by B.B. Pelletier

Today I’ll continue with the physical description of the RWS Diana 34 Panther. I left off with the barrel, which is 19 inches long. The muzzle cap makes it look longer and also serves as the base for the front sight ramp, which is skeletonized.

The breech uses Diana’s time-honored ball-bearing detent, and, lest anyone say a ball bearing can’t hold the breech shut as well and a chisel detent, I have to slap the muzzle to begin breaking the barrel. Hopefully that will become easier as the gun breaks in.

Cocking

This Panther seems like a hard-cocking breakbarrel! The piston seal honks like a goose, which indicates a dry seal, but I know the Diana seal is self-lubricating so I’ll not lubricate it until the gun has some shots on it. I expect it to quiet down with use – to break in, so to speak. Cocking effort is a surprisingly low 31 pounds. The surprise is because it feels like a lot more – probably due to the noisy piston seal.

Front sight is fragile!

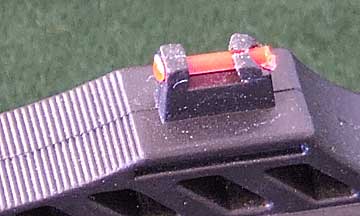

I must criticize the front sight element for being extremely fragile. Mine broke within the first few shots, and replacement doesn’t look easy! This is a flaw Diana will have to fix soon. Fortunately I will scope the rifle, so it won’t prove to be a problem.

This won’t cut it! Plastic on airguns is okay, but there has to be enough to do the job. This sight needs to be redesigned!

Scoping is a challenge!

The scope base is the weak point on most RWS Diana spring rifles. It simply isn’t engineered to accept scope rings with scope stops. There are two shallow holes for a vertical stop pin, but they aren’t deep enough to do the job. I have seen dozens of Diana spring guns with long gouges extending backward from these holes. The earlier form of the Diana C Mount was a cause for some of these problems because it has a tapered rounded Allen screw stop pin that acts like a plow when the gun moves in recoil. But RWS recently went to B-Square to make the C Mount, and they have a better cylindrical stop pin. But at best, these are just field expedients.

The older RWS C Mount used an Allen screw with a rounded tapered bottom as a scope stop pin. It would plow through the backs of the shallow holes on the Diana rifle mount. B-Square fixed this flaw and the pin is now flat, but the rifle base still doesn’t measure up.

The Diana rifle scope base has two shallow holes that are inadequate for scope stop pins. The large-headed screw on the rear (left) of the scope base should NOT be used as a scope stop. It has a thin shank that will shear off under recoil. The ONLY place for a stop pin to work is the front of the scope base (also called the ramp) shown at the right.

This pin on a B-Square one-piece scope mount is the right size and shape to stop the movement.

What is needed is a way to anchor the scope ring solidly to the rifle, and the only way I know to do that with what currently exists is to hang a vertical stop pin in front of the base on the receiver. The stop pin can then be lowered enough to really bear on the steel base and stop all rearward movement. Clamping pressure alone cannot stop the movement.

Velocity

This was tested with the brand-new gun. No break-in was done. I expect some changes after a few hundred shots have been fired. H&N Baracuda Match (Beeman Kodiaks for several dollars less) averaged 820 f.p.s., Crosman Premier 7.9-grain pellets went 919 f.p.s. and RWS Hobbys averaged 1021 f.p.s. This is the first time I have ever seen a .177 model 34 get over 1,000 f.p.s., so something inside must be different. It will be interesting to see what happens after a few hundred shots are fired.

I’ll save the firing behavior and trigger comments for the range testing. But the trigger is light, if not crisp, and the rifle doesn’t buzz as much as I remember my other 34s buzzing. So maybe this is the dawn of a new day.

Certainly sounds different. My ’34 (bought new last Jan) would only do 870’s with CPL’s, and the firing cylce was, er, shall we say – annoying.

That front sight is very dissapointing. I don’t understand why Diana doesnt fix the problem with the scope mount.

My 350M is on the way, before I ordered it I spoke with them about the scope slide issue and they told me “shimming” would fix the solution, although it seems unlikely.

If the scope does decide to move back, would I have to re sight it again if I move the mount forward to hang the pin off the front of the mount? This will be with the accushot 1 piece mount.

Decorus

Decorus,

Shimming does work, and with a one-piece mount yopu can shim between the mount base and the gun. That saves the scope tube. Put the shim under the rear of the scope mount to angle the scope down.

Pyramyd AIR is developing a solution to scoping all Dianas. Until then, hang that vertical stop pin in front of the base on the rifle.

B.B.

BB, about that front sight – there’s a grove on either side of the sight “platform” that looks like it’s made to mount a front sight hood.

Several Gamo’s had similar groves, and Gamo sold an aftermarket hood that did a very good job of protecting the front sight while still letting enough light get to the pipe. Eventually, Gamo started installing these on rifles from the factory.

If RWS offers something similar, or if the Gamo hood fits, this would probably be a good idea.

Hey, it would be really cool if you could do a review on the new Gamo Whisper see how well the gun woks and also test out the dampener!

Vince,

I thought the same thing.

B.B.

Gamo Whisper,

I’ll probably test one eventually, but since is isn’t different in any other way, it won’t be soon.

As I have already mention to several readers, the TX200 also hase a baffled barrel shroud that works as it should, so I know the Whisper is going to work.

However, since most of the noise of a spring piston gun is generated by the powerplant and not by the discharge of the pellet, the amount of quieting is small.

B.B.

bb,

ive been looking into getting a pump .22, and i think i know which one i want, but, your opinion is always a good thing to get. im looking at the benjamin 392, and the daisy 22SG. the benjamin looks WAY better, and on paper it claims to have more power. which is more accurate? which is the better buy?

Dave

Dave,

Here’s how I see it. The Daisy 22SG is a wonderful rifle package for the money. Many shooters want a pneumatic for a very little money, and the 22SG is the best deal in town, for my money. I rate it as a hunter out to about 25-30 yards. If Crosman still offered the 2200 it would be competition, but they don’t.

Now the Benjamin is more of an heirloom air rifle. One that you will hand down to your grandson 50 years from now. The Daisy won’t last that long, but Benjamins already have lasted even longer.

These two guns have equivalent accuracy, but the Benjamin is the more powerful of the two.

B.B.

ok, im gonna go with the benjamin…i feel like i just want it more…i guess because of the look, haha, but if it will last as long as you say, then im completely sold on it.

Dave

everyone,

there has been recent talk about the 1377c and mods that can be done on it…im going to get a 1377c in a week or 2, and i want to know if these mods are done by the gun owner, or if you send out for it to be modified…and websites, phone numbers, or any other feedback would be much appreciated.

Dave

B.B.

What happened to the Benjamin AS312T? I couldn’t find it on the Pyramyd or Crosman web sites.

.22 multi-shot

Hello Dave,

Depends on what you want to do. As I mentioned to Kyle, I just modified mine from a .177 caliber to .22 caliber. This required buying the steel .22 cal breech kit and barrel from Crosman. The breech kit has dovetails for mounting a scope. I also ordered the forearm grip and stock that used to fit on the 2289 model. It now looks like a beefy 2250B, but of course is a pneumatic. I was able to pull this off myself fairly easily.

There are other minor parts that help to pull this together. It looks nothing like the original pistol, but I can easily convert it back to a pistol, leaving the longer .22cal barrel. I’m shooting 14.6gr Beemans at 520fps with the longer barrel, and used to shoot 8.8gr Beemans at 510fps as a .177. I think now I feel more comfortable using it as a short range hunter, that is easy to carry and disassemble.

I’ve seen custom websites that sell multi-shot breech kits, that they can sell you, or you can send your gun to. If you search the web, some people have really/creatively moded theirs.

I can supply you with part numbers for what I have done, if you like. I got all my parts directly from Crosman (took about a month). Fairly inexpensive.

Some people might say, “why not just buy a rifle instead of converting?”. I like its compact size, portability, unique look,…alot of power in a small package…and fairly cheap.

Dave,

p.s. – The gun in the picture is not mine (repeat, not mine), but this is what my 1377C now looks like. The forearm and stock look black, but they are really a dark green (i was surprised when I received them).

follow the link:

http://www.eastsidefreeride.com/cgi-bin/album.pl?photo=99-other/Picture_072.jpg

dave, check out this link

http://www.network54.com/Forum/275684/

that has anything you would want to know

dave, everything you need is here on the Pyramid Blog. check out BB’s August 15, 2005 blog and comments on the 1377, to get you started. then search the web and other blogs

The URL for the 1377 Pyramyd AIR blog is /blog/2005/8/1377-another-crosman-classic/

.22 multi-shot

.22 multi-shot,

I’ll look into it.

B.B.

B.B how did you break the front sight? Did it break during routine use? Did you bang the front sight against something? Just wondering how fragile it is. I’m not saying you abused it. I agree that is just too fragile for a component on a rifle that would more than likely see rough/ field use. Some might want to keep the iron sights. I will be interested in the chrono numbers too. I am reading your review closely as i may purchase the Panther (.22) instead of the BAM XS-26.

Thanks

Regards

Nathan

BB –

Is there an ETA for pyramid’s rws scope mount solution?

Also – is there a way to estimate what power of scope to look at for a particular range (ie, quail hunting @ 100 yrds etc)?

Cheers

Ozark

Nathan,

The front sight is extremely fragile. It broke during recoil on a shot, or it was already broken and the red fiberoptic element fell out .

B.B.

Ozark,

I’d hope the scope mount can be completed this calendar year, hopefully by Christmas.

As for the scope power, it isn’t how far away the target is, it’s how precise you want to aim. With a breakbarrel, fo example, you don’t have that much accuracy, so a 3-9 is fine. For a top PCP, as high as you can get, if you want to shoot field target. 24 power for everyone else.

B.B.

Ozark

Since you are going to use your scope for hunting, don’t forget that higher powered scopes require better lighting, and take longer to “find” the game in the scope.

MCA

Thanks all – it’s for a rws 48, so I’m not how that compares to a top PCP. Still 3-9?

Ozark

can a izh 61 be accurate enough for mini sniping (9mm cases at 35 yards)

thanks

hb

hb,

Very easily!

B.B.

BB,

i got my airwolf today! I am very pleased. I need to get my refill tank charged to shoot it. the trigger is so lite and crisp. I had to adjust the first stage to be shorter but its perfect now. It shoulders well.

My tank only goes to 3000 psi and the airwolf goes to 3300 psi… My carbon fiber tank will be here in a week.

-sumo

B.B.

I was wondering what’s the biggest game a 350M can take down with a good shot? In my area I’v seen oppossums the size of a small child. Scary…

Btw hopefully this scope solution for RWS gets resolved by Pyramydair. My next rifle will deffinantly be the Talon SS with a 24″ barrel or the condor.

Decorus

B.B. would you say the rws 34 is a better airgun than a BAM-40, BAM-30, or Gamo cfx. I want to get one good hunting rifle and need it to be great out of the box. I know I want .22 but just need your suggestion on the best gun for my hunting needs and its going to be my one main airgun. I also am trying to stay $250 or under. I will not be tuning the airgun either. Please give me your recommendations B.B. and anybody. Thanks really prieciate this!

Sumo,

Let us know.

B.B.

Decorus,

A 350 Magnum can certainly take a possum, woodchuck or raccoon, because the less-powerful Diana 48/52 is already doing it.

The next size up is javalina /coyote, and I think the 350 is not powerful enough for them.

B.B.

Gun ranker,

Once again, I will rank a list of guns for you.

The BAM B40 is at the top. Next is the Gamo CF-X. After that, the RWS Diana 34 Panther, with the fictional BAM B30 dead last because they aren’t being delivered.

B.B.

B.B.

thanks for the reply, that helps a lot.

Decorus

B.B.,

Are the internals of the RWS panther different then the standard model 34? Or did they just exchange the wood stock for a synthetic one?

hegshen

hegshen,

The latter.

B.B.

Why is the Cfx rated above the panther, which one would be better for hunting small game as big as rabbits, the cfx or rws34 in .22 (wooden) thanks

I would choose the 34. It's faster to load and better in .22 caliber.

B.B.

ok thanks, any better gun you can think of for the price (240$) in .22 cal? thanks