by B.B. Pelletier

This report is in response to a comment Pyramyd AIR got from a customer who doubts that fixed-barrel airguns can ever droop. His position is that they can only have droop if the barrel is heated in some way (as on a firearm that fires very fast) or if the gun is assembled in a shoddy fashion.

He said he believed barrel droop is only commonly found on breakbarrel airguns, which is why he said he would never own one. He thought that droop was mostly caused by the metallurgy of the barrel.

Today, I’d like to address the subject of barrel droop in detail. It can be caused by many things, but poor metallurgy isn’t one of them. Barrels do not bend from cocking, despite what some people may think. It is true that a barrel can be bent by human force, but the force required to do so is much greater than the heaviest cocking effort on the most powerful magnum airgun. So, poor metallurgy is not a contributor to barrel droop.

What is barrel droop?

I will explain what barrel droop is in detail later in this report. For now, I’ll just say that barrel droop is a condition in which an air rifle shoots so low that the scope cannot be adjusted to hit the target.

You must understand that most scopes cannot be adjusted all the way to their highest elevation settings and still operate correctly. This will differ from scope to scope, but generally most scopes do not work well when adjusted above three-fourths of their maximum elevation. It’s imperative that they get on target before reaching that height, and a drooping barrel can prevent that.

History

Throughout the first five decades of spring-piston air rifles, no one ever heard of barrel droop. It was a non-issue. That was because nobody bothered scoping their air rifles.

The sights on most breakbarrel guns are attached to the barrel, both at the front and rear, so they’re in line with the bore — as long as the bore is drilled straight through the barrel, which it seldom is. The amount of misalignment is usually measured in the thousandths of an inch — an amount the sights can easily account for.

With both the front and rear sight attached to the barrel, there’s less chance for misalignment.

In the 1960s, retailers began attaching scopes to airguns to sell more of them. Firearms had been using scopes for some time, and the general belief among shooters was that scopes extracted the maximum accuracy from any gun.

But scopes had a problem, as well. They were attached to the spring tube of the gun, which isn’t integral with the barrel on a breakbarrel airgun. For the first time, the alignment of the spring tube and barrel came into question.

It soon became known that most breakbarrel guns have a barrel that slants downward from the axis of the spring tube. In the 1960s and ’70s, breakbarrels were hand-selected for scope use when they exhibited less slant than other guns of the same model. You can read about this selection program in both the Air Rifle Headquarters and Beeman catalogs of the period.

What those catalogs didn’t address was the fact that fixed-barrel airguns can and do sometimes have the same barrel slanting problems. They didn’t address it because, at the time, scoping airguns was brand new and not that much was known about it. The people scoping the guns often installed simple fixes, such as shimming the rear ring, and didn’t even think about why they were doing it.

Why the barrel droops

The comment that prompted this blog went on to say that barrel droop was caused by poor metallurgy. Evidently, the writer thought that “droop” referred to a barrel that was curved (or bent) downward — which is not the case. The term “droop” doesn’t refer to a barrel that is somehow curved. It means a barrel that points in a direction away from the sight line, so the axis of the bore and the sight line are diverging. To correct for this droop, the scope has to be repositioned to align with the axis of the bore.

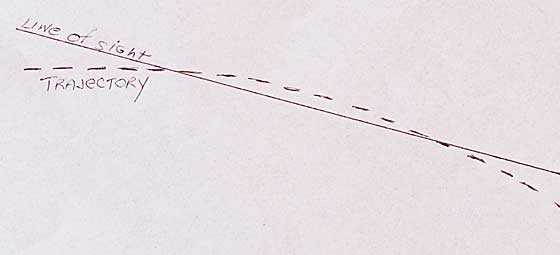

We all understand that a pellet starts falling the moment it leaves the muzzle. The farther from the muzzle it goes, the faster it falls; so the line of flight is actually an arc, rather than a straight line. To align the sight line of the scope with the axis of the bore, we have to align the scope to look downward through the line of flight. To be effective — that is to get any distance over which the pellet is on target — the sight line is made to pass through the arc of the pellet twice — once when the pellet is close to the gun and again when it’s farther away.

The scope is angled down through the pellet’s trajectory. This illustration is greatly enhanced for clarity. This alignment is done the same for firearms and airguns, alike.

But the question is, “Why does the barrel point downward?” With a breakbarrel, it’s usually because of how the breech locks up at a slight angle that causes the downward slant. Some guns, most notably target breakbarrels, overcome this with barrel locks that cam the breech tightly against the spring tube in a straight line. Most guns rely on the spring-loaded detent to both align and hold the barrel during firing. If there’s a weakness, it’s at this point. When a breakbarrel with an unlocked breech fires, the barrel tends to flex in the direction the barrel is hinged. If the barrel broke upward to cock, the problem would be reversed and we would have a barrel “climb” problem.

A breech lock like the one on this HW 55 ensures that the barrel always aligns with the sights — provided the rifle is designed that way.

Do you now understand that the barrels are perfectly straight, and it’s just the angle of the bore’s axis relative to the line of sight that creates the drooping problem? Good, because that’ll make the following easier to understand.

What about underlevers and sidelevers with fixed barrels?

How can a fixed-barrel rifle have droop? Easy — the barrel isn’t attached to the gun with the bore parallel to the line of sight. Presto! Automatic sighting problem. Or the scope base that’s attached to the spring tube may not be aligned with the axis of the bore. Or the bore may be drilled off-center; and although the outside of the barrel is parallel to the sight line, the bore’s axis isn’t. Any of these three things can happen.

Bore not drilled straight

This is very common. It’s extremely difficult to drill a deep (long) hole straight through a steel bar. The drill bit can wander off-axis as it bites its way through the steel, or it can be off-axis all the way through the bore if it isn’t correctly set into the holding fixture before the drilling begins. I’ve had barrels with bores as much as a quarter-inch off-axis with the outside. Granted that’s extreme and uncommon, but it demonstrates the possibility.

The only way a barrel-maker can ensure concentricity of the bore to the outside of the barrel is to machine the outside of the barrel after the gun is rifled.

Barrel isn’t aligned with the spring tube

This problem is also common. When the barrel is pressed into the spring tube (usually into a block that’s held in the front of the spring tube), the bore isn’t aligned with the spring tube. You might think that modern manufacturing processes make perfect things time after time, but the truth is that there’s always some variation.

Scope base on top of the spring tube is not aligned with the bore

Of all the problems with scope alignment, this one is the most common. Off-axis bores are usually held to just a few fractions of an inch for which the scope adjustments can easily compensate. The same is true for barrels that are bushed off-axis. But scope bases are both short as well as attached in such a way (by spot-welds and rivets) that precision is difficult to maintain. Because scope bases are short, any small deviation in their positioning is exaggerated when extended out to infinity by a scope’s sight line. This is the one place where firearms and certain brands of airguns have an advantage over other brands, because they machine their scope bases into the receiver (of a firearm) or scope tube, rather than riveting or spot-welding the base to the scope tube. If the tooling is set correctly, the machining process ensures alignment of the scope base.

Talking about the spot-welded and riveted scope bases brings us to a discussion of one well-known company that makes highly regarded spring-piston air rifles. This company stands head and shoulders above the others when it comes to having barrel droop — both with their breakbarrels and their fixed-barrel air rifles. That company is Diana. Historically, enough Diana air rifles have had barrel droop so severe that special corrective scope mounts have been made and successfully marketed for their models. Even RWS, who exports Diana airguns, has marketed such a corrective scope mount.

But even Diana can change. Their most recent breakbarrel is their 350 magnum model in all of its various forms, and this rifle is very noticeably immune to the drooping problem. Something has changed at Diana. I would think that, over time, we’ll see this change spread to all of their models.

Firearms also have droop

Drooping isn’t just an airgun problem. Firearms have droop, too. But because of how firearms were scoped in the early days, nobody noticed the problem.

When firearms were scoped back in the 1940s and ’50s, many of them did not have optional scope mounts available. It was very common back then for a gunsmith to drill-and-tap holes into the firearm to accept scope base screws. Naturally, when a gunsmith did the job, he would align the holes in the scope mounts so the axis of the barrel was in line with the sight line seen through the scope. If there was any barrel droop, it was corrected as the mounts were installed.

Do barrels only droop (slant down)?

Before someone asks the obvious question, I’ll address it. Yes, there are airguns with barrels that slant up, plus point to the left and to the right too much for the scope to compensate. They’re not encountered as often as droopers, but they’re not unheard of. The reasons for most of these problems are the same as for droopers except for one standout reason.

If a breakbarrel rifle has been fired with the barrel open, so the barrel was allowed to snap closed from the force of the mainspring, that rifle will have a bent barrel. The barrel will be bent upward at the point it emerges from the baseblock, which is the piece that holds the barrel in the action. It’s where the pivot bolt attaches. It’s the blocky-looking piece the barrel is coming out of in both photos of guns in this report.

For this type of problem, the solution is to bend the barrel straight again. Any qualified airgunsmith should be able to straighten a barrel that has this problem, and a number of owners have learned to straighten their own bent barrels..

Most airgun barrels don’t droop

To put this report into the proper perspective, I should mention that a drooping barrel isn’t that common. I have several air rifles whose barrels are okay for shooting with scopes as they came from the factory. And, of the hundreds of rifles I test, only a small percent have a drooping problem. So, it isn’t a given that your rifle will droop.

But you may get a drooper, and you can rest assured that there are plenty of solutions to rectify the situation should you encounter it. The things to remember are:

Not all breakbarrels droop. Only a small percentage do these days.

Rifles with fixed barrels can also have droop, for the reasons mentioned in this report. It is not as common to find a fixed barrel with droop, but any air rifle that has a separate scope base that’s either spot-welded or riveted in place is a likely candidate for droop.

Firearms have droop, just like airguns. But the amount of droop is small enough that it’s corrected by the scope or by the mounts that are supplied by the firearms manufacturers.

Wouldn’t surprise me to know that I’ve owned hundreds of firearms that had droop or were pressed in to the left or right. At long ranges with iron sights or even scopes with typical minimal adjustments AND TYPICAL ACCURACY EXPECTATIONS I never noticed.

My first adult airgun was a diana 54. That gun had typical droop. Dramatic. It’s of course more pronounced at the shorter ranges we shoot airguns combined with the accuracy expectations we have. With our accuracy expectations we mount scopes on airguns that aren’t typically manufacturered for scopes and even in high end pcp’s that are expected to be scopecd there are high end tuners that make custom scope mounts to compensate for centering a scope over the bore. WHAT? On a $2,000 airgun I have to pay to have a set of mounts set up to compensate for a droop barrel or misaligned barrel? Yes.

I am an artist at shimming. I own or have owned almost every adjustable mount. I really like the EAW mounts. I am a great proponent of bending barrels. I have a 100+ year old cottonwood that has bent many airgun barrels. I think bending barrels on airguns is either thought of as blastphomy or witchcraft. It’s neither. It’s common. It’s effective. It’s seldom talked about. It’s easy.

kevin

I also have a 54 that I bought in Roanoke years ago at BB’s recommendation. I wanted an accurate, hold insensitive, .22, quality airgun. It delivered as expected, including the barrel droop. I think the droop was about one foot at 20 yards, but I used a dowel wrapped with sandpaper to make a 1-piece scope mount that eliminated the droop. That is about 1/16″ difference between the front and back rings, which was a lot more than I wanted to shim, so I sanded and sanded until I got it right. I removed so much material from one of the rings that I had to sand material off the mating flats of the rings so that they would actually clamp the tube. After I got it sighted in (CPs in the box, BTW) I didn’t touch any adjustments for years. Now it has lost some velocity and needs some internal work to be brought back to snuff. But whatever droop the gun came with is still there, exactly the same as when I bought it.

Lloyd

B.B.,

The breakbarrel examples you used have both the front and rear sights mounted on the barrel itself.

If a breakbarrel air rifle had a front sight mounted on the barrel, and a rear sight mounted on the spring tube, would the effect be the same as if both were mounted on the barrel?

Les

No.

If the barrel points too much in the wrong direction the rear sight won’t adjust far enough to zero the gun.

I have two that almost are examples of this…

853 barrel distinctly points to the right. RS2 sold as a Beeman something or another with two barrels has both barrels bent (not just in one direction). The sights on this particular rifle DOES have both sights on the barrel (rear is on the breech block). Both rifles just barely have enough adjustability. It would not have to be much worse before the sights would be useless.

twotalon

Not enough coffee yet….

My 48 droops (down), but it was nice of them to make the front sight adjustable for elevation to help with the problem. Then, there is also the ability to work with both front and rear to change the overall sight height a litlle to get better positioning.

twotalon

Les,

I think you have the answer from twotalon. Mounting sights at the rear of the spring tube is where the barrel angle becomes noticeable, which is why most 10-meter target rifles have breech locks.

B.B.

B.B.

Wouldn’t it be more fair to say that most break barrels DO droop, but not enough to cause a problem ?

By the way, most of the springers I get hold of DO droop enough to cause a problem.

twotalon

TT,

You’re probably right about that. I just didn’t want to paint a dark picture for the new person, because so often it doesn’t turn out to be a problem.

B.B.

As mentioned, barrel droop is not limited to air rifles either. Back in the day ,when firearms scopes had reticules that were not mounted together with the erector tube inside the scope as one unit, you could actually see just how bad some barrels or scope mounting holes were off. I have a couple older rifles and scopes from the 1950’s -60’s that show this. One is a Weaver 10X AO 1″ scope on a factory drilled Savage .222, and you can see the vertical barrel droop clearly by the position of the cross hairs when you look through the scope. Another is a grooved receiver Mossberg that wears another Weaver 6X, in Weaver steel tip off mounts. Both barrels and the mounted scopes look perfectly straight. If I mounted a more modern scope on these guns I would never realize that there was an issue .

I should photograph my Marlin Glenfield 60 for this thread. A distinct leftward installation — even the wood stock shows nearly a 1/4″ difference in thickness between left and right where the barrel leaves it.

But the receiver is “straight”… resulting in a definite triangle for one zero distance when sighting a scope. Fortunately (?) the Weaver K1.5 is so low powered it probably isn’t noticeable at .22LR distances. As I recall, I have small strips of Dr.Scholl’s moleskin in the mount as shims.

Changing subject slightly — it probably needs to be noted that having a high-mounted scope needed lots of adjustment downward probably can’t be called a droop problem (I’m talking things like the AirForce Condor with it’s near 3.5” bore center to scope center — Of course if the sights are mounted that high they are going to need significant adjustment… Or pray the gun is powerful enough to zero at a far enough distance that even a small trajectory rise will intersect the sight line).

Agree – my FWB 124 that I bought last year at the Windsor, CT show is a riser and also points right. I’ve tried to bend the barrel down but don’t know if I was doing this correctly. I achieved no correction. I will bring this rifle down to Roanoke and let BB examine it. However, with a sight received from Kevin, I am able to sight the rifle in for 10 yard distance. Not sure if I tried to sight in at 20 yards if there is enough adjustment left in the sight.

Fred DPRoNJ

Trying to fire me up for the week about shoddy mfg practices? Of course there are tolerances and there will always be some droop, rise, left/right and any combination there-of…

My 1st springer, a TF99, fixed barrel, had around 3/8″ droop from receiver to muzzle. That is just sloppy mfg. Period. I had to tweak the barrel AND the receiver in a press just to get it close to straight so that I could scope it. Didn’t know about drooper mounts at the time, which might have saved me some aggravation, but it all worked out with the other work I did to it.

/Dave

/Dave,

When I tested a TF99 for Compasseco, back in 2003, the accuracy (not droop, but general dispersion) was so great that I shot our couch! The hole is still there and Edith delights in showing it off to guests.

B.B.

http://dailycaller.com/2012/05/11/how-i-became-a-hired-gun/

above is a neat little story that was emailed to me.

Long live the Daisy # 25.

Gene

Great story. Thank you for passing it along.

“He thought that droop was mostly caused by the metallurgy of the barrel.”

Actually, I said that in relation only to one possible source on a strictly non-break, or fixed, barrel.

And you are correct that I consider “droop” to be separate from a misalignment of a straight barrel. I cosider it a semantic mistake, however well accepted in certain circles.

To me, the word droop still implies that the barrel itself is curved (or “Broken” and reassembled “crooked” as in the case necessary on a breakbarrel) – and BTW, in the downward direction only.

Otherwise one should say “misalignment”- of either the bore or the barrel. For one thing this avoids applying a term that implies a downward misalignment ONLY, to one that may be in any direction, possibly merely by twisting the barrel, in the case of correcting (or even exacerbating) a ‘bore concentricity’ issue with a “mounting” issue. Again, the foregoing assumes a fixed or non-break barrel.

And it also seems obvious to me yet, that a barrel that is more than one piece, essentially disassmbled and reassembled at every shot in a temporary fashion, has to have relevant probability of misalignment to a degree that would make accuracy problematic. For one thing, the differing random compression of the necessary seal material would ensure it.

I’m sure that on a VERY expensive gun these effects could be minimized. But again, low or high cost, the breakbarrel would seem logically less accurate for the same quality (and as a aside, realizing that price doesn’t always guarantee quality.)

Rodney,

I am impressed! I hoped you would read this blog, but I didn’t think you would sign in and admit it was your question. I actually didn’t know whose question it was — I was just asked to address it, which I hope you feel I have.

I hope from the reader responses you can see that a lot of fixed-barrel rifles also suffer from misaligned barrels. I agree that droop isn’t a very precise term for misalignment, but Tim McMurray of Mac-1 actually coined it many years ago, when he created one of the first, if not THE first “drooper” scope mounts. I still have the one I got from him. It was align-bored on a downward angle to compensate for barrel slant, or misalignment. After he came up with the phrase, everyone adopted it and today that’s what the bulk of the airgun community calls a misaligned barrel.

Anyway, thanks for weighing in on this and I hope you get something from the discussion.

B.B.

There’s obviously no disagreement here. I was just correcting a misquote of my intent, as well as my wording.

While I realize the term had been well adopted, I was just being my usual unreasonable stickler for precision and correctness of terminology. (Incidentally I’ve just discovered the DIY versions of Benji 392 modding, having despaired at Tim’s prices – not that I would doubt at all that he’s worth it! Just honestly not sure he’s still around, and as a retired engineer and vintage racing kart metal fabricator/welder -on a fixed income no less; I love to void my warranties, believing in: “Never own anything you can’t fix” 😉

Being also a notorious spelling Nazi, I must apologize that I didn’t review my previous post or at least use spell check, being used to forums where you can edit your posts after entering.

Thanks again for your usual grace and cordiality, which I first enjoyed over the FB/BSOTW pic discussions. You are truly a class act that’s hard to follow! You represent Pyramyd well, and I hope they appreciate you.

just offhand, I wonder if someone sells aftermarket “centerless ground”/bored (i.e. concentric to .001”) barrels.

Welcome, Rodney!

I kind of doubt that centerless grinding would do anything more than ensure that the barrel’s od would be perfectly round. The bore could still be crooked or drilled at an angle through the bar stock. They would need to be put between centers on a lathe and then ground. You could then centerless grind them but it would be kind of redundant unless you just wanted a different finish, perfect taper or cylinder…

/Dave

BB Which scope in your opinion is the most durable in relation to the shock it receives from magnum springer’s. I have the RWS 460 and the 350, both guns are exceptional as to accuracy,but they hammer the scopes resulting in having to constantly re-zero. I do have the special mount sold for them that converts to weaver. My 350 just managed the other days to loosen the cross hairs on a Leapers 3-9 x40

Primo,

No scope can suffer extreme vibration for very long and continue to operate if it is adjusted outside its comfort zone. I have owned Leupold scopes that have been broken by airgun recoil.

But most airgun-worthy scopes can handle everything an airgun can throw at them, if they are within their adjustment range. Your Leapers scope is one of the most rugged scopes on the market, in this respect. But, it has to be within the right adjustment range.

What do I mean — the right adjustment range? The scope’s adjustments cannot be adjusted very high, nor very far to the right. Both conditions relax the erector tube springs that keep the scope’s reticles in place. If that happens, the scope will shift its zero with vibration. The greater the vibration force, the more the scope wants to be under strong spring tension to hold zero.

So how high and how far to the right is the scope adjusted that you are having trouble with? Look at that before anything else.

B.B.

B.B.,

This is very good information that I would not have considered! Once again, more gems that very likely could only be found on this blog. Thanks!

Victor

BB, regarding the too far up or right in the adjustment. When that scope/rifle combo won’t let you go up or right enough, can we just flip the scope upside down so as up is down and left is right. Will that keep the spring tight?

Gene,

I have rotated scopes 90 degrees to the left for clearance problems. But most adjustment knobs will get inn the way of a 180. However, if you can do it, it will work.

B.B.

geezzz. I did not think of that. And if you need a screw driver to adjust the bottom one, it won’t worky.

Thanks

Is it possible to have a airgun with the opposite of barrel droop? It would come in handy for long range shooting!

Sure it is. Ask anyone who has gotton a gun that has been slam fired. Would work for a REALLY long range zero, but totally worthless up close.

I undrooped one once and ended up giving it just a bit of upward droop. Just enough that the scope was nearly on target with the scope centered. The scope can be adjusted for a longer range that way. It was not intentional, but I got carried away with the file before I checked.

twotalon

Well you also kill your lockup doing that. I mean stock out of the box.

BB I’m new to Air gunning as of Mar. Want to thank you so much for this blog!! Very informative! I purchased a Webley Alecto Ultra .22 (long barrel) as my first Airgun. I find this topic especially interesting as I have learned first hand about it with my Webly. After shooting for about a month began to notice that the power was going down. It would not even clear the pellet out of the barrel with one pump and when the breach was opened the rubber o-ring that seals the breach to barrel would fall out. I was disappointed to say the least. Well with some investigating discovered that the barrel had moved away from the breach a fraction of an inch causing the low power and loose o-ring. You see in the Webley the barrel is held in the frame with a large set screw at the end and a 2 screw clamp at the breach and if not tight will move from the high power air blasts. Well I put the o-ring back in and with light pressure on the end of the barrel set the clamp and set screw. Power and o-ring problem solved but now shooting way low and left (must have rotated the barrel while doing this). Marked the barrel with a pencil, un-clamped, rotated 180′, re-clamped. Now shooting high and right. The Webley is unique in that you can rotate the barrel in the frame thus demonstrating the “barrel droop” (misalignment) problem. Well now I have set my red dot sight adjustments in the middle then rotated the barrel to get close to target then fine tuned with sight adjustments. All is now well after pellet selection and much practice can shoot dime size groups consistently at 10yards on rest and out in the field hit the ends of soda cans consistently at 20yards bracing against tree. Very happy with the Webly and thanks again for what you do.

FlyBoy,

Wow! What a wonderful example of how this works! Of all the things that are possible, I never thought of illustrating barrel droop or misalignment the way you did. I have a gun that allows barrel rotation, too. But, whooda thunk of it?

Anyway, what a great way to introduce yourself to the blog. Welcome.

B.B.

BB Just wondering? My next Air gun will probably be a Talon SS with extra barrels (love the recent blogs on the Talon). Since the barrels can be changed so easy can they be rotated or do they go back in a fixed position? If they can be rotated, might be nice to compensate for misalignment.

FlyBoy,

The Talon SS barrels are fixed in the frame by four screws that engage bushings which are, in turn, attached to the barrels by screws. So those barrels cannot easily be rotated.

The gun I was referring to that can be rotated was my Whiscombe JW 75, but now that I think about it the barrels have a fixed bar to engage the detent, so they can’t be rotated after all.

I guess I was mistaken about being able to rotate barrels.

B.B.

You don’t have to worry about alignment with AF barrels unless you get a crooked barrel (highly unlikely) or have a bent frame or scope rail. A bent frame or rail could not be compensated for by barrel rotation anyway.

When you change barrels, you will have to rezero. It will always be a little off when switching barrels.

The worst problem you could probably have is trying to shoot at 10 yds. The scope is going to set very high over the bore. The scope may not adjust enough at that range.

twotalon

twotalon

I use the mildots when shooting at ten meters with my Talon. The way its set up now 4 mildots down and its dead on at 10 meters.

Loren

that should read 4 up not down

I do things like that too. I will use a dot and adjust the magnification until the particular dot is a 10 yd zero.

A lot of people will try to zero the scope too close (on the crosshairs) with a very high positioned scope and be unable to do it.

twotalon

B.B.,

Do you think the barrel droop with Diana guns is reflective of their prices, I would assume the 350 magnum would be manufactured with greater care/quality control than the model 34 since it is twice as much. My 350 magnum shot perfectly scoped, I even put levels on it, one on the spring tube and one on the barrel and got identical readings. I no longer shoot it scoped as the balance was an issue, it is strictly irons and very nice ones at that.

Matt

Matt,

No, I don’t think price has anything to do with it. I think it has to do with when the item entered the production que.

The 34 is now an older design and harkens back to the days when people didn’t scope airguns. Of all the airgun manufacturers, Diana seems to have had the least interest in scoped guns, because in Europe, where the bulk of their rifles sell, people still do not scope their guns as much as we do in the U.S.

As newer designs emerge from Diana I think a lot more consideration will be given to the barrel angle.

B.B.

I have dismantled my Crosman Trail NP several times for various reasons. I have also purchased a spare barrel/breechblock from Crosman which I plan to try someday. I have a granite(?) machinists flat. I believe it is flat within a few ten thousandths. Hanging the breechblocks off the edge of the flat and rolling them reveals visible curve. The original barrel curved down. The spare curves rightward. I have no way to accurately measure bore-to-barrel alignment. I had, and many other owners report, droop of the barrel relative to the springtube. I originally corrected mine with Burris Signature Zee rings with Pos-Align Offset Ring inserts, somewhat expensive but worth it. You may see bad reviews online which imo appear to be from people who did not understand how to use them…they are somewhat unintuitive. I really didn’t like the idea of shimming and was willing to throw $$ at the problem. Eventually, I read a post about lubricating the detent; if SOME oil on the detent is good, More would be better, yes? Wrong. Enough of my oil migrated behind (read ‘forward of’) the detent to effectively “hydrolock” it, not with water but with oil; before i realized why I could not lock up the barrel by force, I had bent it upward embarrassingly far into the anti-droop region.* Therefore, I would have to disagree that a barrel cannot be bent by hand. Of course, Normal operation should not result in bending, even over time. I straightened that out, but not all the way back down…so no longer any significant amount of barrel-to-tube misalignment. I neglected to recheck any barrel curve before reassembly…next time!

john

*”A common mistake that people make when trying to design something completely foolproof is to underestimate the ingenuity of complete fools.” Douglas Adams, The Hitchhiker’s Guide To The Galaxy

John,

Thank you for your comments. You are the first person I have heard of to use a machinist’s flat to check barrel straightness. That is interesting.

As far as barrel bending, you need to re-read the report, because I said that it is possible to bend a barrel by hand. It’s just takes more force than the effort required to cock the gun.

Welcome to the blog.

B.B.

Not sure if it too late to submit a question

Is there any way to determine if you have significant droop other than scoping the gun. I have a new Diana 34 and would like to know before I order rings if they need to compensating or regular.

Stickman,

with the exception of the Diana / RWS 350, pretty much every Diana has barrel droop. Consider ordering this compensating mount when you order your scope and mounts:

/product/utg-scope-mount-base-fits-rws-diana-34-36-38-45-with-to5-trigger?a=2298

There are others on the PA website but this is pretty inexpensive and works great. Plus, you can switch over to Weaver type mounts from Dovetails. I own one which I use on my RWS 52 and am very happy with it.

Fred DPRoNJ

Stickman,

Be sure you do NOT have the T06 trigger introduced in 2011. This mount Fred Mentioned only works with the T05. Maybe PA has another one by now that fits the T06.

-Chuck

Stickman,

I used the Diana RWS 34 as the worst case when I developed the droop-compensating mount with Leapers. I therefore agree with Fred that all 34s probably do droop.

But the corrective bases (not rings, buy what they attach to) that will fit your 34 have changed in recent years, as Diana has seen fit to change the base on most of their air rifles. So talk to the dealer before you buy droop compensation mounts. If you are buying from Pyramyd AIR they have a lot of experience with this model and problem.

B.B.

Thanks for all your expertise on the scope base for the Diana RWS 34; it is the T05 trigger and will check with PA before ordering.

I am glad that Rodney wrote in to clarify his position. It is certainly understandable to wonder if a breakbarrel can possibly lock up reliably to the point it can compete with a fixed barrel sidelever or underlever. In my experience, it is not an issue. I have seen stunning accuracy from breakbarrels, in person and on this website.

On the subject of barrel droop, my prized Air Arms TX200 fixed barrel underlever could not hit the paper at 25 yards when I first received it. It was shooting about 18 inches low. I was also using the wrong pellets for awhile, so the two problems (barrel droop, wrong pellets) led to some overpowering buyers remorse. I finally wised up and figured out how to shim the scope mounts. Then I found out it really likes CPLs. Since then I don’t have a single complaint about this rifle. I have effortlessly taken out bottle caps at 30 yards, shot the eraser off a pencil at 15 yards, and shot 1 hole groups at 10 yards.

I eventually invested in a set of the Beeman/Sportsmatch adjustable scope mounts. They are a bit pricey, and you must remove the scope from the mounts and the mounts from the rifle to make adjustments, but they are solid mounts that fix the problem. I would recommend them.

I completely agree with everyone here but as a certified auto technician who works with alot of metal parts, I can tell you all metal warps! Start with camshaft and crankshafts. If leaned against a wall standing up, the same way people leave thier rifles in the corner behind the door, it will warp and become un-true. Same with brake rotors, the cheap ones that come from china, most become warped in shipping in the slow boat from china. All of the U.S. distributors of these rotors must re-machine before sale because they become warped. Rotors must be stored flat, all metal presision parts must be stored with care!

I am not a professional with air rifles, just bought my first breakbarrel, stoeger x20 and it had noticible barrel droop from the barrel breach not lining up with the reciever. I also can see…..OVER TIME…….cocking the barrel will stress the metal and warp the barrel. Thats why I returned the stoeger and bought an underlever, barrel is stationary and no cocking force on the barrel.

Bottom line, metal warps, if you want a straight shooting gun….any gun, don’ t hang off the barrel or lean it up against walls for long periods of time, buy a case!

Joey,

Welcome to the blog!

What you say is interesting and I don’t doubt that you have experienced it, but I have a 127 year old single shot rifle that still has a straight barrel. So something isn’t right. I do know that Feinwerkbau, an airgun maker who is renowned for making the best barrels, rifles them while they are vertical. Yet at the same time, Harry Pope, who made some of the most accurate barrels ever made them horizontally.

I suspect there are many subtleties to this that I’m not qualified to discuss.

B.B.

Any material will deform elastically with even the most minor stress or load, but the deformation is not permanent. The metal stresses discussed here are so far below the material’s yield point that even long-term exposure to them will not result in any sort of permanent deformation.

If a new rotor needs truing, it’s because it is because of poor quality control during manufacturing.

I know that combustion turbine generator main shafts as well as major electric motor shafts (5,000 hp and up) must be put on a turning gear and slowly rotated to prevent them from warping or bending but we’re talking major tonnage supported at various points along the shaft. I suspect that in the case of the Chinese made rotors for brakes, they are probably not trued to begin with. Cams are in the same league as these major turbine shafts in that they have heavy weight at the lobes and do not have the strength to support this weight if only being supported at a few points – especially if the cams are hollow – such as the ends – as opposed to the bearing positions. My understanding of the mechanics of materials (hated that course).

Fred DPRoNJ

I bought the Walther Talon magnum, in [ 08 ] I have yet gotten my sights aligned. If I would have none the problem at first, I would have never bought the gun.

Nathan,

What problem are you referring to?

B.B.

B.B.,

I think he’s referencing barrel droop, which is the subject of the blog post.

Edith

Okay, I understand. This report was posted over two years ago and I tend to forget.

Nathan,

Most breakbarrel rifles have some droop. It’s corrected with shims under the scope tube or with special droop-compensating scope mounts.

Common problem — common solution.

B.B.

Hello all, I recently purchased my first new breakbarrel springer, and I noticed slight barrel droop. It drove me insane to know that something wasn’t machined right, and my shots were not straight. So, I took to the internet and found this guy who filed down the breech contact points. He used a sharpie to color the contacts and it showed him the high spots, by opening and closing the breech a few times. he used a jewelers file and filed down the high spots and bam! straight barrel alignment. So i did the same, it took a while because i colored a lot and filed little very often. got the same results! perfect barrel alignment!!! I checked this by using a boresighter in the barrel, and putting a laser on the dovetail. both laser points were right above and below each other, about an inch and a half apart at 50 yards. Measured just about perfectly with the distance of the two lasers on the airgun. I am now a happy camper. A little work and fine tuning goes a long way. I like when things align smoothly and straight. Enjoy straight shooting! Joey.

Here is a link to the site I found.

http://www.network54.com/Forum/419052/message/1203813573/Barrel+droop+fix+by+Scottg,

Joe R.,

Welcome to the blog!

I read that report and it is interesting. But I would not recommend that to just anyone. Filing that way takes knowledge and a steady hand that not everyone has. It’s good to know that it worked for you, though!

B.B.