by B.B. Pelletier

A new reader named Carl prompted today’s post. He owns a Daisy 22X and has some questions about oiling the seals. That resulted in this question:

You mention that you should keep your seals oiled. Where are these seals located?

I’ll do multi-pump pneumatics today and if there is interest, I’ll do the other types of airgun powerplants later.

Starting with the pump head

Think of a multi-pump gun as a progression of events. First, you pump air into the gun’s reservoir. That takes a pump head that can seal air against loss as it compresses it into a small space. The pump head is a pliable material that fits the inside of the pump tube tightly enough to compress air but loosely enough to move easily. The pump head usually swells from increasing air pressure. In some guns, there’s an O-ring, like a piston ring, around the head very near the end. Oil on the contacting surfaces of either the O-ring or end of the pump head seals the air in front of the head, just as oil in your car engine helps the piston rings seal the explosive gasses of combustion.

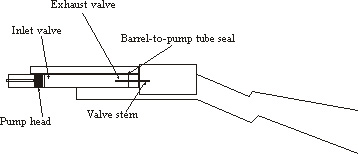

This rough diagram shows the relative locations of the seals in a multi-pump.

The inlet valve

As the pump head compresses air, the inlet valve in the end of the reservoir is forced open by air pressure. Air passes into the reservoir, which in most multi-pumps is nothing more than empty space inside the valve body. It doesn’t take much air to drive a pellet! When the pump stroke is complete, the inlet valve’s return spring closes the valve. As the reservoir pressure increases, more pressure is needed to open the inlet valve, so the pump head travels farther before the inlet valve opens. You feel the increased pressure as feedback in the pump stroke.

The exhaust valve

Air remains in the reservoir/valve until released through the exhaust valve. Typically, a spring-driven weight called a hammer knocks the exhaust valve off its seat, releasing the air. The released air flows through the same tunnel the valve stem operates in, but a hole in the side of this tunnel lets the air escape up to the barrel, where it gets behind the pellet. The bolt that loaded the pellet has an O-ring seal on it, so the only way the air can escape is to push the pellet out of the way.

Pump tube to barrel seal

This just keeps the air sealed inside the tunnel so it has to push the pellet out of the way.

Oiling all the seals

When you oil the pump head, oil migrates through the gun with the compressed air. By oiling this one spot, you are oiling the entire airgun.

How hard is it to reseal a co2 gun? Could Joe Sixpack do it himself if he’s reasonably adept?

Denny,

Resealing a CO2 gun isn’t hard if you have the parts, but getting them is very hard.

Most repair stations make some of the parts they use. Sometimes a manufacturer like Crosman will help with current models, but nobody helps with older guns.

B.B.

I have a Daisy 990 and was told it had 14 seals.

I was told this gun was worth some money but have not been able to find anyone to buy it. Can you tell me anything about the 990 is it worth keeping or should I sell them? Where can I sell them?

thanks

My Legacy 1000 just arrived I think it is really nice gun in .22,it doesn’t look like or feel like an air rifle eather.

Ya I would like to boost the guns velocity(although it is already a magnum break barrel)even though it is well powerfull enough for hunting,it is nice to upgrade velocity on a nice gun like this.

Daisy 990,

Here is a schematic page

http://www.cpsc.gov/library/foia/foia00/compliance/dais9902.pdf

As far as having value, I haven’t heard anything. I see them at airgun shows for $35.

B.B.

Jed,

If Jim Maccari will work on a Legacy I suppose he could do something for you. It might run $100 to 150, or so.

You might try John Groenewold for a replacement mainspring or a tighter piston seal, and I guess you could shim the inside of the piston with stainless steel shim stock.

Increasing the preload of the spring with spacers might also help. And a tighter spring guide will smooth out the action.

B.B.

Hey Jed,

Congrats on your new purchase!! Would sure appreciate an update on the accuracy of the .22 Legacy once you get her dialed in. How do you think the accuracy compares with BB’s experience with the .177?

Any other observations, hold techniques, scope mounting recommendations, etc, are also welcome!

Are you thinking about the Bug Buster 6x? I am giving this scope some consideration. PyramydAir’s recommended mounts are either B-Square on a base or Reapers non-adjustable 2-piece mounts. I think I might prefer 2-piece adjustable mounts personally, but they may not be necessary or justify the expense. Thoughts?

I’m also assuming that a stop pin will be a must with this springer….

Anyone care to share their experience/opinion on mounts for the .22 Legacy/Bug Buster?

Many thanks,

Will

Let me see if I undertand, In a benjamin it means putting oil where it says “air intake not oil” (or something like that)?

No, that would not be wise. In a DAISY, it means putting oil where the DAISY says “oil here.”

The Benjamin is lubricated in an entirely different way, depending on the model.

B.B.

Speaking of oiling, what is the proper way to oil the combustion chamber of a springer?

I know not to over oil and to use ony a drop of proper oil. However, when I have waited until the cocking stroke squeaks, put a drop of oil down the transfer port, left the gun upright for a night, and then repeatedly partially cocked before firing — I get a dieseling shot. I don’t like even one shot that diesels. What am I doing wrong?

You aren’t doing anything wrong, but here is a tip. If your gun allows de-cocking, try cocking and uncocking the gun several times after is has been upright all night. This spreads the oil around the piston walls of the compression chamber.

I like to hold the gun horizontally in four 90 degree rotations around the axis of the barrel. That helps spread the oil everywhere.

I have found this trick will cut down on first-shot dieseling.

B.B.

Well I tried the Legacy firing at 20 yds,accuracy is very good.I hadn’t ajusted sights yet and shot without a scope or much concentration but I got good accuracy half 0.50 to 1.00 inch group.

B.B I would like to ask a question.Did your Legacy puff out smoke and give good kickback when you shot it?Because mine did,I never shot a .22 firearm with this much kickback,though what I am wondering most is the smoke cloud puff after shooting it,this gun really makes you forget your shooting an airgun,that is what I like about it.

You wrote: “I’ll do multi-pump pneumatics today and if there is interest, I’ll do the other types of airgun powerplants later.”

please do, I would greatly appreciate it! Thank you.

Jed,

The smoke is from dieseling. Yes, mine did it, too. Most new spring guns diesel.

The recoil is from the spring and it doesn’t go away. Don’t hold the rifle tightly when you shoot. Let it recoil as much as ity can for best accuracy.

B.B.

Totally off topic;

I am trying to replace the stock on my Gamo CF-X and so far have not found an exploded view of it, so am forced to guess. Anybody know how the front is attatched to the barreled action/chamber/cocking mechanism?

Or maybe where I can find an exploded view if CF-X?

dsw

Ya didn’t have a problem with the recoil in fact I like that it has more recoil.Good to know thats all that was causing the smoke.I definately paid little for a rife this nice.I like the .22 version real good.

I shot Beeman eatra heavy Kodiac pellets(22 grain) in the Legacy .22,the gun definately has the power to use them,they did just fine with accuracy and power.

Whoops that was a mistake,somehow I got a double post there.

B.B.

Thanks for the tip on oiling the chamber! I’ll try it the next time I oil. One of my guns will need oiling before too long. 🙂

OK, it’s a no brainer!

Remove “grips” to reveal forestock screws to seperate forestock from CFX!

dsw

is it really true gamo is doing away with their line of .22cal rifles if so why?

That is stupid of them.If I buy an airgun that is medium or high end and it’s available in .22.I certainly will buy it in .22 not seventeen caliber!I don’t like that caliber .177 is too small,once you get larger calibers you never want a .177 rifle again.At least thats how it is for me.

Gamo and .22,

I covered this some time back. Gamo sells by the truckload to Wal Mart and the other big box stores. They are not interested in adult airgunning unless there are thousands of adults clamoring for something. In this case, there aren’t.

This is a numbers game for them, and .177 is winning the race. One reason for that is the American communities that have demonized .22 caliber by making it illegal. So Wal Mart won’t buy them and Gamo isn’t interested in selling to anyone else.

B.B.

I am going to dust off my late 80s/early 90s RWS Model 34. I haven’t shot it in over a decade. I am going to clean and oil it. I have the RWS shooters cleaning kit. I am not sure if I should both oil the main spring and the chamber. On the RWS site it says you can use a drop or two in the chamber or ALTERNATIVELY just oil the mainspring. So, what would you recommend? Also, to do the chamber…where would I want to use the needle/oil…where is the ‘compression chamber port?

Thanks!

BB,

Thanks a lot for your post. I was thinking that to oil the seals of my Daisy 22X, that I’d have to take the gun apart. It’s nice to know that oiling the one spot will do the trick for the whole gun:)

Thanks again,

Carl

I have a crosman model 140 .22 cal and need seals, mainly the seal from the air tube to the barrel. Know where i can get these?