Spring gun tuning: Part 1

Spring gun tuning: Part 2 – Building a mainspring compressor

Spring gun tuning: Part 3 – Mainspring compressor continued

Spring gun tuning: Part 4 – Let’s disassemble a gun!

Spring gun tuning: Part 5 – Powerplant disassembly

Spring gun tuning: Part 6 – Disassembly completed

by B.B. Pelletier

Thanks for being patient. Today, I’ll show the other common types of spring gun disassemblies. Few other airguns have the screw-in end cap like Weihrauch (except for many Beeman R-series guns, of course); but, in the 1950s, Anschütz made a military model called the Hakim and a civilian version of the same gun and both had a screw-in end cap.

Stock disassembly

When disassembling the action from the stock, you’ll find both triggerguard screws don’t attach to the action on some rifles. Usually, the rear screw is just a wood screw. When you find this, just leave it in place. Some modern guns, such as the Gamo CF-X, have only a single stock screw in the triggerguard area. Because the stock is a one-piece molded affair, the triggerguard doesn’t have to be held on, and this is obviously just the rear action screw.

Study the action

Something has to hold the powerful mainspring in place. If you study the action long enough, it becomes clear what that is. There are two very common methods of holding a spring gun powerplant assembly inside the mainspring tube – the vertical bolt and the crosspin.

Vertical bolt

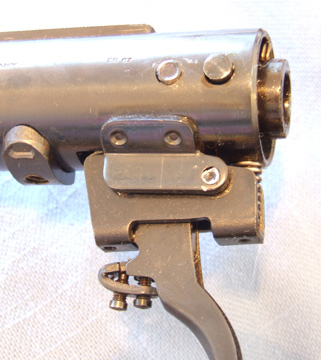

This type is found on the FWB 124, the TX 200 and others. A large bolt comes up from the bottom of the mainspring tube and holds either the trigger housing or a sheetmetal sleeve that restrains the mainspring. Some guns, such as the 124, come apart in pieces, and you have to catch several small parts and springs as the assembly backs out of the mainspring tube. Others, such as the TX200, are modular. The TX trigger unit is held in place by the same two pins I showed you in the R1. The end cap is held in by the bolt.

A large vertical bolt holds the FWB 124 together

Crosspins

The other mainspring restraining method is with crosspins, and two is the normal number. Diana has long been using two crosspins on their rifles. The older models had trigger assemblies that were not constrained by anything more than the mainspring tube. When disassembling these guns, watch for trigger parts that try to fly everywhere. Reassembly of these guns is an art that must be learned and practiced often. Newer guns have unitized trigger assemblies that contain all the little parts. These guns are much easier to work on, except for the automatic safety bar that has to be fiddled in between the two crosspins.

This vintage Diana 27 has two pins at the very rear of the spring tube. Modern pins are farther forward than this.

Tomorrow, I’ll write about underlevers, sidelevers and anti-beartrap mechanisms.

B.B.,

Fascinating series. Your discussion of various configurations is particularly interesting.

Ehrich

Hi,

BB,

I need to ask you for a favor.I need to know if the hw97 pyramidair has has the chequered forend.Its the latest stock with new chequering.Please help me out.I would really appreciate it.

Paul

Paul,

I am checking with Pyramyd AIR for you.

B.B.

BB,

THANK YOU VERY MUCH!!!!!!!!!!!!

When you know the answer please post it here.THANKS AGAIN!!!!!!!!!!!

PAUL

Great pic’s in this series, B.B.. I don’t think I’ve seen such a well put together article on disassembly before. I’m looking forward to the sidelever section, although I still don’t think I’ll do anything to my IZH just yet.

I was wondering if you were planning on doing anything on stock mods and replacement. Seems to me it’s not hard(I did it to my Pumpmaster for kicks), but many are afraid of experimenting with a seemingly daunting project.

.357

above and beyond BB. great stuff for all those (like me) how do I become an airgunsmith…I jumped straight into the pcp guns but I really find this stuff interesting as well.

To the guy asking about the FX Revo. ….well the one I bought from the only US dealer (not pyramid) has spit out three Orings from the action. two were the spacers inbetween the striker weights…probably not needed. However when the gun was sent to the seller to replace them they returned it with a work order saying the rings had been replaced…they had not…and I provided them with photographic evidence of the same.

I was then informed they were told by FX of sweden that an accepable solution was to wrap the area where they were originaly placed with electrical tape…they did offer to pay shipping this time. My next corrispondence with the seller made mention, without insult that they invoiced me that the rings were replaced and were not… and that I felt the residue of electrical tape adhesive was a very VERY bad thing to introduce into the action of a $1500.00 air gun. I recieved no reply. since that time a third Oring broke and was ejected thru the external action of the gun. This being the one that acts as a shock absorber at the end of the striker weights travel to the valve.

sorry to use this blog as a vent but I have to tell of my poor experience with this first gen. gun/seller. that said I have NOT returned it to the seller to have tape wrapped on the weights (as they offered) as it is simply a very bad idea. The gun is opperating well at present but I fear the missing dampners will probably effect the long term wear…but not as badly as the lame “fix” suggested by the seller.

No answers to direct comunication with FX Sweden have been recieved as of this time.

Lack of dependable/ consistant product support forces me to strongly suggest not purchasing a FX Revolution.

Hi turtle,

it´s a shame that arigunsofarizona is acting like this. I would refund a gun that is loosing parts. Sooner or later it gets dangerous. If it is really such a repeating action like a kalashnikov or a dragunov than it is very delicate because of the low amount of air ffor repeating. Is it much louder in comparison with other PCPs?

Markus

Paul,

Gabe from Pyramyd AIR checked an HW97K and it DOES HAVE the checkered forearm that you want!

Pyramyd AIR is a HUGE dealer, though, so when you place your order, please tell the person taking the order that you want the checkered forearm. There is no telling if an older new gun might be picked for you instead. Pyramyd just bought Airgun Express, another large U.S. dealer, so their inventory has been mixed in with what Pyramyd already had. And, on top of all that, Pyramyd has just completed a move into larger spaces within the past two months.

So please ask!

B.B.

turtle,

Your story is pretty shocking! I don’t know whether I could have a $1,500 gun go belly-up and not spray-paint it on all the overpasses. Especially when the dealer didn’t back it up.

I do know that FX has a website, so they also must have an email addfress. It’s usually staff@ and the the address. Have you tried contacting them?

This is the only story I have heard about this rifle, and it’s not a good one. I’m going to keep my ears open for more news.

Thank you for your report.

B.B.

BB,

THANKS A LOT!!!!!!!!!!!!!

PAUL

sorry it was a bit of a rant…FX on the web was where I did try to contact the Co. directly.

My fears of wear are indeed speculative as the gun is firing well…FAST/HARD/AND DEAD ON ACCURATE. It’s easily as quiet as the Tallon SS (a favorite) and really is a very fun gun to shoot…only time will tell Re: wear from the missing parts. You were just the first person to ask since the last ring busted.

I know of one other Revo thats spitting rings out Maverics on the TOG website is having similar issues…but he’s already torn the gun apart and is very confident in replacing them himself.

Well, I was ready to throw away my FWB 124! It seems to of blown its seals, and knowing nothing about airguns, figured, hey, whats it worth, nothing? I bought it brand new in 81′ kept it like new. Now, I see at various sites, its worth some bucks, so, found the seals and with these instructions I’ll have a new gun again. Of course I bought a new gun from you guys before finding out about the seals, but, hey can you ever have enough guns, NOT! Thanks a million. Rich

Rich!

You are a success story! And now you have an airgun that will probably out-live you, because the new seal material doesn’t crumble like the old one did.

Thank you for your feedback.

B.B.

i bought a tasco 4×32 rifle scope for my quest 1000 will this scope work on a airgun?????

It will probably be okay. Most scopes are now braced for airgun recoil.

B.B.