by B.B. Pelletier

When I was writing the R1 Homebrew series of articles for The Airgun Letter, I did lots of side experiments and research to discover what tuning tips did and didn’t work. In the area of air transfer ports, I discovered a lot that wasn’t documented at all, and more that was known to only a few people. Apparently, the air transfer port is one of the most modified areas of a spring gun, yet very few people are doing any research on the effects of modification.

What is an air transfer port?

At the end of the compression chamber, there’s a small hole that the compressed air passes through after being compressed by the piston. That’s the air transfer port. In a spring gun, the amount of compressed air is extremely small when compared to a pneumatic. As early as 1948, the gunsmith and pistol competitor Walther F. Roper surmised that it wasn’t the volume of compressed air that makes a spring gun work but the speed at which the air is compressed and released. Three decades later, the Cardews of airgun experiment fame agreed with his observation.

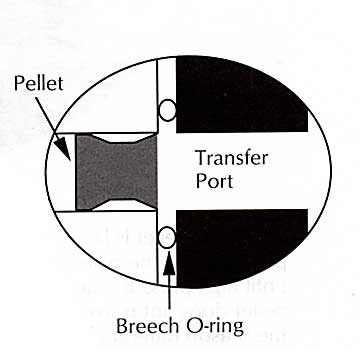

When seen in cross-section, the air transfer port is actually a tunnel that runs from the compression chamber to a point immediately behind the breech, where the pellet sits. The compressed air rushes through this tunnel and blasts into the skirt of the pellet, sending it on its journey down the barrel. How this port or tunnel is made and where it’s positioned play a large part in the efficiency of the air blast, which determines the rifle’s efficiency.

Don’t think for one minute that this design is easily understood, despite being so dirt-simple. Jack Lewis, a famous gun writer and editor of the 1950s and ’60s, saw a cutaway like this and thought the empty space he was looking at was a valve. He described that phantom valve in detail in a 1960s article about spring-piston rifles–not unlike the amateur astronomer Percival Lowell describing the canals on Mars. But now you know what it is–the space between the piston seal and the pellet. It’s the part that’s the air transfer port that interests us.

Air transfer ports are placed where they have to be because of the gun’s design and also in order to do their job. Their job is simple–pass the compressed air from the piston to the pellet. Since they’re open all the time (being nothing more than passageways), they form a part of the total volume of the compression chamber, even though they’re not inside the chamber. Understanding that is important to understanding what comes next.

Concentric ports versus offset ports

The piston is a large hollow slug of metal that’s pushed by either a coiled steel spring or by a charge of compressed gas in the case of a gas spring. In front of the piston is a seal that keeps the air from escaping. The compression chamber is in front of the piston, with the air transfer port forward of it. At the end of the air transfer port is the breech of the barrel, which is sealed by a lead pellet. The volume of air behind the pellet and in front of the piston gets compressed when the piston rushes forward.

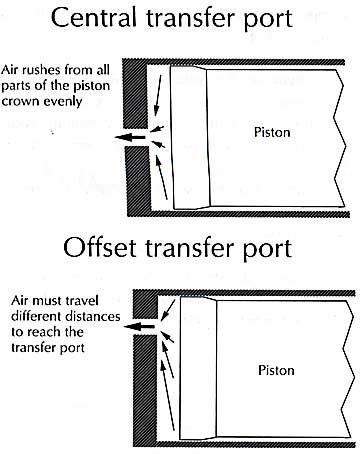

Where the hole is located plays a large part in the efficiency of the transfer port. If the hole is in the center of the compression chamber, the air flows evenly from all around the chamber and into the port. If the hole is offset, some of the air has farther to go, resulting in a decrease in the intensity of the air blast behind the pellet. That’s because some of the air is still flowing through the port after the initial shock wave has hit the pellet skirt and started the pellet on its way.

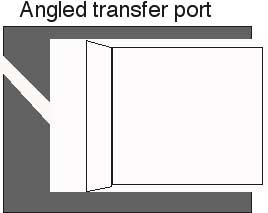

Some air transfer ports are offset rather than centered or concentric because the barrel is a smaller diameter tube than the compression tube. It sits atop the compression tube, making the transfer port offset. The Feinwerkbau 124 (and other spring guns) has a transfer port opening in the center of the compression chamber, but it also aligns with the center of the breech. To do that, the port is cut on an angle.

Unfortunately, when the port is cut on an angle, it has to be longer, and the extra length adds volume to the compression chamber–remember that? Extra volume means the air cannot be compressed to the same degree, and, if we are correct about the intensity of the air blast being more important than the amount of air compressed, well, then it becomes a very big deal.

The TX200 has a curious humpbacked appearance, because the barrel is lowered to align with the center of the compression chamber. Hence, a light spring can produce great power with less effort. The RWS Diana 48/52/54 is designed the same way and produces similar results. The majority of airguns are not designed this way, so their transfer ports either have to be offset or longer to carry the air where it has to go.

This was just our first look at the subject. Before you can appreciate how the size of the transfer port affects things, you have to understand the design of the transfer port.

I’m looking forward reading about the relative area of the port, as well as (funneling) shapes.

Where is the next part to this article? I have been wondering about ports for a while.

Hi Rich,

You can find part 2 here,

/blog/2008/10/the-air-transfer-port-part-2/

and 3 here,

/blog/2008/11/the-air-transfer-port-part-3/

Mike

Mike,

Thank you.

B.B.

Thanks guys.

The port on my XISICO XS28M rifle is said to be 4mm or aproximately .158″ in all 3 calibers. Seems it might be on the big side. I currently have a 25 cal barrel on it and wonder if I am losing some power from the port being so big. I’m going to put a new seal in it and might think about tapering the port a bit on the compression side.

My Hatsan is a completely different cat all together. I can’t even decide between the coil spring or gas spring.

Seems that over the span of time my links got broken, fixed here

You can find part 2 here,

/blog/2008/10/the-air-transfer-port-part-2/

and 3 here,

/blog/2008/11/the-air-transfer-port-part-3/

Mike

Merci beaucoup.

This may be old hat to many but these simple, clear explanations are gold to me.

Like most sports and hobbies the popular airgun literature is either way over the head of the beginner or condescending to them (me).

I can ‘t read bike magazines anymore because they either rehashes old information or goes into such minutiae that I lose the plot.

Thanks for giving us the basics and letting us learn from the bottom up.

I will be in Upstate NY next weekend, not far from Crosman. It seems that this area of the country was a hotbed or airgun development. Is there any museum, or public collection to visit?

Il Bruce

Bruce,

I think if you call, you can visit Crosman. They have most of their old models in the hall past reception and if you smile they might let you peek at the factory.

Tell them you read this blog.

B.B.

Good Morning B.B. I’ve been waiting for this ever since your article on your Wiscomb which included a picture of the different size “jets” for its various barrels. They so reminded me of the jets I was forever changing in my 2 stroke motorcycle carbs. What happens if you change the diameter of it, or it’s shape maybe taper it like one of those jet nozzles for a garden hose or make it like a rocket exaust? I’ll be waiting for the next instalment–Mr.B

B.B.,

Does the size of the air transfer point vary with the caliber of the airgun therefore decreasing or increasing the volume and the intensity of the air pushed in?

Thank you,

Jeff in N. Texas

Jeff,

Please be patient. All questions will be addressed.

B.B.

B.B.,

I apologize. I just realized I got ahead of myself.

Pls keep up the great work.

Jeff,

B.B.,

My compliments. You have a gift for making the complicated simple and understandable for us non-engineering types. This was a great piece, and clear as a bell.

thanks,

paul

So many thanks for this new series. Very interesting and valuable information…

B.B.

Your the man!!

Like the others said, great lesson for us beginners… I’m getting more and more confidence that I could open one up pretty soon..

When the rusty old winchester 422 I paid $50 for, gets here, I’ll tear her apart, and get a hands on lesson.

Do you think it costs more to build them like the TX200, and that is why other manufactures don’t do it that way?

Wayne,

Ashland Air Rifle Range

Wayne,

It definitely does cost more to make a TX 200. However, even they have made some cost savings, by designing some things to be more readily made. But most UK airguns have far more handwork than guns from other countries. That keeps the workforce employed and prices high.

B.B.

Matt61,

You noted yesterday that PA. doesn't have the Slavia CZ634.

I called Paul and Chris today at Pyramyd AIR and thanked them for the great repair and tune job. And asked why they didn't have the CZ line.. Chris said that the Air Arms 200 is made at that factory also, and that they will check into getting them for us. I told them I want to buy 6 or so for the air rifle range.

I got my parts for the Air Arms S410 magazine repair, a complete repair kit with lots of stuff, (no charge, thanks PA.) so I'm going to have to open her up a little to fix her. I'm afraid, but I'll be brave..

Wayne,

AARR&R

B.B.

That’s not a bad business model..

Especially when the TX200 holds it’s value, or actually goes up in value.

You can count on the TX200 being an investment and a great shooter, and not a “cost of having fun”, like others can be…

A little more money up front, saves a lot down the road, both in your fun level and pocket book…

Wayne,

Ashland Air Rifle Range

Do you have Webley Jaguar in mind for future reviews? I doesn’t look like the old Webley Jaguar.

Anything you could tell us about it now?

Tank you

Webley told me the Jaguar was a lower-powered spring rifle at the SHOT Show, and I was happy to hear that.

Now I see it’s rated to 1,000 f.p.s., so I wonder what happened.

I had no plans to test it, but nothing stops me.

Are you just looking for a powerful inexpensive spring rifle?

B.B.

BB,

As Christmas buying season nears it might be a good idea to update your best guns for the price blog series.

DB

Wayne, just a thought, but if you’d like me to fix the magazine for that ragity S410 send it on over–Mr.B

B.B.

Speed of air compression, eh? That’s new to me but I guess it makes sense. Did I understand you to say that the transfer port of the IZH 61 is not lined up directly with the breech but comes at an angle–was it 90 degrees? That would explain some of the reduced power.

Wayne, is the CZ for the Slavia the same as the CZ firearms company? I hear good things about them. I understand that the S200 is Czech made. What did your friend not like about the S200? The reports are otherwise uniformly good. The moment of truth with the S410. Scary stuff but a multi-shot S410 will be worth it. That is a very fine-looking rifle with the walnut stock in your pictures.

Matt61

BB,

I love these kind of blogs, but now we all have to go check to see whether our transfer ports are offset or not! Expect the next day or two we will see a forum post or two looking for a list of rifles with centered ports:).

DB,

That is a good idea! I need something for while I’m on the road to the Roanoke airgun expo later this month. I’ll start a list.

B.B.

BG_Farmer,

Yes, I expect there will be some concern about it for a few days, then people will go back to trying to put stronger mainsprings in their guns.

B.B.

Thank you for everything that you do Tom!!! This subject about the air transfer port is one that I have pondered over for years. I have asked many questions about this subject on other forums, only to get conflicting answers. I wait with *much* anticipation for the next discussion about the air transfer port. Any estimation on when we will see the next???

–davee1

Do you know if the new Webley Jaguar is actually a rebadged Hatsan model?

–davee1

davee1,

A couple days on the next installment.

Yes, I think the Jaguar is a Hatsan, since they are making all Webley springers these days.

B.B.

BB,

Just for your next one on this topic, I'm pretty sure that there are tradeoffs b/t "efficiency" and firing behaviour with the transfer port, just as there are with mainsprings; hope you'll look at it from that perspective, too, if that's true. In my limited experience, pushing out what is really just a little extra power (relatively, e.g. <50 fps on a magnum) can have a seemingly disproportionate impact on firing behaviour, spring life, and the list goes on. I actually wonder, for example, if the offset port doesn't gain a little smoothness in return for its reduced power output, with the increased stroke providing an additional percentage of consistency rather than efficiency.

Anyway, I'm always sceptical about "ragged edge" tuning in terms of how long a finely tuned system can stay in equilibrium, thus my preference for tractors, massive powerplants designed and "tuned" for durability and only necessary power, as opposed to hot rods.

About the Jaguar.

I am always looking for nice inexpensive rifles.

The IZH 60/61 as well as the BAM B21 are in my sights, but the question about the Jaguar is because the specifications are high and the classic Jaguar was a low powered rifle, isn’t it.

Plus I like synthetic stocks

BG_Farmer,

From what I’ve seen, using a concentric transfer port provides a very significant velocity boost with no threat to smooth operation. The Diana sidelevers are very smooth for their power level and the TX 200 is legendary.

But there are a few tricks I haven’t touched on yet.

B.B.

rimugu,

Yes, I believe the old Jaguar was under 12 foot-pounds. I was hoping this one would be 6-8, but it looks like Webley went a different way.

B.B.

This is for Kevin because he wants to know. Wayne because he is my major justification – yeah honey I buy a lot of airguns, but nothing compared to this Wayne guy. Last but need least, B.B. as I’ll need his advice.

PCP # 1 day 1 – Monday

A late appointment meant I did not get home until about 8:00pm. I saw the box still on the front stoop. The wife and kids have learned the long boxes are for Dad, so they seldom bother to bring one in, much to my chagrin.

After dinner I opened it up, my wife commented it was different and she liked the looks of it. My youngest said I better not be spending their Christmas present money. (No, I’m not) Bg-farmer, I would guess you would not approve. It has a gold package for the trigger guard and fill plug. Also “Webley Raider” in gold on the side. I’m guessing that is what attracted the wife to it. I prefer blued, but I ordered it sight unseen for $395.

An attached two shot magazine means you cannot check to see if a pellet is loaded, so I fired it to make sure is was empty. “Dad, that is too loud, go downstairs” In the confines of the basement it was even louder. So a PCP with no shroud means getting the hearing protection out of your range bag.

This rifle will not work like the spring guns for late night shooting or suburban backyard critter protection. I would guess the Discovery would be the same way. Very, very Loud.

PA carries the Tibet Almond stick that I like to apply on a used gun. A heavy application will hide most scratches. I put it on the entire stock and allowed it to sit over night. The rifle has nice blueblack on the metal and a wide flat forearm, similar to a centerfire varmint rig. Little over 7 lbs without a scope and 37 inches long.

Other then “new old stock” this Webley is no longer available. PA is sold out. Best I can tell it was offered for about 7 years.

PCP # 1 day 2 – Tuesday

In the morning, I put a quick coat of wax on the stock. With the two shot magazine I am unable to run a couple patches down the barrel. I give it a generous rub down with Beeman MP-5 on the outside metal, no rust shows on the old white T-Shirt so I am happy.

That evening, I decide to put a few shots over a Chrony. The rifle has no fill gauge, which means one less part to fail, but also means I have no clue how much air is in it. The Discovery has a gauge.

The Webley manual says the maximum fill is 200 bar, but the recommended is 190 bar.

Really doesn’t matter as I have no hand pump for it yet. You can get the Discovery with a pump included.

I take a .22 pellet, put it on the scale first and at 14.5 grains they average 850 fps. My Chrony lacks the printer, so I just shoot a short string to get an idea of the charge in the rifle and performance. I run to the basement PC under my favorites, /article/What_is_Muzzle_Energy_August_2003/5 and it advises 23.27 fps.

I pick a 6-18 Bushnell Trophy that is too long for most my current spring rifles, but will fit fine on the Webley. It was originally on an R-1, and then moved to RSW 850. My first shot at about 36’ misses the Gamo target and trap all together as does the second.

I go to plan “B” an old larger Beeman quite trap at 24 feet. Ball low and left. I dial in as much Up and Right as I can. No use. It is at the limit of its adjustable range. I maybe owe the 850 an apology.

It was late, so I’ll try again this evening.

Volvo

Way off subject BB but I was wondering if you ever had a chance to review the new RWS Lockdown Mount ?? I purchased the 34 Panther scope combo and got the Leapers Weaver style mount and rings but it shot way too high because I didn’t have that much barrel droop I guess ?? Had to resort to putting on the Lockdown mount with two stop pins and it was right on target with barely any scope adjustments. Any word on if this thing will hold without creeping or tear up my stop pin holes ??

Volvo,

Your report is a fine guest blog. Can I interest you?

B.B.

David,

I have not tested the RWS Lockdown mount at the request of RWS USA. They have withdrawn supplies of the mount and are working on it.

There will soon be another Leapers base with very little droop for those few rifles like yours.

B.B.

Volvo,

Gold is OK if you didn’t ask or pay for it:). My son is already talking about “Prissmas” (5 year old pronunciation), too.

BB,

Good point about TX200 and RWS48.

B.B.

I would be glad to.

I don’t know how much technical knowledge I can offer, but I could certainly share my novice PCP observations and experience. Also, I tend to make endless typo errors.

I wanted to enter the PCP world with just a big toe to start, so my options were a used rifle or the Discovery package.

I am still not sure how the rest of this story will turn out.

Volvo

This and the articles of the past week are the ones I’ve been waiting for.

Thank You!

Volvo,

Your user’s perspective is EXACTLY what the readers of this blog want. Don’t worry about the technical stuff. Just tell the story the way you did with your comment (which I want to be the first part of your blog) and it will be fine.

We will edit it here.

B.B.

BB,

When you say that RWS has witdrawn supplies of the Lockdown Mount that is a little scary to me and they didn’t want you to review it either ? Does that mean I have one big piece of junk on my rifle right now that might cause some damage ?? In your opinion should I remove it and just use the Leapers mount I have and shim the front of the scope for temporary until the new Leapers mount with no compensating droop is available ?

Any idea on when the new model Leapers mounts will be ready ??

Thanks and sorry for so many questions !!!

Volvo,

Go for it on the blog thing, my guest blog on the discovery to “glue or not to glue” took a long time, so get started now…. B.B. needs to use it by the time he goes to the show… So get ready to take the class for a day…

Matt61,

As far as I can tell the Slavia CZ634 is the same factory, but I’m not a detective, B.B. would know more..

My friend with the AA s200 was thinking it was way under powered, I think it was a 12 ft lb. But It’s supposed to be for target, which is it’s design. So don’t pay attention to him. He also had the S400 Carbine .22 cal single shot, I think made for Air Arms at the FX factory, like my S410 10 shot. It has a lot of power, like 30 ft lbs…

I notice that the AA s200 is out of stock for a while, but the S400H 12ft. in .22 cal at 581fps. would be an great buy for the way I shoot, lower speed, better groups. And in .22 cal you could do damage to a squirrel at 25 yards, an eye shot, with your offhand skills..

They claim a lot of shots with the 12 ft. lb models, and look at that stock, like my s410… same air tank, just dependable bolt action, instead of the 10 shot mag that breaks..but I don’t care.. I load up my 15, 10 shot mags, and lay them out and see if I can shoot them all before I get to 50 bar, so far only 13 with the 8.4 gr. JSB Exacts that are so accurate in these guns.

So think about trying out one right away, so you too, can do a guest blog for B.B. while he’s concentrating on getting me the most in trade value for the HW-55T.. thank you very much for your help in advance… do not distract B.B. while he is at the show any more than necessary… or I’ll go on strike…

Wayne,

Ashland Air Rifle Range

BB,I believe you remember me asking about transfer port experimentation a couple months ago.I’m thrilled we’re getting into this…Today’s blog was a great appetiser,can’t wait for the steak!!frankb

Volvo,

Congratulations on receiving the webley raider in one piece. Shipping a gun always makes me nervous. The horror stories I could tell about novices packing a gun.

Small and light weight appeals to me. Stupid question, if the gun doesn’t have a gauge how do you know it is filled to 200 bar? Rely on the pumps gauge?

Sent my 124 off this morning for a tune with special emphasis on the trigger. Ordered a new scope and the beeman mount specifically designed for the Webley rifles AND the fwb 124-127. Sure like those folks at pyramyd air. Very helpful and most important, patient with idiots.

Thanks for keeping us posted on your pcp progress. I also think it would make a great guest blog.

kevin

B.B. & Volvo,

I went "traden" today, I decided that I don't want the harder to control springers, so I took a bunch of them down to all the pawn shops in search of more deer rifles…

The cowboy in me won the day, with a Marlin 30AS micro groove 30/30 for my left saddle bag, and a Marlin 336-RC micro groove 30/30, for the right one…

Will I make a good looking cowboy on my donkey?

And can you still cover my back if we ride double?

If not you will have to walk along side, and carry the Ruger M77 in .270 for the long shots…

What do you think, six springer air rifles, for those three?

I had the same issue as David with my Panther. I bought the new Leapers mount with the rifle and had to shim the front rings to get on target. I returned the mount and got the accushot one piece mount at the recommendation of one of the techs at PyramydAir (I forgot her name but she was very helpful). The accushot mount has worked perfectly for about 1000 shots now with no movement. I used the stop pin at the front of the mount in one of the shallow holes in the rail and the rear of the scope base rests against the large screw at the rear of the scope rail. I guess the combination of the scope base stop pin, the screw at the rear of the rail, and the clamping pressure have been adequate. The gun shoots great and seems far more accurate than I am. I also took the but plate off and inserted plastic bags in the void and filled them with sand. This has served to make what little recoil and vibration the gun seemed to have almost undecernable. I also added a second adjustment screw to the trigger and changed the springs in the trigger for a VERY light trigger pull with NO creep. I have also decided on a way to add an overtravel adjustment screw. I’m having fun making small modifications to an already great gun. Maybe I’ll learn something about the transfer port that will inspire another mod.

Wayne,

No, no, “hard to control” for springers is the same as being able to participate in the shot more. When you actually get the coordination right down to the follow-through, it’s like you’re riding the pellet all the way in there. It’s like that movie Dr. Strangeglove where the Slim Pickens character is riding the bomb and waving his hat as he drops out of the bomb bay.

If power was the only complaint about the S200, I don’t care about that. It’s accurate. It has a shroud to quiet it down. And it even has a 10 shot magazine conversion which hopefully works better than the system for the S410. Now if only the S200 had a power adjustment wheel. That also seems to be missing on the upgraded Discovery that is supposed to be on the way. It has a magazine and a shroud but no power wheel. For someone who doesn’t have access to a scuba tank like me and will have to pump, the power wheel is key to extending the number of shots.

Nice cowboy outfit. I’m appreciating the side ejection of the Marlin lever actions after a few sessions using snap caps in my Winchester 94. As I cycle through the magazine, some of the dummy rounds get ejected onto my head. So why are you going with lever actions for deer hunting? Are you stalking on the ground instead of sitting in a stand? From a steady position, a scoped bolt-action would seem to be a better choice.

Matt61

Matt61,

That is why I chose the Marlin over the Win 94, the guy at the counter pointed that out, he said it’s a trade off (heavier to carry), with the slightly heavier Marlin 336, but the side ejection and heavier receiver are better for a scope, and you know me and scopes…

We have both thick Evergreen forests, and Oak woodland on the west side of the Cascades, and then high desert on the east side.

I live on the I-5 corridor, about 80 miles by crow to the coast, at the California border, in the Oak woodland, 2,800 ft elev., as you can see on the photo bucket. We’re in the center of the coast range full of deer and elk, and the Cascade range with the same, eastern Oregon, has antelope to boot…

So the Ruger M77 .270 should be the open hunting longer range rifle, and the the Marlin 336 s are for walking through the thicker brush, (prepared for bear), and hoping for an opening of a hundred yards… Most people around here like the Marlin 336 for that type hunting, and the lever action can be shot from the him if need be for surprise bear attack….. Or so the stories go… I’m a virgin here… Just been a .22 cal semi auto rabbit hunter in the long ago past, and a Hy-score .177 rabbit hunter with my dad, when I was 8 years old..

Wayne

Kevin,

You’re correct in that the gauge is on the pump. I have read that the most common place for a leak is in a PCP is the gauge- weakest link.

Once I figure out how many good shots it gets, I will sort a like amount of pellets and put them in an empty tin. Tin is empty, re-fill rifle.

Volvo

Wayne,

You made a good choice with the Marlins. I’ve seen and heard of many deer shot at 150yds. in a 40 yd. clearing:). I think they also feel more solid than the Winchester, but that’s just person perception. Glad you chose a donkey to ride — adds to the terror and mayhem, assuming you’re riding a fiercely-braying mammoth jack and not dragging your feet astraddle a mini.

Matt,

I like your description of follow-through; it does almost seem like you can see and guide the projectile on its path.

Re: Webley Jaguar and Hatsan Arms

It looks like the Webley Jaguar is a rebadged Hatsan Arms air rifle, judging by the shape of the stock in front of the buttplate.

–WFH

bg-farmer,

Of course it will be a mini, so my feet can be the training wheels.. This will be for protecting the frontiers… I'll be hunting on foot.. You know just like the "Rifleman"… Didn't he have one for each hand and draw them both at the same time, shooting from the hip?

Matt61,

On the number of shots per fill, that is why I think the single shot s400 12 foot lb, with the large tank like my s410, will get the same number of shots I get…maybe…just loading them one at a time, same stock, quite, accurate barrel, air tank, and trigger..for almost $400 less..

just a thought..

Also, we do have a problem with our email, could you send that "bounce" email to our tech guy:

jason.burns@naturalyards.com and his other address; ismscism@gmail.com

Thanks,

Wayne,

AARR&R

Wayne,

I’ll send along the emails if I haven’t deleted them. But I’m pretty sure the address was spelled “naturlayards” in the version you sent me. Moving through brush under threat of bear attacks takes some guts. Are you sure 30-30 is enough for that? I’d only go out with a minigun. You might take a look at Ernest Hemmingway’s hunting story, “The Short Happy Life of Francis Macomber,” about a guy who goes brush hunting in Africa with a Springfield ’03. In the final scene, a Cape Buffalo erupts out of the brush and charges him. He gets off several shots working the bolt–no small feat–but he hits a little high each time and the shots get deflected off the boss of the horns. At the very last second, his final shot hits home, but at the same moment, he gets plugged from behind by his wife, firing a desperation shot with the spare rifle! Anyway, stay safe.

BG_Farmer, now the thing is to transfer the follow-through technique to firearms. It seems like the shot is done before I know what hits me.

Matt61

BB,

This particular blog looks to me like another one of those “greatest hits” right at the core of our dear hobby. Expecting to see more. Please do include the relationship of transfer ports to accuracy. I will be excitedly waiting on that. We all treasure accuracy.

David

David,

I don’t know what the reason was for RWS to hold off on the launch of the Lock Down mount. Perhaps they found a way to enhance it.

If I had one I would keep on using it and just watch it for a while to make sure it still works as advertised.

B.B.

Wayne,

That sounds like a fine deal to me. I should put you on my table at Roanoke!

B.B.

Wayne,

Now that I know where you live, I should tell you that I spent some time in the 1960s in the Marble Mountain Wilderness area, panning for gold. Your area is one of my all-time favorite parts of the country.

B.B.

Volvo,

The gauge is only the weakest link for those ham-handed airgunners who can’t keep their hands off the rifle. If the threads are wrapped with Teflon tape the gauge will seal as reliably as any other part of a PCP.

The problem is when a gun is produced, manufacturers don’t have the time to tape the threads, so they use end seals for the gauges. That can be iffy if the assembler doesn’t go a good job.

B.B.

Hmm..if the “dead volume” of the transfer port plays such a vital role, is it correct to assume that loading systems like that of the Hammerli Nova (or even the bolt-action loading ports of the Crosmans, Sheridans etc.) waste much more energy than a breakbarrel or Diana 52-style loading port, which place the pellet right in front of the reservoir?

Do you believe it would affect accuracy to a noticeable level if the barrel itself can be moved forward and backward inside a sleeve to load the pellet? It was used in a few systems (Air Logic Genesis, for example), but never became popular…

Mel,

I’m not going to answer your first question because I hope to cover it in the upcoming reports. If I don’t, please ask me again, after the third part is published.

As for the moving barrel, unless the barrel has a secure and positive lock to return to after every move, accuracy is out the window. Witness the Anics Skif A-3000 and guns like it that use the barrel as a hammer.

However, the M1911Colt has a moving barrel and will still outshoot most popular pistols any day of the week, when it is properly set up. The barrel comes to a positive locked rest after every move.

B.B.

B.B.

Yes the Marble Mountain Wilderness is a real treasure, and it’s only an hour away… So is the Pacific Crest Trail that goes from the coast to the cascades on the east/west Siskiyou Mountains, through the coast range mountains.. It’s very nice to be here..

Yes it was a great deal I thought, since I get dealer pricing, it’s not to bad to trade at the pawn shops, they hammer the purchase price so much, that the sale price they offer is pretty low, especially with the timber economy off now, and fuel costs up so high.. A lot of folks are selling their rifles to eat and buy gas to get to work..

On the other hand, a chance to shoot in your back yard at $.03 per shot instead of $1.00 per shot, and not having to drive to the range, is driving up the price and desirability of air rifles. So the trade was pretty easy, there are a lot of pawn shops in town, and I also wanted to let them know I was opening the Air Rifle Range, so they could send me customers..

I got scopes on them all last night, the Marlin 336 is so easy to scope with a $6.00 weaver base, I could start real easy, choosing what I wanted from my air rifle scope inventory, to top it off..

I got a Elk tag too, how lucky can I get…

Sorry, your on your own at Roanoke, I would soooooo much love to be there, and shop with you!!!

But it’s a little to far, and too much time from the office.. this year..

Wayne,

Ashland Air Rifle Range

Wayne,

A dollar a shot!!!

We gotta get you into handloading. I can shoot .30-30 for 18 cents a shot, and if I cast the bullets, for 8 cents.

B.B.

B.B.

I guess I should have said the .270 rounds at a dollar per shot, I did get the 30/30 rounds for $7 for 20, after rebate.. but your point is valid if you don't count labor.. and who would in a hobby..

Little by little, I'll get there.

Wayne

AARR&R

Wayne,

And here is where the caliber almost doesn’t matter to a reloader. I can load .270 rounds as cheaply (almost) as .30-30. They do require a little more powder, but the primers and bullets cost about the same.

B.B.

B.B.

I like what you told Matt61 about using the spent pellets, to melt down and cast into bullets.. that seems like a very good use, I can see that there will be a lot more lead from pellets, than I personally would need for center fire shooting.. I'm still looking into remelting new pellets, but the investment vs resell is a little iffy, especially with the prices I can buy new pellets from PA at..

So the reload idea sounds pretty good, even if I make more than

Wayne,

AARR&R

Wayne,

Well, then, we’re just going to have to rev up your firearms shooting. I shoot 200-400 rounds of .45 ACP every month, and that amounts to nearly 11.5 pounds of lead. If I didn’t have about a half-ton in my stash, I would be seriously concerned, because that’s more pellets than I gather in a year.

B.B.

30-30 fans

Have any of you tried the fully POINTED (with rubber tip) Leverevolution ammo by Hornady?

I hear that they are good for some long range shooting with a 30-30 lever action, in the neighborhood of 200 YDS!!

I love my 30-30 Marlin 336. I use it for shooting from a stand and for in the woods. Works great with a scope and I find the shorter length to be ideal when in the tree stand as well. No knocking into branches over head when bringing the rifle up to a resting position.

I also like the fact that the ammo is inexpensive and is very effective. Plenty of power for a whitetail and no punishing kick like a 30-06 which is overkill for Whitetails in my opinion.

I have never had a need for a follow up shot, but then again, I am very carefull about shot placement from habit from having started with a single-shot black powder “Kentucky long-rifle” where a good first shot is critical.. LOL! (and no… I am NOT 220 yrs old…)

Revwarnut,

I’m with you on this. I just got a .30-30 (a 94 Winchester) and I love the light recoil. I also have a No. 4 SMLE Enfield that has very light recoil, as well. Wonderful rifle!

I haven’t tried the rubber tipped bullets and probably won’t, because for 200-yard shots I have a loaded-down 6.5 Swede that does everything I want.

B.B.