*Offer expires 04/30/24 at 3 a.m. ET. Some exclusions apply.

*Offer expires 04/30/24 at 3 a.m. ET. Some exclusions apply.

by Tom Gaylord

Copyright PyramydAir.com ©2009. All Rights Reserved.

Scuba tanks, compressors, pumps and filler devices. Is shooting a precharged pneumatic worth all the hassle? Actually, it's not that bad. While there are a few more things to learn, the reward is extreme accuracy and ease while shooting. This is the powerplant that puts airgunners ahead of rimfire shooters in terms of accuracy up to 50 yards.

This article originally appeared in Airgun Illustrated magazine in 2003. It's reprinted here with the permission of the author and has been updated.

Precharged pneumatic (PCP) airguns represent one of the oldest airgun powerplants of all time. They have been around since at least the early 1600s and most likely a bit longer. In the 1780s, the Austrians fielded over 500 riflemen, each armed with a breechloading .47 caliber 21-shot repeating air rifle and the capability to fire at least 42 shots before returning to the rear for more air. This was at a time when repeating firearms were just a glimmer on the technological horizon, and few armies used rifles in any quantity--most used smoothbore muskets.

In 1803, the Lewis and Clark expedition took an air rifle with them on their Voyage of Discovery, which explored the Louisiana Purchase and opened the west for the fledgling United States. They used their airgun to amaze the natives they met along the way. Although the airgun model they had has yet to be conclusively established, current research points to a military Girandoni that was in Robert Beeman's collection. Beeman has donated this rifle to the US Army War College in Carlisle, Pennsylvania.

In the Victorian era, precharged airguns reached a high-water mark in terms of decoration and performance. Writers have long speculated about the purpose for all those beautiful large-bore precharged guns--whether it was for self-defense or covert hunting (poaching) or for economy while training. But I have a different idea. I think it was for no purpose whatsoever beyond the fact that it was possible. In every era, you'll find extravagant examples of technology like this. Or do you suppose there is an actual need to drive a passenger car more than 200 miles per hour to validate the present-day Ferrari?

If you'd been bitten by the airgunning bug during the mid-19th century, you would have marveled that the push of common air could drive a lead bullet fast enough to harvest a roe deer or a wild boar. If you were a Victorian gentleman of means or perhaps a military officer of some high station, it was perfectly reasonable that you would've wanted to own such a wonder; and you would've wanted it to look as nice as the other fine guns in your collection. Some of these airguns were made as conventional cased sporting arms with separate rifle and shotgun barrels, but a great many more were made up in the last half of the century as air canes--walking sticks with miniature airgun mechanisms built in.

Fine cased airgun sets and canes were being made right up to the 1920s. Production probably stopped around World War I, but there were parts on hand to assemble guns for years afterward. However, after the last air canes had been sold in the late 1920s, the whole world pretty much forgot about precharged guns for the next 50 years.

In the late 1970s, experimenters began producing precharged airguns once more, only this time the technology was also applied to the traditional smallbore calibers of .177, .22 and .25. Big bore guns were also made right from the beginning of this modern renaissance, but this time the smaller calibers were the ones that fueled interests--at least for the first decade or so. These modern smallbores are the guns we'll look at as we explore this fascinating technology.

Getting acquainted with precharged airguns

Let's begin with the terminology. In the United States and in most English-speaking countries, these guns are most often referred to as precharged pneumatics (shortened to PCP). In German, they are called pressluft (compressed-air guns). Ten-meter shooters everywhere tend to call them compressed-air guns as well, probably because the owners' manuals for their German/Austrian/Swiss guns all use that term.

I like precharged better than compressed-air because it is more descriptive. A precharged airgun is one in which all the air for shooting has been introduced into the gun before it is readied for firing. It is pre-charged, so to speak. And most precharged guns fire multiple shots on a single charge of air. On the other hand, there are many other types of airguns that use compressed air but cannot be called precharged--like multi-pump pneumatics.

Except for the pre-charging, though, a precharged airgun operates along the same lines as a multi-pump pneumatic. In fact, there once was a multi-pump air rifle made by Titan (and later improved by Daystate) that had the same high quality as a fine precharged rifle, except that it had a pump built into it. It shot just as well as a fine precharged rifle, which is to say very accurate and easy to shoot.

Air power--the science behind the precharged airgun

To understand how compressed air works, it helps me to think of it as the equivalent of black powder. The similarities are instructive.

With black powder, velocity is directly dependent on barrel length. The same is true for compressed air. Both power sources continue to accelerate a projectile as long as the pressure behind the projectile is higher than the pressure in front of it (ambient air pressure, plus the pressure wave in front of the accelerating projectile). Of course, in this example it must be understood that friction is also always a factor to contend with.

With black powder, a larger charge of powder provides more power--up to the point that the powder cannot burn any faster in the time (barrel length and bore volume) available. The same holds true for compressed air--the higher the air pressure, the faster the pellet--to a point.

What we get from these two facts is a simplistic rule: A longer barrel in a pneumatic gun increases velocity (to a point), and higher air pressure also increases velocity (to a point). As those points are approached, the gains from longer barrels and higher pressures have diminishing returns, so designers must balance that against making a gun too long or using pressures too high for safe and convenient operation.

Beyond this comparison, the behavior of compressed air starts to diverge from that of black powder. Here's what I mean. With compressed air, it's possible to get an even greater "push" by holding the valve open longer so the pressurized air behind the projectile continues to be replenished from the reservoir. In other words, the push doesn't diminish as fast, even though the projectile is traveling up the bore and increasing the barrel volume behind it. Black powder gun mechanisms have no equivalent to an airgun valve, though you can increase the powder's force by grinding the granules smaller so they burn faster.

Think of the longer valve-open time as a person pushing a car. In the beginning, the car moves very slowly and the person has to exert a lot of energy; but, as it starts to move, it speeds up from the continuous pushing effort. Less effort will continue to accelerate the car--to a point. Lower air pressure and a longer barrel can be used to boost pellet velocity as long as the valve remains open longer and the barrel is long enough to use the extra push.

This outside lock rifle was handmade by Gary Barnes in 1998. It's a close copy of an airgun made in 1730, though this one is both rifled and a breechloader.

The heart of the outside lock is a hammer and separate striker, which are cammed together to lengthen the time they remain in contact thus holding the air valve open longer. With this arrangement, the rifle gets 28 foot-pounds of energy on a fill pressure of just 800 psi. If this were a big bore instead of a .25 caliber rifle, it would have performance rivaling a vintage big bore airgun.

Let me give two actual examples of how a long valve-open (dwell) time can speed up a pellet. The first is an outside-lock air rifle made by Gary Barnes several years ago. It is a close copy of a big bore gun made around 1730, and Barnes carefully replicated the operating principles of the early gun's lock-and-valve mechanism. The replica operates on a pressure of just 800 psi, but because the valve remains open for a relatively long time and because the barrel is 32.75 inches long, it accelerates a 20-grain, .25 caliber pellet to 795 feet per second! That's a whisker more than 28 foot-pounds from just 800 psi! And, there are 12 powerful shots of diminishing velocity in this gun before the reservoir needs refilling. Barnes calls this type of firing mechanism a "timed valve," because it has something more than just a simple knock-open operation.

This is the same technology behind the great power of big bore airguns from the 18th and 19th centuries. With just 500 to 700 psi, it is possible to get a lot of shots and a lot of power--provided the barrel is long, the valve is slow and the projectile is heavy.

My second example is more modern-looking and just as amazing. A field target rifle called the Simple Simon designed by Larry Durham gets velocities of more than 875 f.p.s. with heavy .177-caliber field target pellets. It can shoot over 50 shots at that speed--on a starting air pressure of 1,800 psi. That's the point at which most modern precharged rifles need to be refilled! The Simple Simon has no regulator, either. Instead, it relies on a valve that's set up to be efficient on lower air pressure. And it really works. Steve Schulz won the 2002 national field target championship with his. So, you can see there's more to precharged design than just how much air pressure you can cram into a gun.

The Simple Simon rifle, designed and made by Larry Durham, is a smallbore application of a lower-pressure system. This one is .177-caliber and shoots 10.5-grain Crosman Premiers at 900 f.p.s. It gets 50+ shots on a starting pressure of just 1,800 psi--the point where most other PCPs need to be refilled. This one belongs to Steve Schulz, who won the 2002 U.S. Field Target Championship. Mac-1 Airgun has plans to market this rifle.

The Simple Simon action is closed in this shot.

The breechblock has been swung to the side to gain access to the breech for loading.

Mac-1 Airgun has turned the Simple Simon into a limited-production rifle called the USFT. This gun operates on about 1600 psi and gets about 55 good shots with a .177 Beeman Kodiak pellet going just over 900 fps. A USFT won the 2007 World Field Target Championship.

Once a conventional smallbore precharged airgun is pressurized, all the shooter has to do is load and fire--many times between refillings! This lets the shooter concentrate on other things besides cocking a powerful mainspring or pumping up the gun for the next shot. It doesn't get much easier than that!

Precharged guns are also quite free from the disturbances of vibration--the very thing that often makes many spring guns so difficult to shoot well. A precharged airgun handles more like a .22 rimfire rifle, which makes for much easier shooting. Although precharged guns are inherently no more accurate than other types of airguns, shooters find them much easier to use because of how they behave.

Filling the gun

First, we need to get high-pressure air into the reservoir of the airgun. Filling an airgun from a scuba tank is the modern way to go, and it's not difficult. There needs to be an air-tight connection from the tank to the gun and a way to measure how much air pressure is put into the gun. A fill adapter of some kind lets you do all that, and most precharged guns have some kind of adapter available as optional equipment. Those that don't usually come with some kind of small connector to work with any filling adapter you already own for that airgun. You simply connect the airgun to a scuba tank using both ends of the adapter.

Hoses and gauges and clamps--oh, my! These are a few of the different filler adapters used to connect PCP guns to scuba tanks and hand pumps. A gun needs only one of these--sized to fit its fill port and the type of air source the owner will use.

The scuba tank has a valve that you control with a handle. You could just open the valve and fill your gun in seconds, but it's very important to fill slowly. Compression builds heat, and a gun filled too fast can become so hot that actual damage can be done to the synthetic seals. Allow about one full minute to fill your gun--even if you're just going from 2,000 psi to 3,000 psi. Even going this slow, you will feel the exterior of the air reservoir warm up.

Scuba tanks come with two different types of valves--DIN and K. Your air-filling equipment must attach to the type of valve you have. The DIN valve has a threaded hole into which adapters are screwed. There are two depths of holes--shallow for 200-bar equipment and deep for 300-bar equipment. (That's approximately 3,000 psi and 4,500 psi, respectively.)

The K valve is a simple hole that needs a metal clamp to hold onto. This clamp is called a yoke in the diving industry. K valves are rated for 200-bar/3,000 psi operation, only.

This is a DIN scuba tank valve. It's controlled by the Deutsches Institut für Normung e.V. (German Institute for Standardization). There are two types of DIN holes--a shallower one for 200-bar equipment and a deeper one for 300-bar equipment.

A DIN adapter screws directly into the hole in the valve of the scuba tank. There's no wraparound yoke, as there is with a K scuba valve.

A K scuba valve needs a wraparound structure to hold the adapter on the tank. The slang term for these is "yoke."

The yoke goes around the K valve and a screw in the back tightens the yoke to the o-ring in the valve for an airtight seal.

To disconnect the fill adapter from the gun, you must first bleed-off the high-pressure air inside the adapter. If you don't bleed-off the pressure, there will be a loud pop when the adapter is disconnected; and, if there's a flexible hose involved, it could whip around with great force. Also, the o-rings that seal the joints between the adapter and the scuba tank can be blown out of their seats and be destroyed by the escaping high-pressure air. Once the high-pressure air is bled off, you can easily disconnect the adapter from the gun.

Using a hand pump

Instead of using a scuba tank to fill your PCP gun, there are also manual air pumps. With the pump made by Swedish firm FX, you can pump your PCP guns up to 3,000 psi or whatever pressure under that limit they require. BSA offers a different British-made manual pump that pressurizes up to 3,500 psi. This one is both larger and heavier than the Swedish model, and it takes more effort to reach pressures above 3,000 psi.

Any brand of manual pump can be adapted to accept any airgun fill device with adapters. You can use either the gauge on the pump or the gauge on the fill device to monitor the fill.

Both pumps can be connected directly to an airgun with just a simple hose, or they can use the more universal filler devices we show in this report. It's important to ask if your specific airguns will attach to a pump at the time of purchase, for that's the best time to buy any additional adapters that might be required.

The hand pump from FX of Sweden weighs about five pounds, yet it can pressurize an airgun reservoir up to 3,000 psi. A condensation-type filter in the pump base removes some moisture from the air as it is compressed. This pump has a scuba K-type adapter fitted, so it works with the same fillers that use K-valves.

The first step in filling is to attach your fill device to the pump. Next, close the air bleed screw on the side of the fill device. Finally, close the air bleed screw at the base of the pump. Now, you're ready to fill the gun.

The first few pump strokes (up to about 15) pressurize the fill device, not the gun. The air pressure in the gun holds the inlet air valve shut until the pressure in the fill device is greater. Sometimes, the pressure differential has to be several hundreds of pounds before the gun's inlet valve pops open, and there's usually a click when it does. The indicated pressure on the fill device drops by several hundred psi, and you can assume the new lower reading is the actual pressure level that was in the gun.

Now, the filling goes slower because you're actually pressurizing the whole volume inside the reservoir. With a small reservoir like the removable air tank on a 10-meter pistol, it may take eight pump strokes to raise the internal pressure by 100 psi. With a large reservoir like the one on the Talon rifle, it may take 15 strokes to raise the pressure by 100 psi. Whatever the case, there's no danger of filling the gun too fast when using a manual pump. However, the pump can be pumped too fast to be efficient.

This close-up of the pump base shows the scuba adapter, which swivels 360 degrees for convenience. The knurled brass screw is the bleed screw, and the air bleeds out the small hole to the left. The brass blank is a screw for adding a gauge to the pump, if desired.

Make your pump strokes slow and deliberate for the best results. Slow means to take as much as two seconds with each direction of the stroke. This is lets air rush through the pump's inlet ports so there's a full chamber to compress. Deliberate means to extend the pump handle all the way to the end of its travel in both directions. The last few fractions of an inch of travel do the most work, so go to the ends to get the full benefit of the pump. Faster pumping or pumping with short strokes is very inefficient with this device, whose design depends on proper operation to achieve the expected results.

As the pressure inside the gun's reservoir rises, the pump resistance increases (it starts at around 2,200 psi for me). When this happens, lock your arms at the elbows and use your legs to move your entire body up and down. You are using your whole body weight instead of the strength of just your arms to pump. This trick makes it possible for my wife to fill a gun to 3,000 psi while some strong men claim they can't do it.

If both intakes are open, you pressurize more air; if one is closed, you pressurize less air, which should be easier to do. The theory is that you fill your gun with both air intakes open until the pumping gets hard, then close the screw and fill the remaining amount with a single intake. I have never found this screw to be an advantage, though, so I leave both air intakes open for a faster fill.

Don't pump longer than five minutes at one time; break for 15 minutes between sessions. That keeps the pump from overheating. You don't have to disconnect the pump at this time. You can completely fill most guns in five minutes or less. If you have a large reservoir to fill, such as the Talon's, it can take longer.

When you're finished, bleed the fill device in a special way. Use the bleed screw on the pump, instead of the bleed screw on the fill device. The way these pumps are designed, they trap water in their base, and it gets purged when you open the pump's bleed screw.

Once the pressure has dropped, you can safely disconnect the gun. You can leave the device attached to the scuba tank or pump until you need it again--that way, no foreign material can enter the scuba tank's valve (and be blown into your gun the next time you fill). Put a small baggie over the fill end of the device and wrap it tight with a rubber band to keep out dirt.

More on fill adapters and how they work

Fill adapters connect the airgun or removable reservoir to a source of high-pressure air. There are a few standard connectors among adapters, but there are still a lot of proprietary sizes and shapes. We have already looked at the end that attaches to a scuba tank, so now we'll look at the end that attaches to the gun.

At the gun end, the adapter may take any shape that seems good to the manufacturer. Airgun makers seem bent on creating as many different kinds of gun fittings as they can! But they don't get away with everything because they, too, have problems with commonality.

This is a quick-disconnect fill probe for a Career 707. Other rifles such as Quackenbush, FX and Webley use a similar probe, though none are standardized. Always get the fill probe or connector your gun requires.

This is a spring-loaded quick-disconnect fitting. Daystate guns use it, and it's a worldwide standard hydraulic part. Try to get stainless fittings instead of brass because they last longer.

The 1/8-inch BSP connection is the Rosetta Stone of the PCP world. Only a few Asian makers use anything else. Sometimes, you'll find an American 1/8-inch pipe thread, but it's so close to the BSP standard that the two usually fit together well enough. This is a male connector. Most fill probes end in these threads.

This is a female 1/8-inch BSP.

And THIS is an adapter that turns a scuba K valve into a 200-bar DIN valve. If your airgun shop doesn't have it, your local dive shop probably does.

Most fill devices end in a hose with British 1/8-inch pipe threads. The 1/8-inch BSPT (British Standard Taper Pipe Thread--often called BSP) is the most common fitting by far. This is the airgunner's Rosetta Stone, because most adapter probes are made to fit these threads on one end. By the way, the 1/8-inch size refers to the hole in the pipe--not the outside diameter of the threads.

A fill adapter connects to a gun by screwing it on, by inserting a probe into a fill port or with a standard hydraulic quick-disconnect fitting. All adapters rely on seals to do their work. Usually, these are o-rings, but they can be any type of material that creates an airtight seal. Because of this seal, the adapter never needs to be screwed tight to the gun! Just because you see flats that look like they want a wrench of some sort, DON'T USE ONE! Let the seal do its job and tighten the adapter only finger-tight. The exception to this rule seems to be the Falcon guns, which do require a SLIGHT turn of a wrench to seal the fitting, but only on guns not fitted with a Falcon quick-disconnect.

Become a user of Teflon tape--called plumber's tape at the hardware store. Wrap the threads of all fittings with this miracle stuff and end air leaks forever. A few wraps of Teflon tape around the connecting threads usually seals things well. You may need to renew it from time to time, but it takes just a minute or less to apply.

If you plan to shoot PCP airguns, get some of this stuff from the hardware store. It's Teflon tape, but it's also called plumber's tape. It has no adhesive on it--you simply stretch it and wrap the exposed threads of a fitting before connecting something else to it. It goes on very easily and adheres by friction.

Summary

Precharged airguns are fast becoming the favorites of airgunners everywhere. They're easy to shoot, easy to maintain and the most inherently accurate of all airgun powerplants. By following a few simple guidelines when operating these guns, you can shoot them without fear. Remember, a precharged gun is nothing more than a multi-pump pneumatic without the pump built in. Just read this article and the specific instructions that come with your precharged gun so you can be a safe operator.

The precharged airgun is both the oldest type of powerplant and the one undergoing the most development today. There are things to learn when operating precharged guns, just as there are for any other powerplant. The rewards for learning are great indeed.

Common questions about precharged pneumatics

Q. Are they safe?

A. Yes, precharged airguns are as safe as anything else when they're handled properly. Most people will be familiar with pneumatic airguns from Crosman, Benjamin and Sheridan. These guns all store high-pressure air the same as precharged pneumatics. The difference is that a smallbore precharged gun stores enough air for many shots, while the others, with few exceptions, use all their stored air with each shot.

Q. Are scuba tanks safe to have around the house?

A. Again, yes, as long as they're handled properly. They should be stored in a cool place, and they should be protected from falling or other mechanical damage.

Q. How many shots will I get from a fill of air?

A. This is a common question, and it's similar to asking how far a gallon of gas will take a car. The answer depends on severable variables. Some of the most important ones that directly affect the number of shots are the volume of the reservoir, the maximum fill pressure, the presence of a regulator, caliber of the gun, valve return spring strength, hammer weight, hammer spring strength and hammer stroke. The length of the barrel has an indirect affect on the number of shots because a longer barrel is more efficient in a pneumatic...up to a point. By putting a longer barrel on a gun, the gun can be detuned a little and still get the same velocity. That results in more shots for a given fill of air.

Some precharged guns such as the Talon from AirForce Airguns allow the shooter to adjust some of the variables. The .22 caliber Talon with its huge removable reservoir that doubles as a shoulder stock can shoot at a mere 6 foot-pounds, or it can be adjusted up to over 30 foot-pounds. At the lowest power level, the gun may get over 100 shots per fill, while at the highest setting it may get only about 30. That's a pretty broad range.

Typical precharged guns with fixed reservoirs usually get from 20 to 50 shots per fill, again depending on that long list of variables.

Q. Can I leave my gun charged when I'm not using it?

A. You not only can, you should. Like your car tires that you leave inflated all the time, year after year, a precharged gun will hold air indefinitely. Let the air out of the tires or the gun, and both are soon ruined. A general guideline is to keep at least as much pressure in the gun as there is when it's time to refill it (usually about 1,500 to 2,000 psi).

Q. When I ship a gun, should it be charged?

A. No. The Department of Transportation regulates pressure vessels and their movement by public transportation, which would be air, land, sea and any commercial carrier. A pressurized vessel is considered hazardous, and special handling instructions and restrictions apply. Always empty an airgun completely before shipping it.

You may transport a filled scuba tank and an airgun in a private transport, like a car. It's legal for you to take your gun and scuba tank to a match or a range as long as you're in your own car, but putting it in your luggage and taking it on an airplane requires the advance approval of the airline you fly with--even though gun's air tank is empty.

Q. Are precharged airguns louder than other types of airguns?

A. Generally speaking, yes. All airguns that use a large volume of gas to push the pellet are louder than spring guns, which use a small, violent blast of air. That includes precharged guns, CO2 guns and multi-pump pneumatics. The more powerful the PCP, the louder it is, with a few exceptions--such as the Talon SS.

To make the least amount of noise with a pneumatic, use the longest barrel you can and run the gun at a moderate velocity below 900 f.p.s. If the gun doesn't have adjustable power, try using heavier pellets to lower the velocity.

Q. I see where people are using air pressures greater than the recommended fill pressures for their guns, and they seem to be getting away with it. Why should I stick to the rules?

A. They may be getting away with it, and they may not. The valve in a gun has to be able to use the higher pressure. The only thing greater air pressure does--and it only does this in a few guns--is give you a few more shots per fill. It will not give more power unless the valve in your gun is set up to use it.

On most precharged guns, filling to a pressure higher than recommended actually LOWERS your power! That's because the valve cannot open as far against the greater resistance of the higher pressure. It's the beginning of valve lock--a condition where the valve is under so much pressure it can't open at all.

Most compressed-air guns actually operate at pressures much lower than their maximum reservoir fill pressure. Normally, modern PCP guns operate best between 1,700 and 2,000 psi. That's why a regulator can give a greater number of shots. It lowers the air pressure available to the valve to its peak operating pressure regardless of what pressure is in the main reservoir. As long as the reservoir pressure is equal to or greater than the valve's optimum pressure, a regulator will be able to supply just the right air pressure to the valve, resulting in a low variance of velocity from shot to shot.

Q. If regulators are so good, should I be getting one for my airgun?

A. Not necessarily. Like a passenger car that can't benefit from tires rated to speeds of 180 mph, many airguns will get little benefit from a regulator. A rifle with a velocity variation of 30 f.p.s. will be just as accurate out to 35-40 yards as a gun with a variation of only 10 f.p.s. or less.

The benefit of a regulator comes when you need to get maximum shots from a gun on one fill of air. A case in point is a field target shooter. They may take a gun that can go over 1,000 f.p.s., drop its velocity to 850 f.p.s. and install a regulator to double the number of available shots for a field target match. A hunter will seldom need a regulator because he doesn't shoot as many times between refills, plus he wants the greater power an unregulated gun offers.

Q. I don't live near a dive shop, so I use a hand pump, but that also means I can't buy diver's silicone grease. Can I use anything else?

A. NO! Food-grade silicone (diver's) grease will not explode under high pressure. Petroleum greases will! You may actually cause an explosion by using the wrong grease in a precharged airgun. Call a large airgun dealer or get your diver's grease by doing an internet search for "diver's silcone grease"...but don't make substitutions!

The modern way to fill

The primary way a modern precharged gun is filled today is from a scuba tank, and that creates a problem. Scuba divers have established a set of operational rules to ensure the maximum possible safety for their sport. Some of these rules are based on governmental and even international regulations controlling the transportation of pressure vessels, while others are simply the creation of the diving community. One of the homegrown rules is that a dive shop won't fill a scuba tank for anyone who does not have a valid diver's certificate--something many airgunners do not have.

The rationale for requiring a diver's certificate is sound. Handling compressed air has an element of danger. To overcome the danger requires both training and adherence to procedures. Also, if an untrained person decided to go diving and could just obtain the equipment and go, there would be a lot more diving accidents than there are at present.

By refusing to fill a tank for a non-diver, dive shops are policing the sport themselves. The sport is their livelihood, and they don't want to see it destroyed by some untrained person having a tragic accident. They're not legislated by the federal government in this respect, and I'm sure they prefer to keep it that way.

Just because dive shops follow the rules doesn't mean they are unaware of airgunners' needs for compressed air. Every dive shop I have approached to date, and hundreds of other shops that airgunners have reported to me, have been very aware of PCP airguns. Of all of these shops, I have only heard of two refusing to sell air to a non-diver airgunner after the proper steps were taken. I've heard of a great many more that refused because of an inarticulate or clumsy approach, so let's see what it takes to establish yourself.

How to get a dive shop to fill your scuba tank

What the non-diving airgunner must do when establishing a relationship with a dive shop is make a good first impression. Don't call them on the phone. Go in and meet the owners in person. Dive shops are usually owner-run, and employees will probably defer to the owner in cases where exceptions to the rules are necessary. Go and greet these people and show them that you aren't a crazed streetlight-popping lunatic who will get their business on the 6 o'clock news.

DON'T TAKE A GUN INTO THE STORE! Take in the filler adapter that connects your gun to a scuba tank and also take in the gun's manual. Heck--take this article in to show them! You probably won't need that much backup, but it never hurts to go prepared. You're showing the dive shop personnel that you have an honest need for high-pressure air, even though you're not a certified diver.

Dive shop employees will recognize the filler adapter as their kind of equipment. They will see in the literature how the scuba tank will be used to fill the gun. If you don't already own a scuba tank, buying one from the shop at this time is a great ice-breaker.

The dive shop does other things besides filling your tanks. They'll sell you the o-rings you need for your scuba valve. These things get lost from time to time, so buy some spares. They also sell the special food-grade silicone grease that you'll use to lubricate all the exposed o-rings on your gun and fill device. They call it diver's silicone, of course, and a small jar seems expensive, but you won't go through it very fast.

Periodically, your scuba tank requires a visual inspection. After all the air has slowly been exhausted (it can take 12 hours to do this correctly), a trained person will remove the valve and inspect the interior of the tank for signs of corrosion. Even though scuba air is specially filtered to remove most of the moisture, there's always a residual bit that remains. If you were to open the valve on your tank and let the air out rapidly, the exhausting air could cool the interior of the tank, causing condensation to form where it can't be seen. This condensation can lead to corrosion, depending on many factors, such as the material from which the tank is made. Corrosion can, after time, cause the tank to fail suddenly without warning.

If the thought of hidden corrosion in your scuba tank gives you cause to think, what do you think goes on inside your airgun's reservoir--where there's NO inspection? This is another reason divers are leery of airgunners. In their eyes, we treat our high-pressure guns in a very casual manner.

Although there are currently no federal requirements for periodic testing and inspection of airgun reservoirs measuring less than two inches outside diameter, one company, AirForce Airguns, has done something about it. They have installed a safety burst disk in the reservoir of their airguns--the first precharged airgun to have one. The burst disk is designed to rupture and release all the air in the reservoir if the air pressure ever rises to an unsafe level.

Hydrostatic testing

Every five years, your scuba tank has to be hydrostatically tested. That's a government requirement for transportation and handling safety. A hydro test pressurizes the tank to a specified pressure and looks at the metal expansion/contraction data. A scuba tank is actually a metal balloon that inflates and deflates with pressure changes. After many inflation/deflation cycles, the metal loses some of its resiliency and becomes work-hardened. When this condition reaches a certain threshold, and the metal no longer contracts to its unpressurized diameter as indicated in a test specification for that tank, it is condemned. In the trade, this is called a "failed hydro," and it's one reason that buying used scuba tanks isn't always the most economical choice.

Do scuba tanks ever explode during a hydro test? Rarely, but it's not unheard of. Usually, it's the neck of the tank that fails from being work-hardened during the manufacturing process or from improper threads to hold the pressure valve. Sometimes, the bottom of a tank can fail if condensation has run there from gravity and weakened the metal through corrosion.

The hydro test is conducted with pressurized water rather than air, so in the event of a rupture, there isn't a disaster. The hydro test tank is a sturdy pressure vessel that must contain the scuba tank in case of rupture. A station that does hydro testing told me they've had one burst incident in the past 12 years--and that was from failed threads in the neck of the tank.

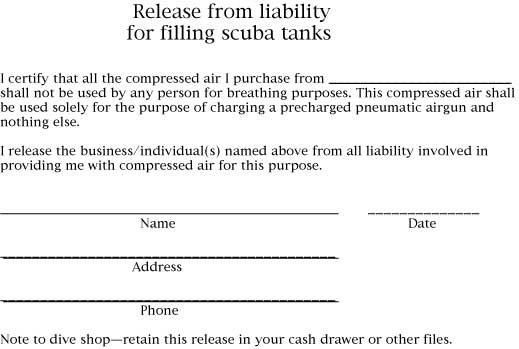

Liability release form

After you've established yourself with the dive shop operators and they've agreed to fill your tanks, give them a release of liability statement, such as the one shown below. You're certifying that you won't be using the pressurized air they sell you for breathing purposes. In other words, you are stating, for the record, that you aren't just circumventing the diver-training program.

Buy With Confidence

Get FREE shipping on qualifying orders! Any order $150+ with a shipping address in the contiguous US will receive the option for free ground shipping on items sold & shipped by Pyramyd AIR during checkout. Certain restrictions apply.

Free shipping may not be combined with a coupon unless stated otherwise.

View Shipping Info

We work hard to get all orders placed by 12 pm EST out the door within 24 hours on weekdays

because we know how excited you are to receive your order.

Weekends and holiday shipping times will vary.

During busy holidays, we step our efforts to ship all orders as fast as possible,

but you may experience an additional 1-2 day delay before your order ships.

This may also happen if you change your order during processing.

View Shipping Times

It's important to know that due to state and local laws, there are certain restrictions for various products.

It's up to you to research and comply with the laws in your state, county, and city.

If you live in a state or city where air guns are treated as firearms you may be able to take advantage of our FFL special program.

U.S. federal law requires that all airsoft guns are sold with a 1/4-inch blaze orange muzzle

or an orange flash hider to avoid the guns being mistaken for firearms.

View Shipping Restrictions

Get the most out of your equipment when you work with the expert technicians at Pyramyd AIR. With over 25 years of combined experience, we offer a range of comprehensive in-house services tailored to kickstart your next adventure.

If you're picking up a new air gun, our team can test and tune the equipment before it leaves the warehouse. We can even set up an optic or other equipment so you can get out shooting without the hassle. For bowhunters, our certified master bow technicians provide services such as assembly, optics zeroing, and full equipment setup, which can maximize the potential of your purchase.

By leveraging our expertise and precision, we ensure that your equipment is finely tuned to meet your specific needs and get you ready for your outdoor pursuits. So look out for our services when shopping for something new, and let our experts help you get the most from your outdoor adventures.

View Service Info

Shop and purchase with confidence knowing that all of our air guns (except airsoft) are protected

by a minimum 1-year manufacturer's warranty from the date of purchase unless otherwise noted on the product page.

A warranty is provided by each manufacturer to ensure that your product is free of defect in both materials and workmanship.

View Warranty Details

Didn't get what you wanted or have a problem? We understand that sometimes things aren't right and our team is serious about resolving these issues quickly. We can often help you fix small to medium issues over the phone or email.

If you need to return an item please read our return policy.

Learn About Returns

Get FREE shipping on qualifying orders! Any order $150+ with a shipping address in the contiguous US will receive the option for free ground shipping on items sold & shipped by Pyramyd AIR during checkout. Certain restrictions apply.

Free shipping may not be combined with a coupon unless stated otherwise.

View Shipping Info

Want More?

Join Our Email List for News and Deals!

Join the Pyramyd AIR mailing list: Our e-mails are filled with new products, deals, sneak peeks, tips and tricks, contests and more - sign up today!

Text JOIN to 91256 and get $10 OFF Your Next $50+ Order!

* By providing your number above, you agree to receive recurring autodialed marketing text msgs (e.g. cart reminders) to the mobile number used at opt-in from Pyramyd AIR on 91256. Reply with birthday MM/DD/YYYY to verify legal age of 18+ in order to receive texts. Consent is not a condition of purchase. Msg frequency may vary. Msg & data rates may apply. Reply HELP for help and STOP to cancel. See Terms and Conditions & Privacy Policy.