is to “flux” a crack with warm water and then apply the glue. Supposedly the glue gets drawn into the crack after the water. Haven’t tried it yet, but I can’t wait for the next big stock crack :).

BG_Farmer,

There’s a place for “simple wood glues.” I like titebond and have been using it for years. The problem with “simple wood glues”, like titebond, is that they work better with larger surface areas and clamping force helps adhesion. For smaller cracks (like the stock crack in today’s article) a simple wood glue is not performing adhesion as much as it is acting like a filler. Without clamping if you x-ray the fix you’ll also see gaps created when it’s completely dry.

kevin

Kevin,

To me it seems like there is a lot of wood there for glue to stick to and many ways to clamp, but if structural integrity really seemed to be an issue, I would inlet some steel sheet (e.g. 22g) with epoxy on the inside after the wood glue dried; that makes a pretty strong joint. I could always be wrong, though.

I haven’t had much luck with “super” glues — they seem to hold for a while and then let go, but that could just be me, and I haven’t tried them on wood. They can also attack some vintage finishes, I think.

Kev, note the part where I write “Close it, clamp it, wipe off the excess and let it sit. Hopefully, it’ll be as solid as it’s gonna get. Repeat for the port side, and I’m done.”

Yes, the joints were clamped quite firmly while the glue set. Remember that I worked the glue only from the outside – the glue seen on the INSIDE means that I got it all the way through the width of the crack.

Glue, proper, doesn’t work by “sticking” to the materials being glued. Instead, it penetrates pores and gaps in said material and then hardens. It’s the form filling nature of that penetration that holds things together.

In my experience, “superglue” is a cement… It doesn’t work by penetration but by raw adhesion to the surfaces. One reason shear forces can break the bond so easily.

Compare the picture holding ability of a small plastic wall anchor that is expanded into the wall material to a one of those 1×1″ tape patches with a hook.

{Of course, after this is the gecko…}

BGF I have done the same with warm water & glycerine and a bit of a soak with a sponge in and around the crack. Works well with the water soluble glues like Elmer’s. Also, if you can get to the crack on the inside or underside (that doesn’t show) I have actually removed some material to create a groove and have used very small drills (like .016 dia.) to side drill into the crack for more glue pathways. This only works if you can get the little holes wet and I usually water down the Elmers a bit to lower the viscosity.

I have been using Brownell’s stock bedding compound to repair wood cracks. I use the jell type that comes in the green box. Once it sets, it is much stronger than the wood. It will also repair a complete break. If you were in a remote area and broke a stock, you could be hunting again in 24 hours.

Mike

Victor,

Re: Your Ruger MK II

Read that you’re having feeding problems with some ammo. Typically lower velocity stuff.

Have you considered installing a volquartsen extractor? The ruger mk’s are notorious for feeding problems. The aftermarket extractor solved this problem in my mk II and mk III. They’ll eat anything now.

kevin

Kevin,

No, I haven’t considered replacing the extractor, but I’ll definitely consider it. The only ammo that’s caused problems for me is Remington Target. And even with Remington, we were nearing 400 rounds before there was a problem, and the one problem was that the round was a dud. Of course, now I know that with Remington, I was lucky to get that far. With my 10/22, it was clear that the issue was with the primer, and not the striking power of the firing pin. As it turns out, the Bleiker smallbore rifle has it’s firing pin at 6 o’clock, where the powder is more likely to be, and thus less chance of a misfire.

Thanks,

Victor

Vince,

Another great job.

Very clever approach to shaping the nylon dovetail clamp for the piston seal. I do have to offer one correction though. Instead of shaping the part with your cordless drill and bench grinder, I think you meant to say that you fashioned an improved part using your Jones & Shipman Precision O.D. grinder. It’s nice to have $1,000’s of dollars of specialized equipment at your disposal, you lucky guy! LOL.

Seriously,I always learn a new trick when I read one of your blogs.

Thanks,

Lloyd

Vince,I admire your out of box thinking.Thanks for breaking it down again to show the trigger group

layout……it’s not often that a group of trigger parts makes any sense to me.I would suggest you call this your “Expresso tune”!

Vince:

What could be better than seeing an air rifle?

Seeing an air rifle in bits getting worked on or tuned.

Great job.

I had an exact same fracture happen on the stock of a very old BSA ‘Senior’ .177 break barrel I owned as a teenager.

I remember using ‘Araldite’ glue as a fix at the time which did the job.(not very pretty though)

Thinking of it, there is a lot of leverage acting on one screw and that portion of the stock whilst cocking a break barrel or under leaver rifle.

I wonder how common this type of fracture is and if it could be avoided by using a different cocking technique?

DaveUK

Howdy Dave

To your point, I’m guessing most of us use the “break the branch” method on spring guns, holding the pistol grip of the stock in one hand and working the break barrel or under lever in the other? That makes the pistol grip area a huge lever and if the wood is weak/aged it gives under stress sooner or later.

I guess the alternative is to grasp the spring tube area above the stock, butt-pad on knee and other hand on the barrel and “break” open?

Hi Brian:

I get what you mean.That should spread the load a bit when cocking.

Cheers.

DaveUK

Vince, nice work and pictures as usual 🙂

The great thing about your blogs/reports are the “generic” tips and processes you illustrate that cut across product types and gun models. Seal repair and upgrade is a perfect example. Your photos help lot’s of folks see whats inside a spring gun, and even if they never DIY on their own guns, they now have a better appreciation for good cleaning and lube practices etc, and why their guns may not be up to par.

BTW, was the R&R work on this for the fun of it or, is there some value to this gun that is (definitely) not obvious from it’s performance and physical condition before you started surgery on it?

Vince,

You did well! This was a marvelous report, and the pictures were stunning.

For those of you who don’t take detailed shots like Vince has today, every time he takes a closeup, he has to wash his hands before he handles the camera. Then he has to set up the shot and get the lighting right, so everything he wants, shows. This is not easy work.

Vince, you do us proud.

B.B.

Uh….. not quite. Washing my hands? Why, when I have a black camera? Seriously – I have a camera dedicated to airgun stuff (Kodak Z812), and yes, it’s dirty. It constantly sits on a charging/docking station on top of my airgun bench computer until I need it. If my hands are gooped up I’ll wipe ’em off first, but that’s about it.

I also do not fiddle with lighting. These are all ordinary, flash shots taken in automatic mode. Sometimes I’ll take multiple shots at slightly different angles if I think the flash reflection or shadowing makes it look funky, but that’s about it.

BB, you’re seriously underestimating my laziness!

Vince,

I thought B.B. was being sarcastic about washing your hands 🙂

Edith

Edith

I thought the same thing. I was thinking, “…here Vince is working on the Falke for free, and BB is making fun of his dirty fingers. Next he’ll be pointing out his filthy fingernails.”

😉

Without getting into all, just for the record Tom refuses to be a moocher. And further for the record, I keep trying to tell him that he certainly does have the right to do a little mooching once in a while.

Vince,

Okay, you’re a slovenly lazy slug who doesn’t deserve the good results he blunders into.

That better? 😉

B.B.

Now that’s funny!

It sounds like you’ve known me all my life!!!

lloyd wrote:

As a model builder who has been using ‘superglue’ almost as long as NASA I assure you that the shelf life of CYA adhesives is time limited! They remain viable much longer if the container is airtight and they are refrigerated, but they WILL eventually need to be replaced!

The thin CYAs wick extremely well in applications such as Vince encountered on the Falke but their ‘instant’ properties are a hindrance since they cure faster than a proper clamping system can be utilized. A far better solution in such instances is an aliphetic resin from Germany sold to modelers that has almost equal wicking properties as the thin CYAs yet allows time to properly clamp a joint. It is marketed under the name of ‘Superphatic’ and shelf life is MUCH longer than CYAs.

I don’t know if it is more widely available than it used to be but for a long time the importer and sole marketer was the on-line model supply house of Hobby Lobby. Be very aware that it is a completely different entity than the retail outlets that do business under the same name!

Superphatic has came to my rescue in many cracked stock instances just like the one Vince encountered in the article. HTH, Tom @ Buzzard Bluff

Tom,

This is interesting. I have used thin two part epoxy “rot fillers” that flow through the pores and pithy areas in wood, but nothing that I would say that really wicks. Doing cabinet work, there have been times that I’ve had to split a crack open to get enough glue down inside it to make a sound repair. I’ve used some beautiful quarter sawn western fir with perfectly straight grain, but it separates so easily along the growth rings, especially when running it through a shaper. A wicking adhesive would be a life saver. I will check it out.

Lloyd

Vince,

How did you get the excess glue off the stock without affecting the finish?

-Chuck

Not an issue. This wood glue is water soluble and doesn’t stick to non-porous surfaces. After clamping I wipe the excess off with a damp paper towel, and if there’s any left externally after it dries it pretty well just flakes off.

BB I was on the Weihrauch site and saw three “4mm” handguns/revolvers. Are these firearms or blank shooters or…?

If firearms, are they of any usefulness or quality if you know about them?

Brian,

They shoot the same ammo as a zimmerstutzen. In Germany, people don’t have the same access to firearms that they do here. Airguns take care of the need for accuracy, but for noise, the Germans use blank guns. These 4mm revolvers are a sort of compromise between a firearm and an airgun.

Read here to find out what a zimmerstutzen is:

/blog/2008/02/what-came-before-the-10-meter-rifle-part-2-zimmerstutzen/

Germans also used to shoot indoor target pistols that were much like zimmerstutzen rifles. They do not look like the Weihrauch revolvers at all. They are large and single-shot. Go here to see one:

http://www.gunbroker.com/Auction/ViewItem.aspx?Item=216570707

That one is a .22, but more often they are 4mm.

In Europe, Weihrauch builds cheap firearms as well as fine airguns. They used to make one of the finest .22 target rifles in the world, but that was a century ago. Today they build what we would call Saturday Night Specials. These 4mm revolvers are part of that. The 4″ and 6″ barreled models do have target sights, but their actions appear to be the same old diecast guns they have been making since the 1960s.

B.B.

Thanks BB, makes sense as the ad copy says “all steel trigger” which makes me assume that all else is not steel! El-cheapo mucho!

Collector’s alert!

There is a Sheridan Knocabout on gunbroker.com right now. It has two days left.

http://www.gunbroker.com/Auction/ViewItem.aspx?Item=217161564

B.B.

Vince, stout work as usual.

Chuck, thanks for your report about the Savage. That’s my rifle brand. I believe I read a report from South African rangers saying that they don’t use anything else as Savages are in a class by themselves. Yours also sounds more forgiving of ammo than my Anschutz which can only really chamber Wolf Match Target ammo.

Victor, my heart bleeds for you having to disable and damage Anschutz rifles. That is just crazy. It is so strange that they can’t be bought for some amount of money, especially as used rifles.

On the subject of giving drugs to animals to calm them down, beware, the chimp that went crazy and ripped off the woman’s face was given Xanax in his tea…. Apparently, some humans will have adverse reactions but the effects on an animal are totally unpredictable. Experts have also theorized that maybe it was the bubble baths with the owner, sleeping in her bed, and being dressed in red and blue onesies that send the chimp around the bend. It messed with his boundaries. I could see that.

Matt61

Me too Vic, it makes me sadder than the color yellow that they want to destroy those guns. Couldn’t an attorney write something up to clear city of any future issues with them. Or you buy the guns through a dealer to keep the city a step away from you. ?? good luck.

Gene,

You’re exactly on the right track. In fact, prior to my reading your comment, I sent an e-mail to the city administrator asking the city to consider donating the rifles to a shooting range that is cleared to buy and sell guns. I explained that it’s not critical that I personally own them, only that they find a proper home. Additionally, it would be nice if I had access to them to start my own junior marksmanship program. After all, this is what my whole fight was originally all about, keeping a junior marksmanship program, like the one I benefited so greatly from. Being involved in something at the highest level, like I was, is life changing. I wish every youngster could know my experiences.

Thanks,

Victor

Matt61,

The elected officials, especially the mayor, WANT to give me the rifles. In this case, it’s the non-elected officials who are being ultra cautious. They are leaning on the ultra conservative side, in terms of language that they are using with me. I don’t believe that they are motivated to damage or destroy these rifles, unless the city attorney convinces them that this is in the cities best interest (which I think is a very long shot).

I am not a gunsmith, dealer, nor have I ever sold a gun. My hope was that someone here might come up with a reasonable alternative to the extreme possibilities that go under the heading, “permanently disabled or inoperable”. To me, “permanently disabled or inoperable” implies “sad and expensive paper weight”. Like the city, I’m kind of reaching for straws of insight. I think I’m doing about all that can be done myself, and that may be as good as I’ll get, and hopefully need.

Victor

Victor, are these air rifles or .22 firearm rifles? If air, I don’t get this at all. If .22 cal firearms, then BBs suggestion is one of many that makes sense.

Forget the semantics of inoperable or disabled, as a wise attorney once told me, “there is no such thing as cast in stone and agreed upon, ever”. More plainly said, you and the City could agree on all sorts of things that allow you to take possession of these guns (firearms) and 5 years from now when the local crack-junkie steals one and shoots somebody, they are coming after you and the City anyway. Justified or not, legally sound or not, some 1-800-I SCREW EM attorney will sue you.

I’m starting to feel your pain, and this is really hurting, a lot, no, I mean it, it’s friggin painful!

Strong problem resolution to follow…?

Bryan in Idaho,

As it turns out, they have both Anschutz rifles and FWB 300’s. When the city proposed shutting down the range, it was implied that they would kill EVERYTHING, including the junior marksmanship program. I fought to keep the range open, but as I said, some self-serving individual decided to toss a grenade in the whole program. I can’t give more specifics as I believe he is still trying to extort money from the city (and again, he was “one of us” – NOT). Anyways, once it became clear that the range was lost, I then proposed that they didn’t need a range in order to continue a junior marksmanship program. After all, they started this program years before they had a range. Up until this past week, the idea of keeping the program was still on the table. Another recommendation that I made was keeping the smallbore equipment on ice until the economy got better. In the meantime, I suggested that they maintain an air-gun program, and possibly introduce sporter class. I just found last night from a buddy of mine who is a coach at another range that he has heard that they are in fact considering keeping the air-rifles for a new air-gun range. That’s promising, I hope.

Our range was setup for high end competition, and it had the equipment to support it. It was one of the most modern and sophisticated ranges in the country. From a single command booth, you could control all targets, and thus tournaments. Unfortunately, they gave away very high end .22 and .45 target, and FWB precision air pistols to local law enforcement. I say, unfortunately because, again, these are guns that are really suited for competition at the highest level.

Victor

I don’t know much about this but some times the simplest things can be done to go around bureaucracy.

Maybe the rifles could be taken apart would end up being only parts? A bunch of parts for you, a bunch of parts for the range (or FFL dealer), no one is getting complete guns yet you can take your parts and the range parts and end up with some nice complete guns again.

I might being too simple here?

J-F

Matt,

I just got two boxes of Wolf Match Target yellow “triangle”. Anxious to see how they do tomorrow.

-Chuck

Lloyd wrote:

I only use it in the part of a crack that is too narrow to accept other adhesives. In fact I just came in from the shop where I used it to wick into the narrowest part of a forearm deeply split from the cocking lever slot almost to the trigger guard. I used regular carpenters yellow aliphatic resin in the wider part of the crack where I could force it in. It’s clamped up to dry now and in a few days I will cross drill it and dowel it since this is a Chinese mystery wood that has stubbornly resisted gluing efforts alone.

This is a B-18 stock and if it won’t hold this time I’ll be forced to get a Quest stock from Crosman unless I can find a used stock—no luck so far. Tom

Does anyone know if the Browning 800 Mag .177 has a choked barrel?

I had one of my friends who owns a Browning Mag push a pellet through the barrel to see if there is any resistance and there is not. I guess the Browning does not have a choked barrel. I didn’t think it did but I wanted to be sure.

Victor,

The rifles are city property that can be disposed of in accordance with law, unless the city has legislation to the contrary. Therefore, selling the rifles to an FFL and putting the money toward some beneficial city program (a tearjerker would be the best) might be the best direction to take.

The city, as an entity, would be selling the rifle the same as any individual who owned them.

B.B.

Victor,

Do you want to get the firearms personally as the only solution or are you just trying to save the guns from being destroyed & never used again?

If it’s the latter, your club might consider donating the guns to the Civilian Marksmanship Program (CMP).

If it’s the former, I wonder why they’re afraid to transfer the guns to you through an FFL. Then, they’re not “handing them over.” They’re in the system.

Edith

Edith, Tom,

Going through an FFL is the only thing that makes sense. This is why I propose that they go through the range that I’m associated with. They are an FFL, and at the same time can provide the perfect home. It’s not critical that I own them, I just know that I could take care of them better than most, and I did. I explained to the city that my first priority would be for the city to continue it’s junior marksmanship program, and that I’d be willing to help in any way, even though they no longer have a range. My second priority would be that they find a good home elsewhere. It was actually the mayors suggestion that they give me back what I used, but the mayor doesn’t have full authority to do such a thing. This has to be voted on by elected officials, and then has to be managed by non-elected officials. But it’s the non-elected officials who have introduced the harsh terminology. I believe that this will get ironed out soon enough.

Thanks,

Victor

See response 5 posts above 🙁

Brian in Idaho,

If I can get these rifles to my current range, everything will be perfectly safe. This range has truly impressive facilities for storing pretty much anything. They own 50 caliber machine guns, and even a tank, if you can imagine that. I’m talking underground, reinforced, bunkers, on 160 acres. Probably only our own air-force could get access to them without keys and combinations.

Yes, lawyers can really be something.

Victor

Vince I want to congratulate you on a great job and an entertaining write up. The way you handled the problems you encountered was very impressive.

I’ve been meaning to do some sort of a strip-down for one of the Falke underlevers since I started the Falke forum nearly two years ago and have never got around to it. So I’m especially glad I have one to refer back to now.

I’m sorry you’re a bit underwhelmed about the rifle now it’s fixed up. I can’t help wondering whether the poor state it was in when you got it somehow tainted it in your eyes?

Most of us who own these rifle marvel at the no-expense-spared, hand-finished quality, the high-grade materials and attention to detail. Along with that quality, I think part of the attraction of the Falke underlevers is the small number made and the mysterious disappearance of the Falke company after less than a decade of production.

I should add that doubt has been cast over the (assumed) manufacturing totals recently by the recent appearance of a small number of duplicate serial numbers. The current best guess is that some 200 Falke 90s and 400 Falke 80s were made. These totals are still plausible (and one mathematician has speculated they might even be over-estimates). But if the incidence of duplicated serials should rise much further, we may have to think again.

Anyway, I digress. Thanks again to you and to B.B. for putting on such a fine Falke show!

Garvin

Garvin, it ain’t done yet. There’s still the shooting impressions to be delivered by Tom’s friend Mac.

Certainly the state didn’t help. And maybe I went a little overboard on the ‘disappointed’ angle. But as I said, that pre-WWI BSA underlever I worked on for a fellow some time back was also a taploader, and so I can’t help but draw a comparison. It really was a wonderful piece of workmanship that makes almost anything else pale by comparison. Someday I’ll blog that one as well.