by B.B. Pelletier

This 3-part blog is a reprint of my article in Airgun Revue #4.

With the current fascination for antique big bore airguns, hardly a thought is ever given to the equally old hand pumps used to fill them. Yet, without those pumps, the big bores could not have existed.

In the scant airgun literature that exists, you can read a few accounts of the performance of the old guns. In doing so, you’ll encounter two very different viewpoints. The first are reports of people who have actually handled and fired vintage big bores. They describe how they performed and give estimates of power and accuracy that seem quite modest.

Then there are other articles written mostly from secondhand information. These are much more effusive in their descriptions of the performance of ancient air arms. What firsthand information they do provide is accompanied by very little hard technical data. Instead, they’re full of subjective descriptions of what it feels like (or must have felt like) to shoot the old guns–guns that the authors may have never actually seen! That got me wondering.

The Barnes outside lock rifle.

Knifemaker and airgunsmith Gary Barnes is the one who really started me wondering. I saw the big bores he was making and listened to him talk about their actual performance in relation to the embellished tales he had read, until I, too, began to suspect much of what had been written. The outside lock rifle he made in 1998 seems to indicate a remarkable level of performance with very little air pressure. Yet, when the wick is turned up in the form of more stored air pressure, the performance goes down. It seems there’s a specific window of good performance for every airgun, on either side of which lie negative returns.

If the guns of the past were so narrowly regulated by design, then their air pumps had to get them only into that optimum range. Greater pressure did not equal greater power; it actually upset a delicate balance of related components the guns need to perform at their best. So, when this relationship is understood, the performance of the antique pumps can provide clues as to the performance of the guns they serviced.

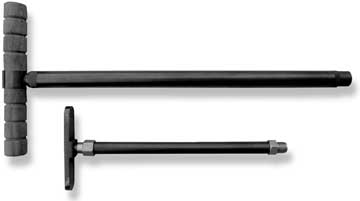

Two of the vintage air pumps made by Dennis Quackenbush. The larger one would be useful for rifles and shotguns. The smaller one would be for air canes. Not only is the size related to the amount of reservoir volume to be filled, the fit of the pump in the case with the rest of the gun and tools must be considered. Because of that, the handles and foot stands are made to be removed for easier storage.

I’ve seen vintage air pumps many times as parts of cased sets, but I never paid much attention to their construction. The assumption was that if anyone wants to charge an old gun today, they’ll use CO2, which gets them up to as high as 900 to 1,000 psi effortlessly. Or, they could fill from a scuba tank or a modern high-pressure manual air pump like the Swedish Axsor. The antique hand pumps are just for show, aren’t they? Perhaps not.

If we can establish the performance parameters of vintage hand pumps, then we’ll also know the range of air pressures within which vintage big bores had to operate. When that’s known, their power outputs can be calculated. Not exactly, perhaps, but it’s certainly possible to estimate the ranges of power within which the guns must be performing.

There are several good reports on vintage airgun power outputs. But, woven in with them are the other reports that lack validity. These are the exaggerated stories that many people, including myself, have tended to believe and to repeat because they are the more spectacular accounts. With them go proclamations of accuracy and of killing power at extreme distances, all based on these dubious and unsubstantiated claims.

Before we proceed, let’s look at another fantastic tale from the world of firearms to illustrate what can happen when facts are based on spectacular accounts. Legendary border patrolman and writer Bill Jordan was reported to have killed a criminal with a shotgun at a range of 100 yards. He was shooting 000 buckshot (.36 caliber shot), and one pellet was supposed to have hit the man in the head, if the story is true. Lethal, yes! Probable? No! No one doubts that the shot was anything but the wildest of flukes. Even if the report is not correct, the fact that it COULD happen is all that’s important for this comparison.

If we accept an account like this, someone who read and believed it might well write another article about how such a shot was possible at even 125 yards. Then, some other writer would key on that and, before long, there would be claims of lethality at 200 yards for a shotgun blast. It’s pretty ridiculous when examined this way, but that’s what’s been happening with big bore airguns for several decades, and no one has so much as raised an eyebrow. Until now.

In 1998 came the science of splatology. From Barnes’ careful observations of recovered lead balls fired from big bores, a correlation was made between the size and shape of the recovered “splat” and the velocity at which it impacted. It’s possible to determine impact velocity to within a narrow margin this way. The splats from the past, recorded by cameras and drawings, can thus be examined to reveal their impact velocity. It is, therefore, possible to deduce how fast those old guns were actually shooting–which turns out to be not as fast as some modern reports have said.

Still, splatology is not 100 percent conclusive proof. Balls going faster than 700 f.p.s. disintegrate entirely, leaving no record. There couldn’t be any historic proof of those. Since a splat represents only the impact velocity, we still have to calculate how fast the projectile was going when it left the muzzle. But, a gun that shoots in the 550 f.p.s. realm is probably not likely to also throw one over 1,000 f.p.s. Although we’ve heard claims of very high velocities for modern big bores, we have yet to actually see one demonstrated. In our experience, it’s been impossible, thus far, to reach such a speed with the big bore guns made today, to say nothing of the less efficient guns of centuries past. [Note: That statement was true when I originally wrote it, but modern big bores have progressed to the point that a few of them can now exceed 1,000 f.p.s. with light projectiles such as round balls.] By knowing the air pressure limits of vintage hand pumps, we have a big clue to the performance parameters of vintage big bores.*

———-

*Note: In the Fall of 1998, I fired a special Quackenbush Brigand rifle in .375 caliber that the maker had designed to operate on 3,000 psi instead of the normal air/CO2 combination valve that’s usually in the gun. The combination valve operates best at pressures around 1,200 to 1,400 psi because it’s set up to work with either air or CO2 gas; the 3,000 psi valve is optimized to that pressure alone. The 3,000 psi gun shot an 83-grain round lead ball through the chronograph at 893 f.p.s., making it the fastest big bore projectile yet tested by The Airgun Letter. This gun got four usable shots on a full air charge, but the first was the fastest and each successive shot was slower.

———-

One thing we know is that a pneumatic gun that functions well at one pressure level will most likely not do well at another. Therefore, if a big bore shoots 550 f.p.s. on a charge of 450 psi, it is unlikely to work at all when pressurized to 1,000 psi. We’ve known this about modern multi-pump pneumatics for many years. If you over-pump them, their velocity decreases until finally they cease to function at all. That’s the point called valve lock. Why wouldn’t the older pneumatics, different in caliber only, work the same way?

In fact, there’s no other way they can work! All pneumatics that use an impact-type valve will exhibit the same characteristics of an optimum performance window within a certain range of pressure. The window can be widened or even shifted by design, but there will always be an upper boundary. If there weren’t, the potential energy of a pneumatic airgun would approach infinity, and we know that it doesn’t. By knowing what air pressure was available to get behind the vintage big bore projectile, we can determine the energy window. And, we can find out the available air pressure by studying the pumps that created it. That’s the thinking that went into this test.

Quackenbush’s tests, methods and findings will be in future segments.

Good morning one and all! Splatology sounds like something that goes on at a frat party. Was the hardness of the lead taken into account? I’m waiting to learn about the seal technology. Were the pumps just single action? Once again good topic.

Good hunting B.B. Mr B.

Mr.B.,

You have to think about this like a blackpowder shooter. The bullets used by Big Bore airgunners and all round balls are pure lead. They are dead-soft, so hardness never plays a part.

B.B.

B.B. I am not a blackpower shooter. Will go read up on pure lead, velocity, and penatration for awhile. Seems to me that too much velocity would cause a “splat factor” limiting penatration sorta like pushing a bullet dsigned for a 30-30 at 300 Win Mag velocties.

By the way, arn’t you suppost to be hunting right about now? Ive got a mental picture of you in a blind rifle near by writing away on a wireless device of some sort:) Mr B.

B.B.,

Interesting article. Since the guts of this article is from airgun revue, it seems like you have a long history of not taking any air gun report/allegation as gospel but must find out the truth yourself. Great attribute. Testimony to your passion.

kevin

B.B.

I hope this is leading to a story about the Lewis and Clark air gun…

And get to hunting we will be fine.. we can get by, just not as informed… shoo, shoo now…

Wayne,

Ashland Air Rifle Range

dr. g.,

Your 54’s shift in poi after 30-50 shots reminded me of the same problem I had with my 54. It doesn’t seem to bother you as much as it did me. Yes, it would be shooting at the correct poi after 2 or 3 shots and a few clicks of scope adjustment, but it drove me nuts.

I’ll pick up the gun after not shooting it for awhile and the poi has shifted slightly. Can be high, low, left or right. One thing I learned is that if I shoot 4-5 shots through this cold gun, set it down for about 5 minutes and then start shooting again, it’s back on the poi from my previous shooting session that may have been a week ago.

When the poi started shifting, even after the gun was “warmed up” I tested everything, i.e., check tightness of stock screws, ring screws, base screws, scope adjustment turrets locked, etc. Not sure what solved my problem but it was one and/or the other of two things that I did. Either the installation of the new leapers base (that even without necessity of droop correction is worthy of installing on a 54 to provide a very positive scope stop and allow for installation of weaver/pictinney rings which are among the best in my opinion for variety of ring choices and lock up on the base) and/or the STEEL (not aluminum) warne scope rings. With the exeception of the first 4-5 initial warm up shots mentioned above, the poi has not moved on my 54 for over 1,800 shots (almost 4 tins of jsb exacts, 14.3 gr. which is all I shoot in my 54 now). I acknowledge each gun is different but this was the solution for my 54.

kevin

BB, speaking of lead – have you ever noticed a situation where a gun needed a few shots to settle in after changing pellets? More specifically, I’m referring to changing pellet alloys – for example, changing from Gamo Match or Hunter pellets to CPL’s, or from CPL’s to Superdomes.

I was looking at something the other day and came across a “user” of the Marlin 336A in 30/30, who claimed it was a great gun (no argument there) and that he had taken his first deer with it several years ago. At 350 yards with the deer running, one shot dropped it dead in its tracks! Of course, he had subsequently swithed to .308 for longer reach and better accuracy. Just thought it was interesting that someone would actually write such a pile of horse-doo. So, yes, don’t believe everything in writing…

Can’t wait to see how the antique guns and pumps work for real. Good luck hunting.

BB,

What is the most powerful air rifle you know of? Do puenmatic potato guns fall in the category of an air rifle?

Thanks

bg_farmer,

You made me smile. It seems as time goes by the distance of the shot grows in almost direct proportion to the size of the rack/antlers in most hunting stories.

At least now that he has a .308 he can shoot up to 1,000 yards.

kevin

Vince,

I’ve had that happen when switching from one to another pellet. I thought one (cheap) brand had ruined my rifle when I switched back to RWS and they shot worse than they had before. Quick cleaning with a brush restored accuracy, but it will also come back with more shooting… No idea what causes that — the rifle in question (Hammerli490) is supposedly too low-powered for leading, but it seems like something is going on.

bg_farmer,

Could have happened – but if it did it was pure luck not skill. Remember, even a blind squirrel finds an acorn once in awhile. I have a hole in one in golf, but on any given day I sure wouldn’t bet that I’d do it again.

Herb

And of course, he shot that deer off-hand. Me, I’d be lucky to see it at 300 yards!

Hi B.B. Always enjoy your post. Could we get some tests of the new CO2 pistols from Crosman and Daisy? Just in time for the holiday. Thanks

Hi BB,

Love this article! I find information about the old airguns fascinating. I’m also interested in the workings of hand pumps (and multi-stage compressors in general).

Like Mr. B, I’m also curious whether the old hand pumps are single stage or multi-stage.

Have fun on your trip!

.22 multi-shot

BB, I suspect it does have to do with traces of pellet material left in the bore. Even if it doesn’t build up enough to really require cleaning, there’s gonna be a little material rubbed into the bore that can affect frictional characteristics. I guess that when the pellet is changed each shot gradually replaces the old film with the new material, and total accuracy isn’t fully restored until this process is complete so that the bore is consistent from shot-to-shot.

B.B.,

Very interesting comments on how a story can be spun and exaggerated, but still be presented as the truth. I’m glad you are cutting through the weeds to give us the facts about the historic big bores.

Your approach of using splatology and achievable pump pressures to estimate the actual velocities of these antique PCPs is clever. I like it.

Calculating theoretical velocities is somewhat straightforward with only a couple of classical physics formulas if you know the bore, pressure, projectile weight, and barrel length. I have to emphasize theoretical, because there are many factors working to slow the projectile down and kill the efficiency before it even reaches the muzzle.

First formula is F=m x a. Shifting the variables around, a=F/m, the acceleration of the projectile is equal to the force on the projectile divided by the projectile’s mass.

Second formula is F=p x area, force on the projectile equals air pressure times the area of the projectile.

Third formula is v=at, velocity equals acceleration times time.

Last formula is distance (barrel length) =1/2at^2, distance (barrel length) equals ½ acceleration times time squared.

Manipulating these formulas in an Excel spreadsheet, with the correct units of measure, will give the theoretical MV based on an infinite air supply. If the gun’s air valve shuts the air off before the projectile leaves the muzzle, that will give a slight, but calculateable decrease in velocity.

It might be interesting to try some calculations to go along with the other observed data. I volunteer if you think its worthwhile.

Great blog, and have a safe and succesful trip!

Lloyd

I asked this last week..dont think I got an answer. I keep my rifle in the shed outside..any problem with shooting with a cold springer.

Tom

Tom,

I seem to recall somewhere on an old blog post that springers are okay down to 0 degrees Fahrenheit. Then, something happens. Could it have to do with the lubricant? PCPs are supposed to be good to at least 20 below which is the lowest at which they were tested with no problems appearing.

Matt61

CowboyDad,

I have a question that I hope someone can help me with.

I think the answer is going to be, ‘send it in’, but I hope not.

I have a Daisy Avanti 853c…their single stroke pnuemantic target rifle.

It’s just less than a year old. About a month ago I had a pellet jam in the barrel…which seemed strange because when I pushed it through with the cleaning rod it seemed to be perfect.

A month has gone by and everything seemed fine.

Until this weekend when it started jamming every 4 or 5 shots.

This is what happens. I cock the rifle and load the pellet. When I fire the trigger released, but no “pow” (if you know what I mean).

When I check the barrel the pellet is half-way down the barrel.

Out comes the cleaning rod.

After this happened 4 or 5 times I noticed that when I cock the rifle their is a very, very slight hiss at the breech.

I came to the conclusion that air was leaking…just enough to push the pellet a couple of inches down the barrel. With the Daisy if the pellet is not in the breech it will not fire…hence the jam.

Though I lubricate the gun as per instructions (every 1000 shots) I really soaked the felt wiper pad (which according to their instructions is the main thing requiring lubing) and it seems a bit better.

Has anyone else had this problem?

Will lots of lube cure the problem after it all soaks in (this just happened yesterday)?

Or do I just send it into Daisy?

Thanks.

Hey Lloyd,

A few other things. The pressure isn’t constant and the transfer port size and valve volume also factor in. The transfer port size limits the air flow. The valve volume limits the highest pressure that will be reached in the barrel. As the pressure inside the barrel increases, the pressure in the valve decreases. At approximately the point these two equalize, acceleration from the internal air pressure stops. From that point on, other acceleration (deceleration) forces take over. If the volume in the valve is large enough, the pellet accelerates all the way to the end of the barrel.

Of course this description is simplified. It assumes the valve is open long enough to equalize the pressure and it ignores air coming into the valve from the cylinder/tank which would keep the valve’s pressure up.

I would guess some calculus along with a formula for the pressure might give you an approximate solution.

I’ve thought about this and wish I knew fluid dynamics so I could have a better idea.

.22 multi-shot

BB said he was going to be away hunting with Big Bores in Texas.

Someone mentioned problems with a RWS 54. I had one for a few years. I found it to be the most hold sensitive airgun I have shot. Moving my front support 1/2″ would open up the group. The slightest cant would open the groups more than with most rifles. The gun was super sensitive to shoulder, grip, and cheek pressure. When everything was just right, it would hold a half inch group at 35 yards. But, get anything wrong and the group size would quickly double or triple. I think most guns are more hold sensitive that we think, but we never explore the limits of their accuracy and never discover it. If you are having trouble with a RWS 54, I suggest a very careful exploration of your rifle. First, make sure there are not loose screws or other mechanical issues. Put masking tape on the forearm and mark it every half inch and see where it likes to be supported. Try different front supports, a supported palm, a supported back of the hand, various rest, etc. Try varying the way you hold the rifle. If you do this carefully, you may discover a level of accuracy you never achieved before.

David Enoch

Hey .22 multishot,

Very good points, and I mostly agree. Yes, there will be an immediate pressure drop when the valve opens and it starts to fill the empty volume between the valve and the pellet. But I belive that once all the internal pressures equalize, the pellet will continue to accelerate as long as the pressure behind the pellet is greater than the pressure in front of the pellet, after deduction for friction and such.

Dealing with the variables is pretty formidable and some of the new fluid dynamics modeling and simulation software would certianly be nice.

Thanks for the comments.

Lloyd

BB – I love the big-bore pneumatic history, but how ’bout a history of springers? I’ve tried searching online, but haven’t been able to find much aside from vague references to post-WWII Germany.

Cowboydad..sounds like a broken spring..not enough umphhh to push it out..Tom

Lloyd,

You’re right! I overlooked the pressure differential on each side of the pellet (duh!). The internal pressure would drop after equalizing since the volume is increasing (the pellet is moving away).

.22 multi-shot

BB,

I built a silencer (MKI) that works…sort of. It is EXTREMELY quiet on 1-2pumps (Remington 77). It sounds like a bomb at 4 and 5. I built an integral silencer (MKII) into my crosman 66. It works great, not nearly as quiet as the MKI. It actually doesn’t distort low velocity shots as well as high ones. On the MKII, the range and accuracy decreases.

Shadow express dude

Guys,

RE: Barrel pressure –

I don’t think that the pressure in the barrel would ever equalize with pressure behind the transfer port (or valve). Also remember that in some 0.177s the pellet is moving almost at the speed of sound. Faster in some cases.

The speed of sound increases as pressure increases, but the point is that the air is moving down the barrel pretty close to as fast as it can in some of these guns. Thus this is a very dynamic situation.

Herb

PS – If it goes “pop” there is more pressure in the barrel than out. Seems to be universal that heavier pellets develop more energy (but less velocity) because they stay in barrel longer. Thus gas has a longer time to accelerate them.

Herb

David Enoch,

Re: A hold sensitive diana 54

I’ve read many of your comments on this forum and also on the yellow forum. You’ve had a lot of experience with a lot of airguns and I’ve learned a lot from your comments. Thanks.

Your comments about a hold sensitive 54 that you owned for a few years has short circuited me. My 54 seems to exagerate a shot with minimal cant just like you experienced with yours. I’ve installed an anti cant device from U.S. Optics on this gun for this reason (only level I have on an airgun). However,I have found that my 54 is the least hold sensitive airgun I own. I’ve shot this gun off a tripod with a V installed on top for support and usually bench shoot with the heavy 54 off sand bags with a towel on top of the bags so it doesn’t mar the stock. Accuracy is usually under 1/2″ at 35 yards (105 feet). None of my other springers will tolerate resting directly on anything but my hand placed where that gun likes it best. In addition most of my other springers want to be held like an ex-wife (lightly if at all). I had a non airgunner friend do better than me with the 54 his first time with the gun at 35 yards rested on the towel on top of my deck’s toprail (he’s not as tall as me and didn’t need my sand bags for height). My 54 is a newer model with the T05 trigger. Did you have an older model? Did diana modify this gun to not be hold sensitive since you had a 54?

kevin

Herb,

Good points!

I’m curious how many valves have a small enough volume that the pressure equalizes. I think the RWS 850 AirMagnum does. If you modify the 850’s valve by enlarging the hole from the tank into the valve, you get an increase in speed. I’m guessing that means the valve pressure equalized with the barrel pressure before the mod. With the mod the pressure from the tank then keeps the internal valve pressure up so it doesn’t equalize.

Thanks,

.22 multi-shot

Wayne: there was an articule in the American Rifleman about the Lewis and Clark air rifle. They think that they have the gun based on a repair done and documented in the expedition’s journel. Was an interesting read. Have you received the USFT rifle? Report please and thank you. Mr B.

BB, I know we aren’t supposed to dry-fire springers, and that multi-pumps are supposed to be stored with at least one pump in them. I don’t want to dry-fire my multi-pumps, but would it hurt them if I did? I worry about doing it accidentally.

–Witt

.22 and Herb,

A 12″ long .177 barrel is .295 cu inches; .22 cal is .456 cu inches. How do those volumes compare to the volume of the valve chambers you work with? Isn’t the purpose of the valve chambers mostly to conserve air?

My original comments were really directed more at big bore guns where the air is fed almost directly from the main tank instead of from an intermediate chamber. That way the pressure remains much higher in the barrel and results in the big “boom” instead of the “pop.” A .457 cal big bore barrel 30″ long would hold 4.92 cu inches if the valve remained open until the projectile left the muzzle. That would be quite the air hog compared to the .177 and .22.

And yes, many of the fluid dynamics laws do break down around the speed of sound, making predictions rather tough.

Regards,

Lloyd

Mr. B.

Thanks, I'll check out the article on the Lewis & Clark Air Rifle… someone put a link last week and I read some it and bookmarked it.. What a story, I'm sure there will be a documentary soon…

Just got a note that the USFT was shipped today.. maybe Sat. or Mon..

Hold sensitive…

Yeahaaah, like I've been saying… When the 54 and Tx200 are too hold sensitive…. (like I just decided with my TX and HW-77)… It's time to get out the AAS410 guys… or something like it.. don't you think?… or maybe you like the challenge of mastering the hold, like Matt61….

The closer I get to 800fps, the more of an issue it is for me personally… 750 -760fps seems just right for my skill level with a springer…

That means giving up springers for 50 yards in the wind.. and that is why the Springer division and PCP divisions are two different contests…Where the TX200 and HW-77 have won in the springer class.. so go for it Matt61 and guys… I'll be waiting right behind you, for my turn in the PCP class… your the real champs, "Masters of the HOLD"!!!

Wayne,

Ashland Air Rifle Range

I can’t believe there are so many problems with the RWS 54. That is supposed to be a fantastic gun right up there with the TX200. Now, I’m not feeling so bad about going cheap with the B30.

Wayne, maybe the thrill of springers is that of manual shifting compared to an automatic transmission. You’re right in there with the mechanism.

Matt61

Matt61,

You're right, I drive a 960 volvo 4 speed automatic with od… smooth as silk just like my Air Arms S410 side lever… one finger cocking while the gun is still at my shoulder & on my knee..

Hey, I'm an old fart now…. I did the 4 on the floor thing, starting with my 66 mustang 289 fast back, when I was 18 back a few years..

Wayne

RWS Diana 54

I’ve been sitting on the sidelines but would like to comment. I’ve had my 54 for over a year now and have put at least 1500 pellets through it, and although I don’t have a great deal of airgun experience, I find the 54 to be the least hold sensitive springer I have. In fact, I would say that it is NOT hold sensitive. I can rest it on my palm, or a towel, or a bag, and get equally good results.

I must admit that I have done a couple of things, though. One was to re-bore a set of one piece scope rings to compensate for barrel droop, and drill and tap it for a front stop. Pyramyd now markets a set up like this that BB developed.

The other thing I did was to fabricate and install a pair of spreaders at each end of the sledge rods to push them to maximum spacing and thus remove almost all the play they had in the bores of the bronze slide block. This pretty much eliminated the minuscule amount of side to side rotation wobble the action had on the sledge mechanism. Try this: with your 54 cocked and resting on a bag, grip the top of the scope and see if the whole scope-action-barrel assembly will rotate side to side. That is the movement the spreaders eliminated. Maybe its nothing, but it seemed to make a difference on my 54.

Just my 2 cents.

Lloyd

Lloyd,

Totally agree. The 54 is not hold sensitive. Great gun. Very accurate. Just need to use B.B.’s new base and a good set of rings and you’ve got an accurate springer.

kevin

Tom,

A cold springer may take a few shots to warm up and get into the operating range. The piston seal will be cold and inflexible and the mainspring will be retarded by viscous grease.

B;.B.

Airdog,

A History of Springers blog sounds like a good idea to me. Springers are relatively new, but they still do have a history that’s at least 160 years old.

I’m going to do it.

B.B.

I’m afraid this is completely off-topic, but I’ve just spent the last couple hours poring over your 10m air pistol posts and had a question about equipment; I couldnt’ find an email, so I thought I’d comment to see if I could get your opinion.

I’m considering adding 10m air pistol to my lineup of target sports, but I don’t have a whole lot of money to spend on a new pistol (the fund is going to upgrade my rimfire). From what I’ve seen in your posts, the Daisy 747 looks like a good choice, but I was wondering what your impression is of the IZH 53M – the grip looks MUCH more like the ones you’ve suggested, that allow you to lock your wrist in place. Which is more important to a beginning match shooter – the (probably much better) consistency of the Daisy, or the grip on the IZH 53M?

On a budget of $200, what should I be starting with?

Thanks!

-Kat-

Kat,

There is no choice here. Get the 747. It is a true target pistol. The Russian pistol is for plinking, only. Though the grip appears to be what you want, the gun is a recoiling spring piston design that cannot hold a candle to even the 747.

B.B.

BB

Well, You made two little boys happy beyond belief seeing their names in your Blog. They both demanded proof in the form of print outs of the blog to take to school to undoubtedly brag to their buddies. Btw, Logan is 11, Ethan is 8, I’d forgotten the thrill a young boy feels when he see’s his name in print. Both are signed up to shoot 5 meter Postal League in January and average 50-70 bb’s down range daily from their Avanti Champion 499. This has been an ongoing passion and their individual improvements has been nothing short of amazing.

Dime size groups shot from prone are fairly common. Needless to say I’m very proud of my Grandson’s and happy that I’m passing down a love of shooting and hunting that started in our family many generations ago.

Now BB, how about helping out a fellow old man who is some what confused about the Air Force Talon and the Talon SS. First off what is the difference and what does the “SS” stand for? I’m now 99% sure that the Talon or the Talon SS will best suit my immediate shooting needs rather than the Condor. (This caused a major debate between the G-Son’s and myself but all have decided against the Condor)

I realize what I am going to ask is hard to answer and by no means will I hold your answer one way or another against you. So that said;

If you did not have to be concerned with the financial obligation of purchasing either the Talon or the Talon SS and you wanted to have the largest amount of possible options what would be your list of items to go along with the basic airgun. (Think big here) I would like to start with 3 barrel in both .22 and .177. I wish Pyramid would put a package together this way as it would be easier for me to make a choice.

No pressure here but, the kids get out of school at 3PM Pacific..hehe

Thanks,

Pete

azpete@q.com

Pete,

Your original comment is having the same affect here, among the Pyramyd AIR ownership and senior staff. They are shooting emails around the office to let everyone know that our readers are really getting something from this blog.

There is no contest between the Talon and Talon SS. Just as I talked you out of the Condor, I’m going to also talk you out of the regular Talon.

The SS – whose initials can stand for whatever you like, because they never had a specific meaning – has the same frame as the Condor, except for the rear sight rail. So an SS can be transformed into a Condor with the right parts. The SS also has a large hollow cavity in front of the muzzle that helps minimize sound when the 12-inch barrel is used. With the optional 24-inch barrel, the SS can accept the same bloop tube silencer that the Condor accepts, which will make your rifle very quiet.

The bloop tube comes from Airhog

http://www.airhog.com

Now here is my list of stuff for the rifle. And I love shopping with someone else’s money, by the way!

Get the trirail, and either medium or high scope mounts (I like high mounts) and the AirForce 4-16 scope. I really like this scope on my own rifle.

Get the bipod.

I would get the B-Square scope level:

/product/b-square-scope-level?a=307

If we are getting both calibers, I would get the .177 barrel in 24-inch length for this reason. With a 24-inch barrel you use air much more efficiently. Think of black powder. Short black powder barrels waste energy and long barrels conserve it. It’s the same with pneumatic airguns.

I enjoy the hand pump, though I don’t have an AirForce pump at the moment. But I know it’s a good one.

As far as pellets go, here are my picks:

.177

Beeman Kodiaks

JSB Exact domed pellets (10.2-grain)

.22

JSB Exact 15.8-grain domed

Beeman Kodiak

Crosman Premier

The Premiers will lead the bore so use them sparingly. The JSBs are the most accurate. The Kodiaks will give you the most power.

I would seriously consider an Alpha model Shooting Chrony just because it will tell you so much about your gun. You can also use it with your firearms.

Say hi to Logan and Ethan for me. Do you know that the NRA Annual Meetings will be held in Phoenix in 2009? I plan to attend, so if you come I would be pleased to meet you.

B.B.