by B.B. Pelletier

This report was requested several months ago, but I needed time to consider it before writing. Maintenance is such a subjective thing. One person just wants to keep his airgun running like new, while another wants to see every screw and seal in the gun. I think that goes beyond maintenance, so I will confine this report to people who just want to care for their gun to keep them shooting as long as possible.

1. Keep your airgun under pressure!

Letting a PCP go empty is always risky, because the ambient air can then get through the valve and into the gun. Ambient (room) air is full of dust, small dirt particles and droplets of harmful things, such as water and solvents (if you clean firearms nearby). Keeping a gun or separate reservoir pressurized keeps the door shut against these harmful things and here is some proof.

I have a DayState Harrier that has been holding air continuously since 1999. But I let the air out of a Career 707 that had held for six years, and it developed a leak. I have several other PCPs that have held air for nearly as long as my Harrier, but many guns that have had the air released have had to be rebuilt before they held again. The seals were not bad in most cases. They were just dirty!

2. Use high-grade silicone lubricants!

These lubricants cost more money than easily available hardware-store lubes,. They’re more difficult to find, but a PCP needs them to operate. They are NOT for lubrication, but for sealing! Regular petroleum-based lubes are used for true lubrication, but put your oil cans away. The amount of oil and grease a PCP needs is very small. In the eight years I’ve owned my Harrier, it’s never been lubricated. Period! It still doesn’t need anything.

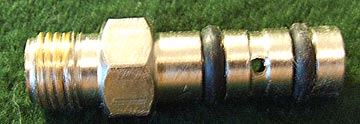

AirForce guns need silicone lube on the large o-ring that seals the tank to the adapter. I do that about once a year, regardless of the number of times I fill the gun. The double o-rings on the fill probe of a quick-disconnect need more frequent lubrication, and frequent cleaning. Because these o-rings are exposed to the air, they pick up dirt, which the lube on their surfaces holds. I either store my probes in a plastic bag, or I clean and lube them before every use.

Exposed o-rings on this fill probe should either be covered when not in use or cleaned before each use. They need a thin coat of silicone grease on them before being inserted into the fill port.

3. Get a chronograph!

PCPs change velocity over time, and it takes a chronograph to properly adjust them again. For example, Falcon rifles will start out at one speed when new, then climb by 30-40 f.p.s. after about 500 shots. It’s just the way they settle in. With a chronograph, you can watch for this and adjust your gun when it happens.

4. Do you need to lube pellets?

If you shoot pure lead pellets below 900 f.p.s., you probably don’t need to lubricate them; it would depend on how smooth your barrel is. If you shoot Crosman Premiers at 900 or faster, then you should lube them in some oil before shooting. Otherwise, you will have to clean the barrel periodically. A PCP is a dry gun, where a springer blows a small amount of oil from the compression chamber into the barrel with every shot. Lead has its own lubricity, but above about 900 f.p.s. it needs help.

5. How often should you clean the barrel?

Clean the barrel as seldom as possible. Only clean when there is an accuracy problem, and then scrub the bore with JB Non-Embedding Bore Cleaning Compound. My Harrier has never been cleaned, and it still shoots well.

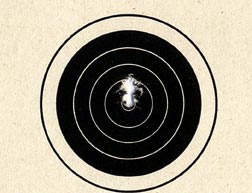

Five JSBs at 35 yards from my Harrier show that 10 years of not cleaning the barrel is no problem. Group measures 0.170″ c-t-c.

Are there more tips? Of course! Here’s one. Don’t take your rifle apart! These are not just PCP tips, they apply to cars, wristwatches and to life in general.

Thank you for covering this subject!

.22 multi-shot

Hi B.B.

Got a question that’s somewhat related, except it’s for airsoft.

Would you recommend putting pellgun oil on an airsoft gas pistol magazine? Would you apply the oil on the bottom where you insert green gas?

Also, do you recommend storing a little bit of green gas in the mag while not in use?

Another question.. any plans for doing part 2 for what airsoft is used for?

Thanks

This is off topic.Told by a friend, so, I tried. Bought a box of .22 aguila, it says 20 gr., 500 fps, no gun powder. I loaded and shoot a few on my old .22 rifle, surprised!,hits very hard, very little sound, even less than my 177 springer. I now use them for my backyard pest control.

Airsoft,

Yes I would keep some green gas in the mags. I always do, and for the same reasons.

Pellgunoil for airsoft? I don’t see why not, but I have always used the lubes sold by the airsoft dealers.

Thank you for reminding me about Part 2. I will get right to it!

B.B.

how about that report on the catapult gun that kills woodchucks?

amazing group. i’m in awe looking thru that pinhole.

dm20,

Yeah, That is a good group. I think you’re right. I will do a report on the big catapult gun.

B.B.

hey bb

check out the new crossman products for 2007

https://www.crosman.com/site/new_2007

check out the destroyer pellet. it a hollowpoint and a pointed pellet combinded

check it out!!!

What ever happened with the Drozd testing? How did the steel bb’s stack up against the round lead balls?

Hello B.B.,

This is (very) off-topic, but I wonder if you would be so kind as to address an air gun topic that is “loaded” (pun fully intended). This regards the sensitive issue of air gun “silencers”, “moderators”, “shrouds”, “dampers”, or whatever name that people care to call these devices. Specifically, my inquiry involves an assertion by Dr. Beeman (“Silencers on Airguns” -an article that can be found on his website) that shrouds, moderators, etc, besides being (in his opinion) illegal, are also, according to him, ineffective in reducing the report of any “springer” type of air rifle.

I am not concerned here with the legality issue, but rather the assertion that these devices do not work on airguns. His logic is that though the moderators may be effective on CO2 guns and PCP’s because of the fact that they involve allowing the slower expansion of a large volume of air rushing from the gun upon discharge, that this is NOT the case with springers since springers merely use a cusion of air as a medium for transfer of the energy of the expanding spring to the pellet, and so, in his opinion, the moderator does nothing to dampen the sound of the spring air rifle.

This seems contrary to both common sense as well as observation to me for the following two reasons;

1) I notice a definite difference between my (very loud) Webley .177 Tomahawk and the sound of a TX200 in the same caliber being discharged (though I do know that the Tommy is more powerful) and;

2) Noise inside of a structure, such as a home, can be “dampened” or moderated by the use of special building techniques involving more insulation and a second layer of wallboard held to the studs by special clips which allow the wallboard to move and cancel the transfer of sound.

It seems to me that dampening the noise from an airgun would similarly involve allowing vibrations to be muffled by an expansion chamber (such as a moderator or shroud), and that the noise of the rifle firing is not solely generated by a large blast of air such as issues from a PCP or CO2 rifle. For that matter, my QB-78 is very quiet and has NO moderator or provision for sound reduction other than a rather long barrel, yet it is very quiet. Further, it seems that these devices would not be so popular in the countries of Europe where they are legal, if they were not effective. I am very interested in reading your opinion on this matter. Thanks for putting up with my (verbose) and lengthy rant on this matter, and thanks also for your attention and consideration.

Regards,

Curtis

BB-

New Year Unresolved:

1. Will AirForce have a multishot?

2. AirForce CO2 conversion?

3. Cannot seem to find .22 barrel for Marksman 2004?

Or any of the other varietes?

Ray

Crosman pellets,

Crosman bought this pellet design from a British maker. I’ve tested the pellet before, but the maker was very sloppy and there was no accuracy. Crosman will do it right, so I’m looking forward to retesting it.

B.B.

Drozd testing,

I guess I owe you a part 4.

B.B.

Curtis,

I guess that it’s time for another blog on silencers. I will use your “rant” as the foundation.

B.B.

Ray,

1. They say yes, but the problems are very daunting. I wouldn’t hold my breath.

2. Yes. I have tested it and it’s now moving towards production.

3. No chance! A single-stroke is very low-powered and the world market will not support a .22 version of this gun, in my opinion. I don’t understand your comment about other varieties, as the 2004 is a single gun.

B.B.

Weihrauch HW 40 PCA is available as .22 (Pyramydair -HW 40 PCA Caliber – 0.22″ 305 ft/sec.)

The Weihrauch HW 40 PCA & Beeman P3 are same gun never been a question. Weihrauch HW 40 PCA marketed by Beeman==>Beeman P3

Marksman 2004 is manufactured in China by same conglomerate having Beeman P3 manufactured in Europe.

History I:

During 1992 Richard Kazmaier Jr., president of Kazmaier Associates Inc. of Maryland, was interested in the purchase of the Beeman company. The Kazmaier company reportedly owns Bike (athletic clothing), S/R Industries (sporting and recreation equipment), and other holdings. S/R Industries, in turn, owns Marksman Products. Mr. Kazmaier was interested in adding the high-end specialty, dealer distributed products of Beeman to S/R Industries, separate from Marksman, to help provide a balance with Marksman’s economy level, mass-market products. April 1,1993 S/R Industries purchased almost all of the operations and assets of Beeman Precision Arms Inc. and the Beeman trademarks.

The tear down photos and parts diagram look identical to my Marksman 2004. Part of excellent work by Todd Cooper.

http://my.tbaytel.net/coopers/HW40Review/

History II

Kazmaier was named an All-American halfback and won both the Heisman and Maxwell Trophies as college player of the year. He was also named Associated Press athlete of the year.

The Chicago Bears made him their first draft choice in 1952, but he opted not to play pro football. Instead, he attended Harvard Business School. After spending three years in the Navy, he founded Kazmaier Associates, Inc.

His daughter, Patty, was an All-Ivy League hockey player at Princeton. She died of a rare blood disorder when she was 28 and Kazmaier memorialized her with the Patty Kazmaier Award, which is presented to the outstanding women’s college hockey player of the year.

Ray

what web site can i find a parts diagram for a crosman pro 77 pistol? need diagrams for breaking down the pistol And re- assembling the gun .PLEASE HELP !!!! CONTACT ME AT: http://www.lukin4dabebots@msn.com

BB.

What is a good high grade silicone lube for a PCP(preferably sold in PyramydAir)

carter

Carter,

If you are asking about silicone grease, Pyramyd AIR doesn’t offer it. If you mean silicone oil, try this:

/product/chamber-lube-1-oz?a=1015

B.B.

Hi BB,

(I wrote this all before but didn’t see it show up so I’m writing it again. My apologies if it shows up somewhere else. Anyway…)

I obtained a used Air Arms S410 FAC Carbine (Incredibly good looking rifle). According to the previous owner it is about two years old (bolt action, not side-lever). The thing is it came in without any pressure in the reservoir. I have no way of knowing how long it’s been like this. Should I lube or clean anything or do anything else to it before I fill it up?

This is my first PCP and I’m actually waiting for my pump from Pyramyd AIR with should come in on Monday or Tuesday, I don’t think I could have waited otherwise.

Thanks

Jacob V.

Jacob,

Your gun had to be empty to ship legally, so if that’s how you received it, it probably hasn’t been empty too long.

Nothing special to do. Just get it filled as soon as possible.

B.B.

BB,

Can a PCP be stored at full pressure or would it be better to store it with just some pressure.

You can safely store any PCP at full pressure indefinitely. That’s how I store all mine.

B.B.

do the orings in the valve assy. need to be oiled and how is it done

Internal o-rings generally do not need to be oiled on a PCP airgun. They are lubed at the factory and that should last a decade or more.

External o-rings usually need a coat of diver’s silicone grease. Smear it on with a finger if you can reach them. Your owner’s manual will specify how, if it isn’t obvious.

B.B.

BB , I just noticed my Benjamin marauder has become a tad louder than before, at 2000 PSI , people started guessing where the shot is coming from. Earlier I was hearing the Ping noise , but now i cant hear it.Is that Strange or its normal ?

I shoot from the balcony in my house. The marauder is still in the factory settings.

Hi

I have a walther dominator

When you are finished it must you remove the compressed air cylinder from the gun when if you want to store it, and is it ok to leave the compressed air in the cylinder

Sameer,

Leave your rifle charged and with the cylinder installed. You can leave them that way fort many years, but if you empty the cylinders they will go bad in a hurry, because dirt gets into the valves.

Do you have the Dominator that was made for field target or is it the newer Dominator 1250, made from the Hammerli rifle?

B.BN.

Thank you for the info about keeping pressure on pcp air rifle I have benjamine marauder was looking for this info. Thank u again I will keep mine at 2000 psi

Hi. Has anyone got a manual/schematic drawings for a Logun mk1. Ten shot please

Have recently purchased one as new, but very old,

I think it’s due a major service all though shoots and works excellent.

Thanks nick

Nick,

Welcome to the blog.

This report is 7 years old and not seen by most people. Come to the current blog page to reach over 50,000 readers.

/blog//

B.B.

How do you know when a pcp rifle needs silicone oil? If it needs it how do you oil it?

Johncpen,

A drop every now and then doesn’t hurt. Put the drop inside the fill nipple, if possible, so it can be blown into the reservoir.

B.B.

Can I use shock oil for RC cars ( what weight?) or is there something else you recommend?