by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Higher price

- Video

- Early talk

- What it is

- Need a shop compressor

- Can a gun be filled from empty?

- No electricity

- The parts

- Can it fill a tank?

- Specs

- Summary

Today we start looking at the new Air Venturi Power Booster 4500 psi unit. I reported seeing a pre-production model of this at the 2017 SHOT Show. That one didn’t have the outer skin on, so this one looks more finished.

Higher price

The anticipated retail price has risen over time. Pyramyd AIR looked at the prototypes and made improvements that made operation easier, but did add to the bottom line. It is what it is, so let’s take a look at that right now.

Video

The best way to see how this unit works is to watch the excellent 6-minute video on the Pyramyd AIR website . You have to scroll down the page for this video. I can’t show you the kind of detail that is in that video, so if possible I suggest you watch it before reading the rest of this report.

Early talk

There has been a lot of discussion about the Power Booster on this blog over the past few days. The thread of that discussion has not been clear, and the conversation has gone something like this.

“Pyramyd AIR has a new compressor.”

“It’s not a compressor; it’s a booster unit like the Shoebox.”

“I like the Shoebox, but it costs too much!”

“You have to buy another compressor to feed into this compressor! That’s another thousand bucks!”

“Speaking of feeding, I’m having lunch.”

“Me too! I’m also having dessert.”

“I like ice cream!”

Okay, there is a lot of excitement and some confusion about this new unit. Let’s start the report by saying what this is and who it’s for.

What it is

This new unit is not a stand-alone air compressor. Air Venturi just brought out their new stand-alone 4500 psi air compressor a few months ago, and we are already looking at that. This is a power booster, which means it takes air that has already been compressed by a common shop air compressor (60 to 90 psi output capable of delivering 5 standard cubic feet per minute {sfcm} of compressed air) and boosting it up to 4500 psi. Booster pumps are not new. They have been around for decades, used in other industries like aviation, to pressurize landing gear struts up to 5,000 psi. Now they are available for airguns, with the Shoebox being the best-known of all.

Need a shop compressor

Here is something that has not been discussed very well. People are getting confused because with the Power Booster you also need to have a shop compressor to feed air into it. If you don’t own a shop compressor already, maybe the Power Booster is not for you. Maybe you need a stand-alone compressor like the one we are now testing from Air Venturi. But many airgun owners do own shop compressors. For them, the Power Booster may well be the best way to go. If you watch the video I’ve linked above you will see a Sumatra filled in under 4 minutes — not from empty, but from where the air pressure was when someone stopped shooting it.

Nobody fills a PCP from empty unless it’s either a new gun or one that has been repaired. We shoot PCPs until they need to be filled again, so there is usually a lot of compressed air in the gun when the fill begins. The time it takes to fill a gun is from where the pressure is when the fill starts until the fill is complete — not from empty.

Can a gun be filled from empty?

Yes, the Power Booster will fill a gun from empty to full. It just takes longer. Some guns may need to be cocked to be filled from empty — the same as if you were using a hand pump.

No electricity

The Power Booster does not run on electricity. All it needs is an input of compressed air at 60 to 90 psi. Please watch the video.

The parts

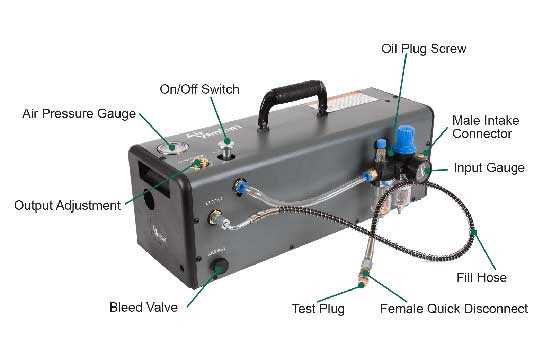

Let’s look at the external parts of the Power Booster.

These are the external parts of the Power Booster.

Can it fill a tank?

This is another big question people have about power boosters. Not just this booster, but all boosters. They have been asking this about the Shoebox compressor for years. Yes, it can fill a tank. But allow me to illustrate with an analogy. Elsewhere in the world, some farmers do not own a car. They hitch their self-propelled cultivators to carts, to take whatever they need wherever they need to go. Using a booster compressor to fill a large carbon fiber air tank is like driving your family on a wagon pulled by a Gravely cultivator. You can do it and it does work, but it will take time to get where you want to go.

Yes, it will get you there, but is it practical?

Specs

The pressure at which the Power Booster shuts off is adjustable from 2000 psi to 4,500 psi. Yes, it does go to 4,500 psi, but only a few airguns get filled that high. The Power Booster comes pre-set to stop at 3,000 psi. If you want to change that, a Allen wrench is provided. The settings marked on the booster are approximate and should be refined by the owner when the booster is used. Then make a mark with an indelible felt-tipped pen to remember the exact setting.

The unit weighs 23 lbs., which is light enough to move easily. Handles are provided for this.

The input end accepts a standard pneumatic quick-disconnect fitting and the output hose ends with a female Foster quick-disconnect fitting. So you need to match the connections on what you are filling to the female Foster. Pyramyd AIR has plenty of adaptors for just that.

Summary

This is just our first look. I bought a shop air compressor so I could test this unit for you. I plan to do just that over the next weeks and months.

BB,

It is great that we now have so many choices for filling all of the new PCPs that have come out. Someone has been listening.

As you have pointed out, it would not have been practical for me to have chosen the Shoebox or this for supplying my air. Before I bought my HM1000X, my Hill pump supplied my needs fine, but with big bore the requirement for air is almost more than these boosters can provide. A day of shooting would require most of it being spent hooked to the booster and filling a 98 CF tank would take many, many hours of run time.

Another issue with the Shoebox is it lacks moisture and particle filtration on the output. This booster does reportedly have such and we hope the wizard will pull back the curtain to show us all of the magic within.

I myself went the route of the AV compressor. It is self contained with cooling and filtration. Being somewhat obsessive I also added an additional air filter to the output. Hey, in for a penny, in for a pound and moisture inside my tank and rifles is now of no concern, most especially in this rather humid region.

I for one am glad this was not available when I bought my AV compressor as it would have just confused the issue and if I had gone with the AV booster I would have had to buy a shop compressor to feed it and still would have had issues with filling a tank. For many others though, this is a superb alternative.

RR

While it does have a moisture catch before the air enters the output hose, my recommendation would still be to get a output filter if you were going to be using the Booster a lot, it’s just the smart thing to do. Especially if you are using an oil lubed compressor.

Tyler

Tyler,

Does Pyramyd AIR have a recommendation for such a filter, or are there plans to sell one?

B.B.

At this point, we do not have a recommendation, but I know there are a few available from other airgun related vendors although I have no experience with any of them. We are looking into offering an output filter now, not sure how long that will take as we want to offer something that is both effective, and affordable.

Tyler@PA

Tyler, what is your business email address?

Bugbuster

BB,

This is the filter I added to the output of my AV Compressor.

http://www.airgunsofarizona.com/pcp-accessories/diablo-dry-air-system/

I would strongly recommend one of these or similar added to the output of this booster or the Shoebox.

PS:

There was an old couple who lived near my wife’s parents who used an old Ford tractor and a trailer with an old school bus seat in it to get around. That was their sole transportation. Around town here many use their riding mowers and a small trailer.

RR,

My ex-boss told me of a family that he remembered when he was a kid that had a car/truck that had the body made entirely of wood. He said that the Dad looked as if he was driving a Rolls Royce and could not be prouder. I would have liked to have seen that creation.

B.B.,

Thanks for the “re-cap” of comments there! 🙂 I would say that is pretty close to accurate. 😉 Short on time here,… but I like it. A good topper pump as you said. Fill a small tank up once and then top it,.. or use direct to the gun.

Of course,… we tinkerers would love to get a peek “under the hood” and have some of the mechanical aspects explained.

I have a Shoebox 8/10 and a 5.5 gal California Air oil-less compressor that cuts on 2-3 times for less than a minute over a 3500 – 4500, 32 minute, Guppy tank fill. Compressor was 178.00 total. So, I will not be in the market for one of these. But I do like it. It is great that we are seeing the PCP world advance so nicely.

Good Day all,…. Chris

B.B.,

First of all, my favorite ice cream is butter pecan in a waffle cone! The simplest pleasures are often among the best pleasures.

B.B., I have a question, if you will bear with me. Since yesterday I’ve been wondering if for an airgunner like me a shop compressor plus booster might be preferable to an all-in-in HPA compressor. But I have severely limited understanding of PCP filling, so if my reasoning is off, please set me straight.

Boosters fill slowly, and therefore, I presume, it is possible to directly fill an air rifle without heat becoming a problem. With a faster compressor, I also presume, it is really better to fill a bottle and then fill the rifle from the bottle with its adjustable output. If taking one’s rig on a hunting trip is not a consideration, it might be nice not to have to buy a bottle in addition to a compressor.

Or am I missing something?

Michael

Michael,

You have a good grasp of the facts. But even large compressors fill slower than tanks, so they can also fill guns directly.

B.B.

Is the sun optic compressor that you saw at the SHOT show a power booster or is it a standalone unit. Is there any more word on it.

glenned,

Welcome to the blog.

The Sun Optics compressor is stand-alone. I have no further word on it.

B.B.

B.B.

I received an answer to my inquiry from Sun Optics concerning their compressor three days ago. Apparently, the first shipment was purchased by Auto Numatic Corporation, aka Airforce, and are due to be shipped on 9/1/17.

Bugbuster

Bugbuster,

Auto Numatic Corp is AirForce, so I should hear about them soon.

Thanks,

B.B.

B.B.,

Off-topic, but your analogy with the “cultivator plus cart equals transportation” reminded me of the story of Tammy hiding George’s car keys, but he got arouns that by driving the lawn mower the ten miles to the tavern.

Necessity is indeed the mother of invention.

Michael

B.B.,

You sure brought back memories. We had a self-propelled cultivator (Tiller we called it). It looked something like the one in the photo, but it only had one wheel (that was in the center). So it had a “kick stand” if you will to hold it up when not in use. It had a cast iron Clinton engine on it. I would hitch up a cart to it and ride it all over the place. Even used it to take out the trash. Thanks again for bringing back memories!

Doc

Doc,

I said “elsewhere in the world” and apparently people in this country do this as much as anyone. Shame on me! 😉

B.B.

B.B.

Anything with a motor that moves itself and can move you too is fun .

Have seen a skate board rigged with a weed eater motor or something like that .

Would GF1 put a big honking chain saw engine on a skate board ? Maybe .

tt

TT

You know me too well.

😉

Doc

I thought that was a cool ride that BB pictured above. I bet that thing would go over some crazy terrain. It would work out real nice out where I’m at now.

Gun Fun,

well sort of. It was ok on flat land, but going up a steep hill or in mud can be a challenge. With all the weight in the “trailer”, aka driver and anything else, the drive wheel(s) didn’t have a lot of weight on them, so traction wasn’t the best. The one B.B. posted about looks to have a counter weight. That would help a lot. Ours didn’t have that, it just had the weight of the little engine on the wheel. It did have the engine mounted a little further than the one above, so they tried to keep weight over the drive wheel. So all by myself it was ok, but more people or any load and it wasn’t good, except on dry level ground.

Doc.

Doc

Yep I seen where the one BB showed was counterweighted out front. And I think it has one of those torque converter drives. If so that will definitely help it go. Plus it looks like they got the forward and rearward balanced pretty well where they sit. Either way. I like it.

Gunfun,

Oh me too! In fact, today’s post caused me to text my dad to see if he still had it. Yes he does, but the cast iron clinton motor is gone. It needs a new motor now. Darn. I have seen stuff like this go for good money on American Pickers. Ours is from the 30’s or so. It had no reverse, just forward. I’m still thinking about putting a motor back on her.

Doc

Gunfun,

maybe I was wrong. I searched the web, looks like it was a 1947 Choir Master. Still very cool

Doc

Gun Fun,

if you look at this video, this is the model to a T. Glass bowl card, funny placement of the gas tank and all. Behind the wheel is a place to hook the implements. That also took a small trailer that we’d ride in. https://www.youtube.com/watch?v=dq6lFayqAnM

Doc

My dad had a air compressor powered by one of those engine’s when I was a kid. I have no idea how old it was.

Ugh, Chore Master…I hate spell check

Doc

Please put something on it. Keep it alive!

It would help a lot to see a video of the booster in action to hear it and see it in operation. Does it require an output filter or is one contained in the unit? It would also be nice to see a photo of it with the cover removed.

Humdinger,

Welcome to the blog.

I linked the report to the web page that has a video doing exactly what you ask. Scroll down the page. The video is on the right side.

B.B.

Unfortunately my 6 gal Porter Cable compressor is only good for 2.6 scfm which means this one

is out for me. To be fair though, a 2.6 scfm compressor is of limited use, can’t drive a paint gun

for example. I just don’t have the space for a larger compressor. From what I’ve been able to

determine, the Shoebox doesn’t have a scfm requirement.

Jayb

Here this is from the Shoebox website.

Home

My Account

My Wishlist

My Cart

Checkout

Log In

Your Language:

Product Sitemap

Category Sitemap

Advanced Search

Orders and Returns

ShoeBox Compressor

Made in USA

0

MENU

FREQUENTLY ASKED QUESTIONS

Q: How much does it cost?

A: Currently the base retail price is 649 dollars. This unit has the mechanical shut off at a preset pressure.

Q: How fast will it fill a tank?

A: The latest F10 will fill a 68 cubic inch paintball tank (12.2 cubic feet) in a little more than an hour to 4500 psi.

Q: I hear it needs another compressor?

A: Yes, it needs compressed air input from an oil-free shop air compressor for maximum fill rate and to shut off at the designated pressure. The F10 needs 125 psi and the MAX needs 85 psi.

Q: What shop compressor can I use?

A: Almost ANY oil-free shop compressor that puts out at least 85 psi at 2 CFM or more will work fine. The Shoebox takes very little air and a shop compressor will only kick on a few times. Small shop air compressors are so cheap it didn’t make sense to try and build one into the ShoeBox. You should get one large enough so it will not run all the time.

BB, is there any kind of rule of thumb law that would you could relate HP of shop compressor to using this device.

In other words what would be the minimum HP of a shop compressor to be useful for this device. I have a 2 1/2

shop compressor , but have no idea of cfs output.

Thanks

Harvey

Harvey

There should be a data plate somewhere on your shop compressor. Of course if it didn’t come off or is all scratched up.

If anything see if you can find the serial or model number and what brand it is. If you search that info you should be able to come up with your compressor’s specks.

GF1

I got my replacement valve (ordered 2 actually) yesterday, installed it and fired 5 clips, refilled and fire 1 1/2 more and all the air blew out of the gun. Took the gun apart to have a look and didn’t find anything so I put it back together and tried to pump it up. To my surprise it pumped to 2000 and held. I shot 1 1/2 clips and all the air blew out again. Took it apart ,put it back together, fired most of one clip and she leaked out again. Don’t know what’s going on here. Any ideas?

Halfstep

Yep I believe I do after I was messing with mine taking it apart trying that return spring pressure and fill pressure I found something out with the leak down. Hopefully I can explain it right. Here it goes.

The main thing was the alignment of that 1/8″ brass L shaped air tube that goes from the air resivoir main tube up to the valve like you got. You know how the front half of the valve is black and has them plastic tabs molded into one side of it and they locate in the left side of the receiver. That peice can rotate on the valve body it’s attached to. If you rotate it will make the back aluminum part of the valve position that spot that brass tube goes in differently. It doesn’t affect the o-ring seal at that place where that tube goes in. But it will affect the angle the tube enters the seal in the spot in the air resivoir tube. So if that angle is off it will put pressure more on one side of the seal than the other down at the air resivoir. There’s room for error. But not much.

And here is why I think it happens when the gun is shot. If you notice when the gun fires the hammer striking the valve does bump the valve forward towards the clip when the magazine is in the gun. So you can feel the magazine bump forward if you have your hand on it when it shoots. But even with the mag and clip out of the gun you can look in the opening where the mag goes and fire the gun and see the front of the valve pump forward towards the barrel.

So I think if the valve body rotation isn’t exactly right it makes that tube not seal right. I think the loss of air that we hear is actually just blowing out any kind of way of the receiver half’s. I think it’s heard from where the mag goes is because that opening probably transfers and amplify’s the sound.

And I have a little trick to help seal those places on each end of the tube. And if I did this on a o-ring inside say the air resivoir I would put a very light coat on the o-ring. Just enough to see the surface of the o-ring shine or change to the grey color of the sealer.

It’s called Loctite PST 592 thread sealant. It is kind of like a very thick grease. And it don’t get hard. We use it at work in different places. But what I did was put some around both ends of the outside of the brass tube. Making sure I didn’t get it inside the tube. Then I took that swivel peice off the valve where the tube goes in. Took the small o-ring and small metal flat washer out. I lightly rubbed some of the sealer on those peices then reassembled the gun.

Haven’t had any leak down problems since doing that. Remember I have mine set for a lower fill pressure of 1400 psi. But I have filled it to 2000 and let it set overnight and also fired the gun and no leak down.

But remember be light on the sealer on the o-rings. A little heavier on the sealer around the outside of the brass tube and make sure alignment of the tube to the valve and resivoir sets naturally in place in the left half of the receiver. Oh and I had the barrel out, the trigger and spring and hammer stuff all out. Only had the brass tube the valve and the air resivoir setting in the left half of the receiver when I was getting that alignment right. Then I put everything else in and assembled.

Hope I didn’t make this too long or confusing.

GF1,

Thanks for the feedback and taking the time to send such a long reply. I follow everything you said and you couldn’t have said it in fewer words.

You presented this misalignment issue before( using the sealant was new info and I will add it to my bag of tricks) I did move that black plastic piece (part 14 detent body) around some because you warned me about it, but that was just wishful thinking on my part. I know for a fact that the air is coming through the valve seat. I have installed the valve and tube into the left half of the receiver and used wire ties to anchor everything in place, then tried to pump air into it and it comes out of the detent. This told me the valve assembly was leaking but not what part of the assembly had failed. Air can leak from the valve-to-puck junction or from around the Oring that the valve stem passes through.(the oring I’m talking about is in the bottom of the valve body and has a washer and spring sitting on it. Part 7g).

When the hammer unseats the valve, air is allowed to pass through the valve’s hollow stem and out into the detent housing and through the detent (part 13) and against the pellet skirt,etc. I took the detent out of the body and installed the valve and detent body ( needed it to keep everything aligned as you pointed out) back into the receiver . Then I used a small length of a bamboo skewer to plug up the hole in the valve stem and the leak stopped ,so that is why I’m confident that the valve and puck seat is leaking. That’s the only way for air to pass out the end of the valve stem. If it had continued to leak with the plug in place that would have meant that the O ring around the valve stem was leaking.

I guess my next move will be to try the second valve that I bought. Do you know what Crosman’s return policy is on parts?

Halfstep

Have no idea on Crosmans return policy.

And sound’s like you got the leak pin pointed.

But I still don’t understand why you keep having the same type of leak down problem. Not trying to be silly about it. But seriously baffling that you had multiple guns and tryed different valves even and the problem keeps happening.

Halfstep

Forgot if your filling from a hand pump or what. But maybe the gauge on your fill device is wrong. Maybe your over filling the gun and the seals or spring that’s in the valve can’t take it.

Halfstep

Another thought.

Maybe there is contaminants that are inside the air resivoir that never got cleaned out before assembly and making it to the valve. But again you had multiple guns. ???

Or maybe 2000 psi is just to much for that type of valve design. That’s what seems to be in my mind the most.

Halfstep,

I feel for ya. That has to be very frustrating,.. and then some. I wish you the best with it. At least you are getting some good “inside” experience. That is always a plus and builds confidence on future endeavor’s.

Chris U

Not speaking for Halfstep. But it is a pain in the butt taking them back apart and trying to figure out where the problem is coming from.

And what complicates things is the gun has to be degassed. So you have no air pressure in the gun to find the leak when the gun is apart and opened up. You have to look in places for different kind of wear marks. Or basically on seals and o-rings where the pressure point contact areas are.

Oh and you know how it was when you took your pistol apart. Well add barrel placement as well as the air resivoir tube along with the trigger componants. The Wildfire along with the 1077 design makes you have to know what’s going on when you take apart and reassemble.

I’m betting Crosman has some type of QS9000 work instructions or something similar documented for assembly of them they use.

GF1,

As you know,.. there are things that can be slapped together and other things that require careful attention to detail at certain steps. Often in the same item.

I do not know what they use for assembly procedures,.. but it appears to need a bit of a “tweak”.

And, as always too,.. there is the human factor and who has a quality/detail oriented attitude for their work and those that are just there for a paycheck.

Chris U

True that.

Chris USA,

I’m gettin’ so much “inside experience” that I’m ready to blow my brains out if I could get the damned thing to hold air long enough !! 🙁

Harvey,

It doesn’t work like that, though your compressor is more powerful than mine, and mine’s good enough.

B.B.