Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

Part 7

This report covers:

- Why Monday and not last Friday?

- Sad thing

- Trigger is simple

- Take pictures!

- Inletting is tight!

- The metal piece

- Stake those pins

- Test it

- Fixed

- Why no instructions in the manual?

- Proof of the pudding…

- JSB Exact Jumbo Heavy

- Summary

Well, the Dragonfly Mark 2 trigger is fixed. I have a lot to tell you about today, so let’s get started.

Why Monday and not last Friday?

Why did I wait until today to tell you about it? Well, experience, mostly. You see if I tear into an airgun and discover that I can’t finish it in time to write the report, I have wasted all that time and still have to do something I can write about. I had no idea what was wrong with this trigger and I didn’t want to find out after it was too late. So I schedule things like this for a time when I have a couple days, in case the worst happens. If my Saturday is open then Friday is a great time for something like this.

As things turned out the worst did not happen, but I still spent a lot more time on this trigger fix than I wanted to. I’m going to warn you now — this is not a trigger to take apart, or even an airgun to take out of the stock.

Sad thing

Now the sad thing is — the guys who really shouldn’t take this rifle apart are the same ones who don’t listen. They will tear into it and then whine and cry when they discover that they can’t get it back together. The guys who know their limits will never attempt something like this — especially when I warn them.

Trigger is simple

Ironically, taking the rifle out of the stock and working on the trigger of the Dragonfly Mark 2 is not difficult. It’s really simple, but it’s also confusing. This action is not held in the stock in a conventional way. In fact, Tyler Patner tells me that this is the same trigger as is found in the Gen 1 Stormrider, which means the disassembly is probably also the same. I will show you the steps I took and what I found. But that doesn’t mean you should do it.

What I’m saying is if your Dragonfly Mark 2 trigger is working, leave the action in the stock. And of course the guys who won’t listen are the same ones who will get in trouble.

Take pictures!

Taking pictures as you disassemble the rifle is something that’s been preached for years, but on this job it really saved the day! Let’s go.

The first picture looks simple, but in the end it saved the day. The stock screws have heads that are shaped differently and that helped me get them back into the right holes during assembly. It seems simple but it really did help.

The rear buttstock is held on by these two screws.

Inletting is tight!

The stock is really inlet well. But the triggerguard came out with one screw and That exposed the trigger mechanism. When the other one came out the stock could be separated from the action.

This is another picture that saved the day. It shows how a small steel piece you are going to see attaches to the rifle. And once more, the shape of the screw head was important.

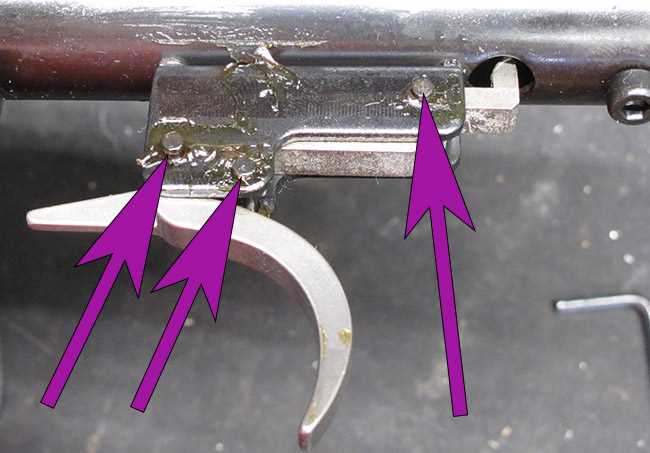

Here is a telling picture. Those three pins (arrows) were all loose in their holes.

I found that all three trigger pins were loose in their holes. One of them was actually not in the right side of the trigger box.

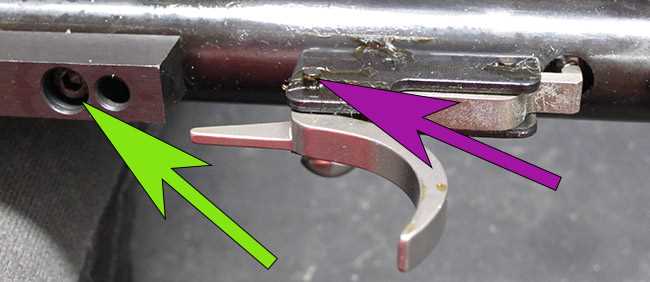

The pin on which the trigger turns (purple arrow) was out on the left side. This is another picture that saved the day. See the screw inside the metal piece (yellow arrow). That was the key to assembling the rifle.

Looking at the other side of the trigger box we see that the trigger pin isn’t even in its hole. And look — the other two pins are sitting loose in their holes, too.

The metal piece

Okay, here is the reason why I say the Dragonfly Mark 2 is not straightforward, as far as disassembly goes. The buttstock is held onto the action by a small metal piece that’s attached to the receiver with a single screw. Look at the trigger that’s exposed but still inside the stock (the second new pic) and you can see the back half of this piece at the front of the trigger guard slot. And there is that pesky screw that holds this piece to the action — at the front of the trigger guard slot.

To remove the buttstock at this point, unscrew the single screw that attaches the buttstock to the rifle. It’s the rounded-head Allen screw in the first new picture — the one on the left.

Now that is straightforward, but what you then realize is that screw does not attach to the receiver or the air tube . It attaches to that small metal piece I have been talking about. Here — let’s look.

There is the metal piece that the smaller screw on the left attaches to the pump tube. This piece receives the stock screw in the threaded hole on the right. When it’s attached to the rifle that threaded hole it in front and the other two holes are at the rear.

Stake those pins

At this point in the process I thought I had found the problem — those three loose trigger pins. So I staked them on both sides. Staking refers to displacing metal with a sharp prick punch. It moves the metal slightly and, if done close to a pin hole, the hole becomes smaller. I did it at a minimum of three places around each pin hole on both sides of the trigger box. Three pins means six holes to stake, so 18 stake punches in all. I had to re-stake a couple times on some holes because I hit the stake pin too lightly. Let’s look.

I staked all three trigger pins on both sides of the trigger box. I hit the stake punch more times than three on some of the holes.

Test it

The result of staking was the pins were in the holes tight. They required a pin punch to come out, which is the way it should be.

With the stock off I could still cock the hammer, pump the rifle and test the trigger. So I did. Nothing! I was exasperated so I called Tyler Patner of Pyramyd AIR and asked him what the problem could be. He wasn’t sure but asked me to send him all the pictures I had taken, and I said I would. I started to go back to my office to do that and then I thought of one thing I hadn’t done yet. I pulled the trigger and watched it move the front of the sear up, which causes the rear to go down and release the hammer. The sear was moving but not far enough to release the hammer. So I took a pin punch and pushed on the front of it a little more and the rifle fired. I did it again. And again.

Then I called Tyler back and told him what I had done. He asked me to film it and I did.

Then he called me back and said he thought he knew what the problem was. He said there is a tiny screw in the short leg on the base of the trigger that presses up (or down, depending on how the action is oriented) on the sear. That screw might need to come out just a little to push the sear up (or down) a little farther. To get to that screw the trigger blade has to come out of the trigger box assembly. I had him wait while I pushed out the pin and removed the blade. I could see the screw he mentioned. It is wee-teeny — a 0.050-inch Allen screw.

I found a wrench and adjusted the screw out about a turn and one-half. The I applied blue thread blocker to the screw and threads of the hole so it would stay where I put it.

The sear engagement trigger adjustment screw is very small (a 0.050-inch). This is after I turned it out. It was almost flush before.

Fixed

At this point I thought the problem was fixed, so I assembled the rifle to test it.

Don’t forget that metal piece that’s the key to assembling the stock to the pump tube.

The trigger now fired the rifle every time. So I assembled the buttstock and checked it many times. It worked every time. However, what I now have is a long single-stage trigger pull with no definite stop point. I will have to get used to the trigger again.

Why no instructions in the manual?

I hope today’s report explains why Air Venturi doesn’t want people taking the rifle apart to adjust the trigger. Yes, it is adjustable but it’s not a job that many people will be able to do without making mistakes. The Dragonfly Mark 2 does come apart rather simply, but you have to know what you are doing. If my words have helped, then perhaps you can do it. But if it seems daunting, leave it alone unless absolutely necessary. Taking the rifle apart like this may void your warrantee.

Proof of the pudding…

… is in the eating. Does the Dragonfly still shoot well after this work? Only one way to find out.

JSB Exact Jumbo Heavy

I shot the rifle from 10 meters with the most accurate pellet — the JSB Exact Jumbo Heavy. This isn’t an accuracy test, per se. It’s a test to see if the way the trigger now functions allows me to still be accurate. And it’s a test to see if disassembling from the buttstock has shifted the point of impact.

I shot 5 shots off a sandbag rest at 10 meters. I pumped the rifle 4 times for each shot. The rifle did need to be sighted in again. The first round hit 2-1/2-inches to the left and 2-1/4-inches low. I played with the dot sight to bring the pellets back close to the center of the bull. Then I was ready to shoot for record.

I put five shots into 0.353-inches at 10 meters. Not my best, for sure, but I had 20 ounces of coffee while writing the first part of this report before shooting. I’m the first to argue that caffeine doesn’t disrupt my nerves, but I would never drink it before a match. So I was off my game a little today and the Dragonfly Mark 2 works fine.

Five JSB Exact Jumbo Heavy pellets made a 0.353-inch group at 10 meters.

Summary

The Dragonfly Mark 2 is back on track and we are headed for the first 25-yard accuracy test next.

B.B.

Sounds like the Dragonfly is a “Humpty Dumpty gun”! lol.

Glad you got it back together, now adjust the trigger properly.

-Y

PS sounds like a great way for PA to go bankrupt, having to fix all those broke triggers. Any explanation as to why it broke in the first place?

Yogi,

Those three pins slid out on one side. This air rifle relies on how closely the stock fits around the trigger assembly to hold the pins in. There is a good chance that any Dragonfly/Stormrider/Chaser could have this exact issue. That is one of the reasons Tyler wanted the pictures/video. Now the PA techs will be aware of how this issue can be fixed quickly.

Did everyone just glance over the fact that staking the pins DID NOT fix the issue? The issue was the sear engagement screw in the trigger blade.

We’ve sold a great many Gen1 Stormriders and original Dragonfly’s, and I can’t recall the pin movement ever being an issue I heard about from our customer support or tech teams. Maybe an issue after a customer took the action out of the stock and couldn’t figure out how to get it back together, but the stock does a good job of keeping the pins where they need to be.

“The issue was the sear engagement screw in the trigger blade….the stock does a good job of keeping the pins where they need to be.”

Tyler,

Thank you for weighing in on this; I’ve had my Dragonfly Mark 2 on order for awhile now, and I’m keeping it that way…can’t wait to get a hold of her and try her out. Using the pics B.B. took here, adjusting the sear engagement screw looks pretty straightforward; I’ve got my teeny Allen wrench and Blue Loctite, if needed; can’t wait till May…yay! Thanks again. 🙂

Take care,

dave

Happy to. For what it’s worth, haven’t had this issue with any of the other Mk2’s that have been sent out to folks. And the one we used for our video review has a lot of shots through it and pumps on it with zero issues. Not sure when exactly you’ll see the review, but I was quite surprised and pleased with the results.

Tyler

I mentioned to BB in a previous report that it sounded like a spring bent or broke that holds the sear up.

Now after your info it sounds like that screw moved out of adjustment.

It either moved or as BB says below, may have had a burr on it that broke off. Obviously it’s too late for us to know which one. But I’m glad BB is back up and running.

Tyler

I bet if there was a picture of the sear we could tell if there was a burr or not by some kind of wear marks.

Anyway as I said it was sear related.

GF1,

No, you can’t. I looked and the sear had no marks on it at that spot. No doubt the sear is case-hardened and doesn’t wear.

The adjustment screw was shiny on one edge and that was the only clue I had as to how this might have happened.

BB

I was just given one of these with the bolt frozen stuck. Could this be the issue?

Sanitarian,

It could be. You might call Pyramyd AIR Monday and ask the tech support guys.

BB

I have a message into them now. Thank you!

Got it! The mag was boogered up and had a pellet lodged in the chamber, plus it had two pellets in the barrel.

Disassembled the rifle and extracted everything, now it shoots great. Just need a feed ramp and mag.

Sanitarian,,

Oh. I never use a magazine with any air rifle that I want to be accurate. I didn’t even think of that.

BB

Tyler,

One of improvements of the Gen 2 Stormrider is they “have the new DIT (Diana Improved Trigger) 2-stage adjustable trigger.”

Will a Gen. 2 version of the Dragonfly MK 2 have the DIT trigger? Come to think of it, why doe it not have the DIT trigger right out of the gate? Can a DIT trigger be retro-fitted onto a Dragonfly?

The loose pins issue can be remedied simply by sending the Dragonfly MK 2 back to Pyramyd AIR for warranty work, but the long single stage pull with the indistinct break will be a problem for many shooters. I’m inclined to wait for a Gen. 2. (I’ve already waited eight or so years, so . . .)

Thanks for your attention to this problem. That is excellent CS.

Michael

The DIT trigger was developed (and owned if my understanding is correct) by Diana, so unless something between Diana and SPA has changed, I do not anticipate that trigger design being available for non-Diana product.

One thing to keep in mind, the sear engagement screw is adjustable (as we have seen here), so it’s certainly possible for BB to adjust it again to alter the feel. Whether he chooses to do so, is up to him. I will say that it’s not advertised for a reason, since it requires minor disassembly. I can tell you that from the many I’ve shot thus far, that I can distinguish between the take up and “wall” quite well. But some are more distinct than others. Granted, when you’re used to shooting 4 oz match triggers, that’s not hard to do on a 3-4 lbs trigger. It’s a solid hunting trigger and does a pretty good job for target work as well.

Tyler,

The blog above describes disassembly of this trigger as being anything but “minor.” Personally, I am all thumbs when it comes to air guns (which is why I try to buy only air guns that are likely to be trouble-free). Furthermore, opening up a Dragonfly MK 2 to improve the trigger would probably void the warranty, and this is one air gun that very well might require warranty attention.

Too bad about the branding vs. manufacturing impediment to upgrading the dragonfly like Diana had Snow Peak implement with their DIT refinement. Perhaps Air Venturi could license it from Diana.

As for trigger experience, I am a mediocre shot, but I enjoy shooting nevertheless. I do have experience with one fine Olympic 10 meter trigger, the one in my Feinwerbau 601. The triggers in my Feinwerkbau 124, 150, 300s, Air Arms TX200, and Weihrauch HW30s are not slouches, either. My feel for triggers is not one of the (many) shortcomings in my shooting technique. That, at least, I have degree of sophistication with.

If I re-order, it will be after I have spent an hour or so reacquainting myself with some of my air guns with so-so triggers. Perhaps I can compensate more for that than I give myself credit for.

Thanks again for being up on this.

Michael

Tyler,

I caught that. Had the same issue with the screw on my stormrider and did the little adjustment on the screw and the trigger worked reliably afterwards. All my pins were in place so they didn’t cause me to go down a false path first.

Half

No, most of us actually pay real close attention. The thing is that the problem suddenly started and then it would not function. Maybe one of the pins had slipped loose, but it was still working until another or two came loose. Once it was properly assembled, it no longer functioned. Then the screw needed to be adjusted.

This is not the first airgun I have encountered where the stock was used to hold pins in place. Most of the time it is not an issue, but sometimes there may be enough slack that a pin can come loose on one end. It will not be something that you will likely encounter often, but how many of those stocks are made and how many do you think that Chinese company is going to reject because some minor tolerance is off?

Personally, I would peen those pins in and likely slide some type of shim material into the stock as I would have it in and out for a bit until I adjusted that trigger juuuuuust right.

B.B.,

In: The Metal Piece

“There is the metal piece that the smaller screw on the left attaches to the pump tube. This piece receives the stock screw in the threaded hole on the right. When it’s attached to the rifle that threaded hole (delete it) (replace with IS)

in front and the other two holes are at the rear.” Makes more sense to me.

shootski

PS: I can see NO way that this is a TWO stage trigger given what trigger parts I have seen in your excellent photographs; there would need to be some magically possessed Sear to do it.

ALSO, the PA Specifications call the trigger: Single Stage.

Shootski,

If you look in picture two, three and four, you can clearly see the sear. In picture two, the arrow on the right points to the sear pin. This is a two-stage trigger. Not the greatest, but…

RidgeRunner,

You and B.B. (in his early reports on this trigger) may in fact be correct that it is two stage. I can only ask why would a seller not have it correct in their specifications?

I will wait for more information and your observations once you get your example of the DragonFLY Mk2; for the time being the “FLY” in the ointment for my potential purchase decision will be the Dragon’s Trigger Group.

shootski

P.S.: I can’t see the trigger sear contact point

Shootski

You mean manufacturer.

It is the allen screw. In the photos it is concealed.

Just so you know, unless someone gives me a Stormrider/Dragonfly/Chaser, I am not likely to ever worry about this thing again.

I am sure you have been around long enough and read enough manuals in your time that you have discovered things written in those manuals that are just not so.

Those in our documentation department have no experience with the mechanical or electrical design or the knowledge of how to operate our equipment to manufacture polymers, but they write our manuals.

RidgeRunner,

I get what you mean but PA usually have at least one or two people around that know a muzzle end from a chamber end…or is that pot!

What company is that? I don’t want any of their polymers!

shootski

B.B.,

Thank you for including so many pictures and explanations; I hope I don’t have to remove my Dragonfly Mark 2 from her stock…and I won’t unless I absolutely have to…yet, should that be the case, this report will be invaluable for ensuring the correct disassembly and reassembly; thanks again! 🙂

Take care & God bless,

dave

P.S. “It is wee-teeny — a 0.050-inch Allen screw.” I actually have a wrench to fit that screw…but I truly hope not to need it.

Dave,

I do also, and it always scares me when I have to use it.

Yep! LOL 🙂

Dave,

Whenever you finally do get yours, you may be able to slide some plastic sheet/shim material between the sides and the trigger mechanism just by removing the trigger guard and ensure the pins do not slip out.

B.B.,

As I recall, you have some degree of colour-blindness. For the caption “See the screw inside the metal piece (yellow arrow). “, that arrow is actually far more green than yellow.

I’m not sure what tools you have to visual the differences, but for reference, that arrow’s RGB (Red/Green/Blue) values are 134/230/19, giving a colour hex code of #86E613

Yellow colours would have equal or near-equal Red and Green values.

Regards,

Nathan

Nathan,

Now that you mention it I do see some green in the arrow. Wow!

BB

BB after all that work this group is “bigger” then in part 7 with the “bad” trigger

Rob,

Yes, and I addressed the probable reason for that in the report.

I just read the blog about air canes. I am grateful my great grandmother did not have one of those. I was a very bad little girl.

“I was a very bad little girl.”

Alex2no, thanks for my laugh of the day; and thanks for the reminder that we have women reading this blog, too…which is way cool, of course. 🙂

Alex2no ,

I’m right there with thedavemyster in thanking you for my laugh of the day. It wasn’t just us boys, then? 😉

BB

Now, I myself would have to go back in and adjust that allen screw back in just a wee bit. I do like a two-stage. Then again, I might bring the screw out a bit more to make it a real nice single stage. Since you will likely send this one back, I would adjust it in just a wee bit more.

Good morning, B.B. Hope all is well with Siraniko, he would ordinarily be your proofreader, but if I may respectfully point out:

In Why Monday and not last Friday?:

“Why did I wait until today to tell you about it until today?” Delete one of the “until today’s.

Later, when you took the stock off you say: “I found that all three trigger pins were loose in their holes. One of them was actually not in the right side of the trigger box.” But in the caption in the picture with the two arrows, you say “The pin on which the trigger turns (purple arrow) was out on the left [right] side.”

In Why no instructions in the manual?

“Warrantee [warranty]”

Hope all is well, and looking forward to the 25 yard test. I’m glad to see innovations to multi-pumps coming to market, and I’m interested to see how your rifle breaks in compared to your first impressions…especially of the trigger feel.

Roamin,

Good catch on the first sentence. It took me some time to see that one even when I knew what to look for.

The trigger pin caption is correct. The pin was out of its hole on the right side And sticking out of its hole on the left.

And warrantee is a second correct spelling.

Thanks for the first one.

BB

B.B., I made the same exact error, warrantee, in my comment. Note to self: Don’t write without having finished the morning coffee. ;^) Michael

Always learning something new here, whether it relates to airguns, model airplanes, motorcycles, or grammar. I always understood warranty as a promise, either of the quality of a product or the title to property or that certain conditions to a contract will be fulfilled, and warrantee is the person to whom a warranty is made.

Anyway, all suggestions are made for the good of the order and with no pride of authorship. Back to airguns!

B.B.,

“The guys who really shouldn’t take this rifle apart are the same ones who don’t listen.” You are correct, of course, but in so many respects I am atypical. I am the single least-handy person I have ever known in my entire life. It is indeed possible I am the least mechanical human being who has ever walked the Earth. I have attempted to repair simple issues on simple air guns. None of the five air guns I opened up survived my working on them. All sit forever in pieces in various parts of my home. I was not even able to install a well-reviewed trigger upgrade kit in a new Crosman 1377. It sits, forever disassembled, somewhere in my basement. Therefore, I am the very last person on Earth who should do any work whatsoever on any air gun, ever, let alone this Seneca Dragonfly Mark 2. I am listening to you.

And therefore, I just now canceled my pre-order for two Dragonfly Mark 2s (one in each caliber).

These, apparently all of them, are trigger failures waiting to happen. The air rifle has a fatal design and manufacturing flaw. What should a buyer of one of these do? Ask Pyramyd AIR to repair it before they even ship it? Have Pyramyd AIR send it to Air Venturi for warranty work before shipping it to the buyer? Shoot expanding foam into the trigger outlet and hope for the best?

Years ago I was deeply disappointed when Crosman teased us with this rifle by secretly discontinuing it many months before even manufacturing it. Then years later I was again disappointed when Covid delayed the air rifle’s release by more than a year. Now I am disappointed yet a third time by the Seneca Dragonfly Mark 2 being a piece of junk.

In November I bought an air gun for the first time in about two years, a $50 Ruger Mark IV. That will end up being the last new air gun I ever purchase. I’m done with any air gun made in the 21st Century. Air gun manufacturers simply no longer know how to make quality air guns. Worse yet, they knowingly sell air guns with trigger mechanisms that are held together with spit and chewing gum.

I apologize to Air Venturi in advance if they pause delivery of these and retro-fit them with an adequate trigger and pay for early purchasers to send their air rifles back for a free repair.

If a Mark 3 comes out with a decent trigger, I will consider purchasing one, used.

Michael

Actually, factoring in an extra $39.99 for Pyramyd Air’s 2-Year Service Contract might make it worth it. I might get one (just one) of these if the trigger issue would be covered. “Covered mechanical or electrical failures due to defects in materials and workmanship.” This would qualify, right?

Michael,

Hear you and understand your frustration. Manufacturers should not release product that is poorly designed and prone to failure. But then that is what warranties are for eh? Customer does final inspection.

To be fair to manufacturers, I understand that they have to build the product to meet the budget constraints. In lower priced goods costs of materials, machining/assembly and inspection have to be minimized. The higher the sticker price the more margin is available for “quality”.

Being mechanically inclined, I enjoy taking a budget product and adding the quality (better hardware, improve tolerances, polished parts etc) changing a sows’ ear into a silk purse if you will. It’s a project to see what improvements can be gained even if the end result is somewhat sub par.

If you’re not into tweaking then you have done the best thing by researching and not supporting products that don’t meet your needs/expectations and (hopefully) the manufacturers will notice and take corrective steps in the future.

That being said, for my serious purchases I do a lot of research and buy the the best quality I can afford. Maybe, instead of black-listing everything made in this century you might want to look at different manufacturers.

Sorry that you had to cancel your airgun order Michael. I’m not preaching, I’m just trying to offer a few thoughts.

Hank

Hank,

I am quite good at tinkering with guitars, but that is all.

I’ve forgotten how to do the two things I used to be able to do with cars (changing sparkplugs and doing an oil change), and I am the worst carpenter of anyone I know. I know absolutely nothing about carpentry tools or techniques. I don’t know how to build anything with lumber. I cannot hammer a nail straight, drill a hole straight or saw a straight line. That has always been the case, but it’s worse now that I’m blind in one eye and have no depth perception.

I learned none of those things a father typically teaches a son because as a boy every single time I was my dad’s “helper” he would end up yelling at me for doing things incorrectly until I cowered (he looked just like George “The Animal Steele,” see below) and went to my room. I had no uncles close by and no siblings, so that was that.

But hey, I can write checks to pay other people to do stuff for me, and that is good enough. :^)

Michael

Before reading your comment, Michael, I was thinking that this review would keep me from ordering the gun, no matter how well it shot. And in a more circumspect criticism, why are trigger mechanisms not any better in these Chinese built designs? They seem to be able (lately) to make a good rifled barrel (major effort)…I knew Bob Werner (Charliedatuna), who made a small fortune with his GRT retrofit triggers for Gamo springers. It would seem that some gunsmith with CAD skill could redesign this (and others) to make it far better, and that is a common design weakness with all the price point rifles. In this case, a severe one, and not one I would be willing to trust to some tape and a few hours of frustrating fiddling. Tyler, hope you are on this.

JerryC,

The trigger upgrade kit that I lacked the skill to install in my practically new Crosman 1377 was a Charlie da Tuna model. I took the trigger panel off, the trigger blade out, and that was all she wrote. No matter how many online diagrams and instructional videos I consulted, once I took the factory trigger out, I was unable to install the Charlie da Tuna one or even put the factory one back in place. I couldn’t get the springs into place so that they would not jump out, much less do anything else. I remember toiling over it for HOURS. Then I gave up, threw the Crosman 1377 and the Charlie da Tuna into a cardboard box, and placed it on a shelf alongside all the other air guns I unsuccesssfully worked on (killed, actually). I am the Undisputed Heavyweight Champion of air gun executioners, LOL.

But I do now know my limitations, one has to grant me that much. :^)

Michael

Michael,

Okay — I grant you the title of clumsiest creature with opposable thumbs in the mechanical department, but you have NOTHING on BB Pelletier when it comes to butchering wood! BB is hands-down the enemy of any product of a cellulose base.

BB

Michael, I can sympathize. Most of my own efforts at airgun tuning have been unsuccessful. Thanks for the laugh, though!

Michael

How about send that 1377 to me. I think I can make it live again. 🙂

Gunfun1,

This is sad, but I hold onto my failures to remind me of my ineptness. It spares me from making future attempts. Every now and then I pass by that shelving unit and see boxes of dead air guns and that reminds me not to try repairing any again. One needs to make friends with his limitations.

My motto is, “If I don’t try, I can’t fail!” :^) Tenacity is overrated.

Michael

Gunfun1,

Now that I think of it, right next to the box (casket, in a way) with my 1377 is another box with a Crosman C11 I bought new. It was one with the deluxe extended barrel hidden in a fake silencer. The day it arrived I decided to see if I could lighten the trigger just a little. I believe I had just one magazine — 20 shots — through it when I opened it up. All hell broke loose with springs flying out and parts slipping onto the table. I looked at it for 10 minutes and could make no visual sense of it. I packed it up and put it on my shelf of failure.

I decided that I would buy another, but that was right at the time those with the longer barrel were discontinued, so I couldn’t buy another one when I went online and looked.

The painful lessons are those we learn the most from. :^(

Michael

Michael

Sad

Don’t let your air guns die like that. They need to be recognized and live. 🙁

Michael,

Are you saying you don’t like your Mark IV?

Half

Half,

It is non-functional now, but even when it was new, I’d bet it was junk. Poor materials, poor workmanship, poor period. It’s nothing like my Mercury, which is very nice. I think BSA might have just been going through the motions when the later Meteors were made. I’m not even sure the barrel is steel. I haven’t put a magnet to it, but where the paint (paint, no bluing) is chipped, it looks like pot metal to me.

I’d love a Cadet Major, but this is sad.

Michael

Michael,

Did you not like the Mark IV/

Half

Michael,

I was asking about the Ruger Mark IV by Umarex. You said it would be your last gun. Is that because you don’t like it?

Half

Half,

I like it, although the trigger is very stiff. I need to shoot it more often. I hope that the trigger will wear in some. I have the Browning Buck Mark, and the two are very similar inside, I suspect. The Browning wore in to the point where the trigger was OK. The Ruger points well and feels very good in the hand. And of course it looks cool! They are both a lot of fun for no-hassle backyard plinking.

Michael

Michael,

I have a Buckmark and just bought a Mark IV and you are correct, they are nearly identical inside. I agree about the trigger on the Ruger, but, I’m sorry to say, it will never “wear in” to the lighter trigger pull of the Browning. That’s because an additional “safety feature” was incorporated into the Ruger. In the trigger group of the Ruger there is a part that blocks the sear from moving once the gun is cocked, unless the trigger is actually pulled. If you drop the gun while it’s cocked, the sear can’t disengage from the spring piston to release it. I guess it will prevent anyone from being able to sue Umarex if they throw the gun down on the concrete as hard as they can so they can trade an eye for a huge cash settlement. That additional part is held in position by a spring and has to be shoved sideways, out of the way, via a ramp/cam arrangement. That adds a lot to the trigger pull. That part can be removed with a partial tear down (I know you aren’t mechanical, but I have faith in you) and your trigger will then be like the Browning’s. The odd thing is that the Buckmark has an identical trigger group that will accept that extra part and its spring, but Umarex chose not to use it in the Buckmark, just the Mark IV. Maybe part of the license agreement with Ruger, who after all, invented the transfer bar safety for their single action revolvers to add the same sort of protection if the gun is dropped with the hammer resting on a loaded chamber.

I found this info on a small YT channel called “Walnut And Steel”. He has 4 videos addressing the trigger and they are worth watching. They involve stoning some surfaces and changing springs and they do result in a nice trigger, but If you just want to do minimal work and you just want to get a trigger equal to the Buckmark’s, this is the video that addresses that. He discovered it at the end of his journey, but I made it the first alteration to my Mark IV, so I know that it alone will make a big difference. Here’s the link for that video and you can decide if you want to watch his others on this trigger job. They will all have “Ruger Mark 4” at the beginning of their titles. He doesn’t have a huge amount of videos, but a large portion of the ones he films are about airguns. He’s a tinkerer.

https://www.youtube.com/watch?v=pLTKoqRk9vQ&t=543s

Half

Half,

That channel is gold! Thanks very much,

Michael

The trigger component pins in all the similar Snow Peak platform airguns (CP1/2/PR900 etc) are all loose and rely on the stock to keep them in place. Easily remedied by a piece of tape on either side if you don’t want to go to the trouble of staking.

Ade C,

Would it be necessary to disassemble it to apply the tape? Is there grease that might impede the tape’s adhering to the sides?

I would be nice if Air Venturi applied the tape before shipping these.

Michael

You’d only need to remove the action from the stock to apply the tape. Just wipe off any grease residue from the sides of the trigger housing in the third of bb’s pictures

Ade C,

Thanks for that. I might be able to handle removing the action from the stock. Given my batting average of zero, I have doubts.

So the trigger housing would then be held together with “spit and chewing gum” and tape. ;^)

Michael

Michael,

I’m not trying to encourage you do do so, but I believe you can work on this one. Today’s description should help, and I will be here for you, if need be.

Please tell Mrs. Michael that I am not enabling you on this one. I just think this is within your capability.

If you do decide to get a Dragonfly Mark 2 and then discover you need to adjust the trigger (lotsa suppositions there) I will talk you through it here in the blog.

BB

Hey everybody,

Tyler is reading the comments and wonders why nobody has tripped to the fact that staking the loose trigger pins did nothing for the issue. Now I did see that Ridgerunner got it, but nobody else mentioned it. The pins are held captive by the stock. Staking them did nothing for the trigger. It was all on that adjustment screw.

BB

Tom, it is beyond my expectation that the trigger adjustment screw could be so far out that the trigger would not reliably move the sear. I had indeed thought the pins were loose enough to change all the mechanical clearances. And, if it is this difficult for a user to change the adjustment, why even design-in a screw for that? It is just a potential element of failure. So, glad to hear that Tyler is on this. But still, wary that this could frustrate anyone who bought the gun today. Hopefully, the trigger can be improved by the factory to bring it up to the quality level of the gun quickly.

Jerry,

“So far out?” That adjustment screw was probably 2 or 3 one-hundredths of an inch out of adjustment. And what I didn’t tell you guys is I found a bright spot on the edge of the screw, where it had worn.

So this is how it happened. The factory had an adjustment screw with a tiny burr on one side and when they adjusted the rifle the trigger worked. Then, over the course of around 100 shots in my testing, I wore that burr off and the problem started. I did say the problem started intermittently.

This is stuff that happens. I showed you guys what I did to correct it and my correction worked. It is similar to retying the shoelaces for a 4-year-old, if they even do that anymore.

BB

B.B.,

Stuff does happen, you are right. Do you have reason to expect those which will fail to do so during the first couple hundred shots? If so, folks who buy one should be sure to purchase the $39.99 extended warranty from Pyramyd AIR. I know I am better at boxing up an air gun than I am at working on one! :^)

Michael

Your detailed explanation is valuable and interesting. Yes, getting past 70 may have me in 4 year old class, but I can still tie my shoes, and I know clearances on trigger elements in the 0.020″ range can make a huge difference. Michael and I are not willing to put the time and effort you did to correct this, and say “stuff happens”, I guess. It’s sort of like the 10 micron changes in pellet size. With a new gun that apparently has a lot to offer, patience and wariness for the needed refinements may be worth it.

B.B.,

I appreciate your gracious offer above to bail me out if I were to re-order a Dragonfly 2 and it went bad. You have twice now bailed me out with air gun repairs. But it would be taking unfair advantage of your generosity to do it yet again. It is easier to do one of two things, either not buy one at all or pay for the extended warranty and send a bad one back.

Thanks again for your selfless offer.

Michael

BB

.200 to .300 is a lot to be out of adjustment. How long is that tiny setscrew anyway. Seriously. That would be nice to know.

That’s screw moved. Especially if there is wear on the sear. If there was no wear on the sear then I would believe that about a burr on the setscrew.

And mind you out of 39 year at the machine shop I have never seen a .200 to .300 thousands bur on a setscrew. Especially one that small of diameter.

JerryC,

Anyone who bought the rifle today can cancel the order as I just did. There is an upside to their not being in stock, it seems.

Michael

B.B.,

If the pins were held captive by the stock, how come your example developed a malfunctioning trigger?

Nope, the pins are only sometimes held captive by the stock but other times they come loose like they did on the Dragoncannotfly Mark 2 you shot only briefly. They also came loose on 4 out of the 141 Stormrider trigger units according to PA reviewers. So they are loose on almost 3 percent. Some reviewers even reported pins coming out.

How long has the Stormrider been out? Might this flaw have been fixed by now?

Michael

Michael,

All of the production has been on containers floating about somewhere! Some might be aboard the EVERGREEN ship currently aground and blocking the Chesapeake Bay!

shootski

“Love ageless and evergreen / Seldom seen by two!” Man can Babs belt ’em out.

shootski,

Use simple past tense, “was” and not the present perfect. The terrible Long Beach backlog has been (yuck, yuck) solved.

Michael

Michael,

Thank you.

Mit mine broken English I try to be present & “Perfect” all the time! ;^)

Danke noch ein mal!

shootski

Bitte. :^)

Ich glaube das Shootski kann besser Englisch dan ich kann Deutsch sprechen!

As someone that attempts to speak some of two other languages beside English, I would never presume to correct minor issues in someone else’s English when they speak it as well as Shootski. Especially, because English is a b****h of a language to learn!

Motorman,

B.B. has set the tone here on his Blog that we are all to learn from each other; I really like that. Micheal made a slick funny out of it…l laughed too!

As far as my German it is of the Viennese dialect. For High German I refer to my Duden often. I wish English had something like The Duden; but since each English (even in the UK) is its own language and Grammar that will never happen.

shootski

I only speak some Hoch Deutsch because I studied it in high school and university (many, many years ago!). My family is actually Schwabisch, so I enjoy no dialectical superiority over Viennese! LOL!

I have been a life-long student of languages, including my own. One of the most interesting classes I took in college was “History of the English Language” where I learned that English is the bastard child of the original Germanic language overlaid with French as spoken by the ethnically-Nordic Normans (see Battle Of Hastings in 1066). Words from both languages give us a rich vocabulary of synonyms, but the hybrid grammar from both languages was irregularly applied (ever wonder why English plurals of child and ox are children and oxen? As a German speaker you’ll understand!).

Motorman

St. Louis, MO

Motorman,

My son translates for Biathletes, their coaches, and officials while working IBU an USBA events.

My daughter went to Kinderarten and the first grade (actually all 3 grades in one) in Kaltental and learned to speak the Schwäbisch dialect like a native Schwob. She continued all the way through Grundschule but switched to an American Public School where she almost taught the German 4AP class because she knew more than the teacher. She is a skilled linguist with French, Latin, Italian, and currently learning Spanish to help with her police work.

My ancestry came from the Black Forrest and traveled down the Danube to the Balkens…”great move” that! Almost all of them failed to make it through WW2 and the immediate aftermath.

shootski

Shootski:

Your daughter obviously has a gift for languages. I think it runs in families. My youngest daughter is like that, too. Speaks fluent English, German (Hoch Deutsch and Schwabisch), Spanish and some Russian. That’s over my head!!!

My Speidel family left from the Stuttgart area (Holzgerlingen) in 1889. Earliest US family member was a Hessian soldier during the US Revolutionary War. Reckoned he was fighting on the wrong side. Deserted and fought for the colonists. After the war he settled in German-speaking part of Pennsylvania.

Motorman

St. Louis, MO

BB

I just read the comments. Read my reply to Tyler at the top of the comments.

This issue will presumably only apply to the dragonfly as it’s a different stock. They’ve left a bit too much clearance either side of the trigger housing

Ade C,

They are also a problem on the Stormrider, according to reviews.

Michael

The Stormrider trigger recall was relating to the adjustment screw, not the pins as far as I know. That’s probably why they’ve used the older Stormrider trigger on the Dragonfly rather than the problematic gen2 version

Everyone,

This trigger is single stage! I goofed in Part one when I said it was two stage. Apparently that burr on the adjustment screw was hanging on like a real stage two.

You guys are wearing me out! 🙂

BB

B.B.,

For your continued HONEST reporting

Thank you!

shootski

So not all burrs are as bad as Aaron! (Sorry, I’ve never thought of a corny joke I could not subject others to.)

Michael,

“I resolve not to tell a corny joke.

Hello, what’s that? The church burned down? Holy smoke!”

Lyrics borrowed from Spike Jones, This is my New Year’s Resolution.

https://www.youtube.com/watch?v=3_4BrQeTFKo

BB

Heard about the two peanuts who walked into a bar? One was a salted!

Heh, heh. I hadn’t heard that one before. Nice! :^)

That oughta cost ya a Hamilton…

B.B., Tyler, and Readership,

Happy 22/7th Day!

shootski

Ah, pi day. :^)

B.B.,

Single-stage triggers don’t bother me, but it being “long . . . with no definite stop point” might or might not make a difference to me, depending on its weight. I have a Beretta Elite II air pistol with a looong indistinct break, but on a bag it is accurate (an underrated air pistol in my opinion). It is also very fun to shoot. In fact, I might dust it off and go into the backyard to help me decide whether to re-order (with the extended warranty) or not.

Michael

Seems to me any trigger with a long final stage would benefit from Gunfun1’s hot glue trigger stop. I have that on my list of tinkering projects.

Great photo’s, nice simple trigger. Is barrel rifling ever roll formed? Are barrels ever cast, like lost wax style? This gun looks like a good value how evere they made it. I like that something needed to be welded on it. Thanks for the peek inside. I dont think it was a machine that did it.

Rob

Rob

When I raced rc pylon planes there was a engine manufacturer that used the lost wax technique. They made the most reliable high horsepower engines of the day when we was racing. Early to mid 90’s I believe it was. I had one. They was called .40 cubic inch Nelson engines. Search them. I’m sure there has to be some history about them.

.40″? Well it’s almost $7 dollars a gallon now here in Ca. I could maybe afford fuel for that hobby now! All the cooling fins are hard to get right.

R

Rob

I don’t understand your comment about .40″ and $7.00 a gallon.

What does that have to do with the size of the rc engine?

Oh I see what you mean now.

But really I don’t know. I remember 15% nitro rc fuel was $10 a gallon back then. I don’t know how much it is for a gallon now.

I fly electric now but also to remember those rc nitro engines don’t consume fuel like our multi cylinder engines do even now days.

Rob,

I have never heard of rifling being roll formed but Roy Weatherby invented the hammer-forging method of rifling, I believe, and FX took it to the next step by forging in the lands from the outside in their barrels.

BB

Drawn, seamless tubing is often thought of as superior, but some of the best stainless tubing for bicycles from True Temper has a seam. Manufacturers are always coming up with new ways to do things. We dont have to worry about chrome lining our airgun barrels I suppose.

Rob

“The zero check”. This is my new axiom. I think nowadays you need to check everything anyway at the beginning by yourself. Perhaps when purchaising a 10m Steyr or Feinwerkbau rifle for 2.5kEUR you can just take it and directly use… but I’m not sure about that.

Hey y’all,

Re-reading this report and all the comments got me to thinking (and my brain hurts! =>).

Of all of the dozens of firearms I’ve owned, I’ve only got two that didn’t need to be “tweaked” after I got them: 1) a Savage Mark II rifle in .22LR, and 2) a Henry model H001 rifle in .22LR.

Every other firearm had to be tweaked for some reason.

Of all the dozens of airguns I’ve owned, I’ve only got three that didn’t need to be “tweaked” (taken apart, or at least taken out of the stock to adjust something): 1) my Dad’s Beeman Webley Tempest in .177 caliber, 2) the Haenel model 1 air rife in .177 caliber I got from Frank, and 3) the HW30S in .22 caliber that my wife gifted me.

Every other airgun, rifle or pistol, needed something to be done to it to make it “suit” me, to make it “the way I thought it should be.”

So, as for my on-order Dragonfly Mark 2, B.B. and Tyler have now pre-warned us what to do, as well as how to do it, if it is even necessary…and it may not be.

You’ve got to love this blog (and I do =>) for the amount of info here detailing everything one could possibly wish to know (relating to airguns that is, not to everything in the world that could be known; God alone knows that! LOL =>).

When my rifle arrives, I’ll wring it out; and if it has any issues, I’ll post about it here and get the answers.

I want this rifle for a very specific purpose: I want an MSP that I can scope for pesting purposes that has a light enough pumping effort that I will not stress the scope (even though I plan to hook my thumb over the rear scope mount, which will not really stress the scope) while pumping it up. I’ve tried scoping my Sheridan four times now…and took the scope off each time (going back to a peep sight), as it either stressed the scope in a way I didn’t like, or stressed ME in a way I didn’t like (i.e. I must be getting weaker! =>).

The best configuration I ever came up with, for scoping, was a 2X scout scope mounted well forward on the barrel; it shot great, but the balance of the gun was terrible.

Hence, from everything I’ve read so far in all the reports on this Dragonfly Mark 2, it appears it will be “the rifle” for which I have been looking…I’m looking forward to finding that out. 🙂

Wishing a blessed day & happy shooting to all,

dave

Dave,

There is a difference between “tweak” to suit you and repair so that it will function. This seems to be a design or manufacturing flaw that prevents proper function. How many firearms and air guns have you purchased new that required that you repair them? Some, I’m sure, but all but three? I doubt it.

Michael

Michael,

Yes; I see your point; I can only think of one gun, an old Ruger Mark I .22 LR, that I bought from my boss at work (note: this was back in “the good old days,” when such things were commonplace =>). He thought the gun was OK, but I told him that if I put it on “safe,” but pulled the trigger really hard, the gun would fire (he offered to take it back, but I declined).

Fortunately, Ruger is a class act; when I called Customer Service, and told them of the problem, they said, “PLEASE, bring it in right now for repair!”

Yes, even though I was not the original owner (more like the 5th owner), they fixed it on the spot for free; I used to pass by their old factory, the Red Barn, on my way to work; I stopped in, and they repaired the gun and had me on my way in 10 minutes…very cool!

Another cool thing about those good old days: many of us were on a pistol team, and our company allowed us to keep our guns in our cars so that we could go to the matches right from work (instead of having to drive home first…30 miles out of the way for me). Good days, sorely missed! 🙂

Blessings to you,

dave

Michael, Michael, Michael!!!

We have a host of good airgun repairpersons here on this blog. If I have already reached my maximum, then please consider sending your guns to some other readers. You get a gun that works and , hopefully, I get at least one guest blog out of it.

Hey, everybody — let’s fix Michael’s airguns! 🙂

BB

Michael, other than the two airguns you mentioned, what others are in the “pet [airgun] sematary” waiting to be resurrected? If any of them are a Crosman Mark I or II, I might volunteer. I have purchased and resealed 6 so far–a new facet of this hobby for me. Here is a rested group I recently made with one of the Mark Is that I was really happy with. It would be my way to pass along the assistance I received from others from this blog. And shooting airguns is way more fun than looking at old boxes on a shelf. I have my old Crosman 760 from my youth, which is nonfunctional, I can’t see spending more money than it is worth to fix it, but that inspired me to buy a Crosman 362 pumper (which I just sent back under warranty). If I can help you out, it would also be a way for me to say thanks for all YOUR contributions to this blog from me as a reader of your comments and corny jokes. :o)

Roamin,

Thanks for your kind compliment!

My other failed repair attempts include but are not limited to (Hey, I can do lawyer-speak) a BSA Meteor MK IV, Benjamin 367 and S&W 77A. The Benjamin and S&W someday will be sent to a pro to be resealed as the former is in otherwise excellent condition, and the latter is an incredible shooter, even in my shaky hands. The BSA has served me well as a bottle rocket launcher on more than one July 4th.

There are others, mostly air pistols, but I get depressed if I think about them too much.

Michael

Roamin, is your 760 one of the old ones with a Tootsie Roll pump handle? Those are some of the best looking air rifles I’ve ever laid eyes on. If I had one of those that didn’t shoot, I’d keep it to put up on the wall as a work of art.

Michael

My Crosman 760 is plastic, molded with a wood grain. It was a present from my Dad when I was 8 or 10 in the early 80s. The forearm looks like a piece of 1 x 1 lumber molded in plastic–rectangular. The barrel has sadly rusted over from the years it lay forgotten in a drawer in an oak cabinet in my parent’s unfinished and stone-walled 1920s farmhouse basement. It did not hold air anymore, the pump handle just flops back and forth. But because of the memories it triggers, it is still beautiful to me.

Not too long ago, I took it all the way apart to see if I could get it working again, and…you’ll like this…the innards expoded all over the place like a cartoon, but even though I managed to put it all back together, I never was able to get it to hold air, not even a little. I have my theories, but with as cheap as new ones are, I have no incentive to fix it. Plus there is one spot where a screw has just about stripped out the place where it screws into the plastic on the other side of the receiver, so it’s basically DOA. Dad is 86 now, so I will probably keep it just for the memories and see if the new Crosman 362 can fill its shoes (although I have my eye on a Dragonfly, too).

Roamin,

If you were that young when you got it, you are a youngin’! ;^)

I have one of those with the plastic forearm and stock. It shoots well, despite not having (I think) a smoothbore barrel.

Definitely keep it, no matter what. I promise you that if you part with it, you will kick yourself. Momentos are important.

Michael

B.B.,

Something tells me that if I send my good friends Gunfun1 and RidgeRunner my dead air guns, I might not see them again! ;^D Those at RR’s will become wayward houseguests, and those at GF1’s will be souped up into super-duper fire-breathing weapons of tin can destruction. ;^)

Michael

Michael,

Well, I can’t say for sure. But I have heard that, like the lottery, you do have to play to win. 😉

BB

B.B.,

True, but if you don’t play, you can’t lose. ;^)

Michael

Michael

Think of it like one does for love. If you don’t play,, you have already lost.

Ed

“Those at RR’s will become wayward houseguests, and those at GF1’s will be souped up into super-duper fire-breathing weapons of tin can destruction.”

Not that there is anything wrong with that. :o)

RG

🙂

Michael

You know me to well. 🙂

Yep, Gunfun1 is where air guns go to be made into hot rods! :^)

Michael

It does seem to end up that way doesn’t. It’s in my blood. What can I say.

BB

From the top of the blog where you said no you can’t to me. No I can’t what?

Like I said to Tyler above about a previous blog that the problem sounded sear related. And apparently it was.

And ok the sear don’t have wear marks but the screw does. There is no way that set screw had over a 1/4 inch burr on it relating to how much you said the screw had to be adjusted.

The set screw moved. And that was the rattling noise you heard. The trigger and sear not contacting properly.

GF1,

No, I can’t see any wear on the sear where the adjustment screw was. Now I didn’t examine it that closely, so there could be a shiny spot I missed, but no real wear.

BB

BB

Pretty easy to replicate the problem.

Back that screw off and see if you get the rattle and trigger not firing correct.

Let me know how that goes when you test it.

GF1

I think he said hundredth of an inch,, not tenths.

And , in truth, I don’t think that any “rattling” would have happened if the pin had not been out of the side hole. I think the inletting wasn’t tight enough in that particular place to hold the pin in “battery”. Hence the “rattling”. Since BB made two separate “fixes” at the same time,, we will not know unless he decides to take it apart again.

Ed

Ed

And we already know that answer.

GF1

Yep,, if you mean as to whether or not he will open her up again. Chances are pretty slim.

Ed

edlee

Yes sir. Exactly what I mean.

I don’t have both guns to know for sure, but the adjustable trigger from the Diana Trail Scout may work in the Dragonfly.

Benji-Don,

That’s an excellent question/idea. The Trail Scout trigger is advertised as being adjustable. Do you know if it is also two-stage? At $100, it would be a cheaper fix than a swap with a Stormrider trigger would be.

Michael

Michael,

I don’t know about the diana triggers the guns seem to share some parts with the Dragonfly, if the Trail Scout or the Stormrider trigger is a direct fit then maybe the adjustable trigger could be offered after market for a few dollars.

I did some tweaking to the trigger on my gen 1 Dragonfly and improved the trigger quite a bit.

Don

B.B. I’m surprised that the fact that one of the pins was out of its hole on one side did not have anything to do with your trigger problems. But hopefully, the trigger issues are behind you.

What does the screw in the trigger adjust? The weight of the pull or the length of the pull?

I’m also surprised that the manufacturer would simply rely on the tolerances of the wood inletting to hold the trigger together, especially with how “touchy” the legal departments of gun manufacturers are about triggers, and with how wood can expand and contract with the weather and relative humidity.

Roamin,

That screw adjusts the amount of push the trigger makes with the sear. It doesn’t adjust the pull weight, but the length of travel is changed a little.

BB

B.B.,

Roamin’s comment about the unusual design of holding metal moving parts together with wood got me thinking, or rather, trying to remember.

Did you report, many years ago, on a springer that held the trigger mechanism together with the wood? I’m thinking Relum or Falke, maybe?

Or is this just a false recollection or conflation of different things in my swirling brain?

Michael

Michael;,

There are several airguns that used the stock to contain pins. I think the Falke might be one.

BB

B.B.,

Thanks to your encouragement and Tyler’s assurances (thank you Tyler), I decided to re-order one Seneca Dragonfly Mark 2, in .177. I’ll tack on a $39.99 extended warranty, too.

Here’s hoping May 11 comes early this year! :^)

Michael

Michael,

Good for you. I hoped you would get one.

I now plan to have a special report just for you with step by step instructions of how to take the rifle out of the stock and how to remove the trigger blade for adjustment.

BB