by B.B. Pelletier

Well, it seems this modification has stirred up some interest among our readers! Today, I’ll pump the rifle and chronograph it for you. I’ll also pass along some tidbits from the inventor.

By now, you know that the whole purpose of this modification is to make it easier to pump the Benjamin 392 and 397. It doesn’t add any power or affect the accuracy in any way. Whatever is built into the airgun at the factory is what you get, only it will be easier to pump.

How does it feel to pump this gun?

The pumping experience is very different than a stock rifle. In the first place, it’s noisy. Bob intentionally designed the linkage with some loose tolerances, so the pivot pins seem loose. That allows the linkages to “clack” when you pump. He found that it’s easiest to pump the gun if you keep a rhythm going, and I agree with that. However, the pumping effort is so easy that I found myself forgetting how many pumps I had put in. With a stock 392, you can feel the resistance increase. Not so with this modification; counting the strokes is more important.

A second thing you’ll notice is that the pump wants to spring open every time you lift the forearm/pump handle. Bob tells me that the main load-bearing links in the pump are made of very high-grade chrome-moly steel and fully hardened, so they act like springs. The pumping arm itself is made from solid steel, though it doesn’t need to be because it doesn’t take that much stress when pumping. The pivot pin, where the three links come together, is an aircraft-grade pin acting as a journal with a hardened stainless steel pin as a bearing. It has shown no signs of wear after thousands of pumps.

It takes just 14 lbs. of effort

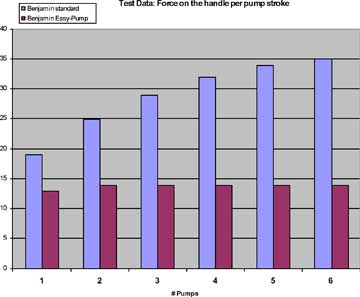

Yesterday, I told you it takes 12 lbs. for each pump stroke, but some test data sent to me by the inventor indicates the force is actually just under 14 lbs. He had a chart at Roanoke to show perspective buyers the difference in force between his modified gun and a stock gun. I’m showing that chart below, but it’s too small to read. The darker purple bars are the modified rifle and the lighter blue bars are the stock gun. Only six pump strokes are shown, but I have taken the rifle up to ten strokes and can tell you there is no increase in effort. What does happen is that the force you apply starts earlier in the pump stroke on the later pumps.

As the modified rifle is pumped, the forearm/pump handle starts to extend slightly from the stock. With no pumps or just one pump, it fits flush and the joint between the two wood pieces is relatively tight. With two or more pumps, it stands proud from the stock. After noticing this, I found I could tell whether or not the gun was pumped and approximately how many pumps it had in it by how high the pump handle was standing. In spite of this, the handle remains tightly in place and shows no inclination to pop out.

Shooting 14.3 grain Crosman Premiers, the gun delivered the following average velocities:

Pumps……Vel

3…………..424

4…………..472

5…………..509

6…………..543

7…………..563

8…………..589

9…………..606

10………….626

Velocities were extremely consistent for a given number of pump strokes. After all testing, I fired the rifle with three pumps and it went 431 f.p.s. again.

The manual says 8 pumps are max, but I fired a second time after shooting on 9 and 10 pumps and there was no air remaining in the gun. The advertised velocity for this rifle is 675 f.p.s., so the one I have isn’t performing up to snuff. I can overlook a small variation, but this one isn’t that small. If you use the recommended 8 pumps as the max, the difference is almost 100 f.p.s. I will test the rifle later to see if there has been an improvement.

Stay tuned for the next report

B.B.

I’m trying to visualize how you pump this gun. My association from police shows is that the pump handle is moved down to the butt of the gun, than back up. But for the Benjamin 397, it looks like the only way to operate the pump is to move the handle towards the muzzle. Is that right? This seems like an awkward motion that doesn’t allow you to bring a lot of muscles into play.

Matt

Matt,

The pump handle is hinged at the front of the gun, so it pulls away from the underside of the gun in the rear.

Look at the manual on Pyramyd’s website and you’ll see a drawing.

/manual/benjamin-sheridanoperating.shtml

B.B.

B.B.

Thanks, that’s clear enough. So more of a lever-type motion.

Matt

B.B.,

I don’t know where my printouts are for Crosman Premier domed pellets but my 392, once broken in, shot Kodiaks at 540 to 550 fps. Hobby pellets got up to 660 to 670 fps.

Shawn

Shawn,

Thanks for that report. I’ll have more on velocity tomorrow.

B.B.

Jersey Joe,

Yes, the 663 f.p.s. for pump number 7 was incorrect. When we went to correct it, the entire blog went to pieces!

Your question that mentioned the error was eliminate3d, as you can see.

Where can I buy one? (or two)

Nuglor,

Thanks, your rifle is awesome!! I’ll be looking to get a more utilitarian model because I know I will bang it up while hunting in Hawaii’s jungles. You know, something that I can disassemble, put in a pack, and be on my way, something that can take some hard use and keep on firing. I could probably go with a shrouded 12″ or 18″ barrel if it can develop about 45 fpe in .25 caliber. Tom

Always wondered about the pump-assists. Great article!

I’d love to see a review of the IZH MP-651K, looks very interesting.

I’ll post purchase info tomorrow.

B.B.

I have tested the IZH 651, but wasn’t very inpressed. It has poor accuracy. Also, the BB and pellet clips are somewhat difficult to load.

B.B.

Hi BB

Do you think that we will see an influx in the use of .20 and .25 calibers because of the airforce rifles? I think these are two great calibers but ive always overlooked the guns in .20 and .25 because there isnt a good selection of pellets. I think these calibers might start to make a comeback.

Nate in Mass

One stroke in the low 30 pound range with a sub-$200 dollar RWS34 gets you another 100 fps over this this thing at ten 14 pound pumps. I’ve never seen a pumper of this ilk that was more accurate than a pedestrian Diana, much less a HW. I’m looking for a reason to get excited about this high-rep calisthenic technology?

Nate,

No, I don’t. Don’t sell your .22.

B.B.

bb,

This a really nice modification. Personally though, I don’t mind having the 392 a little difficult to pump, it’s just more satisfying to me if I have to work to do something.

I would like a pcp for it’s convenience and ease of use, but the 392 (unmodified) just seems more like an air rifle. The only air rifles I have shot have been multipumps so I guess my experience isn’t profound. It’s just my personal opinion.

I see how this would be great for people with back or shoulder problems and can’t use a regular 392 or 397.

Also, my order for pellets on Pyramyd AIR have been on backorder for a while now, what exactly does that mean? Has Pyramyd AIR just postponed the delivery until they get the pellets?

Right now I’m huntin’ with my .20 guage, fixin’ to git meself a big ole buck.

Thanks,

Insomniac

Insomniac,

Weidmanns heil!

Concerning the pellet order, you probably want to call Pyramyd on that. Some pellets they will not be reordering. Also tell them you’ll accept a dented tin and maybe you can speed the order.

Concerning the 392, many who tried it at Roanoke though it would be better for those with bad backs and shoulders. I have a bad back but pumping has never bothered me, so I can’t comment.

B.B.

Sorry it’s a teensy bit off topic, but do you know where could I find the velocity chart you printed above (fps vs # of pumps) — only for the 397?

I know it’s not a target gun, but if four pumps gets me in the neighborhood of 500 fps, then I might just go ahead and get one for indoor stuff in the winter (yes, I have a dedicated “man cave” garage).

You do great work here. I write a top-ranked fly fishing blog, and know how much it really is.

tcwriter,

I don’t have the velocities for a 397, but maybe some of our readers do.

How about it guys?

B.B.

Hia BB,

This sounds like a joy to shoot. I have had my Silver Streak for about 2 months now. The .20 cal. rifle likes Benjamin Cylindrical pellets and shoots them at 472 FPS with 3 pumps and 670 FPS at 8 pumps. After trying several scopes and mounts, I went back to open sights and will be ordering the the Williams Peep from Pyramydair soon. It just seemed every scope & mount combo I tried was to far from the eye or to high up and caused a lot of canting error. I also realized that the open sights where better for short range use, giving me a more manageable point blank rang from 0 yards to about 27 yards with no hold over.

Now if Crosman will use a receiver with a dovetail and bend the bolt knob like a custom Mauser, I’ll be in heaven.

Steve the pumping is not all that bad, and its nice to be able to use 3 or 4 pumps when plinking in the garage.

Joe G from Jersey

That is a great invention! I like it.

When you review the Mendoza RM-2800 and Benjamin Super Streak can you be bribed to review the .22 version? 😉

.22 multi-shot

P.S. To those who have to enter the word verification twice, it seems like there is a time limit on it. If you don’t finish within that time limit, a new verification word is generated to type in.

BB,

jj here,

The number of comments on today’s blog is not showing correctly, nor increasing.

Currently, it is at zero and holding.

Also, yesterday’s blog’s comments are inaccesible.

More fixup for google, I guess.

Maybe, while they’re fixing, they could add a comments search ! ? ! ?

jj

BB,

Witchcraft.

No sooner did I post, than today’s comments updated, and yesterday’s became available.

Now if only the’d include/add a comments search ! ? ! ?

jj

BB,

Could this pump assist be used on 1377? Thanks.

.22 multi-shott,

I do have a Mendoza 2800 in .22, but the enjamin Super Streak is in .177. That’s the only caliber they make it in at present.

B.B.

1377,

A pump assist could probably be built for the 1377, but I doubt one ever will be. With the pistol selling for such a low price, no one would want to pay an additional $125 – twice the price of the gun – for the modification.

B.B.

Thanks BB,

I’ll look forward to the RM-2800 .22 review.

.22 multi-shot

bb,

I think I will get my pellets shipped, it’s just that there is always one tin of pellets that is out of stock (usually jsb’s) and whenever that one gets in stock another one is than out of stock (usually Beeman Kodiaks).

I’ll give them a call though just to be sure. I was expecting to get my order by Halloween, but a couple weeks delay is fine. They don’t get in the way of my deer hunting!

Thanks,

Insomniac

p.s.

Danke, gleichfalls auf deine Jagden. Ich bin etwas weidgerecht. Ich bin nicht der jaegermeister, wenn ich bin so so.

Insomniac

p.s.

I do believe the correct spelling of “safe hunting” is Weidmann heil.

No ‘s’. The German language doesn’t use an ‘s’ to show plurality.

hehe

Auf Wiedersehen!

Insomniac

Insomniac,

Oh, oh! I’m busted!

The last year my Jagdschein was stamped was 1977.

Weidmann heil!

B.B.

I just got a 392PA with a scope & hard case in mint condition for $75.00 a couple of weeks ago & I love it.

Living in Las Vegas, I have mostly CO2’s because of the weather, they perform very well pretty much year round, but I also have a few springers, & a PCP or two, but decided that I needed at least one multi pump in my collection.

So for the price… I could NOT pass this one up, & after shooting it… I’ve decided it’s a keeper.

It’s a great gun, & in my opinion, I think it’s definitely worth getting the pump assist modification, because if you shoot it a lot, you’ll be VERY glad you did, & when they stop making them & they become a classic… The ones with the pump assist mod, are the ones that will be HIGHLY sought after.

– The BBA –

Hey B.B.

Im thinking of getting a Mac1 steroid Benjamin 392 but I would like to get an expert advise first, so what do you think should I get the steroid or the stock one?

Thanks

Zacky

Zacky,

Having owned both the Steroid and standard Streaks, I would go with the standard 392. But you may enjoy the greater power of the Steroid.

Either way, Tim makes a good airgun.

B.B.

B.B.

I too was thinking of getting a steroid benji and happened to read that you owned one can you comment about the good things and the bad things about it? Please!!

Thanks(You are the best!)

Adam

Adam,

There are no bad things to say about the steroid. The pumping becomes more difficult after several strokes, but Mac-1 builds the gun stronger to take the punishment.

It’s jusr as accurate as it was before the mod. The only question is, do you want the extra power?

B.B.

ok heres the deal guys. my mom and dad are a little gun freaky, and will only let me buy one more gun. i like hunting things racoon size and smaller, and dont want a gun thatll break or is too needy. whatt is the best gun for me in the 200-300 price range?

A Ruger 10/22 sounds ideal.

B.B.

Anonymous that wants one more gun and likes hunting things racoon size and smaller,

What guns do you currently own?

kevin