by B.B. Pelletier

This question came in last week in the form of a comment about pellet sizing. Pellets are sized by pushing them through a die, and it used to be popular to do it in the 1970s. Shooters eventually realized that the bores of their airguns were doing the same thing, and sizing wasn’t really necessary.

Pellet head size is a different topic that’s still very relevant, so today we’re going to look at what’s involved. It all begins in the past, when conical bullets were first used in firearms in the 19th century.

History

Conical bullets are longer than they are wide, so they weigh more than the round balls that served as bullets for several hundred years. But because they’re longer, they can also create more friction with the bore. When they’re loaded from the muzzle, this is a problem because it takes so much more force to seat them down on the powder that the effort will usually distort their noses, adding nothing to accuracy.

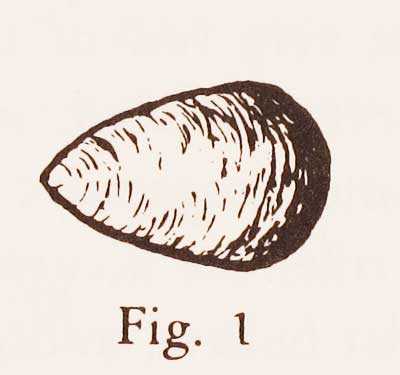

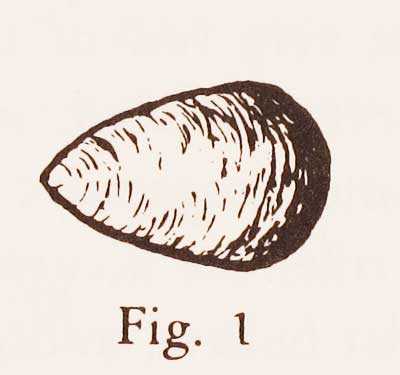

One early solution (ca. 1835) was the picket bullet, which is also called the sugar-loaf bullet due to its shape. It contacted the bore only at a narrow band near the base of the bullet. The rest of the side of the bullet did not touch the bore and, therefore, did not create any friction. Picket bullets were far more accurate at long range than round balls of the day. They pushed the maximum distance for accuracy from about 200 yards out to 330 yards. And they were also heavier in a given caliber, so they were deadlier on game in calibers that were too small for round balls. A .38-caliber round ball might be marginal for whitetail deer, but a .38-caliber picket bullet would be fine.

The picket bullet looks like a large piece of candy corn. It was a big advance from the round lead ball. Image from Ned H. Robert’s book, “The Muzzle-Loading Cap Lock Rifle.”

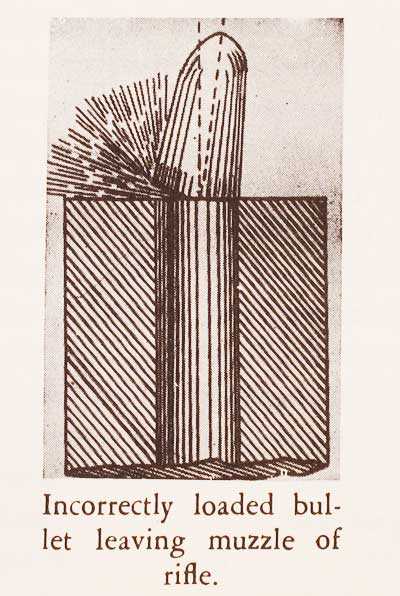

But there was a problem. If you tilted the picket bullet during loading — something that was all too easy to do, it left the bore in a tilted position, allowing gas to escape unevenly at the muzzle. That caused it to fly wide of its mark. Picket bullets were considered very accurate but also very difficult to load correctly.

You can see how an incorrectly loaded picket bullet would cause inaccuracy. Image from Ned H. Robert’s book, “The Muzzle-Loading Cap Lock Rifle.”

Straight-sided conical bullets were tried next, but shooters quickly discovered all the problems associated with friction that are mentioned above. Something was needed that would seal the bore against gas loss yet not create excessive friction at loading. Remember, too, that barrel makers were tapering their bores at this time, so that did help a little — but it wasn’t enough.

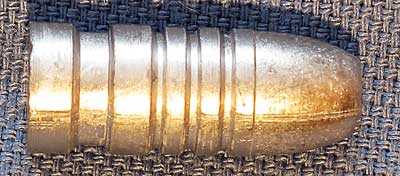

The next innovation was a bullet that fit the bore at its base, but rode on top of the lands for most of its length. A bullet with two diameters! This bullet worked very well and because it did, it increased the distance at which conical bullets were accurate from about 30 rods (330 yards) out to 1,000 yards.

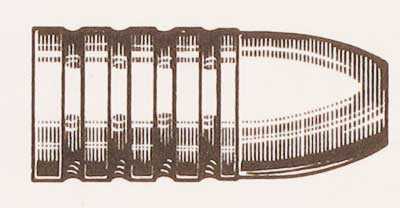

The two-diameter bullet has a nose that rides on top of the rifling. If it’s sized correctly, this can be a very accurate bullet. Image from the “Lyman Cast Bullet Handbook, 3rd Edition.”

By the time breechloading rifles started coming into popular use (around 1850), the issues of bullet friction with the bore ceased being such a problem, so straight conicals continued to be used, as did the new bullets with bore-riding noses. The picket bullet even remained in limited used through about 1880 for handmade muzzleloading rifles.

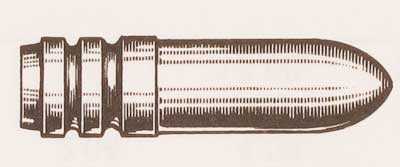

A typical conical bullet has parallel sides and a short nose. Image from the “Lyman Cast Bullet Handbook, 3rd Edition.”

Lead obturates

Black powder has one characteristic that smokeless powder lacks. When it ignites, it does so instantly, imparting a hammer-blow to the base of the bullet in front of it. Shooters of this era counted on the obturation — a blockage caused by expansion of the bullet bases to help seal the bore.

In the late 1800s, a world champion marksman, Dr. Walter G. Hudson, designed a bullet for breechloading rifles that mimicked the properties of a conical bullet in a black powder arm. Dr. Hudson, who was also one of the men who invented the gas check for bullets, designed a bullet of two diameters. The rear bands of the bullet were exactly bore-sized, while the remainder of the bullet was sized exactly to ride on top of the rifling without being engraved. This bullet didn’t tilt while it was in the bore if it was correctly sized.

Dr. Hudson shot his best matches with the new smokeless powder that didn’t obturate the base of the bullet. So his bullet went into the bore already obturated! It was an advancement that would have had far-reaching consequences if it hadn’t been replaced almost immediately by the new smaller-caliber jacketed bullets that went even farther and were more accurate at long range.

This kind of bullet must be handmade for each gun based on precise bore measurements, plus it cannot be loaded into a cartridge because the base bands are too large to allow the cartridge to be loaded into the chamber. The bullet must be loaded into the bore first, followed by a charged cartridge case that has no bullet.

Dr. Hudson’s bullet has two driving bands at its base that fill the bore of the gun. The forward bands ride on top of the lands. Though it’s difficult to see, the base bands measure 0.383 inches, while the forward bands measure 0.376 inches.

You may wonder what the difference is between the Hudson bullet and the two-diameter bullet. The Hudson bullet has bands and grease grooves that ride the rifling. The two-diameter bullet rides the rifling with a solid nose and no bands.

Pellets and their heads

Which brings us to the subject of diabolo pellets and their head sizes. In target guns, it’s considered ideal if the pellet is sealed by the skirt, which also takes the rifling, while the head rides either on top of the lands or is just barely engraved by them. It’s this “just barely engraved” phrase that causes target shooters the greatest concern. How much is enough? There’s really no way of knowing except by shooting the pellet and seeing the results.

Impossible to make every barrel the same size

Some shooters think that because barrels are made by button-rifling or by hammer-forging they can all be made identical, but they can’t. It’s impossible! Every barrel will respond differently to the passage of the rifling button. While the differences are minute, perhaps in the range of ten-thousandths of an inch, they’re still there and they do affect how the barrel turns out.

The goal for target shooters is to find pellets that group the best in their guns. We believe that these will be pellets that are either lightly engraved on their heads or perhaps are not engraved at all, but they do ride on top of the rifling with no tolerance. From the picket bullet discussion above, you can now see how tilting inside the bore would be a bad thing.

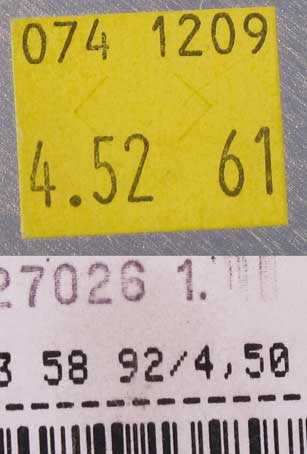

All pellets come with certain sized heads, and all true target pellets (not just those with the name “target” in their title, but pellets that are really controlled during manufacture) have their head sizes printed somewhere on their tin. It will be on a paper label most of the time — and you might have to look hard for it — but if it’s a real target pellet, the head size is there.

The paper labels on the back of two target pellet tins show the head sizes. In Europe, a comma is usually used in place of a decimal that we use in the U.S.

…you can now see how tilting inside the bore would be a bad thing.

Don’t stop yet!

If barrel makers cannot make every barrel the same, what does that say about pellet manufacturers that make tens of millions of pellets every year? That’s right, their pellets do have manufacturing differences. Even though it says a certain head size on the label, there’s no guarantee that every pellet inside the container is exactly the same. And, in the case of certain sloppy manufacturers, the head size might not even agree with what’s on the label.

Airgunners who are target shooters are fanatical about selecting their pellets. They try all the known good brands. If they have a good sense of what head size their gun likes, they might restrict their search to just that size; but often they’ll go both larger and smaller, to make sure they’ve checked everything. When they find the best pellet, they buy 25,000 or more, which will get them through a season of competition and practice.

Because this is such a chore, target shooters will often buy different lots of good pellets of different head sizes and trade them with other shooters. When they find the one best pellet for their gun, they then sell or trade the rest of the pellets they bought and buy a huge lot of the one right pellet.

Head size matters — sometimes

So pellet head sizes do matter — sometimes. But not for everyone. A guy who shoots an RWS Diana 34P for recreation would be wasting his time going through all the trouble I’ve outlined here. He only needs to find a pellet that works, and then shoot just that one pellet. And for most of us, that’s all you need to be concerned with.

When I test airguns for you, I usually don’t even bother to look at the head size. Indeed, a great many sporting pellets don’t even have their head sizes indicated. You can assume that it’s about 4.50mm, because that’s the size that seems to work the best for most guns. And unless you start shooting in competition or at very long ranges, that’s all you have to be concerned with.

So THAT’S what those small stickers are for!?!

I’ve seen this on pellet tins but never knew what they were for! Thank you TOM.

J-F

B.B.,

You’re obviously talking about .177 cal pellets when you say, “You can assume that it’s about 4.50mm, because that’s the size that seems to work the best for most guns.” You’ve probably made 5,000,000 more shots than I have with a .177 cal pellet gun but this statement surprises me. Maybe it’s because I shoot such old relics but 4.52mm, (and in many guns a much larger head size) headsize work best for me. Rarely do 4.50mm, work well for me with or without seating.

I can’t help but think I’m missing something.

kevin

Kevin…

I have one rifle that likes FTT in 4.50 and AA 4.52 both. But it hates AA 4.51. Figure that out.

Something different other than just head size or weight. I think head and skirt shape both are involved along with skirt thickness and pellet hardness too. Some kind of complex interraction with the power curve and barrel vibration.

twotalon

twotalon,

I can’t figure it out. Probably never will. Guess I’ll chalk it up as one of the mysteries of the universe. I don’t have a gun that shoots any pellets in 4.50mm head size best though.

kevin

Kevin,

Like you I used to think 4.52 mm was the ideal head size, but when I helped test the AirForce Edge I saw that 4.50 mm worked best. And in my own target pistol 4.40 mm heads also seem to work the best. Perhaps in sporting guns the larger head sizes work better, or maybe the barrel makers run the buttons so long in sporting barrels that they start with slightly larger buttons — making 4.52 a better choice for earlier guns. I don’t know.

What I do know if I have to try everything in each new gun, to find what works.

B.B.

Hi BB

I know this is slightly off topic, but here it is anyway: Here in South Africa we do not have the variety of pellets you guys have there in the U.S.A. I am looking for the best pellet to use in my Hatsan AT44. I obviously would like the pellets to be both accurate and maintain energy, so heavier pellets will probably be better. If they remain subsonic, so much the better, to reduce noise. We have the following heavy .177 pellets available: H&N Rabbit Magnum (15.7gr.), Prometheus Piledriver (21gr.), Evanix (16.1gr.), JSB Exact Monster (13.4gr.) and Gamo TS-10 (10.4gr.). I would like to try the Eun Jin .177 Cal, 16.1 Grains, but the price of shipping is prohibitive if I buy it from Pyramid. Pyramid sells them on eBay with more reasonable shipping cost, but will not ship to South Africa.

Anyway, as an aside: The AT44 is quite a loud gun, probably almost as loud as a .22 rimfire. I have fitted the Hatsan silencer and it is now about as loud as a Daisy Red Ryder. Performance seems not to be affected, but I stand to be corrected.

Regards.

Vasco

Vasco,

Hatsan now sells direct here in the U.S., so we will soon be seeing the AT44. We have seen similar guns already under different names, but I’m waiting for the Hatsan AT44PA, which has a slide action. That will be a new one in an air rifle.

B.B.

Vasco,

By the way — welcome to the blog!

B.B.

BB,

Will you be doing a review of the AT44PA? It sounds like it would be pretty interesting.

The only slide action airgun I can think of is the Daisy 25.

I have a Daisy/Winchester 600X. Was that made by Hatsan?

Les

Les,

I will review it if I can. I don’t know when it will come to the U.S.

B.B.

Vasco,

I have tried all of the pellets you have mentioned in the AT44 (sold in the USA as the Halestorm) and the TS-10 was decent (.5 inch group at 25 yards, 1.25 at 50). Both the Piledriver and Exact Monster were around one inch at 25 yards. The Rabbit Magnum was not accurate at all, even at 25 yards.

Is the Evanix 16.1 gr just a relabeled Eun Jun pellet? My guess is that they are the same ammo with a different label on the tin. The Eun Jin will group just under an inch at 50 yards.

If you can get the Crosman Premier Heavy, Daystate Li, or Baracuda Hunter they should do very well in the AT44.

Paul in Liberty County

The best pellet I’ve found in at-44 was the h&n barracuda. It has the best pen. and accu. amoungst all the pellets I’ve tried(I’ve tried quite a few)

Welcome, Vasco!

Good to get some input from SA. Is airgunning a popular shooting sport down there?

Les

B.B.,

In the not too distant past, we talked about lubricating pellets. There’s going to be a certain amount of viscosity to the lubricant, so I wonder how much this added element should be factored into pellet diameter? If your airgun likes 4.50mm, might it be better to use 4.49mm, if you always lubricate, for example?

Victor

Victor,

Wow — tough question! I have no idea. I do know that when I lube my pellets I don’t change the head size.

B.B.

Well, at high velocities, I’d expect the lubricant to really do its job, so the effects are probably negligible. In addition to this, over time, the lubricant would form a very thin layer throughout the bore that probably maintains it’s thickness. On the other hand, maybe this is why some lubricants work better than others on a given barrel.

In my choked LW barrel anything larger that 4.50mm will send flyers.

BB

The guy that sold me my Diana 34, said that he had two of them, and that they were equally accurate. The only difference was that the one he kept liked a very cheap pellet, and the one he sold me had more expensive tastes. No biggie, I seem to have expensive tastes as well. As an aside, VAF is a great person to do business with, in my experience.

I agree with you as to how great the rifle is. If I had purchased this gun in the first place, I may have been perfectly happy with it for what I wanted to do… and never been infected with the bug that has cost me lo, these thousands of dollars. It was the shortcomings of that first gun that got me on the internet and looking for ways to improve it. That inevitably led me to this blog. Thousands of dollars later and tens of thousands of pellets later, here I am, one of us. Not that I’m complaining.

BTW: Why is there an illustration of an oyster at the beginning of the article? Does it have anything to do with your pearls of wisdom?

SL,

Clam up! 😉

B.B.

That’s how much BB used to pay for pellets! 1 clam.

Beeman used to offer a pellet sizer with three sizes,it worked but it took a while and now with all of the brands available most of the sizes can bought with a little study of specs.I even purchased a set of conical bullet molds in .22 and.177 direct from England, but they were highly inaccurate and tumbled.How luckey we are in today’s air gun world with such a selection to choose from”Air guns have finally arrived.

No NJ Mike,

I own a Beeman pellet sizer and did an extensive test for “The Airgun Letter”, which is why I made the remark that they don’t really work. After thousands of shots, I was never able to see any difference between sized and unsized pellets. perhaps that is because the gun both enlargers the pellet at the shot (springers do — PCPs don’t) and then squeezes it back down if the muzzle is choked. Of course I didn’t test every pellet, so I may have missed some that did benefit from sizing.

The Brits sold those brass “pellet” bolds that were long conicals that had no chance of stabilizing at pellet gun velocities — especially when they were being made. Even today I doubt whether a Condor could get one of those heavy .177 pellets going fast enough to stabilize, though that might be an interesting test.

B.B.

Yes!! More experiments!! 😀

My initial airgun education was via the 93/95 Beeman catalog wherein they say that you NEED to use their pellet sizer or you’ll NEVER NEVER shoot accurately! When I started to really get into airguns and bought my first good one a couple of years ago the pellet sizing thing was one of the first things I researched. That’s how I found this blog!

My computer is presently wasted. I am on my wife’s computer.

twotalon

B.B., you touched on this, but I would like to add that I thought that the Minie ball for muzzleloaders was a great idea. As I understand it, the bullet was a streamlined shape that was small enough to be dropped down the barrel but would expand with ignition to fit the rifle. Seems like a great idea.

Interesting to hear that blackpowder ignites instantly compared to smokeless. But I recall you saying that blackpowder has a showing action that is less concentrated than modern firearms, and that was my impression too when I fired blackpowder.

Anyway, I will take this to heart about bullet fit when reloading from my surplus rifles. I read about one guy who said that he was marginally satisfied loading .308 bullets for his Mosin, but when he loaded .311, he was getting half-inch groups!

Duskwight, I’ve realized there is a huge gap in my knowledge of Russian martial culture which is staring me in the face! What is the traditional knife of Russia? Americans have the bowie knife. Southeast Asia has the barong/bolo knife. Finland has the Sisu or Pukoh knife. Nepal has the Kukri. The British military has its commando knife and the less well-known Smatchet. The German military used the same design for both World Wars which is kind of a model of economy. It looks like a double-edged dagger except that the point is a little narrower and one and a half edges were sharpened instead of two. Given the great innovations of the German military during the wars, and the immense history of swords in German culture that I’m reading about, I figure that if this knife remained unchanged, it must have been good. Anyway, what is the Russian knife?

Matt61

In paragraph 2 above, “showing action” = shoving action

Matt61

Matt,

I thought of the Minie, but I was writing about precision bullets. Minies are more of an expedient for muzzle loading that are accurate enough to do the job, but no one expects them to be target ammo.

B.B.

Matt,

I guess it would be “finka” – a combat knife basically resembling Finnish “puukko” (name implying Finnish oriin), but longer, heavier clip-point blade and fitted with S-shaped guard. Most famous example is NR-40 – read here https://en.wikipedia.org/wiki/NR-40

duskwight

Black powder is classed as an “explosive”, smokeless powders are classed as “propellants”. Pyrodex may straddle the line…

GREAT article! Great discussion too. This is the kind of stuff that keeps people coming back.

Thank you

It is interesting that pellet sizers are out of fashion. I have one that I must use to size RWS Super Mag pellets in .177 in order to use them in my RWS M-36 and my Beeman P-1. If these are not sized, the breech seals of both the rifle and pistol will blow out. Apparently, I have two different guns with slightly ‘tight’ barrels (undersized?).

My theory has been that a properly sized pellet will both engage the grooves and ride on the lands properly and not consume too much of the scant energy available for propelling the pellet down the bore. I always use another out-of-fashion implement when shooting, a Beeman Pellet Seat tool.

Rapid Air Weapons, of Tennessee, now is manufacturing a copy of that out-of-production tool, and it comes with a lanyard, too, which is very handy when shooting. This tool, like its predecessor from Beeman, allows for a consistent placement of the pellet in the bore time after time.

Lance,

The pellet loading/seating tool isn’t out of production. Pyramyd AIR has been selling them for some time. Plus, B.B.

has written quite a bit about it when he uses it to show how seating depth increases accuracy.

Here are the blog postings that included use of the Pellet Pen with Pellset tool:

/blog/2013/05/walther-lgv-olympia-field-test-part-2/

/blog/2013/01/diana-25-smoothbore-pellet-gun-part-3/

/blog/2012/12/benjamin-titan-gp-air-rifle-with-nitro-piston-part-2/

/blog/2012/07/brownings-buck-mark-urx-pellet-pistol-part-2/

/blog/2012/07/winchester-m14-177-caliber-dual-ammo-air-rifle-part-2/

/blog/2012/06/ruger-mark-i-pellet-pistol-part-2/

/blog/2012/05/el-gamo-68-68-xp-a-futuristic-airgun-from-the-past-part-4/

/blog/2012/05/el-gamo-68-68-xp-a-futuristic-airgun-from-the-past-part-3/

/blog/2012/05/air-venturi-bronco-with-optional-target-sights-part-4/

/blog/2012/05/air-venturi-bronco-with-optional-target-sights-part-3/

Here are the pellet loaders sold by Pyramyd Air:

/product/pellet-pen-holds-20-177-cal-pellets?a=2934

/product/pellet-pen-holds-15-22-cal-pellets-green?a=3693

/product/pellet-pen-with-pellet-seater-loads-seats-22-cal-pellets?a=4870

/product/pellet-pen-and-pellet-seater-loads-seats-177-pellets?a=4140

/product/crosman-pellet-loader-holds-16-177-cal-pellets?a=2932

Here’s a video done by Airgun Reporter Paul Capello on how to use the pellet pen with seater:

/video-details/air-venturi-pellet-pen-and-pellet-seater-airgun-reporter-episode-80/299

I’m guessing the one sold by Rapid Air Weapons is actually the same one Pyramyd AIR sells.

Edith

The Beeman/Rapid Air Weapons pellet seating tool is a different tool than the pellet pen. It has no “magazine” for dispersing pellets for one thing.

They are made of anodized aluminum and have a tapered end and a ball end. The latter is particularly good for seating the skirt of a pellet into the initial rifling at the breech end of one’s air arm. The depth is consistent and usually somewhat shallow.

The conical end is less controllable, and can deeply seat a pellet in the breech if the shooter desires. The Beeman is no longer available but it is well copied by RAW, and the latter even comes with a lanyard so it is handy when shooting.

My Beeman tool, though showing wear from some 20 years of use, continues to give consistent seating of pellets and works with all calibers. When the pellet is seated, there is a subtle “click” that lets me know that the skirt is embossed with the lands and grooves and the pellet is ready for launch. The main thing is the consistency and durability that these things offer.

I am familiar with the pellet pen. A friend has one. It will not work well in a Beeman P-1 Pistol or other breech system that is set in a defile or recess. At this the Beeman/RAW pellet seat works, and works well.

Regarding obturation.

I’ve read reviews containing complaints of “dirty pellets”. I assume the writers are referring to pellets that are dull gray rather than shiny. Over the years I come to believe that, especially in low velocity air guns, dull gray pellets are more accurate than shiny one. I believe the dull gray pellets are pure lead and softer, providing better obturation; the shiny pellets being harder because they are alloyed. If I had to select a pellet strictly by appearance I would chose a dull gray pellet with a ribbed skirt. I believe that such a pellet will be soft enough to fill the bore and provide good accuracy. If my choice was limited to shiny pellets I would opt for a design with a ribbed skirt. I don’t have the means to determine the Brinell hardness of an object as small as a pellet and I’m too frugal to melt a couple of tins to get a slug large enough to do the test. Selection on appearance aside, I buy different pellets and shoot them to find out which is best for a given air gun. I am fortunate because my vintage LVG Special, with an intentionally choked barrel, is amazingly accurate with every brand and type of pellet I’ve put through it.

Lots of interesting stuff today and thanks for the revelation on target head size stickers. Having both a Webley Tempest and a set of troublesome accessory rotary magazines for the S&W 596 revolver, different sizes of nominally .177 (.450) pellets has made both items shoot much better, indeed.

I’m finding the Webley Tempest pistol, which seem to be notorious for having over sized chambers/bores respond very well to something like .452 rather than the .450 nominal size. While the S&W revolver works well with the two factory magazines in came with, the accessory 3-pack allowed standard pellets to fall our or fall through, or otherwise be left individually in your pocket, on the bench, or on the floor. A .452 pellet seems to salvage the situation and be more accurate to boot.

On choking a barrel, while I can’t comment on air guns, I’ve found an interesting comparison between a 3-inch barreled Colt Python vs a 6-inch barreled S&W “K” frame Model 19. Both are beauties, both pretty close in size & weight, both I’ve owned and shot with the exact same recipe “target” wad cutters for many years.

The peculiarity is that the short-barreled Colt has always consistently out-shot the long barreled Smith. Not a big difference, not even a very significant difference, but…noticeable. What’s the difference?

All I’ve been able to figure is the Colt has a choke barrel, the Smith doesn’t.

Go figure.