This report covers:

- My cane history

- Making air canes

- Sealing air canes

- Shooting air canes

- All kinds of canes

- Fascinating hobby

Sorry everyone. This is Monday’s post. WordPress got me again. I did schedule it correctly, but since it is up I will leave it up. Let’s get started

There has recently been a lot of discussion and interest in air canes on this blog. We have even heard tales of them showing up in Sherlock Holmes novels. So today I thought I would present what I know about them.

Here is what reader Hank said last week:

“RR,

As a teenager I had a chance to checkout a couple of air-canes.

A friend’s father had a collection of air-canes and sword-canes. I got to repair one that was around .45 caliber that needed a new leather piston seal. Took a lot of pumps to charge the thing and the muzzle blast was LOUD.

Those things were powerful! Didn’t see it happen but saw the damage after his father tested the air-cane by shooting it into the fireplace. The shot blew all the ashes into the room and turned several firebricks into gravel.

Would love to have one of those old air-canes, I’ve often thought of making one.”

Hank

Now, I think Hank repaired the cane’s pump and not the cane itself. The pump would certainly be sealed with leather, but I’ve never seen a cane that was sealed with it.

My cane history

I have owned two air canes in the past. Both were similar, but only one had a rifled barrel insert.

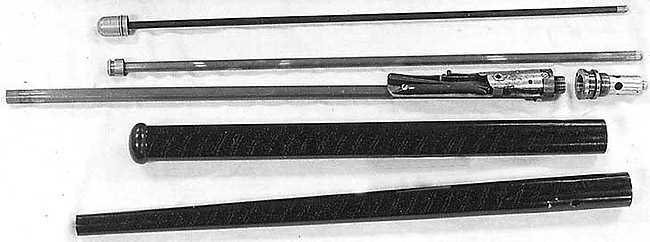

This is my last air cane. I have disassembled it to show all the parts. At the top is the ramrod that also has the cane’s brass tip for when it’s used as a cane. I screws onto the end of the cane. Below that is a rifled barrel that screws into the smoothbore barrel. Below that is the smoothbore barrel that’s attached to the cane’s firing lock. Just to the right of the lock is the cane’s valve that screws into the large black section just below. That is the air reservoir that fills through the valve when a hand pump is attached. At the bottom is the lower part of the cane that the lock and barrel slides into to conceal it. There is a small hole in this part just forward of the join line where the trigger, which is a black button, pops out when the action is cocked.

Here you see the air cane’s cocking socket on the right. A square-shaped clock key is inserted and turned to cock the lock. I have cocked the lock for this photo and the firing button (the trigger) has popped out on the cane’s body at the lower left.

The cane shown in these two pictures wasn’t sealed when I had it, but I did have an earlier cane that had a smoothbore barrel and was in firing condition. No doubt it had a rifled barrel when it was initially purchased around 1900-1920, but that part was not with the cane when I acquired it.

Making air canes

Pneumatic canes were produced by some large makers, who used their own workers plus the collective output of many cottage industries. For example, things like leaf springs were a specialized item and you didn’t make them, you bought them. The cane makers brought all the parts together in a design that did not vary over many years. Hence, there are common types of canes, yet each cane is also a unique, handmade object.

A lockmaker fashioned the lock to fit inside the housing used by his principal customer, the cane maker. And that is all he did. He was motivated to work within the envelope of his customer’s design, so to speak. And he probably bought his leaf springs from a different maker.

A barrelmaker probably knew very little about making a reservoir or a valve, but he probably made barrels for everyone in the trade. Only at the cane-making house, whose name sometimes graces the lock, did all the components come together.

The straight cane shown at the beginning of this report is by far the most commonly encountered style. It could be purchased as a smoothbore alone, a smoothbore with a rifled insert barrel or with all the tools and the necessary hand pump, cased together in an attractive display box. Sometimes there was an additional reservoir shaped like a shotgun butt, so the cane could be converted to a more sporting use.

Sealing air canes

Many air canes date back to the 19th century and even back to the early part of that century. That was a time before there were modern synthetics to seal the pneumatic valves. What they used was what had been used to seal airgun valves for many centuries before that — the horn of a ram. A skilled craftsman would carefully cut a section of ram’s horn to fit the recess where the seal was needed, then he lapped it in place with a tool and with rotating pressure, using chalk for the lubricant. When the seal started squealing like a vixen fox in heat, the seal was perfect. Such a seal could hold a charge of air for many hours or even for days.

Shooting air canes

Many air cane owners shoot their guns regularly. I used to shoot mine a lot. As I just mentioned, the original air valve had been sealed with a piece of animal horn, lapped into an airtight seal by turning it against the valve seat under pressure. Common chalk and oil were used as a cutting and lapping compound, and the valve maker knew when to stop by the squealing sound made when the seal was perfect.

But perfect is a relative term. That animal horn was porous and did leak over time. So a lubricant like whale oil was applied to the horn seal, to enhance its airtight nature. That is the purpose of the small oil bottle often seen with cased specimens.

When a cane is prepared for use today a modern Delrin valve face is substituted for the animal horn valve face, but all the other original parts are retained. Delrin is non-permeable, so the whale oil is no longer needed to seal the cane.

The operating pressure of an antique cane is in the 500 to 650 psi region, so the modern owner can either fill it with air to that pressure level or substitute CO2 gas in its place. Because CO2 operates at around 850 psi at 70 degrees F, the cane’s reservoir should be hydrostatically tested before filling.

Once the cane’s reservoir is filled, you will get no less than 10 and often as many as 20 powerful shots before a refill is required — that is if you use CO2. In my experience you get shots that are more powerful when you fill with air than with CO2, but there are fewer shots per fill. With either gas the final few shots will be so weak that they’re not worth the effort. However, each cane is unique and requires the shooter to learn its characteristics.

The smoothbore barrel of a typical straight cane will accept an unpatched round ball of about .433 caliber. That’s what caliber my shooter was. A greased or oiled patch does not improve accuracy nor velocity, as long as the ball fits the bore reasonably well when dry.

The rifled barrel that’s inserted was smaller. I remember that mine was around .30 to .32 caliber.

Back to loading the smoothbore. The ball is rammed to the bottom of the barrel. Then the lock is cocked, causing the button trigger to pop out of the cane’s side. On every cane I have examined, this button has been positioned for release by thumb pressure of the left hand (for a right-handed shooter).

David Yost shoots my air cane that I bought from him at the St. Louis airgun show around 1997.

The top knob of the cane is held to the tip of the shooter’s nose so the tiny open sights (yes, these canes do have tiny open sights) can be seen. Once the sight picture is right, the button trigger is pressed and the cane fires with a loud, deep bellow. You feel a rocket-like push from the recoil that is approximately equal to a .32 S&W Long cartridge fired in a medium-weight revolver.

I’ve shot several smoothbore canes that were accurate enough to hit a soda can every time at 20 yards, so there is an element of close-range marksmanship to them. When a 121-grain .43-caliber lead ball connects with a full soda can at 600 f.p.s., everyone in the vicinity knows it!

All kinds of canes

I used to see all sorts of air canes at airgun shows in the 1990s. There were exquisite cased canes that came with their original hand pump and the tools to cast balls to shoot. Outfits like this cost $2,500 and up in the days when gasoline cost $1.16 per gallon. BB didn’t have that kind of money, so it was all looky and no touchy.

But a working basic cane could be purchased for $400-450 in those days. That’s what BB could afford, so that is what he bought.

I also saw unique canes that looked like real walking sticks. One of the common yet unique styles was the bent cane. It was one level of sophistication above the straight cane. Its steel reservoir is curved gracefully to showcase the maker’s skill. Bent canes were often sold as cased sets, and sometimes they also came with an additional shotgun-style reservoir butt to replace the bent reservoir when the owner wished to shoot it for sport. It wasn’t a very practical sporter with the button trigger, but no one seemed to care.

A bent cane is similar to a straight one, but demonstrates the cane maker’s skill at bending a steel reservoir this gracefully.

Then there are the shillelagh canes. Their outsides have knobs that are just like those found on blackthorn sticks and one of them that I saw was actually housed inside a real blackthorn! I have seen a couple of them at airgun shows, but the most unique one I ever saw had a ball flask where the cudgel was.

Where traditional shillelagh air canes are built with spots of spot-welded steel or brazed brass to simulate the knobs of an Irish blackthorn branch, this particular cane was housed within a genuine blackthorn outer sheath! The wood was carefully hollowed out to accept the cane’s action and barrel, a difficult feat in the days before Dremel tools! The brass air reservoir is fashioned to look exactly like a genuine blackthorn root cudgel that might be found on a real shillelagh fighting stick.

This rare shillelagh air cane is housed inside a genuine blackthorn stick! The cudgel is a ball reservoir.

The cudgel/reservoir has been removed to show the inner workings. The small pin in the center of the cane (on the right) is powered by the mainspring to hit the large steel button in the center of the reservoir on the left. That larger button is actually the firing valve’s stem.

Fascinating hobby

Air canes are a strange, yet fascinating niche within airgunning. They are the pneumatic equivalent of a primitive flintlock rifle. Their owners travel life in the slow lane with the windows rolled down, enjoying airguns that almost defy classification.

BB,

Sometimes they do not post, sometimes they post early. A preview of Monday i suspect.

Mike

Well, I suspect that you’re correct about the post being a preview for Monday. Hey . . . maybe BB’s giving a freebie? Anyway, he caught us looking and hoping. Orv

BB,

WordPress is really unpredictable!

Monday on a Saturday again!

Siraniko

This is Monday’s post. WordPress got me again.

I will leave it up.

BB

BB-

Well, you did your job. Take Monday off. Definitely a peek into workmanship of a bygone era.

Errata- section- ‘All Kinds of Canes’, first para, third sentence-

‘Outfits like this cast (cost)……’

Yep, Monday should be a BB holiday. All in favor, raise your muzzle (or other appropriate gun related)….

Paco,

Thanks for thinking that Monday should be a holiday for BB, but if it were there would be no Tuesday blog.

Today — Saturday — is BB’s holiday. He gets to race his Pinewood Derby car at church. 🙂

BB

BB

Let us know how the Pinewood Derby goes.

GF1,

I won one race and finished second in three others.

BB

Congratulations!

BB

Nice.

How did Denny do?

How many cars was there?

GF1,

Denny did better than me. When I finished second he was the one who beat me.

BB

BB

Ok. That’s what use to happen when me and my buddy raced rc planes. One of us on each race would at least be in the top 3 places.

Cool. The main thing is that you had fun.

Don’t work too hard. Work is for people who do not know how to fish, or shoot airguns. Going to discipline meself and wait until Monday to read this, otherwise won’t have interesting material to help stimulate the brain into wakefulness.

BB,

There is a very good book on these type of canes in general with a chapter on canes à air.

Les Cannes à système : Un monde fabuleux et méconnu (The canes with a a technical inside: a great and unknown world)

I do not know of an english translation.

Regards,

August

120 grain ball at 600 fps is serious. More untapped potential is still waiting. Could the next Discovery be in the making?

Deck

Deck

Yes it is. My. 50 caliber Wingshot ll will shoot these round balls at 675fps and will go through 2 hard pressed particle board and each is about 1-1/4 inches thick from a old counter top at 50 yards

/product/air-venturi-50-cal-177-grains-round-ball-100ct?p=1049

These slugs will go through one and almost through the second board. On occasion acouple will pass through both. It’s shooting them a little above 600fps.

/product/air-venturi-50-cal-210-grains-balle-blondeau-flat-head-50ct?p=1015

GF1

Serious indeed, even for home defense if it was all you had. Especially the balle blondeau 210 grain flat head.

I think you are having fun with your Wingshot. Are darts next?

Deck

Deck

You never know about the darts but probably not. Don’t want to shoot any steel through the barrel. But definitely having fun with the #6 and #8 shot shells.

B.B. and Readership,

For B.B.: Checkered Flag or BUST!

Yesterday’s (or was that Friday’s) discussion about Chokes and Crowns got me digging into some R&D files that also apply to the old air canes as well as Decksniper’s wish for a modern build.

First off is this linked file on what is Honing: https://www.sunnen.com/Resources/EducationalInformation?gclid=CjwKCAiAsYyRBhACEiwAkJFKos3GMujePXXr841tDFuwMm1WYKFgBqGR8VdoSB-jTtV-BHlbKQqYIhoCS4cQAvD_BwE

I found it interesting and informative. But then how do you know if you are done Honing…yes you can push a pellet through the bore, like Gunfun1, or you can push a tight fitting patched Jag through like B.B. but what exactly are they feeling? You can also use an Airgage or one of these other types: https://www.sunnen.com/Catalog/Gages You will not need to ruin numerous Ram Horns (or DELRIN® disks) learning exactly what “…started squealing like a vixen fox in heat…” sounds like.

The other educational material may be of interest to some of you and is very applicable to this hobby (ADDICTION) of ours.

Gunfun1 I think SUNNEN isn’t far from you.

shootski

PS: I’ll bet TCFKAC and SIG has something like this: https://www.sunnen.com/Applications/FirearmsDefense

We’ve got five Sunnen hones on the shop floor–vertical and horizontal. A good operator can hold sizes to 0.0001″–or tighter. Surface finish is typically exceptional.

Shootski

Yep Sunnen is about 20 miles from me. I pass by the road its on every night going to work. I wanted to get a job there when I was a kid building the old muscle cars to drag race. Got the machine shop job I have now for 39 years and never looked into it anymore.

But we have a old horizontal Sunnen hone like this we use all the time for honing out bushings and such when rebuilding machines and other things to do that come up. Only ours has a foot pedal coming out the bottom that you press down to make the honing bar take more or less material off. And it’s also used with various pressure to polish or cross hatch a bore. I have cleaned up pcp air gun air tubes like what the Marauder’s and Discovery’s use and old brake cylinders. Great little machines. And I never thought that Sunenn was honing gun barrels. Pretty cool stuff.

Gunfun1,

Love it! I’ll even bet the electric motor has Felt lined oiling tubes with spring loaded caps or maybe grease cups with screw down plugs! Oh, and replaceable commuter brushes.

shootski

Shootski

At some point in time the motor got replaced with a newer motor that is 3 phase (240 or 480 volt) ours runs on 240 and it has zerk fittings to grease the bearings.

But we do have some electric pumps at work that still have the replaceable brushes.

Now you’re playing my tune. I spent most of my career in the electric motor business…from 3.3″ diameter stuff all the way to 15,000 HP.

Motorman

St. Louis, MO

B.B.,

I love reports like this; they are an awesome look back at a really cool period in airgun history!

Thank you. 🙂

Take care, enjoy your weekend, & have a nice Monday off,

dave

when you pick up that weapon to fire it would it be called raising cane?

Mildot52

🙂

Glad to see FM is not the only one affected by the PJ (Pun Jab) Recessive Gene; there are a couple ones in there. 😉

Would love to raise cane with this guy…

FM

Sorry my friend but I can’t comment on your target you posted here without Gunfun1 probably getting into trouble.

But as it goes time will tell. Pray’n for all those in the Ukraine and every were else that thier invasion has caused problems.

God help him when the time does come. That’s the best I can say right now.

Thanks to you and WordPress for this early post BB! Did confuse me though, being retired I often lose track of what day it is and had to check a calendar LOL!

“squealing like a vixen fox in heat” …yeah, know that sound. I live on 10 acres in a rural area. It’s that time of year for the resident foxes.

Yes, it was the pump I repaired – sorry I wasn’t too clear in my post.

My friends father (a doctor) had quite a few air-canes in his collection and IIRC five or six were those boxed sets. Beautiful craftsmanship on them. I understand that he didn’t shoot them but they all were in working order.

Speaking of walking sticks, here is a Buckthorn one that I recently made.

Cheers,

Hank

Hank,

What a beauty!

BB

Glad you like it BB!

I have a couple of more pieces dried that are ready for carving.

H

Unlike Dave, I hate reports like this. This highlights other old gals that really should show up at RidgeRunner’s Home For Wayward Airguns. One of the boxed sets with pump and tools would be awesome, to say the least. I am certain Mrs. RR would welcome it and allow me to display such.

Ah well.

BB,

I always wanted an Air Cane, along with a Giffard CO2 rifle and a Girardoni rifle. Of course, these are things I will probably never buy but they all at the top of the fantasy wish list. I seem to remember that there used to be an Air Cane shooting competition at the old airgun show on the east coast.

David Enoch

David,

I think you are remembering the Baldwinsville show.

BB

Hi David haven’t spoke to you in a while quite a while actually.

When you are ready I have an 8 mm tap loading Giffard rifle in splendid condition. It might be just the thing….. talk to me we might be able to make it happen.

Hi Frank,

Good to hear from you. I cannot find your contact info. Could you email me at davidcenoch@gmail.com.

Thanks,

David

Tom:

A week or so ago I asked what the big deal was about slugs since I’ve been happy with diabolo pellets for the last 40 years. Well, I found a 2019 interview with Florian Schwartz of H&N in which they talked about slugs. I know that was 2 1/2 years ago and much may have happened since then, but here’s a synopsis:

Herr Schwartz said, “Although they can be fired in conventional airguns, they work best in barrels which have been specially developed for slug use.” I was sure he’s talking about rifling twist rates. Sure enough, farther down in the interview, Florian says, “…the barrel requires a much faster twist rate than is usable for pellets.” And, then there’s getting them to feed thru a magazine if the rifle has one.

Another quote, and he’s talking about .22 caliber here: “We have achieved excellent results with Muzzle Velocities between 920 and 940 FPS in .22 caliber. So really they’re only for use in powerful PCP air rifles.” At that point in 2019 they’d not started working on .25 caliber slugs yet. I’m interested in that because I have a couple .25’s.

He also says that matching slug diameter to barrel diameter is critical and that ballistic coefficients are much better than diabolo pellets.

So the big deal is apparently high precision long-distance accuracy and higher ft lbs of energy delivered to long range targets, but it will likely require a .22 or .25 caliber PCP gun with a barrel specifically designed for slugs. Just feeding slugs to your existing air gun may not work out well.

Let you know if I find anything more current.

Motorman

St. Louis, MO

Motorman,

Isn’t it wonderful to know of a blog where you learned (could have for those not paying attention) all that, and more, years before the Herr Schwartz interview!

Thank you Tom and the active readership!

shootski

Motorman

Nowhere to reply above. So replying here.

You by chance didn’t work at ABB Westinghouse in St.Louis. My brother worked there in the late 80’s to mid 2000’s I believe and worked his way up through the ranks. Then decided to open up a heating and air conditioning business then quit and been doing the A/C repair ever since.

We use to use alot of ABB motors on our machines at work.

Motorman,

Thanks for this info. I guess the world of ballistics hasn’t changed that much in all the years. 🙂

BB

Motorman,

You’ve hit most of it.

A typical pellet gun is optimized (barrel and power plant) to shoot drag-stabilized diabolos at sub 900 fps.

Slugs are spin-stabilized and (generally) preform best at speeds from 930 to 1000 fps . With the “velocity wars” there are a fair number of airguns that have the raw power to drive a slug at high velocities but they still have “pellet barrels”.

You need an airgun specifically set up for slugs if you want to get into that game. I’ve hedged my bets and bought an Impact plus a slug barrel. That way I can try slugs and satisfy my curiosity then switch back to the pellets I prefer to shoot.

Like BBs to pellets and pellets to slugs, each has their own niche. IMHO, slugs will never replace pellets – they are best for a totally different application. For my applications pellets are best.

Slugs are available in calibers from .177 and up. The .22 caliber is well supported but I’m not about how well the other calibers are.

There is a lot of variation in airgun barrel diameters so finding the right slugs can be a problem.

Think that the biggest disappointment (and complaints, accuracy wise) with slugs comes from people shooting the wrong size slug through a pellet barrel.

Interesting times!

Hank

Hank

My .50 caliber Wingshot ll likes these very well.

/product/air-venturi-50-cal-210-grains-balle-blondeau-flat-head-50ct?p=1015

Now here’s the the thing. You know I have many times voiced my opinion I’m a air gun pellet shooter. They kind of go hand to hand.

But if a smart pellet making company would start making. 50 caliber Diabolo pellets I would be all over trying them in my smoothbore Wingshot ll. Even more so in one of thier very big caliber other rifled caliber .50 caliber guns.

Remember that saying slinging lead. Yep thats what I’m talking about. 🙂

BB, this was a wonderful post! Thanks! I assume you’d have included a photo if you had it, but I’d love to see a close-up of the iron sights.

BB,

I have always wondered about air canes and whether they were actually considered a real form of defense or just a novelty item. But, since a .41 short rimfire out of a derringer is in the 52 ft lb range, the cane may be considered in the defensive realm (for the period).

Off topic – how is the mulch trap doing, now that you have had some time to ‘test drive’ it? Any revelations as to improvements, or short comings?

Thanks again for an interesting and informative part of my day.

billj

Bill,

I think the .41 rimfire derringer is more like 140 foot-pounds, but we will see soon.

The mulch trap is working fine but the box wears out sooner than I expected.

BB

BB,

I understand that the trick to making the box last is to have all the pellets go through the same hole 😉

Hank

On the subject of different barrels for slugs vs pellet, while looking for something else I found this. Below is a statistical analysis of the accuracy of several FX Impact .25 cal 700mm barrels with pellets and slugs, of Ted’s data. – Don

https://sites.google.com/site/davemyownself/fx-impact

Teds HoldOver Vlog.

Description of test conditions and video of shots:

https://www.youtube.com/watch?v=qxDqZTmBlG8

Teds Comments:

https://www.youtube.com/watch?v=xhhl2GtGFks