by B.B. Pelletier

First, an announcement. The 2008 International Airgun Expo is coming up in just a few weeks (Oct. 24 & 25). I make it a point to drive out from Texas every year to attend the show. It’s THAT good! Pyramyd AIR will be there again this year. Like last year, they’ll have loads of new and used guns, scopes, accessories, a boatload of pellets and just about anything else an airgunner would want. If you didn’t go to the Pyramyd AIR garage sale last month, then here’s another chance to get in on some good deals. Go to the show’s web page for time, location, a map and a list of hotels.

Now, on to today’s blog.

There’s a lot of interest in this subject. More than I would have guessed. So I’m running this second part today to give you something to talk about this weekend. Let’s look at the shape of the transfer port as it relates to efficiency.

Many air transfer ports are simply straight holes bored through the end of the compression chamber. I’ll discuss the size of those holes in the next and final report, but it’s surprisingly similar across a wide variety of air rifles. Today, we’ll look at transfer port holes that are not just straight tunnels.

Stay away from mirror-smooth

In a discussion I had with Jim Maccari, I was cautioned to not polish a transfer port to a mirror finish (assuming I could have done so). Jim told me his experience was that super-smooth transfer ports are not as effective as those that break up the airflow to some degree. In fact, he shared one of his tuning secrets – a transfer port shape he likes to use on lower-powered air rifles like the FWB 150 and 300, which are both target rifles. Both have a concentric transfer port, so this tip may work best for them and not as well for guns that have slanted transfer ports.

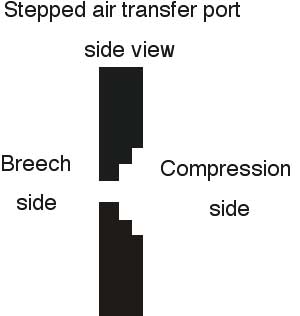

Jim’s tip is to bore several graduated sizes of holes on the compression side of the transfer port – making a sort of bizzaro funnel, if you understand the Superman reference. A stepped funnel if you don’t.

According to Jim, this makes the rifle shoot smoother. I presume it’s breaking up the airflow by creating eddies and swirls at each of the corners of the steps. I have no personal experience with guns using this kind of transfer port.

The changeable transfer port

I wanted to test several theories about transfer ports, and Dennis Quackenbush was kind enough to make up several ports that I could install in an R1 compression tube that Jim Maccari donated. Ironically, Jim donated this tube because it was ruined by an airgunner who drilled out his transfer port for more power. Of course, that didn’t work and his rifle was ruined, so he went to Jim for repairs.

Dennis drilled out the port even larger and made up several transfer port inserts that could be installed from the outside of the gun in less than a minute. I had an excellent testbed for testing transfer port sizes and shapes.

What about a Venturi shape?

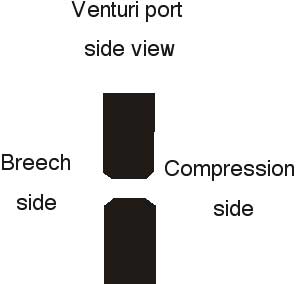

This question always comes up because we know the Venturi shape increases the speed of the air flowing through the port. When I did the transfer port test on the R1, I asked Quackenbush to make some ports that approximate a Venturi shape. The shape he made is shown below.

I copied the shape after the port on a Webley Patriot, which is similarly beveled at both ends. I figured if it worked for the Patriot, it might also work for my R1. However, I saw no increase in speed with this shape. It may have been too large and may have reduced the compression by adding too much additional volume, like a slanted port. I don’t know. I do know is that there was no increase when using the Venturi port when compared to a straight port of the same diameter.

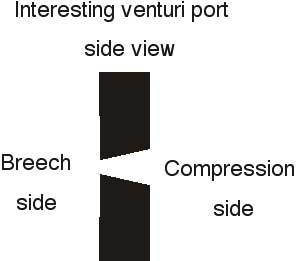

A shape that might be worth trying

Here’s a shape I never tried, but one that I think might hold some promise for airspeed improvement. The trick will be to get the angle correct, so the total volume doesn’t drop compression too low and offset any potential gain.

I bet you never thought there was so much to a simple thing like a transfer port, eh? It’s not just where it’s located, but also how it’s shaped and even how much volume it contains. Next time, we’ll look at the diameter of the port, which was the question that started this report in the first place.

B.B.,

Looks like Jim design creates less energy as it leaves some air along the steps. A less noisy/quiet rifle, Ay !

Jeff in N. Texas

Has no one studied these transfer ports in a smoke tunnel? In highschool, I made a smoke tunnel that ran off a vacuum cleaner to study airfoils. Perhaps the velocities from compression chambers couldn’t be approximated, but I still think it could be an interesting project.

Matt

I played with transfer port sizes a bit, and I’ll be very curious how my experience compares to what you’re gonna tell us…

It is certainly easy to see how the size of the ports are critical to getting the maximum amount of airflow. The other factors are not something that most of us would even consider.

There is another factor to consider as far as any port that is highly polished is concerned, and that is especially true with longer ports such as an angled one. Any fluid moving in a straight line, whether a gas or a liquid, will tend to create a vortex which slows down the airflow. That is why airducts in buildings are square instead of round. The square shape breaks up any vortex and improves the airflow. You can see this effect from those “tornado in a bottle” kits you can get for large soda bottles that will create a liquid tornado in the upper bottle as it drains to the lower one through the connection between them.

While a square transfer port would be impractical and expensive to manufacture, perhaps other shapes could do as well. Perhaps even an insert to break up the vortex, like a flat piece of metal in the center down the length of the port.

Seems kind of crazy as we are talking about only a few Millimeters of travel though…. but it might be interesting to try this especially on larger high powered calibers with a large airflow. FYI, for those who don’t quite get why a vortex is less efficient, it is really quite simple. The air has to travel farther in a vortex to get from one end to the other than if it traveled in a straight line. To see how this is so, wrap a piece of string around a 12 inch long tube several times, then unwrap the string and measure it. It will be quite a bit longer than 12 inches. Oddly, the larger the tube you use will show a larger effect with the string length, but the reverse is true with airflow. The larger the diameter of the path, the less likely you will get the vortex. Also, the higher the pressure or rate of flow, the greater the chance is that you will have a problem with the vortex issue as well.

BB

What are those 3 interesting looking guns shown on the Airgun Expo’s webpage?

(I sure wish they were mine…..)

The beveled transferport has actually been tested in Germany. They created a port on an HW97K which started at 3.5 mm (.138″) and ended at 3.2 mm (.125″). The speed dropped by 10 m/sec (30 ft/sec) but the shot-to-shot differences improved by 50%. And then they blew it all by mirror-polishing the port… ;-(

Pieter

Revwarnut,

Thanks for the vortex explanation. That clears up a lot of stuff for me.

The guns on the Roanoke Airgun Expo website are three guns by Gary Barnes. Fred Liady, the show’s promoter, bought a lot of guns from Barnes over the years.

B.B.

Pieter,

That’s interesting about the Weihrauch experiment. I never thought to check shot-to-shot consistency in my test.

B.B.

BB

Great topic! Reminds me of working on motorcycle carburetors.

You show the piston with a flat head and a matching flat end on the compression chamber. Has anyone ever tried a cone shaped piston with a matching cone in the compression chamber and a concentric transfer port? Sort of like exagerating the idea of a stepped port with a matching shaped piston.

MCA

MCA,

BSA, Anschütz (the Egyptian Hakim) and Falke have all used conical ends on their pistons. See that here:

/blog/2008/4/the-hakim-air-rifle-part-2/

Now I wonder if a hemi would work?

B.B.

Morning B.B.

This is not on topic.I have just gotten into airguns and I bought an SS in 22 caliber. 1st do you recommend lubing the pellets? Some sights I have read say no need. second is there a heavy pellet that you would recommend? currently I am shooting 14.3 jsb’s lubed with your whiscombe honey mix.

thank you for you time

Justin (no catchy airgun name yet)

Justin, forevermore known as the Lubricator,

I don’t lube pellets for the .22 SS. They don’t go fast enough to need it. I seldom shoot Crosman Premiers in my own SS, which are the only pellets that will leave deposits at slower speeds.

Try the 15.8-grain Exact for the best possible groups. On calm days I often group five shots at or just under a half-inch at 50 yards.

The Kodiak works well in the SS, but once you see what the 15.8-grain JSB does, I doubt you will ever use a different pellet.

B.B.

B.B.

thanks for the information I will order some of the 15.8’s and give em a shot. No lube makes life even easier.

the lubricator (HAHA) i like it!

I don’t know if it applies in this instance, but golf balls are dimpled for a reason, and all those high-tech time-trial suits used by cyclists are now being subtly textured, the tests showing they offer less wind resistance that way.

Perhaps a rougher finish transfers air more quickly (I’m assuming that’s the goal) because of some odd boundary layer effect.

And, on a completely unrelated note, BB, are the Crosman Premier Ultra Magnum .177 pellets (come 500 to a tin) the same as the Premier Heavies that come in the cardboard box?

I’d like to have some heavy Premiers around to test, but I’m unlikely to need a whole box worth (at least until I start messing with PCP guns).

B.B.

Yes, thanks to revwarnut for that detailed explanation which cleared things up for me too. That explains everything except the beveled version which, with its gradual opening, would seem to be reducing the rate of compression which is what you want. Actually is the desired quantity speed of compression or decompression? The final model looks like it will cause slow compression and rapid decompression, so the distinction seems important.

I bet that explanation about vortices explains those full-body suits that Olympic swimmers are wearing. I had read that the fibers are sewn in a way to reduce drag but did not know how.

Matt61

B.B. & All,

Compressed air flow through tight places, is not my background, but it seems like the last drawing of the venturi port should work the best, just from a simple minded point of view..

So I'll tell about the result of my pawn shop trading: 6- low budget, w/scopes, heavier recoil springers, for 3 deer rifles.. A marlin 336RC 30/30 walnut stock, a marlin 30AS 30/30, (same gun but newer model I think), but with a checkered beech stock, and a Ruger M77 in .270 cal., real nice clean action & bluing, but a beat up stock..

I put a Leapers 4-16x50AO on the 336RC. With the short rings, I could only fit a 3-9×32 on the Ruger M77, and Josh wanted to try the 30AS with open sites, so I took off the scope I'd put on. Then he couldn't make it, so I shot them all myself.

I started with the Ruger M77, I wasn't close, so I lined up the rifle in the bench rest, and watched the ground, instead of looking through the scope, to find I was right and high.. so it took 12 shots to get in the red on the 8" shoot & see at 50 yards..

I like the 336RC walnut stock best, it's got a smoother action than the 30AS and the walnut stock is beautiful..

Sight in was quick on the 336, first shot was within a foot at 50 yards, so by the 5th shot, I was on, with a perfect center hit on a 3" "shoot & see"

With the open sights on the 30AS I couldn't see where I was hitting until I looked through the scope on the 336, but it was sighted in, and I'd got 4 out of 5 on the 8" target, two close to center, two on the edge.

Since I was alone on the 200 yard range, I told myself to cold fire, and moved the targets back to 150 and 200 yards.

The Ruger with the 130gr only dropped 1" from 100 to 200 yards, so after a couple 6" and 5" – 5 shot groups at 200 and a 4" group at 150 yards, I called it ready..

I didn't want to stop shooting the 336RC, with the "limbsaver" butt pad, the recoil was almost enjoyable, it has a very satisfying sound, lower, thud like, like launching a cannon ball, so different from the Ruger .270…

The guy at the pawn shop said he only hunts with his 30/30s now, because the .270 or 30-06 goes right through the deer, leaving them standing, while the 30/30 goes 3/4 through, and knocks them off their feet…

At 100 yards, I got a 4" group with the 336RC, but had to shoot about 1' high with the 170gr at 200 yards, but I still got a 6" group of 5, before it got dark and I went home…

So, B.B. your right again.. I'll start saving my pellets to melt down for reloading in the future, I'm hooked on the big boys, at least the Marlin 336RC, I'm totally in love with it..

Sorry for the long comment, it just kept coming out..

Wayne,

Ashland Air Rifle Range

I understood the Superman reference.

BB,

I have no doubt that JM’s design works well. During my brief home-tuning experiment, he easily told me more in two sentences than a gaggle of forum searches. I bet it is also easy to make such a venturi with a step drill.

I also suspect, as someone stated above, the stepped venturi works on a principle similar to golf balls: rough surfaces create a boundary layer of still air, which helps prevent vortices from forming at the interface with the rapidly moving “laminar” stream.

Wayne,

Don’t forget, I was the one who badgered you to check out the 336’s:). There are some new safe ballistic tipped bullets (“Leverevolution”?) that supposedly make the 30-30 good for longer distances.

bb,

Did you check out the steoger Xseiries. It’s owned and supervised by Beretta.The X50 looks to be of similar design to the falcon hunter. In the video at steogerairguns.com, it looks like fire was spitting out of the barrel because of detonations. Maybe I’ll buy one once Steoger gains some experience. I saw a walther falcon huner at my local gun shop and the stock, the sights and the trigger seem to be borrowed from the winchester 1000.

Shadow express dude

Trout Underground,

Gary Barnes invented a way of roughing up the outside of a lead ball for better performance. It did work. he called it “screening, because a metal window screen was used.

On the Premiers, ten years ago I would have said they were different pellets, but today I’m not as sure. I think the ones in the tin are just not sorted by die lot, but that doesn’t mean as much as it did years ago. Try them.

B.B.

Shadow Express Dude,

As the airgun editor of Shotgun News, I have my request in with the Stoeger marketing department for a couple guns, when they finally come to the U.S.

B.B.

I never thought I’d say this, but, after reading about transfer ports, (which I never gave a thought to), air rifles are indeed “rocket science”. Regrettably, some of us are not applying this knowledge to the sport.

Rocket nozzles are air-transfer ports. Somethings the rocket scientists, (I’m one), know:

1. Absolutely polish. Smooth the curves and polish the surface. Even race-car drivers know this – polish the intake ports, mandrel-bend the exhaust tubes.

2.Round is better. Vents in houses are square because it’s cheaper to install, no other reason. There are plenty of cylindrical vents where air needs to move and space is tight. There are no square rocket nozzles.

3. Straight is always better. The only time we angle a rocket nozzle is when we need to vector the thrust. Being that I’d never want a pellet to go at an angle skewed to the barrel, I’d always prefer an in-line port.

4. The constriction angles, diameters, etc, can all be calculated with proven formulae for passing air through a nozzle.

Trial and error is hard because the margin of error in the measurement systems, (muzzle velocity), is too dependent on other variables.

5. Column velocity needs to be considered. At a certain speed, air molecules behave more like a fast flow of solid BBs than like a fluid.

The objective of the air transfer point, from a fluid dynamics perspective, is the same as the rocket nozzle: transfer as much of the energy created on the high-pressure end to the low-pressure end.

I wonder if any of the air-gun designers have any nozzle-scientists designing their transfer ports.

Jane

trout

I have shot a lot of ultramags in my TSS and find them to shoot pretty much the same as cph.

Can’t say there is any difference.

twotalon

Bg_farmer,

I'm sorry I forgot it was you who gave me the lead.. BLESS YOU, THANK YOU, BLESS YOU, THANK YOU.. and I mean it…

I'm thinking my Marlin 336RC deserves a place next to my Air Arms S410 as far as love goes..only slightly different in foot pounds, I would think..

I did buy some of the new 30/30 Hornady LeveRevolution rounds in 160gr…. but I didn't try any yet, it got dark on me, and I was finishing a box of the win 30/30 170gr, that was on sale for $7/20 (after rebate) the Hornady were $21/20.. They are way more pointed, with a plastic tip & copper jacket. The tip is suppose to let them slide better on their way to the breech as well as the safety and longer distance issues.

The sales guy said that they are safer, less risk of setting off a round while loading these center fire rounds.. Is this really an issue? The 30/30 win rounds I used had a soft rounded lead end, but I was so worried about it, I pushed them in all the way with my thumb, and the guard pinched me, I would rather push the final way with the next round, is that safe?

Wayne,

AARR&R

Regarding Macari’s tip on porting, what you are looking at is the old hot-rodder’s trick of the 3 angle or even 5 angle valve job. It improves flow through the valve into the cylinder over a single angled valve job. The hot set-up today is a radiused valve job – a smooth line without steps for that intake valve. I also remember reading that you don’t want a mirrored finish in your intake port but slightly rough without protruberances or bumps. Something about a laminar layer of air adhereing to the walls of the passage allowing less friction and faster speed of the air or fluid by reducing vortexs. BB, I recall in the Cardew book that they had discovered through their research an optimum size for the transfer port. I’ll have to review it tonight but too small and too large reduced air flow velocity.

Great stuff, here. Keep up the Great Work!

Interesting to hear from a rocket scientist on this topic. I would bet that many airgun designers use less science and more imagination and trial and error than they should be. I think it is interesting that one of the most well-known airgun tuners says to avoid polishing the transfer port while someone with formal education in the science involved gives the exact opposite advise. I would like to see a direct, thorough comparison between these two theories.

Wayne,

Just giving you a hard time — your description of the use made it sound like a perfect fit.

I don’t know for sure, but I doubt there’s any danger of firing the round by pushing it into the mag with the next one. My understanding is that the round tip requirement on lever actions is to prevent accidental firing during recoil, which is obviously a much more intense impact than loading.

We’ve got some conflicting information about polishing here. One idea is that polishing a port enhances the “vortex effect” which is bad in an airgun port. Another idea lightly touches on polishing of ports in automotive and rocket nozzles, which is considered favorable. I figure that there must be a big difference in the velocities of airgun ports and automotive/rocket ports, and thats why the confliction. Anybody agree/disagree???

–davee1

Jeff & Matt61,

On my Air Arms S410 .177 vs. my Condor .22 cal.

In a bench rest, and the Condor is not easy to get in mine, they are about the same, 1/2"- 5 shot groups on a good day.. But you asked about field target sitting position.. In that position, with the AA S410 my groups are 3/4" to 1", but I'm thinking that Matts' idea about the small focus point might be helping me knock over the field targets at 50 yards with the 1/2" hole.. Because, sometimes I get in a groove and can knock it down 3 out of 4 times.. the problem is that groove is hard to find.. with 1 out of four most of the time.

The Condor in the FT position is not quite as good for me, but I really like a standard type wood stock over the round tank stock, and being .22 cal. it has a disadvantage over a .177 cal from the start.. But all in all, the Condor is almost as good at knocking over the targets for me… in .177 it might be a tie..

I've not tried any farther than 50 yards yet.. with either gun.. I'm mostly focusing on the FT thing, and 50 yards is top distance, isn't it B.B.?

Wayne,

Ashland Air Rifle Range

Hi Jane: Thank you for your comments about the transfer ports. I’m very interested how a nozzle scientest would design them. Do your formulas apply? How would you measure what goes on in the compresson chambers? Just some thoughts Mr B.

Jane knows theory, but obviosly not pracitce. What she says ajpplies to huge rockets, which have nothing to do with shooting air guns. Common sense.

I see this all the time with shooting wtih people who dont actually make anything.

How is that common sense? Many times things may be very similar eventhough they do not seem that way. What is your area of expertise? Yes, rockets have nothing to do with shooting airguns, but, it very well may be the case that designing rocket nozzles relates very closely to designing airgun transfer ports. Your statement does not relate to the statement made by Jane. Do you think that since you shoot airguns you know how to design them on fully understand all of the principles that make one work? I think it would be much wiser to examine the theories and see if they do apply than to assume that they don’t apply and bash someone’s ideas because they’re a rocket nozzle designer instead of an airgun designer. THAT’S COMMON SENSE!

Wayne

The maximum distance in Field Target is 55 yards and a minimum of 10 yards.

jeff

Ahem, Jane sounds smarter than all of us here put together.

And I see this all the time too, with “anonymous” posters who don’t actually contribute anything.

Jane,

From what I know (I’m definitely not a rocket scientist), I would agree with the points you listed. I do have a question though. It would seem link a rocket engine would have different back pressure dynamics than in the pellet gun. The transfer port is creating pressure against a solid pellet which plugs up the works for a brief time period (bouncing air back). Could this change the situation and require modification of the equations (and possibly make a stepped surface better than a smooth one – maybe keeping the back pressure from disturbing the thrust against the pellet as much)?

Thanks,

.22 multi-shot

Guys..

I didn’t mean to offend anyone or start a debate by my comments. I’m a casual shooter, and I never gave thought to an air-transfer port. But, it is what it is, and as such, its behaviors can be predicted by well-developed laws of fluid dynamics. These are used to design everything from jet engine ports and rocket nozzles, to Ferrari intake manifolds and water-craft jet-drives. While not quantum mechanics, it is a fairly exacting science, and we depend on it when we design many systems. Whether you flying fighter jets, watering your garden, or shooting a pellet, you are forcing fluid through an orifice in attempt to optimize the transfer of energy. And yes, backpressures, viscosities, densities, etc, all are factored into the equation, these things go more to optimize length, angles, orifice diameters, and other physical parameters. Certain fundamentals DON’T change – straighter is better, polished is better, smoother is better.

We need to be careful of laymen observations. For example, there are cases where intake manifolds are deliberately made less polished and less smooth, but this is a compromise – a compromise of energy transfer in favor of turbulence. This allows the car company to save money by using shorter intake runners and more compact engines, but not something you find in a Lamborghini. Turbulence is bad, stepped surfaces are bad. I just think it would be fascinating to have a rocket-nozzle expert design one of these air-transfer ports.

Whether or not Jane knows anything about transfer ports, I’d say she “obviosly” knows how to spell “pracitce”. When one seeks to summarily dismiss the technical expertise of another, it usually helps if one doesn’t make oneself look like an…. ah nuts. Now how can I put it kindly?

Jane,

I really appreciate your viewpoint. I wish that someone like you would systematically characterize airgun mechanics — it would be a service to us all.

One thing, however: JM said the stepped port made the gun fire more smoothly, which may imply that the most efficient transfer of energy is not achieved, but rather traded out for another desirable characteristic. This kind of distinction might be one of the pitfalls of having rocket scientists design airguns, or airgun designers design rockets:).

In Chapter 8 of the Cardew’s book, they experimented with transfer ports. For a 3/4″ long port, their experiments showed the optimum size diameter to be 1/8″. They also advised polishing the port but did not specify the “mirror finish” Jane mentions, as well as keeping the port as short as possible. They also found that a “bell mouth” at the compression side of the transfer port increased pellet speed over just a straight port. When they machined a venturi type port, they were disappointed with the results, which they cited as insignificant. They also found out that if the airflow goes supersonic in the port, the resulting shockwaves choked the port. They cite further work carried out at Bristol University where tuning and negative shock waves (such as you get with tuned exhaust manifolds in cars and even tuned intake runners and airboxes) appeared but I guess this is getting out of hand now. Get the book, The Airgun from Trigger to Target” by Cardew and Cardew. It’s available in the UK and if you search on Google, you’ll find a website for G.M. Cardew watches. That’s the son and he’ll have a link for you to order the hard cover version with his brother.

Ha ha. This is great. Just when we are trying to figure out a scientific principle a genuine rocket scientist shows up. I have wondered at the eyes which are reading this blog. I do believe that the scientific method says to privilege experience over theory. However, reading about guns has shown me that experience can be a very tricky thing. Here some enormously credible people have told me that a stainless steel rod is the best instrument for cleaning guns. Then the Dewey representative tells me that they are the worst and that the national shooting team has used nylon rods for 30 years on the completely opposite principle.

Or take the M-16, America’s longest-serving service rifle. You would think that after 40 years there has been a large body of observation about this gun. But people cannot seem to agree on the must fundamental things. Some say this rifle is super-accurate; others that it can’t hit anything. Some that it never jams; others that it jams all the time. Some that it is extremely lethal; others that it is a mouse gun. If this body of information is so conflicted, I expect that the experience about airgunning must be even less certain.

I, for one, have no doubt that Jane knows absolutely what she is talking about. The only question for me is whether the analogy between rocket engines and transfer ports is entirely exact. Is there an important difference in the scale? Is there some other factor in the context of airgun operation that changes things? Is the assumption that rapid compression is the key factor correct after all? I really don’t know but I would be most interested in having a real scientist evaluate and design airgun parts. That would only help.

All right, Wayne, tomorrow is the big day. Here I go with my ritual cleansing and meditation….

Matt61

It looks to me like we are getting lost here with an analogy between rocket motors that produce a constant thrust like a PCP with a stuck air valve and a springer which operates on a balance between two pressure curves. This is looking like apples and oranges.

Springers have the compression chamber pressure curve and the breech pressure curve interacting. The pellet weight and the transfer port should be the controlling factors on how these pressure curves interact to get the most energy transfer between the compression curve and the berrch pressure curve.

twotalon

Twotalon,

Well said. I would add pellet fit to bore as a possible third variable, though once the pellet starts moving, I believe it goes away – the lead having swaged down to fit the bore.

B.B.

B.B.

I should have added something like that…friction between the pellet and the bore as also having an effect on the breech pressure, but with only one cup of coffee……

twotalon

Jane,

I was out yesterday and missed your initial posting, but now that I’ve read it I want to say thanks for that information. I won’t respond to each of the other comments or to your own rebuttals, but I will say that I hope you will continue to be a reader and a poster on this blog.

Your transfer port designed by rocket scientists sounds intriguing. Since the air volume in the port is one variable that affects performance – or at least seems to be from all my empirical observation – I am asking, can that be quantified in a ratio? And do you think it would relate to the caliber of gun? In other words, an optimum transfer port should be 1.5 calibers long and 0.125″ wide – for example?

The thickness of the metal at the end of the compression chamber is going to be a constant from gun model to gun model, because manufacturers try to hold as many dimensions the same to lower production costs. But might there be an optimum thickness that would determine the air volume of the transfer port, and would that then vary by caliber? If that were true, could a significant gain on efficiency be realized by thinning the end of the compression chamber to the optimum thickness?

Perhaps I have asked too many questions for you to answer right now, but could you consider them and reflect on them, given your professional training?

Thanks,

B.B.

B.B. & twotalon,

I was thinking that too, in addition the thinness of the edge of the cup of the pellet, in that the thinner edges are forced into the rifling better on some pellets than others..

Matt61,

OK, I'll put aside my desire to go shoot the Marlin 336RC today, and try to get Randy to shoot the contest with me, he's a college football fan.. GO DUCKS!!

So we start with 25 yards, in bench rests. 25 dots on a page, 5 shot groups… Add the group sizes and divide by 25?

Then, same type targets, and Field Target sitting positions.

Then, same again, with "my favorite" ha ha, and your worst, off hand?

Maybe we should add bench rests at 50 and 75 yards to test the guns more for the guys.. And I'll get out the Air Arms s410, for the 75 yard test to compare the Avenger 1100, with the Slavia CZ 634… and maybe the Condor to AAs410..

Sounds like a full day of air guns.. It's cold outside today…fall has come for sure, snow at 4,000 ft last night..

Wayne,

AARR&R

It might be worthwhile to have a few thoughts what the air blast does just when it has left the transfer port. My guess is that it will be greatly obstructed by any kind of additional curve, bolt probe etc and there will be a small loss of air until the pellet skirt has been “blown up” and seals the bore.

Thus, might it increase efficency to use a small tube as transfer port that protrudes into the hollow skirt of the pellet, acting like a spigot mortar in the first split-second, and blowing the skirt faster?

mel….

Then you would have to worry about keeping it perfectly centered to keep from getting nonsymmetrical skirt expansion or bumping on the breech block when closing the action.

A question also arises…will a Crosman pellet skirt or a Kodiak skirt expand with anything short of gunpowder?

twotalon

B.B. Jane, twotalon, mel & all,

The JSB, Air Arms, and BSA Wolverine, all look like they are made in the same factory in the Czech Republic…. These are the thinnest edge pellets I can find so far. I believe it's best for sealing to the barrel….

They all have thin edges that dent easy, which you would think would be a problem, and it is in some lower power guns for me…

Dented or not the Air Arms S410 gives pretty good groups without sorting pellets….

The other day Randy was sighting a scope on a new Discovery we got and was having a heck of a time, until he started sorting pellets, pulling out the dented edge ones..

The groups started coming then.

The discovery and air arms have different fill pressures, and I guess much different valves and air transfer ports… The discovery is .22 cal and my s410 is .177, but does this add to the soup of ideas your cooking?

Wayne,

Ashland Air Rifle Range

Jane,

Finally a kindred soul, I too am a Rocket Scientist. Albeit, the toy ones from the early Seventies are my only area of expertise. But still.

My favorite was Big Bertha. The rest were too small and would be impossible to track after launch. Big not Big Berta, huge and slow it was always retrievable. It even had a payload area that would accommodate Grasshoppernauts and the like.

Don’t let the naysayers on the blog bring you down.

Welcome and kudos on your post.

Volvo

B.B.

If I understand it correctly, the answer to your question is extremely complex, but in a word, no. As the transfer port gets shorter, the air molecules can exit the port at more "diffuse" angles, and also shorten the pressure build intervals. This can be offset by a smaller orifice, but then energy transfer suffers.

The transfer port, I imagine, performs multiple functions.

1. It holds back the air to allow pressure to build.

2. It forces temperature to rise. The gas laws tell us that this drastically increases pressure, and must provide a serious component of the energy.

3. It then transfers all of this pent-up energy to the breech. I've never studied it, but obviously the energy transfer has started long before the piston has stopped moving. (ideally, we'd put a valve and let the pressure build to max before we released it)

4. So now, it's all about transfer efficiency. These fast-moving molecules, (think marbles), now move from the chamber to the breech. Any change in direction, any roughness, any drastic angles, etc., causes them to bump and grind, and burns up energy along the way.

You can start to see how the equations work:

Smaller orifices allow more pressure & temp to build.

Larger orifices allow air to transfer faster. Diferential calculus enables the engineer to optimize this compromise.

Longer ports align the marbles and deliver the energy to the pellet within a very narrow angle, shorter ports have less volume, support higher pressure, but will have more diffuse "marble exit angles" and some of the energy gained will be lost. Again, the equations optimize the variables.

Not surprisingly, the parameters have much more to do with pressures, and less with volumes, (volumes determine pressures, so we can focus on pressures). Similarly, there is nothing to suggest that the diameter of the breech will cause us to change our calculations of the orifice, hence, a .177 rifle transfer port need not be different than a .22 – as long as the compression system is the same. That's not completely true, because the column velocity effect suggests the exit size should exactly match the pellet diameter, but this effect varies with velocity.

One thing that will keep the nozzle scientists busy is that the dynamics of the compression chamber change repidly. Each pressure will have an ideal port, and the designer would really need to study the pressure curves to pick the port that would behave the best overall. Lots of variables, lots of compromises It's clearly not a simple job.

Maybe when I retire I'll have some time…

Say, could I kindly ask if any of you could give this amateur air-gun hunter some feedback on hunting rifle selection? I’m torn between Evanix AR6 and Career Infinity.

B.B. did some great articles on the Evanix. Has anyone tried the Infinity?, Does it chamber the pellets, does the action work well, will it give 15 – 20 good shots, how’s the overall build quality..??

Hunting season is upon us..any input would be greatly appreciated.

Jane,

If no one here owns both the rifles you are considering, you may want to ask on the yellow forum. It also has a large number of enthusiasts.

http://www.network54.com/Forum/79537/

Volvo

Where does the pellet’s inertia fit into the equations, Jane? Wouldn’t that play some part in the port’s dimensions as well; i.e., a lightweight pellet would want a smaller port than a heavier pellet for maximum acceleration?

And I really am curious, not trying to pick a fight.

–WFG

BB,I think all the pertinent laws of physics define the toolbox we have for optimum transfer port design,but the final design is about the relationship to a particular pellet’s fit,weight,friction surface[both stalled and moving],rifling surface,…etc.It is up to a particular set-up.it seems that lots of further experimenting is needed.I love the idea of changeable ports to make exploration possible.it sure beats guessing!frankb

Oh man, this is the best topic in all my reading for years. Jane, it is my belief that you know what we need to know. Please don’t go away. There are many people here who will greatly benefit from the knowledge that you can pass on. In fact you have already taught me a few things. Please keep it coming.

-davee1

I think I can answer Walther Falcon Hunter: Does pellet inertia fit into the equation?

It makes sense – seems like it should, but probably less than we think.

First and foremost, the port has to “back up” the air to build pressure and temperature. The temperature effect will prove to be dramatic, but it is has nothing to do with the pellet – this all happens in the compression space.

Next, we have some column-inertia factors – line up all the air molecules, speed them as fast as possible, and whack them into the back of the pellet. (this is a big part of rocket nozzles, and, like rockets, we don’t care what the target is – even if it is the vacuum of space)

Finally, and very important, we want the port fast enough to transfer all available pressure into the breech before the pellet leaves the barrel. With the exception of very short barrels, (pistols), we probably have plenty of time for that.

Why?

Because we know springer-recoil affects trajectory, and that springers “bounce”, we therefore know that the pellet is slow relative to everything else happening. So we can assume that the transfer ports are “fast” enough, and we’d be more concerned about balancing the inertia, seal,and friction, of the pellet against the length of the barrel. I think these will prove to be much more important factors.

I think B.B. demostrates this by showing that every barrel/powerplant combination has one pellet style and weight that is “sweetest”.

In sum, unless we have a very short barrel, and a super-light pellet, inertia of the pellet will not alter the design of the transfer port.

Thank you, Jane. That’s something to chew on.

–WFH

Jane and et al.,

There is one factor that you’ve ignored. The pellet has “stiction” in that the pellet has to deform to rifling, then start to move. This would cause pressure on the breech side of the transfer port to build up too.

Ideally, it would seem that the pressure in the barrel should increase as the pellet travels down the barrel so that the pellet either maintains its velocity or actually keeps accelerating. If the pressure in the breech drops, it would seem to cause drag on the pellet.

As far as inertia of a heavier pellet, it would have multiple effects. The exit velocity of the pellet would be slower. The drop would be more relative to the bore line. The pellet would stay in the barrel longer (since it would accelerate more slowly and be traveling more slowly when exiting the barrel), assuming same friction with barrel.

But as you point out Jane, different guns of the same model “like” different pellets. Thus when you have different pellet designs other factors come into play. For example if you jam a 0.20 inch ball into a 0.177 barrel, it will come out slow if at all. There are no doubt 0.177 caliber pellets which would be heavier than the ball, so it isn’t just inertia.

Herb

I looked into this a bit more and it appears that I made a mistake. Jane’s comments made me remember something that I had forgotten to consider, which is that high pressure actually prevents a vortex from forming rather than intensifing it. So it is NOT true under HIGHER pressure! It made me think of how a water jet cutting system works, and I realized that I must be mistaken.

So, Jane is correct about that. I did ask a friend who has been doing HVAC system installs for decades though and he did say that there is some truth to the vortex effect in a round tube and that a square one will prevent it. However, the real reason the ducts are square is that you get the maximum amount of airflow capacity since with a round duct fitting into a square space (walls, ceilings, etc.) You simply waste the space that a round duct cannot fit into. It also just happens to prevent the vortexes, which he says would only be a problem with long duct runs anyhow as with tall buildings.

Thanks to Jane for setting me straight!

jba

Matt61,

I got blown out today, so I did a windy test….

The CZ634 .177 cal, Air Arms s410 .177 cal, and the Condor .22 cal.

Outdoor at 25, 50, and 75 yards in a bench rest….

25 yards

The CZ634 couldn’t do well in the wind at all 1-1/4″ best group, others 1-1/2″..

The Condor’s best was 2 – 5 shot groups of 5/8″ worst 1″…

The S410’s best was 2 5 shot groups at 9/16″ worst 5/8″ with the JSB heavy 10.2gr

50 yards

CZ634 best was 6″ and that was really waiting between the 15 mph gusts..

The Condor’s best @ 50 yards was a 5 shot group of 1″ and worst 1-3/4″

The Air Airms best at 50 yards was a 10 shot group of 1-1/4″ and worst a 10 shot group of 1/5/8″

75 yards:

The CZ634 was not even close… 18″

I shot the Condor and AAS410 18 shots each, at the 3″ dots at 75 yards, the Condor made a 5″ group and the Air Arms S410 a 3-1/2″ group.

Randy and I are shooting the CZ634 and Avenger 1100 indoors at 20 yards tonight… I’ll report tomorrow..

Here is the photo bucket with todays’ results:

http://s424.photobucket.com/albums/pp325/wayne177/?action=tageditmany

Wayne,

Ashland Air Rifle Range

BB and all,

To me, only accuracy counts. And I mean precise, repeatable hit on the target, as long as I do my part.

Transfer ports, just how much do they contribute to accuracy? My guess is that 99.5 percent of accuracy belongs to the barrel/pellet combination, the remaining 0.5 percent is shared by transfer ports, trigger, hammer springs and related issues.

How does efficiency in air flow relate to accuracy? I have seen rifles with very minimal muzzle velocity deviations but do not give tight groups.

Accuracy is still an elusive parameter.

Any real scientists out there willing to help us get that accurate airgun?

Thanks.

David

Hey anonymous,

the accuracy may not be affected too much by a proper transfer port, but if you can choose, would you buy a silent rifle with 80 shots per fill and 20 fpe power or a noisy one with 50 shots per fill and 14 fpe? The transfer port play a huge roll in the airgun’s performance.

@jane hansen: Many thanks for your contribution! Always good to see people who have the ability to check the theoretical background!

You said that the transfer port has a lot of time to get the pressure into the barrel. This is correct, BUT keep in mind that the overall amount of compressed air is very small (very unlike a rocket with its continuus combustion), and the further the pellet is down the barrel, the higher is the overall volume for the compressed air, and the less force is exercised on the pellet.

An article about the Daystate Airwolf’s efficiency shows how the pressure should rise in a sharp peak” for better efficiency:

http://www.airgunsofarizona.com/Daystate%20Mk3%20-%20CDT%20information.pdf

By the way, I onve have spent an afternoon making some integrations, and came up with a spreadsheet that allows you to calculate the theoretical power your airgun can acieve with a given caliber, barrel length, pressure and reservoir volume: You can download it here:

http://www.melchiormenzel.de/science/Energy.xls

Mel:

You are absolutely correct – the CDT Daystate valve does exactly what I suggested earlier – ideally we’d replace the transfer port with a large valve, then we could close it, and blast it open at just the right time. Someday maybe someone will figure out a way.

The current ports don’t allow such luxury, and someone, either by complex equations or trial and error, needs to balance the need to be small and restrictive, with the need to be fast.

Current behaviors of springers suggests the designers chose to err on the “faster” side, else we wouldn’t be seeing, (“feeling”)the effect of the pellet on the piston.

I’d like to go a bit heretical here, with a comment on “accuracy”.

None of this effects accuracy, (I can hear the uproar now..)

First, we don’t really seek accuracy, we seek precision. If a rifle shoots left 50cm at 50yards, but lands the pellet in the same hole 100% of the time, it is inacurate, but precise. We simply adjust the sights, and we’re happy.

Precision is all about repeatability, and it doesn’t matter whether the port is fast or slow, high-pressure, loud, quiet, etc, as long as “everything behaves exactly the same way, every shot” we’ll get the precision we need. (yes, I know, for certain applications we need flatter trajectories, proper spin, etc, etc. – but put all that aside for now).

If you want to improve the accuracy of your rifle, concentrate on repeatability. All the pellets need to be exactly the same, the level of lubrication needs to be the same, the closure of the bolt and barrel, the whip of the barrel, the hold, the grip, etc. Is the barrel completely free-floating, does the grip force you to hold the same way every time, does the stock position your cheek, eye, and shoulder the same way… These are the things that make the match rifle more expensive, and more precise.

Jane,

Thank you for that explanation of the airflow in transfer ports. As I suspected, the optimum design changes as the variables change. So my advice of picking a single pellet and sticking with it seems to hold true for efficiency as well as for accuracy.

You also mentioned that the port size isn’t as much of a variable as people think. When you read part three of my test, I think you’ll see that my observations support that.

This has been one of the most interesting blogs we have ever done. Thank you for your comments and your simple explanations.

B.B.

Jane,

I am working on getting an Infinity to test. There are now several requests for it.

B.B.

David,

The barrel and powerplant are the controls for accuracy. The transfer port has very little influence.

How airflow efficiency relates to accuracy is when a powerplant has an efficient airflow it becomes smoother. And a smooth powerplant does little to disturb the pellet while it is in the barrel. It is also more repeatable.

The artillery hold is based on letting the pellet leave the muzzle with the rifle in the same orientation time after time. A smooth powerplant helps this happen.

There is one more important component to accuracy and that is the fli=ght of the pellet. In recent days we have discussed the spiraling of pellets in flight. To get accuracy you need to shoot a pellet that doesn’t spiral in flight.

B.B.

B.B.

I would love to read a review of the Infinity. While I respect all you engineers and scientists, I am a lousy marksman, and always will be, so the fine tuning doesn’t excite me much. To me, (great hunter of coke bottles), I like to read about the feel of the gun, the smoothness of the action, the ease of operation. Little things, like how easy it is to load a pellet, how convenient things are laid out, the pull of the trigger, and the lack of “twang” all make the experience more enjoyable to me.

My AR6 is nice, but I’m always eager to add to the collection and have limited funds, so the more I can read, the better.

Hi, Herb.

That’s a very nice summation of the effects of increased inertia on the entirety of internal and external ballistics. I was more interested in the small handful of milliseconds between the time the piston starts moving and the time the pellet starts moving.

My initial thought was that a heavier pellet, needing more force to overcome its inertia, could make better use of a wider transfer port since pressure would rise higher before it started to move and that a lighter pellet, possessed of less inertia, could make better use of a narrower transfer port since pressure would rise higher as a result of the smaller passageway. Jane pretty well put paid to that notion.

–WFH

Ed,

I will try to get to the Infinity as soon as possible. But I think I’ll find that the AR 6 is smoother to shoot and the Renegade is bar far smoother than both. I say that because of the sidelever operation, which is rough and jerky on eve the expensive European rifles like the Air Airs S410, to say nothing of the cruder Korean guns.

B.B.

B.B.

On the topic of skirt expansion (which was mentioned)…

I shot 3 each of 8.4 exacts and cpl into a trash can full of water to see if the skirts were blown into the rifling with my Crosman Storm .

So we have a test of both the hardest and softest pellets….

None showed any sign that the skirts had touched the bottoms of the grooves. One cp barely showed any sign that the skirt had touched the rifling at all..must have been a bit small.

Perhaps one of the super fast springers might expand the skirt, but not a 800-900 fps gun.

twotalon

Twotalon,

I’m jot surprised that the Premier didn’t expand. It’s too hard to expand. And I think you are rifle about the one pellet being small. There are such things as peewees in the Premier boxes.

It’s the super magnums that blow skirts out.

And the RWS pellets do it the easiest.

B.B.

I'm impressed with the responses on what wouldn't seem to be a "hot" topic — obviously we all think it interesting. Before anybody can answer any of the resultant questions with any certainty, it seems like a model or simulation of a springer in operation could be useful. The parameters should include (but are not limited to):

— Spring rate/compression

— piston bore and stroke

— piston mass

— Piston & seal friction

— seal efficiency vs. pressure

— transfer port shape and dimensions

— dieseling

— barrel length and diameter

— pellet mass and dimensions + ability to deform

— friction between bore and pellet

— two dozen other things, of which I'm ignorant or have overlooked

The quantification of results could include the lock time, recoil vectors (to characterize hold sensitivity and smoothness), mechanical efficiency (in vs. out), and power output.

Anyway, I had this crazy idea after Vince's efficiency blog, and quickly relized it is not a simple system to model. I doubt any airgun specific simulation & design tools exist (for obvious reasons), but it would be an interesting project for someone, perhaps a graduate student:).

According to Vince's blog IIRC, 30 percent efficiency is pretty good and we all know that many higher-powered springers behave pretty badly out of the box, so there seems like ample room for improvements if we could model the system comprehensively.

BB,can you tell us,is the set of experimental transfer ports stepped on the side to index the depth?and is that a set screw on the r-1?frankb

Volvo,

your Big Bertha comment hit a nerve with me… I had one too… Countless launches and always retrieved. My mother has a hoarding disorder – so Big Bertha is surely stashed somewhere between piles of newspapers.. many decades since it’s last flight.

Coincidentally, I was visiting my mother and finally located my late father’s HW 55. It hadn’t been fired in over 12 years, and it was in need of something prior to its storage. After firing maybe 5 times and seeing something negative in it’s firing behavior – I disassembled it, cleaned and lubed it thoroughly. Replaced a scope for the original front globe and HW rear peep. Now it’s shooting 1/2″ groups at 10 yards, and it is amazingly smooth (gentle “thunk”) and the trigger is probably the best I’ve squeezed, period. Early 70’s from ARH, tuned twice that I know of.. I just need to know how I’m supposed to be able to shoot with the peep sight – it’s like shooting in a dark tunnel. Everything is clean, and it sounds like the problem is my eyes… A shame to put a scope on such a class target rifle.. I love scopes, just that this rifle seems to have “born” with the peep sight. Any suggestions or hints would be appreciated. When I had 20/20 vision in my early teens, my brothers and I could hit .22 casings at 10 yards, and I never noticed anything like the problems I’m having now. Excellent timing on that HW 55 post… very helpful.

Western Pa.

Your trouble with the peep sights, is mine as well… that is why the HW-55T is in B.B.s hands instead of mine, now… I just couldn’t have as much fun, switching back and forth, to a spotting scope, to see where I hit. My other problem is it’s a perfect “off hand” 10 meter rifle, and I’m really into trying to master the Field Target thing first and foremost.. They are too different for me right now.

I’m lucky mine didn’t have a scope rail, or I would have ruined it by taking off the sights, which B.B. said are even better than stock..

That said, I too, will listen closely to the advice for offhand and practice a little with the CZ634…late at night, when no one can see my groups..

Wayne,

Ashland Air Rifle Range

BB,

What happens when the transfer port opens? A close look tells me that it has become an extension of the bore itself, only that space becomes variable as the pellet travels on its way out. A port of smaller dimension than the bore constitute a stepped junction, causing turbulence in the airflow at the edges of angles surfaces.

To Jane: I qualified my point on accuracy by stating about repeatability. As a metrologist, I know fully well what precision is. As a lousy shooter, it pains not to have an accurate airgun yet. As a scientist, I know the search for the accurate airgun for the masses is at best almost elusive as the holy grail.

David

BG_Farmer,

Yes, spring piston design is certainly a confluence of imponderables.

It is interesting that the Beeman R1 was designed by computer. The man who did the work meets me at the Little Rock airgun show every year.

B.B.

Transfer ports,

The ports are not stepped (they don’t have a shoulder) and yes, that is a setscrew.

B.B.

Wayne,

Your HW 55T does have a scope rail. It’s two parallel grooves cut into the top of the spring cylinder, the same as on an R1 or a TX 200.

B.B.

David,

The transfer port doesn’t open, because it never closes. It’s just a tunnel. It is an extension of the compression chamber, and the link from the chamber to the barrel.

B.B.

B.B.

I wonder how I missed that, must have been divine intervention.. or I would have messed things up for sure..

See I told you from the start she was trying to find you…

Wayne,

BB,

I have a question about the length of time that I can leave a spring gun cocked. I know that overnight is a no-no, but in a hunting situation should I be firing every 30 minutes, 1 hour, 2 hours?

Is there a short term change in accuracy or velocity leaving a gun cocked for a few hours(enough to miss shot at a hare’s head) or should I just worry about the long term effects of leaving something cocked too long?

I am pretty new to “adult” airguns…I wore out several cheap daiys and crossmans as a kid, but it has been years since I have shot a pellet. I am been reading backwards through your blog for the last month and have thoroughly enjoyed it.

-phil

Phil,

I did a pretty long test on mainsprings for the R1 book. Read about it here:

/blog/2006/5/how-long-does-a-mainspring-last-part-2/

Others have since chimed in with stories of leaving guns cocked for more than a decade.

B.B.

For that matter my Hammerli 490 Express was cocked when I took it out of the box. No telling how long it had been in that condition.

–WFH

Wow the possibilities.

How about stepped on the compression and dished on the brech end. Or pellet shaped: coned on the compression side and dished on the breech side.

I suppose the spring cycles too quick to have some kind of metered pressure relief valve in there.

How about small tank that would charge with the spring cycle that you could shoot later like pump up or pcp air rifle? Just a thought.

RE: Skirt expansion

Too much thinking and not enough action always gets me into trouble…

Anyway, I realized that we had neglected what is probably an important factor in all of this. It would seem that the air from the port should hit the rear of the pellet in its center and then spread out radially towards the bore to blow the skirt outwards to grip the rifling of the barrel. (maybe the back of the pellet should be formed to help skirt blow out…)

Also it would seem that the barrel should be tapered so that at the last bit of the barrel the head of the pellet touches the barrel’s rifling too. Since the head is slightly smaller than the skirt, the pellet could be off ever so slightly from center just based on skirt hitting.

My next order to PA I’ll have to get some of the pellets with the plastic sleeve. My Daisy 22SG won’t get these near sound barrier, and I’d be curious as to how they shoot. They should seal well and the rifling should make contact for quite a distance, centering the pellet well.

Herb

RE: Heavier pellets (more mass…)

870 fps w/7.0-grain pellets 0.876947904

725 fps w/10.5-grain pellets 0.9134874

650 fps w/14.3-grain pellets 1

Got above data from PA’s website on B26-2. Used m*v^2 for energy with 14.3 grain pellet being 1.

My interpretation is that the heavier pellet stays in the rifle longer, thus more energy is transferred to he pellet. If you could measure sound well, I’d expect that the heavier pellet would be less noisy than a light one. The “pop” of course being air exiting the gun as the pellet leaves the rifle.

Conundrum: I wonder what would happen to accuracy/velocity if you drilled a couple of holes through barrel very near the end to relieve the air pressure. I’d expect that velocity might drop a bit, but I wonder if the puff or air can blow the pellet off track. By the time the pellet gets to the last 1/2 of barrel the last bit of energy lost shouldn’t be much. This should also reduce the report at the muzzle.

Herb

Hi, I know alittle about venturi systems and airflow dynamics from my days as a mechanic, and my understanding is that a rough surface I.E. not polished, holds air molecules in the grooves and the passing air over the top of these pockets of air molecules (which are sitting static) has no resistance, but if the rough edges of the metal are too rough then they create too much drag you need a good balance. In turboed engines the ports should be roughened as they have compressed air forced into them (very much like an air rifles port) but they should not be too rough any machine marks would be enough no need to atack with a small reamer.

Hope this helps. Condyboy