Spring gun tuning: Part 1

Spring gun tuning: Part 2 – Building a mainspring compressor

Spring gun tuning: Part 3 – Mainspring compressor continued

Spring gun tuning: Part 4 – Let’s disassemble a gun!

Spring gun tuning: Part 5 – Powerplant disassembly

by B.B. Pelletier

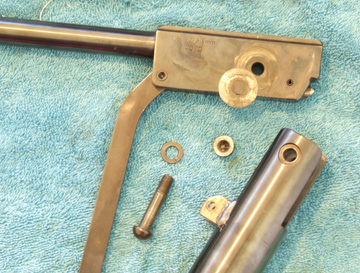

Now, the pivot bolt can be unscrewed from the left side of the compression/mainspring tube.

The pivot bolt has been removed from the left side of the compression/mainspring tube. The large washer sitting on the base block next to the bolt hole is one of two thrust washers that fit between the base block and the sides of the compression/mainspring tube. They allow the base block to pivot freely without galling the compression/mainspring tube.

Notice the large thrust washer laying on the base block. It is very thin, but it allows the base block to pivot without scraping against the compression/mainspring tube. You can see where it wore some of the finish from the base block around the pivot bolt hole. Lubricating these washers (there is another one on the other side of the base block) with a heavy-duty lube is very important to a smooth cocking cycle. Also, lubricate the pivot bolt, itself, for the same reason. I use a moly-impregnated grease, because molybdenum disulfide particles bond with the steel and continue to lubricate the region for a long time. Moly is one of the slickest substances known.

Notice that the cocking link is riveted to the base block. It never needs to come off unless there’s a problem. As of this moment, the cocking link is still attached to the piston by a sliding link. It is quite easy to now separate the barrel cocking link from the sliding link by just moving the barrel away from the compression/mainspring tube.

The cocking link has been separated from the sliding link in the piston. The sliding link is seen at 7 o’clock to the center of this photo.

You can see an enlargement in the cocking slot under the cocking link in the picture. The sliding link can be slid up to this enlargement and drop free of the gun, making the piston free to come out. The piston will require some coaxing, because it is really tight in the compression/mainspring tube. Use a screwdriver blade through the cocking slot to gently shove the piston to the rear of the tube.

BE CAREFUL – SHARP EDGES!

The edges around the cocking slot are razor-sharp, and I am not exaggerating. Working around the slot to remove the piston, you can easily slice your fingers. Please be careful. Also, the piston has a cocking slot in it that’s nearly as sharp. Handle these parts as though they were knives.

The powerplant consists of the piston, mainspring and spring guide. The end cap is aligned with the spring guide exactly as it was inside the gun (look at the picture of the end cap when it came loose from the mainspring tube).

Okay I’m posting this question here instead of calling pyramyd air because I will be working all week and they won’t be open at the times I’m availible to call. So here it goes I just bought a AirForce Condor and I want a pump. I was going to get this pump.The Logun/FX3000 three stage pump. What fill adapter do I need for this pump so It will work on my gun?

This looks like the item you need: /product/airforce-1-4-male-bspp-adapter-for-airforce-guns?a=105

Enjoy your gun.

Ehrich

Thanks I will enjoy it. But the downside is I have to wait untill friday to get it.

Howard

Baldtructer,

Look at the AirForce pump under AirForce accessories. It has the specific adaptor you need. The other adaptors on the site are not complete. They lack the 1/8 BSPP to 1/4 BSPP adaptor that connects the black steel tank adaptor to the pump.

B.B.

BB,

I have a question about seals and was wondering if you could help me. If I were to put chamber lube in a chamber that has a synthetic seal how long would it take for the seal to burn out? What other problems could this cause?

sav300

BB,

Thanks for this tuning posts.

I really really enjoy them.I havent talked much about it but every day I wake up and read this while eating my froot loops lol.Anyway,THANKS A LOT.

CF-X guy

Cool thanks BB. I didn’t know that pump existed untill just now.

Howard

sav300,

It sounds like you are asking whether there is a link between chamber lube and piston seal burning. Chamber lube provides a seal of oil around the piston seal that is supposed to increase compression. As long as you don’t overdo the amount of lube, it’s a good thing.

In my experience, piston seals burn for two reasons. Either they are dry and they melt from friction (common) or they vaporize from continuous detonation (uncommon).

B.B.