by Tom Gaylord, a.k.a. B.B. Pelletier

This is the second report in this series on swaged bullets. My initial purpose for testing these bullets was to see if I could make a swaged bullet that would shoot more accurately than patched round balls in the rifle barrel of my Nelson Lewis combination gun. While testing that gun, I blew out the nipple and had to repair the gun before it would shoot again. Thankfully, that’s all done now; but I decided, instead, to use a Thompson Center muzzleloader in .32 caliber as the testbed for this idea.

When I first tested the swaged bullets at 50 yards, I couldn’t get a shot on the paper; so this past Monday, I shortened the shooting distance to 25 yards, in hopes I would be on paper. Since I’m reporting this now, you know that I was successful.

One thing I thought might be causing a problem was using too much black powder for the swaged bullets, so I selected a 9mm Luger case as the new powder measure. But there were ignition problems, so that wasn’t the right thing to do. I then adjusted the powder measure back to its smallest measure and shot some patched balls as a control group. The first one was a hangfire that was delayed about 100-200 miliseconds. It sounded like I’d shot a flintlock with a slow lock time. But the second shot with the same load went off perfectly, so I put 4 more downrange after it. This gave a nice group that measured 1.504binches between centers. That’s not great for only 25 yards, but at least the group seemed to be centered on the bull, if a little low.

Five patched balls went into 1.504 inches at 25 yards. The 6th shot that landed low was a bad hangfire.

I was exhausting a supply of 3F Goex powder that was at least 30 years old. I’d received it as a gift about 12 years ago, and I think the giver said it was about 20 years old then. So, black powder does hold up over time when properly stored.

One thing I did with the patched bullets was quit cleaning the bore between shots. I used a patch lubricated with saliva, which is recognized as the most accurate round ball lubricant. To do that, I put the patch into my mouth as I began the loading process; then it was wet when I laid it across the muzzle about 30 seconds later. You can only use spit patches if you’re shooting right away; because if the saliva dries, it won’t do anything. Plus, you can rust the bore where it sat. But after 6 rounds had been fired, the bore was still clean enough that I could seat the ball flush with the muzzle with thumb pressure. That told me the bore was not getting any dirtier as the shot count increased. With real black powder, the bore gets dirty on the first shot.

Then it was time for the swaged bullets. The bullets I swaged from .310 lead balls proved too small for success. They missed the target altogether. Then I switched to bullets swaged from .350 lead balls. These seemed perfect and went to the same point of aim as the patched balls. After 4 shots, I thought I had a winner; but shot 5 went almost 6 inches higher, opening the group to 6.25 inches. The first 4 shots measured 1.816 inches between centers — not that much bigger than the patched ball group.

The larger bullet on the left was swaged from a .350 ball. The smaller one came from a .310 ball and didn’t shoot very well.

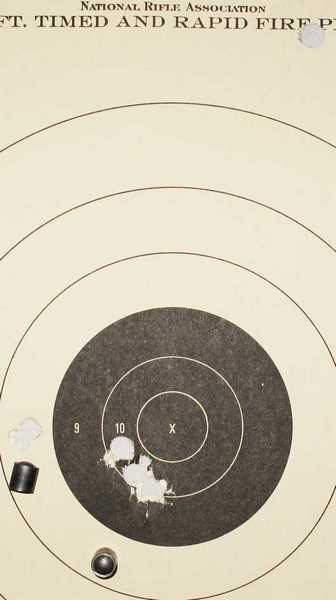

The swaged bullets did okay until the last shot (upper right). The bore was getting too dirty to shoot well. Notice that at least 2 bullets hit the paper sideways.

This target held a clue to what was happening. Two of the 5 shots appear to have struck the paper sideways, indicating they’re tumbling in flight. Because the bullets are swaged into cylinders rather than spheres, this is very easy to see. Instead of round holes, you get rectangles. Obviously, these bullets aren’t stable in flight, which means they probably aren’t engaging the rifling. Either that or the rifle’s twist rate, which I believe is 1:48″, is too slow.

Some of the holes are perfectly round, however. This either means they were either tumbling and happened to strike the paper point-on, or they were actually stable and for some reason the other bullets weren’t. More work has to be done to sort this out. But let’s now look at the next discovery.

I told you I wasn’t cleaning the bore between shots this time. Well, that came back to bite me. The swaged bullet that had previously slid down the barrel easily was now just entering the bore and staying put. That’s the unmistakable evidence that powder residue is building up on the walls of the bore.

And the next 5 shots on a different target tell the story. Only 4 landed on the target paper and 2 of those went through sideways. The 5th shot landed below the target paper on the paper backer I was using for just this reason.

On the final target, only 4 or 5 bullets hit the target paper. Two of them hit sideways. The 5th shot landed low, off the paper.

That target marked the end of this day at the range. In all, I shot about 25 rounds in about 45 minutes, which is moving right along for a muzzleloader. I tested two weights of swaged bullets with 2 different powder charges and determined that the heavier charge and heavier bullet were both needed. In fact, the next time I test this bullet, I’ll use an even heavier powder charge and try a heavier swaged bullet, to boot.

For the record, I weighed the powder from the measure and discovered it weighed 19.4 grains. This is a light load for a .32-caliber muzzleloader.

I figure the heavier powder charge will help swell the base of the bullet better to grab the rifling, and maybe the heavier bullet will add a little more resistance to help that along. I also plan to clean the bore after each shot, as I now know these swaged bullets require it.

There’s a whole lot more to explore with swaged bullets, but I’ll keep working with this swage set until I know what I’m doing.

BB

Do you think it would be easier to test with a air gun than with powder?

Maybe a air rifle would help to overcome some of the problems with powder. Air pressure and tuning of fps could maybe be controlled easier. I don’t know just a thought. Then apply those things to your powder gun.

And the swaged bullets in the pictures above look like the back of them are at a slight angle to the outer diameter (not perpendicular to each other). Maybe the picture is giving a illusion or something I don’t know.

But if it is angled back there wouldn’t it load one side of the bullet harder on one side and make the bullet start pushing through the barrel sideways as it starts moving through. Could that possibly make the bullet get set up to tumble when it leaves the barrel?

The bigger swaged bullet made from the .350 ball looks more uniform. And what kind of taper do you have from front to back on the outside diameter? The front of the bullet is smaller in diameter than the back of the bullet. Right?

GF1,

There should be no difference between a powder arm and an airgun in this testing. Black powder is one of the easiest things to test with, as it is so pliable.

These bullest have no taper. They are a uniform 0.316-inches at all places.

B.B.

I think gf1 was saying that the base of the bullet isn’t square. Looking closely at the pictures, it does look like the base is off. That would give the same effect as a bad crown. But, it might just be the camera angle giving that effect. I’d still check tree bases of acouple with a machinist’s square. You can use your vee blocks to accomplish that too since they should be perfectly square.

/Dave

“the bases” not tree … My phone hates me…

/Dave,

Okay. That makes some sense. Yes, the bases are not square. I had to be very careful about which bullets I loaded because if they were struck too hard in forming, that was the result.

I will keep that in mind for the next test, as well.

Thanks,

B.B.

Using the Greenhill formula for rifling twist, the twist for a .32 inch round ball is 1:48, so your rifle was designed for ball. Your longer bullets appear to be about one and a quarter calibers long, so they really need a 1:38 inch twist to stabilise.

rikkochet,

Or they need to go faster, which increases the spin rate.

B.B.

BB

Is there a reason for no taper. And is taper a bad thing?

GF1,

I have never seen a tapered bullet, to my knowledge. I have seen exotic 2-diameter bullets for special purposes, but never one that was tapered.

Since the object is to fill the bore to seal against the loss of gas, why would the bullet be tapered? Are there tapered bullets?

Are you referring to the bullet’s ogive? Maybe I don’t understand what you are asking.

B.B.

BB

What Dave explained above about the bullets not being square at the base. That is one thing I was talking about. I really believe that is what its causing the tumble.

And no not the ogive. We have had different designs on the dome of the M430 grenades we made at work.

But I bet if you made a bullet with the front diameter (caliber of your bullet) closest to the front of the bullet (and not the ogive) about .002″ smaller than the diameter by the base of the bullet it would free the bullet up in the barrel when it gets fired.

It would accelerate faster because of less contact area and drag and still seal good to the rifling of the barrel. Of course if you got the sizing correct.

When I have checked diameters of the different pellet brands I have. The base of the pellet/skirt is usually about .002″ to .004″ bigger than the head of the pellet. I don’t know if all pellets are made that way and I’m using a micrometer not callipers so I’m pretty sure I’m measuring accurately. And I know your talking bullets but maybe some things from pellets could be applied to a swaged bullet.

I know its easy to talk about trying something. And when you try it seems that it doesn’t work out as planned sometimes but when you get things right its amazing.

Slow day ? How about another “off the wall” ?

Did a bit (beginning ) of a barrel / gun warming test…

Took the .22 R9 out to my father in law’s barn (no wind or sun in the barn ). Checked the temp of the gun at all metal points. Used a glove on my cocking hand to minimize heat transfer. Shot 10 FTT as fast as I could.

Temp increased by about 2 degrees measured at the midpoint of the barrel, and the front part of the compression tube where the compression takes place .

Temp slowly bled off over the space of a few minutes interval between two successive measurements being taken after shooting, even though the ambient temp was slowly creeping up.

Will have to try this again in my basement where there is a more stable ambient temp and no chance of wind.

Will try a PCP next to see what the barrel temp does.

twotalon

tt,

I would expect that temp rise from a springer due to the sudden compression (mine all get warm). Maybe less so from a pcp, but still a little from the friction of the pellet traveling trough the barrel. It’ll be interesting to see what you come up with.

/Dave

/Dave

I pretty much expect a PCP to get cooler. That’s a lot of high pressure air decompressing in the barrel . Will probably over ride any friction heating, but I will find out.

twotalon

TT

I think the heat would make some difference in the way the projectile (pellet/bullet) leaves the barrel.

GF1

Hope they all leave the barrel front end first.

twotalon

GF1

Just ran the test with the R9 again, but in the basement this tine.

70 degrees , ten shots.

Barrel did not heat as far as the IR could tell. Compression tube came up one degree.

So I got results that were a bit different from the first time. Cooler conditions and better climate control ?

PCP will be next.

twotalon

TT

Here is something I thought about.

Could the bullet or pellet absorb the heat. If it does that would definitely play a big factor in the sizing of a bullet/pellet.

I know when I shoot my pellet guns and my .17 hmr that the POI changes on a cool day verses a hot day. I know the humidity and other things contribute to the POI. But outside temperature does make a difference.

So maybe that’s why you seen more of a change when you were outside ???

GF1

Outside conditions were not stable as I would have liked. I think the indoor test gave a more reliable result because of the steady temperature and lack of drafts.

There will be some heating of the pellet and gun for sure because of friction. What I was after is the extent of heating of the rifle . There is some in the springer as anticipated, but it is insignificant compared to changes caused by environmental conditions. The heating time for each shot is very small, no matter what the temperature may peak at. The heat that is absorbed by the metal will spread out to the point that it will vanish. And the gun will continue to try to stabilize to environmental conditions.

Firearms are going to change temp a lot more because of more friction, and the white hot fire under extreme pressure against the bore. How much dimensional changes caused by heating from firing or environmental conditions is anybody’s guess. Then there is the scope (not temperature stable ).

Some guns seem to need to be shot in the shade. They don’t like getting hot.

twotalon

Victor,

From yesterday… Strangely enough, 6 of my 60 shot qualification for my ccw were 3 sets of double taps at about 3 feet were required with my eyes closed, drawing and firing twice then reholstering between sets. I wasn’t expecting that, but luckily I had been practicing instinctive shooting with my pellet pistol every day for about 6 months prior to that and spending 2 or 3 days at the range with a DE 44 mag, so I did well even with the rented Springfield XD .40 that I had never shot before. There is a lot of work involved in being able to hit anything without looking! Really felt strange shooting live ammo with my eyes closed, after all the safety, safety, safety drilled into me all my life…

/Dave

Dave,

When I competed, before each shot I would get into my shooting position, close my eyes, and then check to see where I was aiming (my sight picture). I never shot with my eyes closed, but I have turned a target backwards to see how well I could do. We use to have an annual turkey shoot, where we had to shoot at the back of a piece of paper with numbers on it. To my surprise, I did pretty well.

But no kidding, some of the worlds best shooters really do shoot blind to test how well their natural point of aim is. For what you are doing, it’s all about muscle memory and practice finding the right stance (natural point of aim). The more you do it, the better you get.

Victor

I missed the last few reports and just got time to read them back to back. The Evanix Rainstorm is also starting to grow on me. If it was available here with a lower velocity/higher shot count I think I’d seriously consider one!

I also just received the “Tom Gaylord top 10 tips to better accuracy” and I’m totally stealing number four as my signature on different website as well as an excuse to get more guns!

“4- Right gun for the right purpose

One size does not fit all. You can’t buy a single airgun for every need. Golfers use many different clubs. Airgunners need more than one gun.”

If that isn’t pure genius right there, I don’t what is. It’s the perfect analogy and it’s perfectly worded.

Thank you

J-F

And there was much laughter, frivolity, joy, dancing & wild celebration throughout the land as the elusive lefty, TX200 had arrived (b/o’d since 5/1)! Got the Mr. BB/Myagi scope, rings & pellets + the Walther multi tool, great call, sir. Now all I gotta do is read the destructions, mount the scope & find somebody ta shoot it for me. At this point, me shootin’ a TX would be like handin’ a kid who’s still on trainin’ wheels the keys to a V-Rod (Harley’s 4 cylinder, water cooled screamer). Will keep ya posted. Thanx ya’ll. Have a great weekend. Shoot/ride safe.

Beaz

P.S. /Dave, buddy, 2 words, SMART FONE.

Beazer

The end of the cocking lever has two grooves cut into it. I suggest getting two appropriate sized rubber O rings and put them in there. It protects the lever/shroud much better than that silly rubber bumper that comes installed in the shroud.

I think you are going to like this one.

Howdy Slinger, thanx for the tip. Will add the o rings when I get ready ta shoot. For now, all I can do is carry it around the house gigglin’ & droolin’ like a fool! Any hold tips, please? Hafta go out this afternoon, lookin’ for a good daycare for him!?!

Beazer,

you will find the TX 200 is NOT very sensitive to hold but for best results, the artillery hold is still called for. This rifle is a really fine piece of engineering and I suggest you get away from the blog and shoot the dang thing. Now! Shows just what the English are/were capable of building when quality matters.

As for the V-Rod, you can buy one for real cheap (at least in the Democratik Peoples Republik of New Jersey) as “real Harley riders” want a 60’s era technology undersquare, pushrod engine 🙂 made in Milwaukee and not by Porshe in Germany.

Fred DPRoNJ

Beazer,

Congratulations to you! I hope to hear your observations soon, when you experience that rifle!

B.B.

Mr. BB, thanx for the response, I’m honored. Fred D, thanx for the hold tip. Truth be told, had a dozen shots through it before the packin’ paper had hit the floor. Observations thus far: I’m not worthy, I’m not worthy! Keep ya posted. Thanx again, have a great weekend.

Beaz,

Lol! This one has a quad processor! It’s almost as smart as a quail! (dumb bird here in Colorado that I have personally stepped on the head of when I didn’t see it and it didn’t get out of my way….)

/Dave

Beazer,

Congratulations on having achieved such a fine acquisition! You’ve earned it!

You started off with some good intro guns, took the time to work on the fundamentals, saw real progress, and then rewarded yourself with a masterpiece of a gun that will allow you to take your skills as far as you choose. Get some good pellets deserving of this gem and you won’t have to wonder who to blame. 🙂 I’m very happy for you!

Victor

Liked your accuracy tips… But really leaving the 1720T off the list… My 1720T is my most accurate air pistol I own. It even out shoots my LD (sorry Tim, still the best C02 in the universe) and is better than my Prod (although I love it also)… The 1720T is amazing considering the power… I do not own a 1701 yet… But with zero recoil it better have one hole groups in expert hands (I am no expert)…

bltaxes

The 1720T are like crazy accurate. And I thought I saw it listed under the pistols. Maybe it ain’t? I don’t remember right now.

I got the 1399 custom stock on it from Crosman and a Hawk 2.5 X 10 power side wheel scope. Mine wont miss. And I have shot many different brand pellets through it and they all shoot good.

All I got to say is Crosman got the 1720T right and it would be the gun to take apart and see what they did. Its got the Walther Lothar barrel on it as some of Crosman’s other guns. But this gun definitely has got it. I love it.

That T/C should cut a ragged hole at 25 yards with the right patched RB load. I would suggest getting an adjustable powder measure. The right charge makes a big difference. My .36 flinter shoots best with 30 grains of FFFG. But, another rifle of the same type might want 35 or 25 grains. You just never know.

Mike

Mike,

I am using an adjustable powder measure. And this rifle has been able to shoot groups like this at 50 yards, which means the 25-yard groups would have essentially been just a single hole.

B.B.

What is swaged? Is that the same as making your own bullets in a mold?

I see that Slinging Lead is here to make fun of me on the occasion of another trip to the range. I was loaded up with two rifles in a double rifle case, a bag on rollers containing two pistols cases (holding 3 pistols) all of my ammo totaling hundreds of rounds, a scope, appropriate Allen wrenches, spotting scope, iron sights for the Anschutz, eye and ear protection, sandbag rests, staple gun, staples, scope stand broken down. I was also carrying a bow case with two bows, an arrow case, quiver and 6 cardboard targets. How did I carry all that stuff? I’m not even sure. But I had things I wanted to accomplish.

First up was standing at 50 yards with the Anschutz. I’m gratified to report that someone about my height who looks a lot like me is holding the black on standing! Thanks to Victor and BG_Farmer who kept me from foaming off in a new direction with my enthusiasm for the trigger squeeze. Now it will be working the sights against the trigger squeeze both at the same time. At first, the millimeter at a time trigger squeeze was not working for offhand. But I speeded things up while keeping it steady, and things started to happen. I even felt the Jaws of the Subconscious on occasion. Chomp. For the woman that Victor mentioned who cleaned standing is almost unimaginable to me. Quoting from the movie Cocoon, I can say, “Stay away from her. She’s not normal.”

While this was going on, I overheard a guy say to his girlfriend, “Can you talk? I feel like I’m talking to myself here.” So the couple that shoots together does not necessarily stay together. It gave me the creeps. What if they started blazing away at each other right there? It could be like the story of a woman dentist who finally lost it and drove her car over her philandering dentist husband. Then she jumped out and said, “I love you.”

Anyway, next up was my Mosin sniper rifle. With a 192 gr. bullet, that rifle has some kick, and follow through kind of went out the window. Nevertheless, it was stunningly accurate. I put four and then three rounds each inside of an inch at 50 yards. Then I moved to the 100 yard range. Part of the goal here was to check the scope on my Anschutz which had experienced weird problems the last time I went out in going from 50 to 100 yards. Sure enough, it happened again. It took awhile to get the scope zeroed at 50 yards since it looked to be about a foot to the right. Somewhat to my surprise, I got it dialed in, and the Anschutz was putting bullets through the same hole. I took the scope off while I moved to 100 yards and when I remounted it, it was now a foot to the right again! Is this what is meant by a scope that doesn’t hold zero? Even when the turrets were locked? I managed to dial it in again to my even greater surprise. Does the optical centering business explain this? My scope must be as far from optically centered as it is possible to be. With a scope and a windless day, I shot 10 or 15 rounds into about two inches.

With the Mosin, while sighting, I got groups of three and two around an inch. I occurred to me to just quit while I was ahead and call it a 1-2 minute gun. But I decided to man up and shoot a consecutive five shot group. But here is where things started to go wrong as the next group was 3-4 inches with horizontal stringing. I thought maybe the problem was the sight picture. I was holding the tip of the point of the black vertical reticle line in the middle of the black bull for the 100 yard military target. So, I decided to try a 6 o’clock hold with the tip of the reticle just below the bull. Now the Russian sighting system began to really mess with me. I’d had some trouble at 50 yards but managed to get zeroed. Now, I tried the same procedure and was no longer on the paper! And trying to think about it, I had no idea what I was doing.

Given that when the reticle moves instead of the scope tube so that you must adjust it by going in the opposite direction that you want the bullet to move, how are you supposed to make an adjustment from a center hold which is more or less on to a 6 o’clock hold where the bullet is still hitting center? I don’t think the shooting range is the place for higher cognitive function because my brain shut down. I positively could not solve this problem. Finally, I got it right sort of, but the groups were about five inches. I think partly it was because I wasn’t sighted, partly because the metal shod buttplate was giving my shoulder a walloping after 40 rounds. Also relevant is a video I aw which showed that the Mosin is extremely accurate up to about 5 shots. Then, its thin barrel gets heated and those shots start to wander. There’s not a lot you can do to counter the physics of heat build-up with that thin barrel. And with that big cartridge, the barrel heated up very quickly, especially the way I was reeling the shots off airgun style. As cold as it got in Stalingrad, the soldiers could have always warmed themselves on their gun barrels.

I also noted that in the later part of the shooting session that the bolt of the Mosin became almost impossible to open. Does that have something to do with case expansion or heat? The Mosin is loose enough so that you can see the bolt move around as you apply pressure to the trigger!? I can’t imagine how the Russian soldiers opened their bolts with those short straight bolt handles in the middle of a battle.

I wonder too if declining performance was not based on the target. We’ve talked about guns and their ammo as being factors but what about the target design that you’re shooting at? Maybe the black bull is good for a G.I. post sight, but I don’t know if you can get any decent sight picture when you’re aiming with a vertical post that ends in a point. Similarly the Anschutz was doing great with a scope at 50 yards because I was using a grid target which worked well with the crosshairs of the scope. But at 100 yards, I could no longer see the grid, even at 24X. What is the optimal design for crosshairs? I would guess a gridded target with perhaps a very small red dot to indicate point of aim.

Then it was off to the pistol range. It was a banner day for the SW686 with my .38 Spl +P load. I hadn’t really appreciated it while shooting it next to the .357 but this was a deadly accurate and gratifying load to shoot. Make sure to put it on your bucket list gents (and ladies). One hears about taking a cold bore shot with a rifle but never with a pistol. Why? Is it because with a heavy caliber like a .45 ACP, your first few shots inevitably go off target as you get used to them and learn how to follow-through? I can’t seem to get rid of this warm-up period. And oddly enough, when I forget to follow through and get more muzzle flip, the shots seem to go down as if I were heeling the gun instead of up.

Anyway, just as I was getting dialed in and doing well overall, here comes a very youthful looking rangemaster with a troubled expression asking me where I learned to shoot a semiauto(!) What would you say to question like that? I should have just said B.B. Pelletier. Anyway, he went on to tell me that my thumb should not be on the thumb safety of the 1911 but should stay tucked below to stay away from the slide. Reciting from the blog (and my own experience) I told him that the thumb safety on the 1911 was flared out to support the thumb and reduce muzzle flip. The guy had never heard of this(!) But just when he was backing away, along comes another character. This was a much older fellow with a long pure white beard like Santa Claus, a kindly face, and what looked like a suit pants, a vest unbuttoned, and a loud tie. He tells me that muzzle flip should be controlled by the off hand pulling back and something about the last two fingers of your shooting hand on the gun butt.

To give him his due, some of the business about the two fingers sounded not unlike Lt. Col. Bonsall’s grip method. I try to apply even pressure front and back on the grip as shown in a video by Bill Wilson. As for the off hand applying backwards pressure, I believe that applies in the variations of the Weaver hold. But that does not apply with the Isosceles grip right? I thought the whole point of that grip–and one reason I like it–is that it is so easy, natural, and symmetrical. So to apply different pressure from each hand in the midst of that doesn’t sound right.

Anyway, what was I supposed to do as they stood watching? I thought about humoring them, but I was dinged if I was going to waste any ammunition on bogus advice–especially when I was shooting better than the old guy anyway. I kept my thumb on the thumb safety. As I continued shooting, I heard these two carrying on a conversation about how one of the wonderful things about a shooting range was the sociability. Yes, but not if the advice is bogus. And even if it isn’t, I don’t go there to yak. How could I possibly access the Jaws of the Subconscious while doing that? And some of it is positively dangerous. One guy on a different occasion kept up a running conversation of babble so that for the only time on record I actually called my Garand safe on the firing line when I had the bolt closed on a loaded clip. Fortunately, it was caught. They would have been entirely justified in booting me off the range. Something that this guy told me after. I forebore telling him that if he would just shut up, I would be able to concentrate on what I was doing.

On a brighter note, B.B. take heart. You have mentioned that you don’t know who will teach people shooting skills these days. Well, maybe the internet will do the job. With the internet in general and the blog in particular, I’m way ahead of where I would have been with this advice I was getting on the range. Could it be that in former times, gun knowledge was passed along in a haphazard oral tradition by these dubious characters? But maybe I’ll have fun the next time, and when someone asks me where I learned to shoot, I will say Naval Special Warfare.

Matt61

Matt

I remember making fun of your trips through the airport, but not your trips to the range. Perhaps as I get older, I forget stuff. However, as long as we are on the subject…

In my eyes your trip seemed a bit ambitious. 2 rifles, 3 pistols, and 2 bows? I would need a Sherpa to lug all that equipment. Shooting fatigue is one factor, compounded by too many shooting disciplines. There is only so much we can concentrate on at once.

And a staple gun? I don’t know what kind of groups you expected to get with that.

As far as the rangemaster is concerned, my response to the sarcastic question of where I learned to shoot semiauto would be a dead serious, “that information is classified.”

The way I see it, if Santa with the clown suit wanted to impart sound advice, he would have done it before junior got his nose out of joint, instead of piling on afterward. His inferior groups and meaningless talk of “sociability” tell you everything you need to know. Ranges are for concentration and shooting, BARS are for sociability, and beer, and should be visited in that order. Also, Santa’s advice is in complete contradiction to BBs advice about shooting pistols. I know who I believe.

Matt61,

It was Karen Monez (formerly from San Leandro CA) who cleaned the offhand position. She later married John Chapman of Texas. Karen is very petite, standing no taller than 5’2″. I know that she won the CA four position state championship 3 times with a score of 797 out of 800, cleaning standing at least a couple times. I heard that she won that same match at least one other time with similar scores.

Regarding your Mosin and the pain of the recoil. You might want to see if there’s a good recoil pad for it. Also, it helps if your scope rings are as low as possible, and that the scope is brought back as far as possible. That will allow you to hold it more comfortably and better (more square with your shoulder). If your scope isn’t mounted optimally, your forced to shoulder it at an angle, which can increase the felt recoil.

As for as optimal design for cross-hairs, it depends on the application. For target shooting, fine cross-hairs are preferred, but some prefer a small dot and no cross-hairs. Thick cross-hairs would prevent you from seeing the bull well enough to center them perfectly.

I can’t say why your first shots were hitting low with your .45, but since you say that you failed to follow-through in the beginning, that could be the reason. A common symptom of not following-through is that you drop the pistol a fraction of a second before completing the shot. Don’t let the recoil stop you from following through. In fact, try to fix your eyes and wait for the pistol to come to rest to see if everything is still lined up.

Stan Hulstrom taught that the thumb should be relaxed along the side, without exerting any pressure against it. Gripping is done with the base of the hand (between the thumb and index finger) and the three lower fingers of the hand such that pressure concentrated at the top two fingers (middle and ring), and that the pressure of the grip is applied directly to the rear. The little finger acts as a wedge to hold the ring and index fingers in place. Regarding the advice given to you about using “the last two fingers of your shooting hand” for controlling muzzle flip, the guy is right, but the advice is bad. If the little finger (the last of the last two fingers) is allowed to apply too much pressure, then you will pull your shots below the point of aim when the hammer falls.

I’m not sure what the guy meant by “offhand”? Where you shooting with two hands, or one hand?

Victor

Matt,

Edith and I shoot many rounds of .45 per session and we both have the initial round break-in you describe. I probably shoot several thousand large-caliber handgun rounds each year and I am not comfortable with the muzzle blast or recoil yet. I think for most people it never happens.

As far as the thumb rest goes, it’s only the world champions and those who emulate them that use it — not the riffraff. And, as you have discovered, there are far more riffraff than quality shooters.

B.B.

TT

Moved down here. Was getting thin above.

I’m going to start here saying (Scope).

It was a long week. Had all kinds of stuff going on this week. And I was looking forward to shooting this Sunday.

Got out to shoot about 11:00 am. Beautiful sunny blue sky day. Wind was calm at 2 to 4 mph. And the hill and tree line that I was shooting towards blocked any wind that would come my way.

It did turn out to be a great day.

Totally had something happen that you and BB discussed.

As I said above (scope). The more the sun shined and things heated up the more the POI changed.

I thought maybe it was because of the fill level heating the air reservoir and causing partial valve lock.

Took the guns in around 12:45 and ate lunch. Checked the fill level and they were down about 400 psi. Topped them off. Shot good for about 20 minutes then the guns started changing on the POI.

Checked the fill level and they were down about 250 psi more.

I was shooting two guns and both scopes were pretty warm to the touch. Took them inside for about an hour in the A/C came back out and shot with the same fill(not filling the guns anymore) and the guns were right on the POI.

They warmed up and POI started changing again.

Went in and ate supper. Filled the guns.The sun was going down and we shot in the shade and the guns were dead on till I stopped shooting.

So yes. The heat and sun changes things. And I believe it affects the scope the most. I’m going to try to cover my scope the next time I shoot in the sun.

I remember my Dad saying something about that was part of the reason why they covered their scopes. Not only for camouflage but also for the heat.

GF1

I am glad you saw this and how it’s happening. Not because it posed a problem for you, but because you got to see it and understand that this is going to happen under these conditions.

It is also good that you checked your operating pressure. That tells you if it is at least part of the problem or not.

The more attention you pay to what your rifle thinks about things, the better you can understand it. It can take quite a while to run down a long list of tests because you have to wait until you have a day when conditions are right. Any time you notice something unusual, look at the prevailing conditions at the time. Everything happens for a reason. Much of the time we have no control over it, but we do need to be aware of it and learn to expect it.

There is another thing I need to look at on the right day with my T200. It could be something I need to watch my Talons for…

So far, all three PCPs need to be shot once if they have been filled or have set overnight . But what if there is a temperature change from the time they were shot ? Let’s look at a typical fall squirrel hunting situation…..

Fill up the gun the night before. Get up, fire the gun (with pellet) and hit the woods. It’s in the 50s out there. Gun cools off. Later in the morning it will hit the low 80s. Maybe it was a slow morning and I don’t get many shots as the day warms up. All this temperature changing with very little shooting might tempt the valve to start pulling some bad tricks on me. See where this is going ? I don’t want any surprises. And I want to see if this is going to happen or not. Then I could also throw in what the scope may be doing too.

So many things to look at.

twotalon

twotalon

GF1

An extra for you…

I just checked the temperature of the top of my wife’s car (dark blue). 108 degrees in light breeze at 9:30 in the morning (sun is still fairly low). This might give you a clue as to why I am interested in finding out some things .

It measured 180 degrees a few days ago in early afternoon, by the way.

twotalon

GF1..

And another extra..

Went out a little while ago and came up with this….

Temp low 70s when started. Reached high 70s when done. Start time 10:40, stop 11:10….one half hour.

Milky sun, intermittent thin high clouds. Set up in an area pretty well protected from the breeze. T200 set up in a gun vise on my shooting bench, and broadside to the morning sun.

Scope is matte black, air tube flat black, barrel is white (no finish).

Original temp all parts 70 degrees from indoors.

Ending temp….

Air tube 98.5

Scope 92

Receiver 92

Barrel 85

At a few times I checked some temps to see what was happening. The air tube and scope were generally about 1/2 degree cooler on the shade side as opposed to the sunny side.

So I saw what I expected to see , but without knowing the specifics. I would expect to see some differences under different conditions.

So I have uneven heating in the sun. How much effect this would have if I were shooting is any ones guess, but I would expect to see SOMETHING.

twotalon

TT

I believe you mentioned it above.

I try to take one shot before I go into the woods to hunt to get a idea where the gun is shooting at. But I don’t always get to do that at home when I’m doing pest control. Sometimes I have to make the shot count the first time because I wont get another.

But yes so many variables it ain’t funny.

GF1

Yeah, that one shot…

Just learn what your rifle is going to do with it, but see if it does the same thing consistently. Seems like PCP guns need the valve to be bounced once in a while under different conditions.

twotalon

TT

I agree.