by B.B. Pelletier

Charging the pistol

The way the pistol is pumped is simple. The rod is pulled out until it stops, then pushed back in to force air into the reservoir. Many, many front-pumpers will have problems with their inlet valves, causing the pump rod to push back out as the air slowly releases. With this kind of fault, the gun will eventually leak down to nothing.

Others will have too much space between the end of the pump head and the opening of the inlet valve. This traps high-pressure air between the head and the opening. The air cannot enter the valve because the pump head has gone as far as it will go. The pressure of the trapped air is not as high as the air inside the reservoir, so it sits outside the inlet valve. When pressure on the pump rod is relaxed, the trapped air will push the pump rod back out. Because the internal pressure in the reservoir keeps building with every pump stroke, the pressure level of the trapped air continues to mount, as well, pushing the pump rod back out further each time. A little bit of rod rebound isn’t bad, but if it comes more than halfway out, your gun probably needs service. When the inlet valve is working correctly, the rod stays all the way down (or in) after each pump stroke.

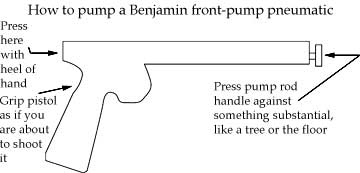

Our subject gun, which is in very good operating condition, will hold the rod down if a certain procedure is followed. After two or more pumps, the rod starts to climb back out. I just push it back in with the heel of my hand, and it stays down the second time. I don’t pull it out all the way before doing this; just press the rod back against the small amount of residual air that’s pushing it out, and it goes in and stays. You can hear the air entering the inlet valve on this gun. Maybe that’s typical of the performance of a new gun, too; I don’t know.

The end of the rod is shaped like a mushroom to give a broad surface against which to push. I like to use something solid against the rod end, with the floor or a stout table being ideal. Folks with post-and-beam barns are blessed with unlimited flat surfaces to push against. Let’s not use mother’s dining room table, though, as the mushroom will shatter the finish and compress the wood fibers rather quickly. And stay off modern countertops with their low friction, because the mushroom can’t find a surface to grab, allowing it to slip and damage the gun.

Before pumping a gun, cock it and put on the crossbolt safety. Remember to keep your fingers out of the triggerguard as you pump. Grasp the gun in your shooting hand and put the heel of your other hand against the receiver cap for extra support. Don’t rely on just the pistol grip to support the gun. The screws may hold fine for a while, but eventually they’re going to elongate the holes through the brass tubing of the receiver. If you’re pumping a rifle, the same procedures hold true–don’t just push on the end of the wooden butt.

This pistol is not a magnum, and no amount of pumping will turn it into one. All you’ll do if you overpump a gun is ensure an earlier trip to the overhaul shop. About five strokes is the most I ever put in, and three is all it takes for most shooting. If you also own a Benjamin underlever pump, you will notice that the front-pumper has a much longer stroke than the underlever. You can pressurize the front-pumper in half the number of strokes or less. With rifles, this is even more evident.

You can get pretty good accuracy from an old Benjamin pistol, if you slow down and take the time to shoot the gun as the manufacturer intended. “Pretty good” means tin-can-plinking accuracy. These guns were made at a time when the pace of things moved slower than it does today, and their sedate method of charging reflects that. Treat them as the fine single-shot handguns they are, and the reward will be shots you can be proud of. Just remember, they aren’t CO2 pistols–you’ll have to invest some sweat to keep them going. But they can be okay if you do your part.

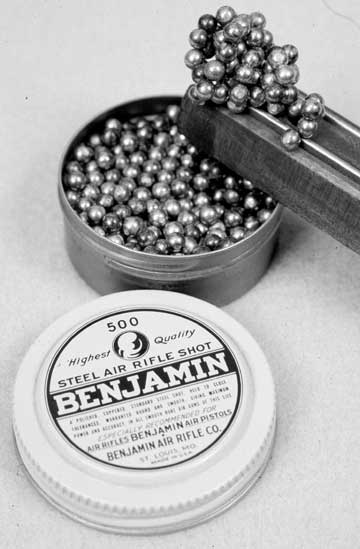

The smoothbores are not as accurate as the guns with rifled barrels, of course. Benjamin used to say in their advertising that their pellet guns were good for one-inch groups at 30 feet, while their BB guns would shoot into about two inches. While testing the gun, I found that it would group in about two inches at that distance, as long as good-fitting BBs were used. I found the slightly large 0.174″ lead balls sold as 4.4mm round balls worked best. Regular steel BBs range in size from 0.171″ to 0.173″ and do not group as well. They went into three- to four-inch groups.

As an experiment, I also tried the gun with 4.5mm Eley Wasp pellets, which are quite similar in shape to the original Benjamin High Compression pellets from the same era as the gun. The Eleys did not shoot reliably, perhaps because they are not lubricated like the early Benjamin pellets. Several times, the pellet would not exit the barrel, even with five pumps.

The trigger is the simplest sort of hammer/sear arrangement. It’s rugged and reliable, but it will never be confused with a target trigger. There’s plenty of travel and creep. Behind it, the crossbolt safety passes through the frame. It operates in the conventional way, convenient for right-handed shooters and backwards for southpaws. A spring-loaded ball detent retains the safety in whatever position it was last placed.

The bolt is also conventional. Rotate the bolt knob counterclockwise to unlock it, then pull straight back to cock the hammer, and withdraw the bolt probe to allow a pellet or BB to be loaded. Since our subject pistol is a smoothbore, it’s meant to shoot BBs, darts or pellets. The bolt probe is hollow, where there would be a solid rod with a rounded tip on a rifled gun.

Although Benjamin sold copper-plated steel BBs for their guns, I’m conservative about shooting anything steel in a brass bore. I try to use lead shot instead. You can buy Gamo or Beeman round balls in .177 caliber, and they function fine in guns like these. A BB is pressed into the hollow opening of the bolt probe, which allows the muzzle to be depressed below level and the BB will not roll out. Incidentally, if you’re shooting a model 150 or 160 BB repeater, you have no choice but to shoot steel shot, as those guns are designed to work with it.

Darts are made of steel, but their design prevents the metal from touching the sides of the bore. Shoot them on low power only and always shoot them into a regulation dart board to prevent penetration and distortion. All it takes is one pull with pliers and a dart is ruined forever.

Accuracy with pellets isn’t as good in smoothbores as it is in guns that are rifled, but it is adequate. The diabolo shape of the pellet helps stabilize it in flight without the spin that rifling would impart.

Sorry everyone. Looks like we forgot enable reader comments. Now open!

Edith

BB: I have a tin of Benjamin Round Air Rifle Shot (full tin) for my Model 3120 .22 cal repeater rifle. Would the "shot" be the same size as the .22 round balls sold today? The gun must be 50-60 years old and still shoots accurately and hard! Thanks, D.G.

Thanks Edith!

pellet manufacturer H&N's website:

http://www.hn-sport.de/engl/index.htm

Something like this might work as a hammer spring adjuster on a Discovery:

http://anotherairgunblog.blogspot.com/2009_07_19_archive.html

DG,

You would think they would be the same as today's balls. They should measure 0.2165"-0.218" in diameter.

B.B.

B.B.

Haven't heard of steel darts before for airguns. That sounds extremely lethal.

I was looking at rear elbow postures for competition rifle shooting. For highpower, the rear elbow is at right angles. For smallbore, it is uniformly glued to the body. For air rifles, it seems to be in between. Is there a reason for this? I've heard that the raised elbow creates a pocket in the shoulder that perhaps can help with recoil. But for the other two categories–supposing my observations are right–I'm defeated.

Matt61

Chuck,

Yes, I've heard the testimonial about pellets spiraling. The person on the website claims that he has seen it too. My problem here is that people see all sorts of things. During the Cold Fusion flap some years ago, people were claiming that they had not only seen Cold Fusion but verified it in a lab. Then all the claims disappeared.

I myself have seen pellets in flight on two occasions. Both were at 25 yards. One was with my Walther CPSport and the other with the Crosman 1077. I was able to see a slight arc to the trajectory (which amazed me) but no spiraling–although that doesn't mean anything either.

I know that pellets spiral somewhat. I think a good benchmark is whether the spiral diameter is bigger than common group sizes or smaller. I say smaller! 🙂 I also don't consider it impossible that people could see a spiral of that size.

BG_Farmer, what better time than now to learn about projectile stabilization. My understanding goes like this. The stabilization from rifling falls into three categories. I don't believe that a pellet can be overstabilized from skirt drag, so I don't think any of this applies to pellets–just bullets. Under-stabilized means the spin is insufficient and the flight will be erratic. Stabilized means the spin is sufficient. Overstabilized means that there is too much spin. The effect is as the trajectory starts to drop, the spin will maintain the bullet's orientation so that its axis will start to deviate from the flight path (the nose will not drop). Depending on the details, the overstabilized bullet can become stabilized but it will never make up the lost ground by orienting itself correctly on the flight path. The model suggests that accuracy problems with the overstabilized bullets will only appear in the later portions of a pronounced trajectory.

Anyway, that's pretty much everything that I know. Does that check out? What's the next step?

Matt61

Matt61,

Your comment, and B.B.'s, about darts brought back some childhood memories.

Very heavy, sharp points with blue bristle's in the tail. We shot them out of benjamins and shot at things we shouldn't have.

Don't know if they are still sold but were the rage when we were kids. Expensive for us kids.

kevin

Matt,

Those elbows are not uniform, though the traditional stance always had the elbow straight out to the side.

Airgunners have modified the hold to suit themselves.

B.B.

Kevin and Matt,

Here they are:

/product/marksman-airgun-darts-12ct?p=326

B.B.

Yep, those are the darts of my yuut.

I really like these articles that dredge up those old memories. Now I remember I wasn't an angel.

kevin

B.B.

Over the weekend, my brother dug out an old bb gun of his. A Daisy M1 Carbine with a detachable paratrooper butt stock. The multi-pump with plastic stock and peep sights is in excellent condition and even still has the plastic box magazine with it. After dislodging an old bb lodged in the barrel, we shot the gun a few times and it seem to still work great. We had thought the gun was a Crosman, but it turned out to a a Daisy. We're thinking the gun is around 20+/- years old. Any experience with one of these?

Bub

BB,

Those darts are nothing compared to Yard Darts:). Those were the days. I bet the lawyers these days would have a fit with the pumping hand in front of the muzzle, also, if I'm not misunderstanding the procedure:).

Matt,

I think you got it, and I'm in the same boat as you, trying to keep an open mind, but the spiral seems unavoidable. I'm still not sure where pellets fit in, either — being drag stabilized in theory, but also spun by rifling. The next step seems to be some really ugly math to see what size the spiral for certain cases should be and compare that to typical group sizes — feel free to race ahead of me; I was hoping Herb would do it:). Thanks for the degree, by the way:).

TwoTalon,

Pillow Ticking rules. 4/5 of my 25 yard benched group went into much less than an inch, and 7/10 of my offhand group went into roughly 1 3/4". With a little more practice, I think I can shoot this thing:). I think my bore is pretty tight. Even clean and with a well-lubed patch, the .490 ball with pillow ticking patch was about as tight as I would want to go.

Matt….

Since you have not seen looping to a degree that you can see it does not mean that it can't be severe enough to cause trouble.

Do not write it off as canting or parallax.

I have seen it, and I went through all kinds of fits attempting to correct it before I found out about precession. It does happen and can be bad enough to make a rifle about hopeless unless you can track down the fault and correct it.

twotalon.

BG_Farmer

It will load easier as the rough spots wear off.

Usual rule of thumb…..

Shallow rifling …..approx. .005"…ball .005 under bore size with .015 or so patch.

Deep rifling …approx .010"….ball .010 under bore size, patch .017-.018 .

When well broken in you can increase ball size a bit but will load pretty hard when doing deep rifling.

Let your used patches tell the story about the fit.

twotalon

B.B /Edith..

My first pumper was a smooth bore benji rifle.

Steel bb's shot very poorly, Crosman ashcans were better, but still poor.

What was best was a bag of lead BB shotgun pellets. They required force to seat them, and shot very good. These were very old shotgun pellets. I understand that they were larger in diameter than the BB shot that is presently made.

twotalon

RE:/product/marksman-airgun-darts-12ct?p=326

Be aware that there is a significant difference between the darts and the bolts. I picked up a Marksman pistol and darts pkg from K-Mart several years back because I wanted the fun I'd had shooting darts from my Crosman 760 in my office, into a standard dartboard, back in the late '80s. Although the pkg said 'darts', they were bolts, and they were awful. They mostly hit the 10'-distant cardboard target sideways, and the accuracy was yuck, even when shot from a foot away that I employed out of total frustration. I took it back.

Also, steel darts will supposedly ruin the rifling in an airgun. That's why they make all-plastic darts. The steel darts work best in smoothbores. After reading this I could swear that my 760s were no longer as accurate with pellets, but this may have been an over-active imagination.

I wonder if the bright metal of the Marksman darts are aluminum?

I just read the reader reviews for the bolts. One man said "These do NOT work particularly well in the Marksman 1010 as they do not fit well, therefore the accuracy suffers considerably." Perhaps that was my problem.

BG_Farmer…

I managed to work up a good system for my Renegade one time…

Plain Renegade (TC) with single trigger and large trigger

guard…much appreciated in cold weather when wearing gloves.

Anyway …with rear peep sight I got down to one hole groups at 50 yds with .495 rb from a bench rest. I could lay a ball on the cardboard backing from behind the target and it would not fall through.

Well broken in rifle, right ball/patch, right powder charge, right lube, right swabbing between shots,right loading strokes.

twotalon

Bub,

A Daisy M1 Carbine? That's a new one on me.

B.B.

TwoTalon,

I'm really excited about it now — today was the first time it seemed like I was in more or less complete control of where the shots went (not that I always did my job:)). I think the patches and swabbing b/t shots made a big difference, and I instituted an arbitrary but reasonable way to seat the ball consistently. Probably the results weren't too impressive to anyone but me, but I tend to go slowly at first and then get it:).

What will I give up if I go with hand-cast balls? I can get them online, surprisingly much cheaper than I can buy swaged ones locally.

By the way, I hope you're doing well and possibly that you're done with chemo by now.

Matt & BG_Farmer,

RE: Exterior Ballistics & Spiraling

I'm very interested in math, but I don't have mathematical programs nor data to do meaningful calculations.

The science of exterior ballistics has been studied for hundreds of years and I doubt that we'll solve the problem here. So the real question is what categories of problems exists, and if there is anything you can do to mitigate particular problems.

The fundamental notion is that all the errors in shooting are additive in that the group size gets larger with each source of error. Thus if there is spiraling (or corkscrewing) of the pellet, then the group size will be larger than if the phenomenon did not occur.

All in all it seems testing errors between rifles, between shooters, between pellets is about all that can really be done. So let's assume that you shoot your Discovery and the result is 3 inch groups at 10 meters. Is the problem you, the Discovery, or the pellet? So you borrow a friend's Discovery and shoot 0.25 inch groups with the same lot of pellets. Well now the problem seems to be your particular Discovery, not you or the pellet.

By and large such one factor at a time experimental plans depend on one error factor being much larger than any of the others. That factor then dominates the overall error, and improving that factor alone will result in a significant improvement. Unfortunately in real world examples you eventually, if not quickly, reach a point where multiple factors are interacting. So if for example if there are 4 equal error sources, reducing one of the sources to half its original size doesn't do much to reduce the overall error. Also as the differences between the overall errors get smaller (eg between different brands of pellets), you need ever larger amounts of data to make a proper statistical decision.

Now, back to spiraling. Enough folks (who have been good contributors to the blog) have stated that they have seen spiraling, so I have to accept that it can occur even though I've never seen it myself. Heck, with my eyes, I'm doing good to the see the target.;-) I also guess that ever pellet spirals, it is just a matter if the spiral significantly increases the group size or not.

This does create several questions about spiraling.

(1) Is there any way to measure spiraling itself?

Not that I know. Using paper screens some distance apart has been suggested, but the impact on the screens could effect the flight of the projectile.

(2) Can the spiraling be "dialed in" for distance?

I think the answer is no. For example, the exact velocity of each shot varies enough to throw such an attempt into chaos. Thus spiraling adds to the overall group size.

This is not to imply that distance adjustments, beyond ballistic corrections, are erroneous. I do believe that spiraling would induce some additional curve to the path of the pellet. Thus a correction could be made for the overall curve, even though the spiral itself couldn't be corrected.

So all in all, it seems that we're left with group size as an indirect measure of spiraling. Also range charts would have to be created with POI measured against distance to make the best corrections possible. So all in all we're just left with the time honored methods.

Putting spiraling aside for the moment, I purposely damaged some pellets, by cutting a notch in the skirt, or filing a flat spot on a dome, and with a rifled barrel they still grouped amazing well. So I'm a true believer that spinning and the diabolo design are a great combination.

Herb

Yard darts, I got a set for my birthday when I was younger. We had yard darts stuck into everything but the yard. Nothing like the thrill of a loose yard dart to get you heart pumpin'. Anyhow, once they've hit the concrete a few times their fins break away and they lose their fun. I'm not blaming the yard darts for anything, yard darts and kids don't mix.

BG_Farmer

Certain problems with balls…..

Swaged balls are usually beat up looking, and show flaws from the swaging dies that make them have a ring around them.

Cast balls can have dirt or air pockets that affect weight and balance of the ball. In addition, cast balls have a sprue mark and must be loaded with this inherent defect straight up as best you can.

The moulds that I have found the best are Lyman and RCBS steel blocks. Lee blocks are aluminum that are formed by methods that don't give you a very round ball, don't index well, and do not maintain a consistent temperature very well….aluminum heats fast and cools fast, and has an expansion coefficient greater than steel. Ball size and weight tend to vary a great deal more with aluminum blocks than with steel.

Started round 3 of chemo this morning. Round 1 went badly…ended up in the hospital for a week for an infection that nailed me when my white count dropped.

Doc adjusted the mix, and round 2 went well.

This round should go well also.

Problem on each day 1…The poison or the pills that are supposed to counteract side effects mess me up a bit for a few hours. A bit shaky, short attention span, cant keep thoughts in a straight line very well. Must be about like ADD or ADHD. Feel about normal after the first day.

This will be the last chemo with 3 drugs. Next comes 3 more rounds of one drug only that is boosted , and to run concurrent with daily radiation.

So not half way done yet.

Still have some hair left.

Shaky, bad eyes, lack of concentration…not much shooting.

twotalon

Hi B.B.,

While were on the subject of Benjamin Pistols, when does Crossman plan on releasing info on the Benji PCP Pistol. Will you be reviewing and testing a prototype on this blog also?

-Ben

Ben,

I already shot a prototype and made a mention of it in the blog. Crosman hasn't shared their launch date with me, but the SHOT Show is in January.

I believe they will bring it out before Christmas, to get those important holiday sales.

B.B.

twotalon,

Even in your current condition I think you could outshoot me.

I've sure enjoyed the many tidbits you've unselfishly shared about blackpowder. At this age it's still hard for me to understand why bad things happen to good people.

My thoughts and prayers are with you.

kevin

Kevin

Eventually we all fall apart.

Attempting to do something worthwhile with the time we have seems important to me.

My last night on duty before retirement processing out of the AF I was out there fixing an RF_4C with a wiring problem. Most other guys would have sleazed off and left it for someone else.

Be helpful when you you can, and for as long as you can. That's something I would expect out of B.B.

Have a fairly good chance. Dice are still rolling.

Thanks for the thoughts.

twotalon

B.B.,

I was parousing another airgun review site (sorry) that reviewed the NPSS. In their review they stated that the Owner's information stated several times that the rifle should be shot more than 100 times before accuracy and velocity is measured. Obviously for a break in period. Did you happen to shoot your copy more than 100 times and if so/not was there a change in accuracy after that point? I'm trying to get at the hold sensitivity issue of the rifle – would it perhaps be less hold sensitive after the break-in period? Or are they referring to accuracy because of velocity variations during the break-in period?

Herb,

On those days when my target shooting seems all over the place, I use the force. ie. I allow some inner knowing to tell me when to finish squeezing the trigger as the target wobbles by. Works surprisingly well.

TwoTalon,

My kindest wishes and regards to you as you go thru treatment.

twotalon,

Your life philosophy is to be admired.

I man that I was very fortunate to get to know and greatly respected said to me many times, "He who would be greatest amongst you must be a servant to all."

Your shared thoughts reminded me of him. Thanks.

kevin

twotalon,

My thoughts and prayers, as well, are with you. I remember now you saying a while back you were having some health problems but your 4:30pm post really hit me in the gut. You're a brave and caring man, don't lose your spirit. People like you are hard to come by. Oh, and yeah, hair is overrated, anyway.

I finally made it to the range today with Ms. M. The weather was pleasant with just a hint of wind. Since my scope was set up for 10m it took me several shots to zero it in at 50yds. Mainly because it was hard to tell where the shots were going until I tried all compass directions. I'll say one thing, a .22 Marauder sure kicks up a lot of dust when it hits a dirt backstop berm 60yds out. Before I ran out of time, I finally got things settled down a bit and hit a .959" outside diameter 5 shot group at 50 yds. This translates to .744" c-t-c. I think this is pretty good for my first outdoor try, and beyond 10m, and I know I can do better. I didn't get a chance to shoot at 100yds but I will some day. Maybe in three weeks.

-Chuck

TwoTalon,

My thoughts and prayers are with you (as are those of many others it is certain), and I'm glad you think enough of us to let us know what you are going through. Keep up the fight — you don't sound anywhere near beaten yet.

I think I'll try the hand-cast balls. Daniel and Davy shot them pretty well, also:).

I really appreciate all your help with the blackpowder, but I'll try not to go overboard and ask too many more questions:).

Herb,

You stated the complexity quite well. I'm fascinated by the "spiral" because I can't see any other mechanism that results in nice round groups (which all groups will be if they are aimed consistently out of a well functioning rifle). The way that seems most natural, at least to me, to think about it is that the initial state of the projectile at the muzzle (velocity, spin, angular displacement due to blast, imperfect symmetry, etc.) works in conjunction with prevailing wind, gravity, etc. to produce the exact path of the bullet's spiral. Pretty obvious, I suppose, but what would be interesting is to posit a perfect rifle/projectile (preferably of an existing type) under perfect conditions and calculate the dispersion simply from the spiral, then change one variable at a time (bullet symmetry, velocity variations, spin rate, angular displacement, ad libitum) to see "what happens". My assumption in this is that the spiral is not an anomaly but the normal path followed by any projectile, i.e., not "an error" that can be added to other errors, but the sum and result of them, directly responsible for group size. Crazy, huh?

That's a nice experiment with the damaged pellets — I bet that out of a smoothe bore there would have been worse results.

BG_Farmer

Feel free to ask anything. Others also will have some different methods that work with their guns.

Work on the feel of loading and cleaning procedures. Certain things will develop a "right" or "wrong " feeling.

Don't buy a lot of hand cast until you try them out first. Sloppy casting can produce some really bad ammo.

Be careful of excess oil or solvent in the breech….soaks into the powder and causes misfires and hangfires. Have a ball puller and a patch puller for accessories …and a nipple wrench…….some day you will need them. Always verify that the ramrod is not still in the barrel before you shoot.

After a misfire, point he muzzle in a safe direction and wait a long time before attempting to pull a ball. A hangfire can smoulder quite a while..then go off.

Stay cool and deliberate. Take your time…it will save you a lot of trouble.

twotalon

BG_Farmer …

Forgot to mention an accessory….

A ramrod extention or an auxillary ramrod that will give you more to hang onto when using the other ramrod acessories.

twotalon

TwoTalon,

Useful advice again, thanks.

The hand-casts I'm looking at are Hornady, so I think they are probably decent. I'll just try a couple of boxes. Surely I'll shoot them, even if they're only good for plinking, as I haven't been so excited about a rifle since my Hammerli 490.

I've got a virtual checklist: damp solvent patch (check empty mark taped on ramrod), dry patch, reverse dry patch, measure powder (gives bore time to dry a little more), powder (and check measure), patch, ball, short (ball) starter, ramrod to "loaded" mark (taped for current load), tamp firmly but gently 3 times, check that ramrod is not sticking out muzzle(:)), grab cap, walk to firing line, position cap, shoulder rifle, full-cock, shoot, half-cock, extract primer, repeat…sounds bad, but its really easy once you get into the rhythm of it.

Good idea with the extension — I had a patch stick on a rough spot and nearly gave myself a hernia pulling the rod out:). Already have most of the other accessories (using small regular wrench for nipple currently).

Fused,

I probably did shoot the NPSS over 100 times, but that doesn't mean much. When I tested the Beeman R1 it took almost 1,000 shots to break in the powerplant.

The guns I test should be considered brand new. They will all benefit from more shooting.

B.B.

twotalon,

"Courage is being scared to death – but saddling up anyway." -John Wayne

God Bless You!!!

AJ