by Tom Gaylord

Yesterday, we saw what kind of performance to expect from an inexpensive Chinese airgun. The velocity was just over half the advertised speed, and accuracy was out the window. Let’s see what can be done to correct these problems. You’ll have to decide whether or not it’s worth the effort.

One of my most vocal readers was a man by the name of Ray Apelles. He and his father, Hans, had modified several Chinese spring rifles with varying degrees of luck, but he strongly recommended that I test and tune one for The Airgun Letter. He said he would even provide the tuneup guidelines. As it turned out, Ray actually wrote most of the report.

What’s inside?

Upon disassembling the gun, I was pleased to find that the piston seal was leather. Leather is much more adaptable and forgiving for the home tuner, as long as you aren’t going for magnum power. The TS45 could never achieve that power level with its narrow piston bore and short stroke, so a leather seal was most welcome.

I also found all the metal parts to be durable and properly hard. They did suffer from too many burrs and rough edges, but several hours of careful stoning took care of that. Ray had me sleeve the transfer port to reduce its diameter. That improved the airflow pattern and kept the piston from slamming into the end of the compression chamber

A brass tube has been swaged into the walls of the air transfer port. It reduces the inside diameter from 0.141″ to 0.125″.

New piston seal

Ray had me make a new leather seal for the rifle. Since I had written an article about how to make leather piston seals of any size, I just followed my own instructions and made a tight one. I lubricated the compression chamber with moly grease (Beeman M-2-M), soaked the leather piston seal in petroleum oil and put the gun together. Velocity with H&N Finale Match pellets went from 460f.p.s. to 580 f.p.s. from doing just these minimal things, plus removing all the burrs in the action. Accuracy remained poor, of course.

New mainspring

Next, I installed a Maccari mainspring and lubricated it with Beeman Mainspring Dampening Compound. Today, I’d use Maccari’s Velocity Tar (it wasn’t available in 1996). Velocity increased with the same H&N pellet to 666 f.p.s. The firing behavior was now very calm and free from vibration.

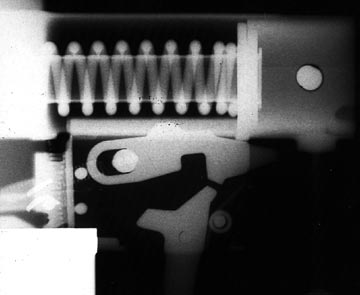

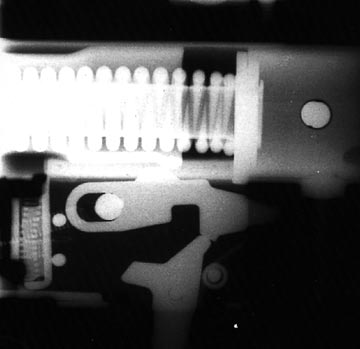

X-ray vision

Ray works in the radiology department of a hospital, so he took some X-rays of the trigger parts both cocked and uncocked. They show a different picture than most shooters conceive their trigger looks like, so I included them here.

This is what the trigger looks like when the gun is not cocked.

Here’s the trigger when cocked.

I did lube the trigger parts with moly. That resulted in a crisp, positive 26-oz. pull. No stoning was done because Ray warned not to do it. As you can see in the X-rays, the trigger doesn’t function like you might think.

New barrel

Finally, I shipped the action to Dennis Quackenbush, who installed a Lothar Walther barrel for me. He was kind enough to polish and blue the barrel and action before returning it, so it looked more like a European gun afterwards (except for the stock). Accuracy went from 2″ at 10 meters down to under 1/4″. And, this barrel was cut off, so it wasn’t even choked. Who knows how much better it might have been?

What did I gain from all this work? I took a $30-40 Chinese sidelever, spent about $150 plus 12-15 hours of time and got the performance of a CZ 630 that I could buy for $80 at that time. Was it worth it? No – if the goal was to get a good rifle cheap. Yes, if the goal was to play around inside a rifle I wouldn’t be afraid to damage. After it was all over, I still had the same opinion of cheap Chinese air rifles, but now I had added some hands-on experience.

You spent $150 and 2 days labor to get $80 worth of performance???

That’s the story of my life!

It seems that Chinese barrels (especially Shanghai) are very much hit-ot-miss… get a good one, and you can make it into a nice shooter with a little massaging. Git a bad one, and ferget it!

I seem to have gotted a bad one on my recently purchased AR1000 (TF89/SS1000). I’m gonna try fixing it by boring it out and fitting a 1077 barrel as a liner.

You mentioned an article on making leather seals.

Might you be able to direct me to where I could find that article?

Thanks

Rob3dr

You have found the fun part of the lower end Chinese guns, take them apart and learn what can be done.

i had a few questions on the 392 peep sight.

1. does it mount on the barrel or reciever

2. do i need to take off the back sight to use it

3. is it even possible to take off the rear sight

4.how much will it improve my accuracy

thanks

Hi Tom,

I read some of your recent reviews of the Contender series and they were all favourable. Could it be possible that you were given some select samples or it’s the result of a “great leap forward” of a manufacturer? I am tempted to give them a try but still a little worried that it’s still a luck of the draw. Thanks.

I to would very much like to read your article on making leather seals, is it available online? BTW thanks for all the great info!

JEFA

Leather seals,

I will ask B.B. for another time slot for thi article.

DKY,

It is possible I got set-up guns, except half of them were drop-shipped from a different source. It’s hard to stop the cherry-picking that goes on, but I BELIEVE THESE WERE GENUINE OUT-OF-THE-BOX GUNS.

However, anything Chinese is still a lottery.

Tom

Tom,

Rather than taking volume out of the transfer port, how about removing the cone shaped seal from the sliding compression chamber, cutting the seal’s cone shaped seat deeper while preserving the angle, and installing the new barrel DEEPER so that the skirt of the pellet pokes into the compression chamber? Cut out the parallel part of the transfer port and set the barrel back into it.

OK, this is the guy who posted the last comment. I did not realize I was looking at the muzzle end of the compression chamber in the picture. I guess it’s not a flat seal seated in a cone cut into the metal but a cylindrical cutout, with a seal which is a cylinder on the outside and a cone on the inside. However, I still feel you could make a cone shaped cut TO THE SEAL so as to allow the barrel to be set back. The lower sealing area would probabaly be more than made up for with higher sealing pressure.

Say, Tom, how was the barrel attached to the receiver? Pressed, threaded, or pinned?

392 peep sighty,

The receiver, leave the rear sight on, it is possible to remove the rear sight but difficult and about 50 percent.

B.B.

The barrel is pressed on

B.B.

Did the leather piston seal article ever surface?

I am about to repair a couple of old springers, (one chinese, and one spanish) – I know one needs a new piston seal.. I’d liek to know what I’m doing since parts are impossible to buy locally.

Thanks,

Dyb

Here’s an option 2, use a rubber breach seal instead of leather. I got an increase of 40-50 fps.

For the Chinese B3-2, the underlever .177, use a 1/4 beveled washer, with a 9/16″ OD, found in the plumbing section of Home Depot, 10 washers for under $2.00.

Dyb,

No, I haven’t done the leather piston seal post yet, but I will schedule it soon, just for you. Be sure to read the current posts.

B.B.

The article appears at /blog/2007/12/how-to-make-a-leather-piston-seal/

and a very big THANK YOU for writing it!!!

Dyb, aka Des