by B.B. Pelletier

Some time ago, I sent my Sterling air rifle to blog reader and all-round nice guy Vince. He knows his way around old airguns and has worked his magic on this old one.

If you’d like to write a guest post for this blog, please email us.

Now, here’s Vince!

I just sort of blunder in because I generally don’t look where I’m going. Like when B.B. attempted to test his unusual Benjamin Sterling underlever rifle and found he was rather perplexed about the ridiculous velocity variation he was getting — on the order of 50-150fps. I let it slip that I have a smidgen of experience with these somewhat oddball rifles, and next thing I know it’s on its way to me.

So, I wandered into another tear-up, beat-on and generally-trying-not-to-screw-it-up airgun repair. But even when I blunder thus, I do it slowly, so B.B.’s unfortunate rarity sat in my basement for oh, about 9 months or so before I finally got around to it. Heck, he could of had a baby in that time! Well, sorta, coulda — if you know what I mean.

By the time I finally got to look at this gun, all my hard-earned experience and knowledge from working on exactly two examples a few years ago had leaked out of my head. “No problem,” I thought. “If I figured it out once, I can figure it out again!” A little before Christmas, I finally bit into it.

Right! OK. Here we go. Let’s see. Lefty loosey. The gun starts to come apart in pretty much the usual fashion by removing the rear triggerguard and front stock screws located in the usual positions:

I’m pleasantly surprised to see those small, thoughtful gestures you should expect on such a high-class instrument of plinking. Like the metal bushings in the front stock holes that allow you to tighten those screws without squishing the wood:

After the screws are removed, the action simply lifts out of the stock. To get the guts out of the action, however, is a bit more involved.

The first thing I need to do is remove the mainspring, which on most rifles means compressing the rear spring stop and removing some pins. But this gun follows an old practice that you generally doesn’t see much of anymore — a threaded end plug.

There’s nothing inherently wrong with a threaded end plug, although it IS expensive to manufacture and can lead to some interesting histrionics during disassembly. Problem is that you can’t just push on the end cap, remove the anchor(s) and release the pressure. You have to merrily unscrew it (which takes many revolutions) while applying enough pressure to keep the spring compressed and eventually prevent it from sproing-ing all over the place. This can be a bit tricky with a standard spring compressor (which I never use anyway), but no matter — I’VE GOT A PLAN!

First step is to loosen the spring plug with a screwdriver, like so:

We really don’t need to worry about the plug trying to escape until it’s at the last few threads. I continued to unscrew it until I can get a thin screwdriver all the way through it and put it on the floor, holding it this way:

This lets me put much of my weight (Anybody need any extra? I’ve got plenty!) downward while I rotate the rest of the action counterclockwise. My foot holds the screwdriver that keeps the plug from turning; and when the threads finally disengage, it’s easy to let the spring uncompress in a controlled fashion.

Especially when the preload is, oh — about 10 lbs, which it is on this gun — very anti-climactic. But no matter. The plug unscrews and the spring guts slide out the back:

Obviously, though, we haven’t entirely dismembered the rear of the rifle. There’s another threaded plug in the tube-thingee above the cylinder, which we need to remove if we’re going to take out the bolt and feed mechanism. There’s no spring behind it, so it just unscrew it without any drama:

Now, I remember a major boo-boo I made when I first worked on one of these. I have to pull off the bolt handle, but that won’t happen until the setscrew in the end of the bolt is loosened:

Finding that setscrew, by the way — AFTER trying to unscrew the bolt handle — means you’ve made a bit of a mess. But since we’re not repeating that mistake, the bolt handle unscrews and everything just slides out the back.

Note the itsy-bitsy o-ring circled in yellow.

The piston’s going to come out next, but there’s some stuff in the way — most obviously the trigger. It’s not modular like, well, most guns anymore, so it actually has to come apart.

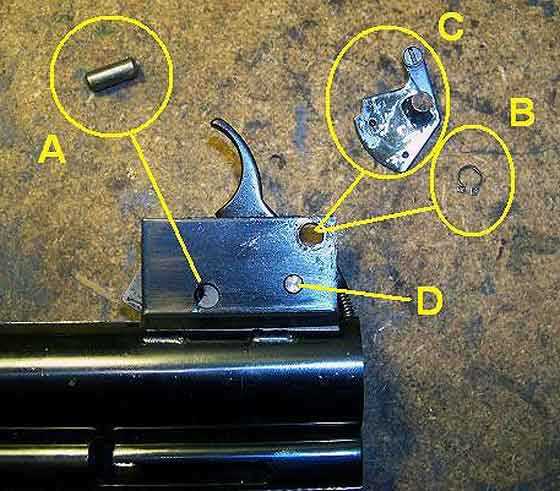

First thing out is the sear pivot “A,” otherwise the safety lever “C” will fight until the cows come home. But once that’s removed, the circlip “B” and safety “C” pop right out:

Unfortunately, there’s also “D” in this picture, and I’m pointing it out because the OTHER side of this pin (which we can’t see because I forgot to snap it) contained a spring-loaded detent ball for the safety.

Notice that I said “contained.” So, I find myself singing (yet again) that ancient tune of the absent-minded tinkerer: “Where, oh where, did my detent ball go?”

Not a clue, but more on that later.

Pin “D” slides out, and now the trigger blade can be removed:

Best to grab those trigger springs before I lose them, too:

The cocking lever pivot comes out easily enough — first by removing the lock screw on the port side of the gun, then the pivot from the other side. After that, the entire cocking lever/cocking link assembly can be removed:

FINALLY, the piston slides back and out, and (disturbingly) the piston o-ring seals don’t look that bad. I say “disturbingly” because I was hoping to find an obvious reason why the gun was running so badly:

The Sterling is unique in several respects, but perhaps the most evident is the way the spring cylinder sits below the barrel and bolt tube. This does necessitate something of a convoluted air path (ensuring it will never become a “magnum” rifle), and it also means that there’s a seal between the tubes. Since B.B. was having so much trouble with this particular gun, it seemed prudent to replace it, which means they have to be separated.

Looking at the spring cylinder (from the muzzle), we can see two Allen-head screws. Back those out, and the spring cylinder just drops away:

The seal I was talking about is circled in yellow.

The seal I was talking about is circled in yellow.

Unfortunately, that seal also looks fine. So far I’ve got this thing completely torn down, and I see nothing wrong.

Next, I inspect the spring cylinder, and I’ve got mixed feelings about peering inside. On the one hand, I hope I find something horribly wrong that explains the poor performance; on the other hand, I know that a damaged cylinder will be almost impossible to replace. Well, to my suprise and delight both hopes were fulfilled!

And what did I find loose inside that cylinder? Say “rubber baby buggy bumper” three times fast:

Since the Sterling uses o-rings as seals, there’s nothing but metal on the front face of the piston. That’s not good. When the piston slams home, a metal-on-metal interface doesn’t make for the gentlest of landings. This rubber bumper was somehow fitted to the front of the piston to cushion that shock.

And I really mean “somehow.” The face of the piston has no provision for a pin or screw or anything else that will actually hold this bumper in place, so I have no idea how it was originally secured. Or theoretically secured. Regardless, whatever Benjamin did obviously didn’t cut it.

Setting that aside for a time, I turned my attention to cleaning out the cylinder. I’ve come around to the general opinion that if the inside surface finish of a cylinder is good, there’s really no reason to do anything more to it.

First thing I did is scrunch up half a paper towel, jam it into the cylinder and push it all the way to the bottom:

I then squirt a generous amount of some sort of solvent down the cylinder and give it some time to soak into the paper-towel plug…

In this case, I’m using simple mineral spirits.

In this case, I’m using simple mineral spirits.

…and use “claw” to retrieve it while rotating it and moving it back and forth:

Repeat, repeat and repeat until it starts coming out clean. I follow that with a couple of dry ones to mop up the remaining solvent. Another peek inside the cylinder shows a nice smooth surface, so it’s ready to go.

Now, I’m back to that stupid rubber baby buggy bumper. I’m determined not to repeat Benji’s mistake, so I check with B.B. and get his okey-dokey to drill and tap the end of the piston:

Now all I need is a bumper. Using the original was out of the question; and since I harbor an odd desire to stick pieces of dead cow into airguns, I made one out of leather. I used a flathead machine screw to attach it to the end of the piston AND KEEP IT THERE:

The next issue is, of course, to find replacements for the seals in this gun. JGairguns.biz doesn’t show them; and if they exist anywhere else in the US, they managed to remain hidden from me. Besides, these are simple o-rings that I have to replace. How hard can THAT be?

Starting with the piston:

We see that it dispenses with a standard piston seal. Unfortunately, what it uses are not exactly traditional o-rings, either. First, they’re metric. And 2mm width has no decimal substitute. Second, they’re square in cross section. Two strikes and you’re out. I couldn’t find exact equivalents. So, round ones will have to do, and I ended up using size 2×19.5mm.

Finding a replacement for the itsy-bitsy bolt o-ring was also a bit tricky, but it turns out that a 1x3mm seems to be perfect:

Fortunately, the spring cylinder transfer seal is virtually identical to a common #106 o-ring. A little grease holds it in place for reassembly:

Now, the entire gun can start going back together. A process which, I’m sorry to report, I sort of forgot to photograph. But, no matter, really — it’s essentially just all the above in reverse order.

There are two home-made moly lubes I generally use for springers. The first is a mix of “tacky” grease and 25% moly powder, the second is a sticky chainsaw bar oil (30w) with about the same proportion of powder. I use sticky base lubes for two reasons: lube clinging to surfaces lubricates better; and if it’s clinging to surfaces, it isn’t atomizing and exploding.

The seal and the inside of the compression tube gets a light coating of the oil mix, while the piston and the cylinder behind it (after the piston is reinstalled) get a light coating of the grease. I use Maccarri’s tar on the spring — nothing heavier than that on a medium-powered gun.

And, so, the pieces start coming together…tubes, piston, cocking linkage, bolt — uh, oh. Right. I still have one little problem. That stupid safety detent ball the aliens beamed up. I need to replace it. As far as I can tell, it’s a 2mm to 2.5mm ball, and loose ball bearings aren’t exactly in stock at any of the local hardware stores.

This turned into one of those problems that I just NEW I could address with SOMETHING I had in my house SOMEWHERE. It took a couple of days, but I finally remembered some sliding door pullies I had laying around:

So I cut one apart…and am I gonna get lucky?

BINGO! Although, in all honesty, these balls were a smidgen too big — and I mean a SMIDGEN. I opened up the detent well by a couple thousandths, literally, and it fits like a glove.

It took a few dozen rounds for the excess lube to work its way out of the gun’s innards, but eventually it put down this string of velocity numbers with Crosman Premiers:

695

689

692

692

694

687

696

681

683

693

683

697

That’s a 12-shot average of 690 with a spread of 16 f.p.s (pretty close to B.B.’s subsequent 705 with a 14 f.p.s. variance), so we can safely say that the old Sterling is back up to snuff.

And that about wraps it up. I think the overhaul went fairly well; the only thing I’m tempted to be concerned about is the piston o-ring substitution. But considering how consistent it seems to be shooting now, I think my concerns are unwarranted. It appears that after an anxious 9 months, B.B.’s baby is finally ready to wail!

Very nicely done Vince! Here is something really odd….check out what our own Derrick found inside his new,old stock Sterling.You can see his tear-down at “Another Airgun blog” . com.His spring had about 3″ of preload,very different from this one.These Sterlings are so unique I’m feeling a need for one before they get even harder to find.I like your technique of removing the end cap safely and your improv skills are to be envied.Your writing is entertaining as well.That’s all the criticism I can muster for now…..thanks for the blog.

This spring is not the original – BB talks about it in, I think, part 1.

Thanks for this fine article. As a owner of a .22 Sterling, I appreciate all the info. Keep up the great work.

Great job Vince.

Pete

B.B. owes you a lot for this one.

twotalon

TT,

He sure does!

B.B.

No, he doesn’t.

Thanks Vince. It is good to read a rebuild article again. It’s a good stimulus for me to do some rebuild of my own that I’ve been putting off for months and months now. It is very satisfying to see great improvements as the fruits of our labors.

I agree; Great job, Vince. You are truly resourceful and innovative as well as skilled, and your detailed report proves it. BTW, I could have successfully torn it down. Then B.B. would have had a lot of nice parts to look at 🙂

As an aside:

While the MAV77 is getting all the notice, Crosman has slipped in a new Benji Titan.

The Crosman web site indicates that the Titan now comes with a 3-9x40mm AO scope (the scope was a major complaint previously); it boasts “average muzzle velocities from 950fps to 1200fps” (rather than the “up to 950 fps” that is still claimed for the Trail) and has a weaver style optic rail (I suspect this is an error based on the picture and a reply I received from an inquiry, but who knows). Note that on the air rifle page there is no price listed for the Titan (as of yesterday). The product page has the “This item is coming soon” with the “Notify me” button.

Okay, it’s still a Titan, but I am curious to learn just how different it is (or isn’t) from the original.

It appears Crosman has made at least a few modification to the Titan.

The Sterling is such an interesting rifle, and I enjoyed your report on the repair . I wonder if this gun could benifit from a O-Ring replacement cap made of Delrin . I did that with my Luznik pistol and it worked well. You would have had to have access to a lathe though, and since the piston in BB’s gun was not damaged, I think your repair was the best solution. I like your common sense repairs of the guns you have worked on, and the use of subsitute materials that makes the reader think outside the box.

LOVED the article/details AND the writing style, Vince! Looks like BB has some real competition hidden away in the wings!

Vince,

I enjoy your natural writing style. The concise presentation of facts coupled with your oh so subtle humor is a joy to read. Your source of those little bitty ball bearings got me wondering how many of us would have thought of them? (me-most assuredly no).

Bruce

Nice work as always, Vince! The Sterling I’m working on has a very different mainspring–much longer I think and it’s made from traditional round wire. The owner’s manual says the preload on the spring is forty pounds and mine was easily that much. The rubber bumper on the front of my rifle’s piston was glued in place with what looks like an epoxy. Agree with you that it’s a lousy piston design. I didn’t find the need to disassemble the trigger unit to remove the piston, so I don’t know if the triggers are the same. Hope to find a fix for the damaged compression tube today.

Vince,

very nicely done – I probably would have overlooked a couple of those hidden screws and the end product probably would have been a boat anchor (albeit for a very small boat). Quick question – on the machine screw you installed to hold the piston bumper in place, did you feel the need to put any restricting agent on the threads, such as Lok-tite?

Fred PRoNJ

Actually, I used Vibra-Tite VC3. Fergot to mention that.

Ah yes—-the adventures of the part-time tuner! That report could have just as well have issued from the TLAR Eng., Buzzard Bluff Div. shop in the shed on the back of the barn here! We do see some interesting challenges.

Perhaps it’s just as well that JG didn’t list parts for the Sterling since I recently donated $35 to him for a piston 0-ring and buffer washer to fit a BSA Meteor and an HW-80 breech seal in lieu of the cheesy Meteor seal. Admittedly that price included S&H and a mysterious ‘small order premium’, but hopefully John will invest my money wisely since I doubt that I’ll be sending him any in the future. Heaven knows I can be similarly abused closer to home and it will trickle into the local economy.;o)

Great story well told! I perhaps more than most—really enjoy your reports. Tom

Good job, Vince! One of my biggest challenges in life (I have a few), is I’m “a custom made guy, in an off the rack world”. The clinical name for this “disease” is, H-D syndrome. Mine is stage 4. It’s terminal. Pray for me. I have to tinker with everything (ok, screw up) before it’s mine. Apparently you have the same affliction. Maybe we could start a support group? My name is Beaz & I’m a tinkaholic!?! Thoughts & prayers, buddy. As a rookie here & to the sport, I have much to learn & from your attention to detail, even I learned a few things about lubes, the hows & whys & thinking outside the box. But the biggest, is a reminder of someting I’ve started doing, but still get in a hurry & forget too often. With digital cameras & even cell phone cameras, detailed pics during disassembly, is alot easier than constantly stopping to write notes & then later trying to figure out what I meant when I wrote it & trying to label all of those itty bitty piecespartsthingys. Well done, thanx.

Beaz

Beazer,

My name is /Dave and I’m a tink-a-holic….. 🙂 (Just not the H-D type. Too rich for my blood….)

/Dave

Vince,

Nice job! Both in the rebuild and the report. I am always impressed with the abilities of those with enough patience to do what you did about the safety detent ball thingy. Stopping in the middle of re assembly for two days to come up with a fix would have killed me! I have spent two days on my hands and knees combing the floor for miles before only to find the ball in the tread of a shoe!! Lesson learned, hopefully.

ka

Vince, nice job and a very nice report! I have worked on lots of firearms but leave most of the air gun work to those that really know what they are doing!

Mike

Off topic question that I’ve been thinking about for a while. Why isn’t their an alternative to Co2 powerlets? Seems like a simple question but I know it’s complicated. If a container can be filled to 4,000 psi (HPA) then why not sell them instead of Co2, in either 16 or 88 grams so they can be compatible? I understand Co2 is denser but not sure how that affects the decision. Any answers would help get this out of my mind, thanks.

jkherberger,

A gun that’s built to use CO2 cannot just switch to high-pressure air by inserting a tank filled with it. At the very least, you’d have to change the valve.

Edith

Jkherberger,

Air doesn’t pour out of the cylinder like water. It slams out with 4,000 lbs of force behind each square inch! Also, a CO2 molecule is like the size of a city block compared to the size of an atom of gas in air that is the size of a car. So the seals that will prevent the molecule from passing may not hold back the much smaller atoms.

Guns that use both air and CO2 do exist, but they have to be specially designed for it.

B.B.

Thats my point,make a gun to replace Co2 guns. I feel like my Hammerly 850 is a perfect canditate for this. Intead of having to hand pump ($) or buy a refilable scuba tank ($), if a valve and some gaskets increase the cost of the gun by $25 so be it.

Well, the Walther 1250 Dominator is more than double what the Hammerli 850 that it is made from. That’s what you can expect.

B.B.

Wouldn’t the very small container be a potential hazard?

Wouldn’t it be like a bunch of little grenades?

Would it even be possible to hold 4000psi in such a small container?

Also when you fill your air reservoir you open the scuba tank slowly what would happen if you ponctured a small similar container, how could the suden pressure be held?

So are we Friday yet? I can’t wait to read that SHOT show report.

J-F

The old Steyr LP-1 could be easily converted from bulk co2 to compressed air at 200 Bar. They sold a kit with valve and tank. Some of the late model FWB pistols could also be converted, but the kits are all gone.

Not the same thing as little “12 gram” Powerlet equivalents. But I don’t think those would be safe. They would work on 3000 psi air and use the boiling of a liquid. Wouldn’t have many shots either.

..pz

All good answers,makes more sense to me and now I can sleep. Thanks

A great write up. The UK built guns had no safety and so no annoying littel ball bearing to use. The oddest problem I’ve had with these is that the worm screws tend to workd thensleves loose and the gun gradually disassembles itself, or used to until I applied Loctite. Extraordinary bolt assembly.

Remeber to cock the rifle before loading.

remember*

Vince,

You just never cease to amaze me.

Pure genius to someone like me that got lost at ” Lefty loosey”.

You saved another one.

kevin

Kevin,

While reading his blog, I was totally enthralled by the incredible detail he included. It’s like watching a good surgeon…they notice everything. Maybe that’s a good nickname for Vince…airgun surgeon 🙂

Edith

Edith,

Vince certainly has the gift. I’ve lost count at the number of these contributions he has made to the blog where he opens up a gun, diagnoses the problem and in a ho hum humble way fashions a customized fix. Everytime I read one of his contributions I get airgun tuner envy.

I’m not a tinkerer. Never have been. I repair things out of necessity but don’t enjoy it. Vince reminds me of a very good friend of mine. Fred can fix anything and looks forward to the opportunity to fix anything. When Fred was a kid he would take things apart, that were in good working order, just to see what made them tick and then re-assemble them. Even when he was a kid he usually got it back together correctly.

Frankly, I don’t have the patience or desire. Using a toaster or a microwave is about the end of my mechanical ability.

kevin

Excellent post, Vince! I see why I have no repair talent – you got it all. BTW, if you ever find that ball bearing you’ll probably find KA’s and mine right next to it. I think they all fly through the same black hole to a planet in a galaxy far, far away.

-Chuck

Chuck,

they actually become dark matter to be discovered several hundred years from now. I’m looking forward to the day when the several dozen ball bearings and tiny springs I’ve lost over the years, re-appear.

Fred PRoNJ

Fred,

Yes, and I hope the day those appear, all the socks I’ve lost in the dryer will reappear and all the extra wire coat hangers that have magically appeared over the years in my closets will then disappear 🙂

Edith

By crackey, Edith you’ve hit on the answer to matter / anti-matter in this Universe. All those lost ball bearings and springs become metal coat hangers! Makes PERFECT sense.

Fred PRoNJ

gettin’ close to quitin time here and I’m getting a bit punchy, it seems.

Vince,

Beautiful writing and photography. Even better engineering and improvising. But I did guess in advance how you were going to invert the gun and remove the pre-load on the spring.

pete

Great job, Vince! Always resourceful and entertaining.

Derrick over at Another Airgun Blog is also working on a Sterling ; except his sample has significantly more problems than B.B.’s did. In something of a cliff-hanger, his latest post implies that the gun may in fact be irredeemable. He also concluded (with convincing evidence) that it was a manufacturing defect that destroyed the gun.

http://anotherairgunblog.blogspot.com/search/label/Benjamin%20Sterling%20HR-81

BTW, he puzzled over the bumper pad on the end as well and concluded that it was simply glued on. Looks like the glue gave in B.B.’s gun.

Vince’s use of the pulley as a ball bearing source was pure genius. It’s safe to assume now that anytime there’s a ball bearing detent for the safety, I lose both the ball AND the spring.

Great job, Vince. You actually make it sound doable. One thing I’ve learned about tinkering is that it is all important to maintain equilibrium and not fly off the handle at the first misstep. Along those lines, in the novel Smilla’s Sense of Snow there is a guy described as the “mechanic” who is master of everything…mechanical. When driving, he moves smoothly through traffic with no jerking or discordance, and when he removes screws, they seem to come out on their own. I bet Vince is like that.

Robert from Arcade, thanks for the Fadala Winchester 94 reference. I’m always glad to gain knowledge in virtual fashion from the comfort of home.

Kenholmz. Thanks for your good wishes shooting–and you too. I am actually extremely happy whenever I’m shooting.

Matt in NC. You’re like my Star Trek double from an alternate universe: Name of Matt with an IZH 61 that doesn’t work right. Well, here are some suggestions on connecting the universes. Put loctite on those screws that keep working lose or get Mike Melick to tune the gun. He’s done great work for me and to say that his prices are reasonable is an understatement. Finally, you can improve your performance by lowering your standards. In other words, shoot offhand. With the larger groups expected, yours will bother you much less. Also, you’ll find that the less stable standing position actually facilitates a natural artillery hold.

Edith, so there is another boy who went to Heaven and came back?! It is cause for skepticism that in both cases the boys belonged to families where the father is a Christian minister, and for that reason the people to whom I’ve recommended Heaven is for Real were inclined to be dismissive. However, the content of the book is compelling to me like you said. And there is a case of a child, a girl named Akiane Kamarik born to atheist parents, who claims to have had similar revelations as found in Heaven is for Real. AND she is an artistic child prodigy who has painted her visions. So, if you want to see what Jesus really looks like go to her website… And the boy in Heaven is for Real, without knowing anything about Akiane, said that her painting is completely accurate. Those with an interest in double-blind statistical tests can hardly fail to take note.

I’ll confess to a deep fascination with this kind of material but out of the same impulse I have reservations. It seems to me in the category of predictions about the future or paranormal activities. Even if true, it’s generally in partial or suggestive form and beyond our understanding, so what good does it do in the end? As great American Benjamin Franklin said about theological mysteries: “I don’t concern myself much about them since I expect very soon to see for myself whether they are real or not.” (He was in his eighties.) Supposing that a divine force has placed us here in particular circumstances implies for me that there is a reason and that trying to grope beyond for answers in the supernatural is not really the point. I have enough to do keeping track of the real world. For instance, when I see the sights and crosshairs jumping around it takes all the faith I can muster to believe that my shot technique will get me on target. 🙂 As Walt Whitman says: “I think a mouse is a miracle enough to convert a million infidels.” But Heaven is for Real is certainly a good read for those with an interest in these things. (I was encouraged to see that the boy who is the subject is fond of sword fighting and Spider Man, both before and after his revelations. So, this proves that those with such interests can be in good standing. :-))

On the general subject of appropriate material, I was reminded of a gathering with relatives where we turned to a channel with a cable movie. It started out as an action film but moved into adult content. The relatives finally changed the channel (although not as quickly as they might have I noticed) and switched to a football game. Right away we saw a young man ram his brightly colored gold helmet (I think it was Notre Dame) into the sternum of another player giving himself a mild concussion (in a way that was not well-understood at the time), shocking the body of the opposing player, slamming him to the turf, and probably giving him a concussion as well. I made a comment that we seemed to have exchanged sex for violence which was not too well-received since they were all football fans. The point is that two areas that have significant moral and ethical implications seem to have an asymmetrical treatment in our society in a way that is not entirely consistent.

Along these lines, I read that the original Star Wars was banned in certain European countries because of its violence. The problem scene is where Obi Wan Kenobi cuts off a creature’s arm in a bar and it briefly shows the arm. Horrors! At the time I didn’t even think twice about this. Yet, the same countries were broadcasting shows on prime time tv that would be completely at the opposite of the rating scale from G like they were nothing. I don’t claim to know the answers to all this or what the New Jerusalem will look like. I suppose these complexities are more not less of a reason to protect our children and provide a safe place for them. And, Victor, I would say they are also a reason not to flagellate yourself over acronyms that have been used (or me either :-)). Chastened, we continue to thrive.

Now then, on the subject of relaxation, what do you think about the importance of maintaining a slight degree of tension in the body for the sake of preserving form? I’ve found that if I really go wet noodle, it is impossible to maintain any position. In particular while standing, there is a tendency to relax and allow the weight of the rifle to start canting me over to one side. The antidote is to assert the hip slightly forward. Maybe the principle is not pure relaxation but something like targeted relaxation within a body position that is built mostly (but not entirely) on bone structure. As an analogy, a Karate punch with all its force is thrown with relaxation but one isn’t entirely limp either.

What was the name of the national championship that you won? Small bore at Camp Perry? What were your thoughts on the final shot knowing you were within a point or two of competitors? Would it have been along the lines of focusing on the shot, observing npa ….? 🙂

Matt61

Matt61,

We have Akiane’s book of paintings. We bought it after we read “Heaven is for real.” You should read her book, if you have not already, especially regarding how she came to find the model for her subject painting. It will most definitely send chills up your spine!

Edith

Matt,

You can question the claims made by the two boys, but nobody who sees the painting that an 8-year-old girl did can doubt that it is a masterpiece! Her talent is where the questioning breaks down and the recognition must begin. And that is where the Maker puts His mark.

B.B.

Matt61,

It was the US Internationals. This was the situation I described a few days ago where a teammate and I were leap frogging over each other between championships. Even though he was standing right behind me, I had no idea how close we were. I never think about how I’m doing relative to anyone else in competition, and I wasn’t interested in seeing his targets. Knowing how well, or not, he was doing couldn’t help me, so there was no point in it. The only thing that matters is the shot that I’m taking. The US Internationals is a step up from Nationals, and you only shoot one shot per bull, even at 50 meters with small-bore. I think the more interesting cases were when dropping a single extra point sent you down to 4th place. Actually, the first time that happened to me, I wasn’t even considering that I might win, so there was no drama for me. I did somewhat choke because I had a 1599 going into the last 5 shot bull at 50 yards (the easiest part of the match). I dropped a second point. The 2nd time was a huge deal because a 1600 out of 1600 was on the line. Again, I wasn’t thinking about winning, but was dying by the last shot. As they say, my heart was in my throat.

Victor

Oh, I just remembered something about that same US Internationals. Me and that same teammate tied for 2nd place in the prone match, but because he did better towards the end, he won the tie-breaker. Otherwise, we shot identical scores. Again, going back to my original post, the point is that competition is fierce, and the guys at the top tend to be very good. It’s mental, as well as physical.

Matt61,

Yes, it’s targeted relaxation. Think pistol shooting. You have to use muscle to hold the gun up, but you also want to first establish the perfect “natural point of aim” so that you’re body is not fighting against itself. Offhand rifle is similar to pistol, except the rifle is 4 times as heavy, and requires two hands. The use of hips, side, and palm-rest, help hold it up, but you still need a little bit of muscle. That’s where muscle tone comes in. With pistol it’s more obvious. The stronger the shoulders and forearms, the better control you have. Both rifle and pistol shooters need well conditioned legs as well. Of course, there are lots of details that are very personal, depending on body type.

Victor

About that new Benjamin Titan. The only thing that appears new to me now is the messed up product page. The general text says it comes with a CenterPoint 4×32 scope and the Spec Overviews list the 3-9x40mm AO. I am giving it a rest. Crosman may eventually offer some reason for offering this as something new (and presumably different, if not better).

Nice job, Vince!

If I were to take apart a pulley for a ball, it would be the wrong size by an unworkable amount…. Thanks for doing this and giving us a peek inside an interesting gun! 🙂

/Dave

Vince

Let me join the chorus of thankful airgunners by saying great work, and God bless. Posts like this make you a patron of the airgunning arts, and I mean that with all sincerity.

I’m not good at fixing things. I do it because I must, too broke or cheap to pay someone who is qualified to do the work. I can take things apart, sometimes even without instructions. Reassembly is usually at least half again as difficult. Where I fail miserably is diagnostics. What is perplexing to a hack like me, is how you instinctively know how to do these things. Not only taking things apart with nothing to guide you, but understanding what the source of the problem is once you are in there, with no prior experience with that model. Not to mention being able to fix these problems that would stymie or flummox most folks including experienced mechanics, and with creative solutions.

Then you button it up, and all is done. Not! You also take the time to take photos at all the crucial steps in the process along the way, and make sure the photos are crisp and clear enough to illustrate what you need them to convey before moving on. What is amazing is your ability to recognize to show the steps that are crucial only to novices, but redundant to an ace mechanic such as yourself. The amount of willpower that takes is astounding.

Then you are finally all done. Wrong again. Against all odds, and with moly stained fingers, you type out what will become the blog article. This could be done in a very straightforward and cold manner which would facilitate expedience. But you write in your trademark conversational and sometimes infuriatingly modest tone, which is more conducive to understanding among laypersons, and a heck of a lot more enjoyable to read. You are a quadruple threat Vince. I hope that everyone understands the work involved in your top notch blogs.

I enjoy the pride of fixing things myself. The truth is, the process brings me a great deal of anxiety. I have the specter of potentially having to pay to have it fixed anyway, paying more because I had taken the care and hours of my time to make things infinitely worse.

Sometimes I get so stressed out and worked up, that my critical thinking and self control lose out to my angst and frustration. In these instances I have no other option but to scream out a profanity worthy of such trying circumstances. “Grawlix !!!” It makes me feel better.

Sorry Edith, for the language. Feel free to edit my comment if need be.

Slingin’ Lead,is that wookie or Klingon?? 🙂

Vince,

Gotta love your passion and love for what you do. This is precisely the kind of thing that makes one special and appreciated.

Victor

Vince I think you’re my hero. You said it would be a little while to write that report and I wake this morning to already see the report, with good pics, so well writen.

Congrats on an another excellent report.

J-F

We have a power outage so I’m wrting this with my phone and I just got tue easiest math question since first grade, easier than the one Duskwight got. ?+1=2

Isn’t it a great feeling of accomplishment when you’ve fixed something complicated?

I find a very common problem with things is, they got built with too many parts inside. (hehe!)