by B.B. Pelletier

An anonymous reader asked how to determine if a pellet fits well in the bore of an air rifle, and also if there’s a lot of air blowby. Today, I’ll discuss this and also, for those who can watch videos, I’ll point you to a very revealing website where you can watch high-speed photography of what I am talking about.

Do you think that a pellet seals the bore so no air gets past? It sounds nice, but it doesn’t happen. Air does get past (blow by) all pellets when they are fired. The best situation is for the least amount of air to get past, and several things contribute to that. They are pellet skirt diameter, skirt wall thickness and the hardness of the lead. We will look at each in turn.

Pellet diameter

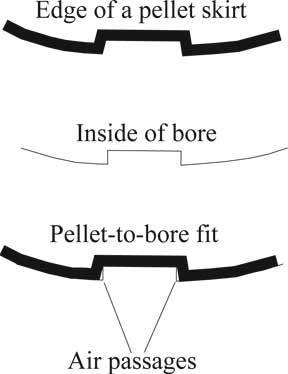

You might think that if a pellet is larger than the diameter of the bore, no air could get past it. But some always does! I reckon it blows past at the instant the gun is fired. In the time it takes for the pellet to go from stationary to moving, air is rushing past – going through any available passage. But if the pellet is larger than the bore, what passages can there be? Well, for starters, the rifling distorts the pellet in many places, creating small openings. Air can rush through those tiny openings that form at the junction between the smooth part of the bore and the point where each land starts to rise.

Where the lead is forced to conform to the rifling lands, tiny openings form at the junctures where the lands start rising. This drawing isn’t to scale, but air doesn’t need much of an opening to escape.

Lead is the most malleable and affordable material from which to make pellets, so even though these small imperfections occur, there really isn’t anything better at doing what lead does.

Here’s the proof

For those with computers that can run videos, the proof of this is shown here. At the top of the page choose English. Then choose examples. On the left side of the page, choose videos. On the page this takes you to, click on the third video from the top, which is a .45 ACP exiting the muzzle at 70,000 frames per second. When you select that video, it will download to your desktop as a zip file that you must then click on to unzip and see. (A lot of work to see a video!) The unzipped file size is just 3.5 MB, so the download is quick if your internet service is broadband. My thanks to the anonymous reader who gave me this link.

For the rest of you, here is what they’ll see. When the .45 automatic fires, the first thing that exits the muzzle is gas from the burning powder. Then the bullet comes out, followed by a denser cloud of gas. This is dramatic proof that gas does blow by, even when the bullet fits the bore exactly.

Skirt thickness and hardness of lead

Thin pellet skirts tend to be blown out into the walls of the bore by the sudden blast of air. This is not significant in PCPs, but it is in spring-piston guns, where the air blast is both sudden and violent. PCPs use more air than springers, but they release it over a longer time, so the push is more gradual.

Thin-skirted pellets that are also made from soft lead deform the most. When I shoot the Hakim .22, which is a taploader, I always use RWS Superpoints, which have the thinnest, softest skits I have found in a premium pellet. Even though the Hakim isn’t powerful, it seems to blow out the skirt of the Superpoint to fill the loading tap, and I get more energy with them than a lot of other pellets.

RWS Superpoint has a thin, soft, lead skirt that lends itself to distortion.

Tomorrow, I’ll finish this discussion, unless your comments give me more to consider.

what about the pellets used with a pellet

lube do they have less blowby. ? should a

pellet fall into the barrel or should it be forced when loading?

BB, what i would like to see is a test to determine how much air is lost through the breach seal in spring powerd air guns,we take this for granted that a if a seal looks alright that its working alright,i have in the past changed seals in my hw80 then later test it over the chrono to find the guns lost power,i have done the old trick to put talcom powder over the barrle block seal area to see if you get that puff of air shoot up when fired,but also the affect of fireing heavy pellets has if any on the seals performence,i now one off shoot is piston bounce, but to me its one area that we dont talk about,but one thing thats important to the guns funtioning properly ,by test i mean slowed down film to see the afects ,i think it woud be intresting.

b.b.

I can push any pellet I have through either one of my Talons and see light around it in the grooves at any point in the barrel.

Fired pellets show no sign that the skirt ever touched in the grooves.

Apparently the rifling squeezes the entire skirt to a smaller than groove diameter.

Twotalon

BB,

Very nice post.It explained a lt.Looking forward to seeing the next one.Now for a little question.Im planing on buying the utg m14 airsoft gun.Since I dont know much about airsoft I know what a hopup does but dont know where it is and how do I adjsut it.Can you help me out??

Thanks

Hernan(CF-X guy)

BB,

So, should a pellet always be loaded by pushing it as flush as possible with the end of the barrel, or does it not matter if the skirt protrudes a very small amount? Sometimes it is difficult to get the pellet fully seated and, when firing lots of rounds, the tip of one’s finger begins to get a little painful.

Mark C.

CF-X guy,

The Hop Up is explained in the UTG manual. It’s in the magazine well, so the mag has to be removed to adjust it.

Try playing with it while shooting at va dark target at distance (30 yards, ot more).

B.B.

Everybody with pellet fit questions,

Tomorrow, tomorrow…

B.B.

I like to use the “BEEMAN Pell Seat” I got from Pyramyd. I don’t use it to push pellets up and into the rifling but to just allow the pellet skirt to kiss the froward edge of the skirt leaving a consistant seal from shot to shot. I try to be very carefull to not to over push and start the deformation of the skirt into the rifling. With a loupe I can see that with finger pressure alone there are many times gaps that are not present when using the Pell Seat. This method is more useful in some of my AG’s than others. The HW50S for example is very tight and Premiers are more easily seated with the pell seat wearas the RWS 36 it doesn’t help as much as the breach is loose and the pellet drops in all the way to the skirt.

KTK

everybody

look at the second video down on the page bb showed us. it demonstrates how soft lead is and how pellets transfer there energy to the target.

bb

on the video you showed us why doesnt the slide blow back? would that happen after the bullet comes out or was this a non blow back gun

Nate in Mass

BB, have you ever maybe tried a pellet gun with polygonal rifling or tried to form a pellet completely to the bore in order to measure how important the loss is? Although a muzzleloader has a lot more gas to spare than your typical pellet gun, I read that Sam Fadala measured or reported someone else’s measurement of a patched vs unpatched round ball which was presumably smaller than the BORE, and the velocities were more or less the same. I would guess that even with an airgun the loss does not amount to a whole lot.

Nate,

Yes the slide blows back, however this video is taken at 70,000 frames per second and then played back at the standard broadcast speed of approximately 30 frames per second. The slide won’t start moving for a long time at this rate.

B.B.

Polygon,

No, I can’t say that I have tried a polygon bore. I do know back in the ’60s that certain handgun makers were claiming a slight velocity increase with polygonal rifling.

And I didn’t know that Sam Fadala had done that experiment. You wouldn’t happen to remember where he published it, would you? That would be something to read.

B.B.

i thought polygon bores were generally used for airguns that shot bb’s and pellets interchangeably… like the crosman 2100…

RE: Sam Fadala: ’95 Lyman Black Powder loading guide. I think it was a few sentences describing someone else’s work.

Hey I just saw this and it looks really cool. Beretta CX-4 Storm by Beretta. It looks like the Nightstalker but has a larger clip (and $150 more). But can you please do a review of this gun!!!!!

Nate, the slide and barrel recoil locked together as a unit. They move back only about 1/16″ before the bullet exits and the pressure starts to blow down. When that happens, though, the barrel and slide are speeding backward with a lot of momentum. The momentum is what completes the recoiling of the slide and the functioning of the gun.

If you had a recoil-operated pistol with a defective extractor, it would leave the empty case stuck in the barrel because the momentum of the slide is supposed to pull it out after pressure has dropped.

If you had a blowback auto like a PPK on the other hand, the case would blow back with the slide even if the extractor were completely removed, although it may not eject at the correct angle when it hit the ejector.

I remembered you talking about the airmag then i looked that memory up and found that you did mention it before. Heres what you said:

Big bore airguns do kick and some of them hick hard enough to hurt! I remember shooting an 8.5-lb. 118 caliber dart gun called the Mag Air 1180, which shot 550-grain mild steel darts. It was for hunting big game, such as mountain lions and elk, and it kicked about as hard as a .30/06, which is to say…a lot!

BB,

the daystate air ranger comes in three models. 35 50 and 80 fp models. is the 80 realy 80 foot pounds? If is or even if it is not, is there anything that makes it unworthy of the daystate name? I have heard that there was a recall or somthing.

Just got done testing out my Mendoza RM-200 after a tear down lube and tar. I kept the factory spring so it has about the same velocity and power. It does cock a lot smoother. I don’t remember it vibrating a whole lot before but the spring is covered in velocity tar now. So were my hands lol. The tar is non-toxic but it takes solvent to get it off. For a first time tune it was really fun to do.

I set up my chronograph in my shed with incandecent lights over the sensors 20 feet from where I was shooting. Velocity is the average of 10 shots in feet per second.

RWS Hobby 7.0 gr (.177), 642.20 fps, 6.41 ft lbs

Crosman Premier domes 7.9 gr (.177), 564.77 fps, 5.60 ft lbs

Beeman Lazer 6.5 gr (.177), 574.31 fps, 4.76 ft lbs

The Beeman Lazer pellets must have had a lot of blow by. The head fit better than the skirt in the bore. For a goof I put one in skirt first and it gave no resistance going into the rifleing. A very picky gun when it comes to pellets. Tomorrow I’m going to test and tear down my Diana 46E and see how that goes with a new spring kit and seal if it needs it.

Shawn

I would like to ask if you ever considered the air in the barrel prior to shooting. There has to be some resistance/compression of this air prior to shooting. A missle/pellet would have to push this air out would it not? Also would it cause the missle/pellet to always be smaller then the bore itself, if it were exactly the same size how could it go down the barrle without causing tremendus heat/fricton. Isnt this what you dont want to happen???

Daystate AirRanger,

The AirRanger was poorly marketed and designed. It was an attempt by Daystate to capture the title of world’s most powerful smallbore, but they missed the boat.

First and foremost, the original rifle was barrelled with a .22 rimfire barrel that would only fit .22 rimfire bullets. Daystate officials said they intended to do this, but it meant that their owners had to buy bullets from Eley – an unreliable supplier in the U.S. So the gun was unfit for the largest market of unlimited power air rifles – a major mistake, in my opinion!

Second, they brought the rifle to market claiming over 100 foot-pounds, but with a barrel that measured under 22 inches in length. That is impossible for any air rifle – the brand doesn’t matter. To get power requires a long barrel, so Daystate missed that boat, as well.

Daystate has a long history of excellence in PCP rifles – having actually started the modern revolution in 1980. But along the way they have had some bad advice, with the Air Ranger being the baddest of all.

I would avoid it.

B.B.

Air in the barrel,

Yes, there is air in the barreel that does get pushed out of the way, just like all the air the pellet has to fly through to get to the target. It is of very little consequence.

Yes, there is friction with the bore, which is why lead is the best material for pellets and bullets. Lead is self-lubriucating. A muzzleloader that shoots a lead ball surrounded by a cloth patch has a very limited barrel life – something on the order of 1,000-2,000 shots before the rifling is worn down. The same barrel shooting a lead bullet without a patch may shoot 50,000-100,000 times without appreciable wear. I’m not making those number up. They come from Ned Roberts’ book.

B.B.

Sam Fadala,

Thank you.

B.B.

Beretta CX-4,

The review starts on Friday.

B.B.

bb,

when you do a review on the beretta, could you see if the nightstalker tacticle kit will work on it?

Dave

BB, Great info! On those slo-mo videos how come the pellet strikes skirt first?

Brian.

Brian,

They loaded the pellet backwards intentionaly. For what reason I don’t know.

B.B.

Dave,

I have a NightStalker kit, thanks to Crosman, so I will check that out for you.

The CX-4 test will be postponed until Monday, due to a late shipment.

B.B.

Thanks bb,

i will stay away from the air ranger. I hate 2000$ mistakes. I heard daystate had some of the finest trigers available. Thats why i was interested. Thanks for the detailed response.

Stay away from the Air Ranger, but not from Daystate. They make a wonderful PCP rifle. I love my Harrier single shot.

B.B.

BB,

What about the air wolf? Its electricly regulated!!! What do you think is more accurate, the air wolf or an fx revolution or gladiator. Thanks bb.

AirWolf,

Accuracy come from the barrel – not the action. I think these rifles will be fairly equivalent.

The solenoid valve of the AirWolf makes that gun very well-regulated. And the trigger is excellent. Accuracy, though, isn’t out of the ordinary for guns in this price range.

B.B.

BB,

what group size should be expected at 50 yards with NO human error? Thats for the daystate air wolf. Thank you!

-sumo

Sumo,

Something less than 0.5 inches.

B.B.

BB,

i think i will get a daystate. The revolution looks to good to be true. I fully understand it mechanisme and it sounds to hard to balence a system like that. One could say that about the electric regulation and trigger in the daystate. I dont think those will be problematic because that its been used in paintball guns for years. I would pay anything for the gun you discribed to me. I cant wait to put one next to my theoben because theoben is daystates #1 competition in the industry.

Thats sorted out but where do i get one? The price would be the same from any dealer. I called ctico and they did not have on but were expecting some to come in within 6 weeks.

Do you know were i could get one?

-sumo

Sumo,

Well, that’s a problem I can’t solve. As good as Daystate is, their dealer network in the U.S. is too small. The dealers don’t keep guns in stock, and it takes a long time to get them from England.

I’m afraid you’ll just have to wait for it.

B.B.

BB,

Ok, they said they would get some in stock in 6 weeks. Citico was the dealer that told me that

-sumo