by B.B. Pelletier

I will be gone next Monday through Thursday. I’m going big bore airgun hunting on an exotic game range here in Texas. I’m asking you veteran readers to cover me on the comments during that period. Next Friday, I’ll reveal a big new product for you. It should be worth the wait.

I had completely forgotten about this series, but Stingray reminded me on Wednesday, so here’s the next part of the lube story. This is a really important report, because much of airgun operation and efficiency depends on the right lubrication and I’m glad to record it in one place.

Before I begin, we have a new reader who has just purchased what he believes to be an unfired Beeman R1 rifle in .20 caliber. I invited him to come to this blog and promised to answer his questions about keeping his new rifle in top working condition. This report on lubrication will go a long way toward that goal.

Today, I’m going to discuss how to oil the piston seal and breech seal on spring-piston guns including breakbarrels, sidelevers and underlevers.

Different oiling categories

Spring-piston guns must be divided into several categories before a lubrication plan is put into practice. I’m not talking about how the gun is cocked (breakbarrel, sidelever, underlever or any other method) but how the powerplant is constructed. The age of the gun plays a large part in making the lubrication schedule, so let’s begin there.

If you absolutely cannot find the air transfer port, you can drop the oil directly down the muzzle with the gun standing upright. On most guns, the oil will flow straight through the barrel to the transfer port. Only a few, like the IZH 61, have a transfer port located 90 degrees to the axis on the bore.

Leather seals

Some airguns are bound to have leather seals, and the older they are the more likely leather becomes. Leather piston and breech seals need lots of frequent oiling. Many of the older guns are also lower-powered, so the oil can be petroleum-based, if you like. For a gun with a leather piston seal, I would oil the seal every time you shoot the gun if you only shoot it occasionally, or once every two weeks if you shoot all the time. Drop 5-10 drops of oil down the air transfer port and allow it time to soak into the leather. Then cock and uncock the gun without firing, if you can, to make the seal flexible. Often, you can hear the seal go squish when you do this.

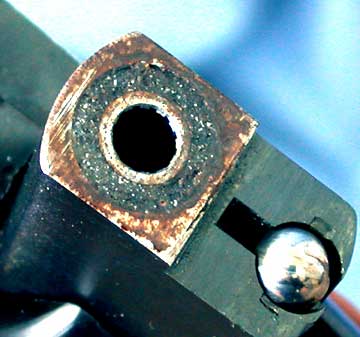

At the same time, if the gun has a leather breech seal, drop two drops of oil on the seal and allow it to soak in. If the seal is synthetic, it doesn’t need any oil. It will be oiled by the small amount of oil that’s blown from the transfer port as the gun is fired.

That dark circle around the bore is a leather breech seal! It doesn’t look very good (kinda flat), but with frequent oiling it still works after 40 years!

Synthetic seals

Guns with synthetic seals require far less lubrication. The best of them are the RWS Diana rifles whose piston seals are nearly self-lubricating. The worst are possibly the cheaper Chinese guns whose seals are made from softer synthetic and may need more lube to do their job. I’m talking about guns like the B3-1, not a Beeman gun made in China. On average, a single drop of silicone chamber oil every 1,500 shots or once a year is about all they require. You can double that time for RWS Diana guns. The oil goes down the transfer port, the same as for guns with leather seals.

Unique seals and special circumstances

Some target springers, like the FWB 65/80/90, have piston rings that require oil infrequently. Follow the owner’s manual for these guns. Other target guns, such as the Diana model 6 and 10 pistols and the model 60, 65, 66 and 75 rifles, have synthetic seals that require very little oil. Older guns, such as the Webley Senior which are pre-WW II, have a beryllium-copper piston ring that needs more oil. A couple drops every month or every time you shoot the gun will do. These older Webleys also have a fiber washer that serves as a breech seal. Oil them like leather breech seals.

Another special circumstance is a gun that’s been lubricated in such a way that it lasts for many years without any extra lubrication. When I lubed my Diana 27, I loaded the mainspring with white lithium grease. It continually wicks into the piston seal and keeps it lubed, and that’s been happening for about a decade now. When I tune a gun with synthetic seals, I coat the compression chamber and seal with moly grease. A gun will last 5 years lubricated that way–maybe less with hard use. So take the advice the airgunsmith gives you when he tunes your springer.

There’s a final special circumstance I need to describe for you. Some spring guns made in the 1970s–like the FWB 124, Walther target rifles and Diana target rifles and pistols, have a poor formulation for the synthetic piston seal. The piston seals in these guns can dissolve in minutes when they’re oiled for the first time after a long dry spell. The symptoms are that the gun won’t shoot a pellet out the barrel, and you’ll find chunks of a dark yellow waxy substance in the barrel when they’re fired. Those are parts of the disintegrated piston seal. Stop shooting and replace the seals immediately. The new seals you use will not do that.

Beware of older information

Beware of reading the older airgun catalogs. They contain instructions for more frequent oiling of synthetic piston seals because people were not yet accustomed to the longer intervals they really require. Consequently, they tell you to oil every 500 pellets and to use three drops or more, which is way too much for a synthetic seal.

I have purposely not covered any other lubrication for spring guns. That subject will get its own report, next.

B.B.,

First off, have a great hunting trip!

Last weekend I was given a beat up and dirty Marksman 1790. I tried to get a drop of oil or two down the transfer port but on this gun the breech seal is on the breech side not the bbl side. I managed to get a nice oily seal but I am not sure the oil made it where it was supposed to.

Can I give the tube of oil a good squeeze? How much is too much? When do I have to worry?

Cheers,

Bruce

Bruce,

A nice oily seal is what you want. That’s enough oil to do the job.

Three drops through the transfer port will take care of the piston seal, if it’s in good condition.

B.B.

B.B.

Enjoy your much deserved break from the computer… I bet your going to test out a new big bore from Korea..

This oiling blog is just what I need, I’m going to print it out and post it on the wall.. Then I can refer to it until my brain gets it.. Also, others can see what to do if some of these old springers, (and new ones) I’m buying aren’t preforming…

Thanks

Wayne,

Ashland Air Rifle Range

BB

Received the package yesterday– Thanks again!

Joe

A late good morning B.B. Enjoy the big bore hunting trip–do you possibly need a gun bearer? You know that we’re all waiting to hear about the hunt. Are you going to shoot some video for us? Tell us about the guns used and why the choice of A vs. B gun? Is there a general rule of thumb that will tell us when the manufactors switched from leather to synthetics for piston seals or is each a world unto itself? Thanks much Mr B.

B.B.,

Where did you obtain the white lithium grease you “loaded on the mainspring” in your diana 27? Is this a maccari proprietary blend or is it easily obtainable?

Enjoy your hunt away from us needy kids.

kevin

Sorry CowboyDad, my comment yesterday was criptic. I meant make sure and put a drop of pelgunoil on the tip of the CO2 powerlet. 🙂

.22 multi-shot

Joe,

Thanks for letting me know.

B.B.

Mr. B.,

Just call me B’wanna and the job is yours.

As for which guns have leather seals – it’s a crap-shoot. Nobody knows without cracking them open and the factory can change directions in mid-stream.

B.B.

Kevin,

I use the white grease the Army issued for the M1 Garand. You get it at a gun show or in a surplus store.

White lithium grease is fairly common as a new product, too. You can find it in automotive stores and farm supply houses.

B.B.

.22 multishot (or B.B.).

I have slight dilemma. I received the PPK Wed evening. In the instuctions it did to say to put a drop of RWS Spring Cylinder Lube on CO2 powerlets.

Of course I had none and ordered some from my local supplier but it will take a week to get here (there isn’t a single sporting goods store where I live that takes airgunning seriously).

So my question is, if I only shoot a couple of powerlets over the next week will I hurt the gun to use a drop of non-detergent motor oil (the kind that Daisey recommends as a lube) in place of the RWS or Pelgunoil.

Thanks,

CowboyDad

B.B.

So, how does one oil the seals for the IZH 61?

Matt61

CowboyDad, you won’t hurt the gun. So go ahead and shoot allover the place.

Thanks anonymous

bb,

what happens if you over oil a spring gun (damages). I’ve put 1 drop of oil every 500shots when using my storm xt. It still shoots as good as the day I bought it. How much should you oil the main spring? I have RWS spring cylinder oil which is pretty thin. I apply 6 drops across the spring when I start hearing vibrations.

Stormk XT,

You are oiling too much now, but if it seems to work, don’t stop. The mainspring doesn’t need much oil at all. But you are oiling when you hear or feel vibration and that’s one of the symptoms that the gun may need oil, so just keep doing what you’re doing.

B.B.

CowboyDad,

Like anonymous said, go ahead and enjoy! As per one of BB’s prior blog entries, pellgunoil is 20 weight motor oil with o-ring preservative added (no other additives).

.22 multi-shot

BB,

I usually oil (2xdrop of silicone chamber oil) by the squeaky/honking-cocking sound, and it seems to be much more often than you state. Even my 36-2 with the Apex seal (i.e. known good) needs a drop every 800 shots or so. Is this a symptom of seal being too tight or some other problem, perhaps with me:)? Otherwise the rifles seem to work fine and are consistent, except for perhaps the first few shots after oiling.

BG_Farmer,

I would say your seal is tight, but who is to say it’s too tight? If the gun develops normal power the seal is doing its job.

Your rifle may consume oil faster than other makes or it may have a rougher chamber wall or any of a dozen things. The important thing is you are oiling according to the symptoms of a dry seal (i.e. squeaking). If the gun shoots fine I would keep right on doing what you are doing now.

B.B.

B.B.

Matt,

Pour oil down the muzzle of your IZH 61, then set the gun down so the muzzle is elevated about 45 degrees with the receiver upright. The oil should be able to turn the corner when it gets to the 90 degree transfer port.

B.B.

BB,

I think you may have hit the nail on the head with rough chamber wall, at least on 36-2. I did that on purpose (like a cylinder hone), but I probably went overboard:). I’m sure it will wear in — it was originally like glass from the old leather seal.

Hi BB,

Maybe you can answer this…

BG farmer mentioned hatching the compression area and i was wondering which seal types like the honing better synthetic or leather?

I figured the leather seals would love a smoother”like glass”finish and the synthetics a very mild crosshatch hone.

What’s your take on that?

Thanks

FC

The white grease everyone is talking about is most likely Lubriplate. It used to come in a tube, like toothpaste, and in small cans. We used it in the Marines to coat the camming surfaces of M-1s and M-14s. The company, Lubriplate, has a website, but it isn’t very informative; it lists products without showing samples of them.

–Witt

B.B.,

Have a great trip next week, and its nice that its not 1200 miles away, like Roanoke!

Like Mr. B asked, I’ll be interested to hear about what guns and calibers are there, and if success hinges on the gun or the hunter, with some luck thrown in.

I’m also interested in the logistics of the air supplies: How far afield do you go? The tanks are generally left in the truck? Does anyone bring a little 4500 pound carbon fiber paintball tank out with them for emergency backup, etc. What happens if you are in the field and you take a few shots and the pressure drops too low for a strong shot?

Enjoy your much deserved break,

Lloyd

Hey B.B. –

I have a Gamo Multishot, breakbarrel air rifle with an 8-shot rotary magazine. Over the past 6 months, I have noticed a decrease in performance, and the consistency of the nose after each shot has really changed. I have put about 4,000 rounds through the gun. Unfortunately, I have never oiled it. I am planning on buying some Pellgunoil and starting to oil.

After such a long period of time without any routine oiling, should I just oil the air transfer point? Should I just use a couple drops of oil, or should, because I have never oiled, use a little more than usual? Also, concerning the placement of oil, is the oil just dropped down the air transfer port?

Thanks,

Richie

B.B.

So the transfer port comes up from below? Is Pellgunoil okay? Thanks.

Matt61

BB

What sort of lubbing must be done to the compression chamber and piston rings of the FWB 300? I am due to take ownership of one soon and have ordered seals and springs for it.

Ton

BB and all,

A friend suggested fabricating and installing piston seal made of engineering plastic on an FWB124. What are your comments on such material? Will oiling such improve anything?

Thanks.

Hi BB, thank you for your blog. Which would you say is more accurate- a Gamo CFX or RWS Diana 34? I would scope the rifle,and at 20-30 yds, which is more accurate? I might tune either gun when I choose them ( I have some experience with tuning from cheap chinese Crosman springers).

Wayne,

About how many shots do you get from your TX200 before you have to adjust the scope point of aim due to the scope moving around from the recoil of the rifle?

Thanks.

– Dr. G.

Richie, just drop a few drops down the transfer port and your good to go. 8 more months do it again.

B.B. and all,

First, B.B. – Have a great trip and (as above) the break from ‘the kids.’

How about lube for a IZH 46M?

Waiting to see the stills and video from the trip.

Al Pellet

Dr.G.

I haven’t noticed too much… But I haven’t shot it that much. I got it right before the Air Arms S410, and that’s when I became S410happy.. and lost most desire to shoot any springer.. but for you my friend, I will shoot 100 -200 shots on it tomorrow and let you know.. It will be good for me to “widen my horizons” again… and besides Billy Lo is sending the USFT (grand prize in the 2005 Field Target nationals) I bought from him and I’ll have it next week and won’t be shooting anything else for a while after I get it..

So I’ll let you know tomorrow afternoon..

To “fabricating a piston seal out of engineering plastic for a fwb 124”,

The fwb 124’s have a parachute seal design. This may present you with a challenge in replicating. Look at the picture in the bottom of this article B.B. wrote on the fwb 124 seal:

/blog/2008/3/spring-piston-seals/

Not sure what specific material “engineering plastic” is, but after you read the above article I provided a link to you will see that even manufacturers have made mistakes with the seal material they used. If you’re handy and want to experiment go for it. Just realized that if your seal disintegrates a little and you continue to shoot you risk damaging the compression tube.

A lot of thought and experimentation has already been done on fwb 124 seals since the original material failed. Here’s a link to the most popular seal used in the fwb 124/127’s. Please also note on this site that you are also able to purchase complete “drop in” kits for your fwb 124:

http://www.airguns.citymax.com/catalog/item/251483/483181.htm

Good luck.

kevin

BB, Good luck, be safe and have fun. When I bought my Beeman RX-1 back in 1992 I had read everything I could get my hands on at the time. I THINK I remember Robert writing an article or maybe it was in my owners manual about how the guns typically come WAY over oiled from the factory and not to oil it until I heard a squeak or at a bare minimum until at least 1000 rounds had been through it. Then it was one or two drops into the port. BB, I’ve oiled my gun one time in probably 5000 rounds. From SavageSam

FC,

Leather likes a smoother finish than synthetic.

B.B.

Richie,

Drop a couple drops of oil down the air transfer port. That’s all you need to do.

B.B.

Ton,

One drop of silicone chamber oil after every thousand rounds.

B.B.

Engineering plastic (Delrin) is too stiff for piston seals.

B.B.

Hello everyone:

This time I have no questions to ask… But I am just going to say that 5 minutes ago I ordered the Airforce Condor… It was a huuuuuge investment, but that’s what savings are for (sometimes… LOL)… Anyways, Im just excited, but many of the things are out of stock… That sucks (more waiting)…. But I just want to thank you B.B. and Wayne and the others for always responding to my doubts…….. You’ll be hearing soon enough about my experience with the Condor… Take care everyone!!

Cheers,

Jony

ShootThePigeons ,

The Diana 34 is more accurate than ther CF-X, but it requires more technique. Held the same, the CF-X will be better.

B.B.

Al Pellet,

Crosman Pellgunoil is great for a 46.

B.B.

Wayne: a question please. Which moderator did you buy from Anthony and how well does it work? Thanks for your answer. Mr B.

Jony: congradulations and welcome to the world of PCP’s. You’re right cause it’s sure a major expendicture but :):). Just remember to respect it awesome power.

B.B. Enjoy the hunt B’wanna

Wayne,

Air Arms needs to pay you as a spokes person. You constantly remind me that my small collection is inadequate due to the lack of an S410.

Anyway, some tips for selling on the yellow classified. You may already know this, but:

Once you get pushed down to page 3 – it is a good idea to repost the item. When you complete a transaction, ask the buyer to post feedback on the BOI. It is like a rating on Gunbroker or EBay. You should do the same for them.

Also you can post want to buy ads, such as WTB an FX Whisper. : )

Volvo

Wayne,

Listen to Volvo.

Marlin can use a spokesperson, also. Maybe you can get endorsements as “professional airgunner, well-known elk hunter, sportswriter and entrepeneur”. There could be a line of “Waynee Boys” comfort shooting chairs, also.

Heck, I already got a deer tag for this year and sighted in, even though I’ve not hunted anything (for sport, not control) in 15 years, just based on the vicarious excitement derived from your elk hunt:).

Bg_farmer & Volvo,

You found me out:)!!! you should see the size of the kickback checks I get from the "WayneeBoy" chair line..

They want to endorse a field target line with my name on the back… but, I'm holding out for more money..

I do want to try a FX Whisper, but might have to wait until Feb., when the raised bed business goes crazy.. unless I can trade my heavy recoil springers for one….. how about 8 for one anybody?

I've been emailing and answering adds, so I haven't shot the TX-200 yet, still time this afternoon..

Wayne,

Ashland Air Rifle Range

BB – God Speed and Good Luck on your hunt. Hope we’ll get to see some of the guns you’ll be using (and the air sources).

Wayne – Do you have a link for the WayneeBoy? I have a space at my garage range laid out for one. It’s good to have your name on the back of an FT, as long as your face is not on the front.

Randy,

That’s for sure, they’d never sell one with my face on it.. better stick to my groups or guns I shoot..

You’ll have to get one at the goodwill for now, they have a big Halloween blitz planned… then they will use my photo on the back..

Wayne

Bg_farmer,

Air Arms TX200 HC Hunter Carbine .177 report,

Well with a sore left arm from cocking the 35lb short carbine lever, I’ll try to type a report…

If you don’t want to read, here is the photo bucket…

http://s424.photobucket.com/albums/pp325/wayne177/

I started out on the crony to be sure my memory was right about the best pellet… JSB exact heavy 10.2.. I was right.. 30 shots gave a difference of only 6 fps and averaged 796fps.. So I put up a sheet of 25- 1/8″ dots with 3/4″ crosshairs on the clay silent trap, at 20 yards indoors over the pool.. Then settled into the “WayzzBoy” recliner and assumed the field target position.. gun resting on my knee with semi-open palm under the forearm.. The first row of 5 dots showed I needed to adjust the scope up and left… I did, and adjusted my hold a little looser, just a little side holding on an open palm.. The second row of 5 shot groups gave 3 one hole, with the largest hole 3/8″ and one group of 4 at 3/8″ and a slip in the hold 1/2″ low and right, and the other dot not bad..

3rd row: only 1, one hole group of 5/16″, but the worst was 3/4″ (outside to outside). The 4th row about the same.. The last row had two one hole groups of 3/8″ and three wild 3/4″ groups…

I think the TX200 HC didn’t loose POI after I adjusted on the first row.. so that’s 100 shots with no adjustment. and it needed adjusting to start with.. The worst group was 3/4″, but 11 out of the 25 were that 3/4″…

This is a fine under lever air rifle, probably the best springer on the market for under $600.. but for me I can’t be consistent like any of the PCPs including the super low price point Discovery, which would do about the same as I just did with the TX200.. But someone who can master the proper springer hold could probably get all 3/8″- 5 shot, one hole groups on all 25 dots… but that’s not me, I’ve got an Air Arms S410, which I can do all 3/8″ one hole groups with, so back to case for the TX200 for another long while..

Wayne,

Ashland Air Rifle Range

Mr b,

I added to my order, (for the FX Timberwolf, BSA Lonestar, and the Discovery) and so, have not received them yet… I should get my "sight extenders" or "barrel weights" as Anthony calls them, late next week.. I'll let you know then..

Wayne,

AARR&R

Wayne,

Thanx for testing the scope’s ability to hold its Point of Aim atop the TX-200 through 100 shots. That is better than my 54 does, which is what I was wondering.

It is my understanding that Anthony makes one type of moderator, and it is the quietest out there. If he makes more than one type than I would like to know.

– Dr. G.

So, BB – how did you like the QB88? The one in the pictures?

I just got one (used), and find it’s a crudely constructed and finished gun with a trigger that is easy to improve and the ability to make easy one-holer’s at 10 yards. It’s also a smooth and quiet shooter that’s great as an indoor gun. One of the best performing rifle’s I’ve ever seen from Shanghai. A real surprise.

Dr. G,

Yeah, it's the shooting hold, (me), not the scope moving on my TX200 or the TX200, they can do better than me… I need my PCP to do well…

Anthony makes all kinds of stuff, he's got a machine shop I guess.. from what I got talking with him on the phone.. I think he works on guns too… He seems like a Great guy.. and like I said I haven't got my order of "barrel weights" yet..

Wayne,

AARR&R

Vince,

I don’t know why someone like Hammerli or Beeman doesn’t get Shanghai to dust off and clean up the QB88 a little bit (round off the stock and maybe add peep sights, etc.) — its a really nice little rifle to shoot, especially at 10M targets.

I own a Gamo Whisper VH… I believe it has a synthetic seal… How can I differentiate between leather or synthetic…???

Cheers,

Jony

Wayne, looks like Anthony is about done with yours and ready to start on mine. So maybe I’ll be letting you know. Got my 24″ .22 barrel, aleady have the barrel weight, for my Talon SS. Will run the chronny tomorrow weather permitting. However, it’s noticably quieter than the SS with it’s own barrel weight with CO2 and HPA. Look out woodchucks and red squirels. Mr B.

Jony

All of the new spring guns have synthetic seals including your gamo.

jeff

Wayne,

It is my understanding that Anthony makes adjustments on the Air Force triggers, modifications to the stock (and different stocks), and his attenuator for sound.

If he has begun working on other rifles or has agreed to make modifiers for other air guns then let me know.

-Dr. G.

Dr. G.,

The poa on your 54 is moving in less than 100 shots? Do you have the new leapers base installed? What rings are you using?

kevin

Transfer port length guy here, from a few columns ago. That chinese sidelever was what I had in mind when I asked about transfer port length.

I don’t know if you often speak to the pyramydair management but I think the poll they have concerning plastic parts is poorly worded.

A plastic part is OK if it is properly designed, not JUST durable. I have had plastic triggers that flexed, and ones that don’t flex. So a plastic part has to be durable AND strong/rigid enough to perform its role, not just a substitute material in a part designed for zinc or steel.

anyone know how the loudness of a 22 discovery would compare to a 22 cb rimfire?

Hello:

I was browsing through the Internet and found out this website that sells EXACT replicas (framework, velocities, etc.) of the AirForce Condor/Talon models, but under other names…….. Is this legal??? Just curious…

Cheers,

Jony

I forgot to write the link… sorry:

http://www.gunpower.org.uk/

Cheers,

Jony

TPL guy,

I forwarded your comment to PA.

Thanks,

B.B.

The Gunpower “replicas” are most likely the real deals simply imported under another name, with a few custom pieces for the local market, (silencers being somewhat restrictive in the US).

If not, it’s only leagl if AF did not protect their IP in the UK, which many companies fail to do.

AF vs Gunpower Stealth,

I covered this on Airgun Illustrated third edition.

Same same.

B.B.

Vince,

Yes, the QWB 88 is a bit of a surprise. I don’t know how accurate mine is, but I’ll have to look into it.

B.B.

Question:

What do you people recommend for me. I am going to buy either the Condor or Talon SS; but i am unsure of which one to choose. I am not much of a hunter (only ocassionally. LOL) And I would like to obtain as much consecutive shots before refilling.

I know that the Talon SS shoots more per fill than the the Condor (am I correct??). But I also know that the MIcro Meter tank will help the Condor last longer… Personally, I prefer the Condor for its power, but as I said, I dont really need 60fte. Now, can you guys help me decide over which one?? Is there big difference between the longevity of each fill??

Conalon

Dr. G, & Volvo…

See what you did, in testing the TX200, I decided to sell/trade it and my HW-77 for a FX Whisper or Monsoon… so I put the TX up on yellow and http://www.gatewaytoairguns.com There is also a non carbine up there… so go shopping folks wanting a good deal on a TX200 HC or MKIII in .177

Wayne,

Ashland Air Rifle Range

Wayne,

Good luck with getting a Monsoon that works well and consistently. I had one and it was awful for every reason imaginable, including the “service” that I received by the seller, AA. The concept of a semi-automatic is great, but the design has not been perfected.

I notice that you buy and sell used airguns, and so perhaps you can answer something that I have wondered. It seems to me that any airgun that I have that shoots really well is staying with me for a long time, and only those that are not highly accurate would be even considered for selling. So, I imagine that there is a tendency (a trend, not a hard and fast rule) for the air guns sold used by other people to not be the really accurate ones. I would even think that anytime somebody has a really innaccurate air gun then that is one good reason that prompts them to sell it. So, Wayne, do you tend to sell your air rifles in part due to their lack of accuracy (or conversely, when you have a really accurate gun do you decide to never sell it), and are the air guns that you buy used as accurate in general as the ones you buy new?

Kevin,

On my 54 I did not need to use the new Leapers base, as there is no significant barrel droop. I have a pile of bases and rings of all sorts that I use, and so I will have to look at it when I have time and answer your question in the next couple days. You are correct to ask this question.

I have tightened all the screws and bolts (none of them were loose anyway), and have now simply gotten into the practice of making small adjustments about every 30-70 shots (e.g., it might suddenly shift 3/8″ down and 1/4″ to the left) and within 2 shots I am back on target. The wierd thing also was that I would put the rifle away shooting accurately, and the next time I shot it sometimes the POI had shifted.

This to me seemed an obvious case that I was holding the rifle a little bit differently when I picked it up after a couple days, or perhaps was suddenly holding it differently while shooting groups. So, I became very careful to hold it the same way, and even still get the POI shifting. It is not that big a deal, and actually it is not even enough of a hassle for me to shoot it any less often or to consider selling it. Because I use this rifle 99% of the time for 10 meter target shooting, I know just how many clicks of windage or elevation I need to dial in when I am a bit off, and so I am only slowed down by one or at most two shots.

I think that this is primarily a hunting air rifle, as it is very powerful for a spring gun, and I surmised that it was not designed for shooting hundreds of shots at a target (obviously fatiguing pulling that lever 100s of times). I figure that it was more likely designed to shoot 20 or 30 hunting shots in an afternoon, and that perhaps asking it to hold its POI precisely beyond that is asking too much.

– Dr. G.

Dr. G.

Thanks for the report on the FX monsoon.. I’ll wait on that one for sure… have you tried the FX Whisper?

The reason I’m selling some springers now is two fold…. 1). I’m selling the ones that are hard to shoot accurate for a new person at the range, one that needs a special hold, to be consistent… and that to me is most all springers over 750fps with a JSB 8.4.. I want people to take a rifle off the shelf and shoot good groups off a bench rest if they can be steady.. so mostly I plan to have springers like HW30, R7, R9, win 422, 425 and 427, diana 25, 27,and 35, CZ 631, 632 and 634, RWS45 and the like… those I’m collecting, having rebuilt and saving for good….

2). My TX200 and HW-77 I would normally keep even though they don’t fit into that group, (but close)… But since I know about them now, and I want to continue to taste new air rifles… even though my cash flow is not as good as spring time (raised garden bed business)…

“so I be tradin” for now…..I can get a TX200 and or HW-77 next spring if I want one again…

Accuracy has many different levels of tolerance with different people… The guns I’m selling are not less accurate than their counterparts, just not as accurate as any of my PCPs..

And, all the used PCPs I got, the AA S310, the BSA Lonestar, and the FX TimberWolf are all almost as accurate as my Air Arms S410 I got new…. And tie with the Condor for very, very close second… They are all what I call accurate on a consistent level.. 1/4″ one hole groups at 20 yards, when I do my part..

Wayne,

Ashland Air Rifle Range

Hey BB,

I was wondering if Pyramyd AIR sold any lubricants for use on PCP’s, I know you always say divers dope should be used, but there is nowhere around my house that sells it. however Pyramyd AIR does sell a crosman product that is a silicone lubricant, but is it the pure silicon you always suggest for PCP’s?

Thanks, John

John,

Crosman silicone oil is pure enough for use in PCPs.

You want pure food-grade diver’s silicone grease. It is sold all over the internet. Google it and you’ll find hundfreds of places to buy it.

Here is one:

http://scubagear.stores.yahoo.net/030045.html

B.B.

Talon SS vs Condor,

I recommend getting the SS and then adding the 24-inch optional barrel. You could get a rifle in two calibers that way.

B.B.

Dr G. et al,

Re: scope shift

Do you store your gun and shoot in temperature, pressure and humidity controlled environment?

Resistance to pellet going through air (ie fluid dynamics) would change when any of these factors changes. Also as temperature changes the optics in the scope can shift.

Zeroing scope seems to cancel out all sorts of crazy factors.

Herb

BB,

I have been a little hesitate on adding anything to your blog as I’m a bit new and have been researching your archives and other other sources in hope of posing some what informed questions. Six months ago my two young Grandson’s interests in buying a BB gun lead me to discover Pyramid’s website and your excellently well written Blog. To date we have purchased a number of BB guns and air rifles and pistols after researching them on your blog. We all have been extremely pleased with our purchases and the Grand Son’s follow your ever word and I must admit you have attained almost cult hero status with them. “Grand Pa, did you see what BB had to say about…..”, is a very common statement heard lately. Our air armory consist of:

–

Benjamin HB 17 Pistol .177

– (2) IZH 53M Pistol .177

-Daisy Red Rider

-Daisy Avanti Champion 499

-(2) IZH 61 Kits.177

-Gamo 440 Hunter .177

-Gamo Whisper .177 VH with Venturi Ram Air Gas Piston

A bi-annual project we all enjoy is emptying the gun safe and doing a thorough clean and polish job. As I no longer do much hunting other than an annual trip home to South Dakota each fall to hunt pheasants, I am recycling a few pieces to finance our growing interest in air gunning. We have decided to take the plunge and purchase a PCP rifle. The Grand Son’s hand down thinks Grand Pa really needs an Air Force Condor with all the bells and whistles. Jointly we have researched your archives and have reviewed most everything you have written on both the Condor and the Talon SS. We are blessed with a backyard range and bench that is laid out for 5 meter, 10 meter, 25 yards and 35 yard. Noise is not a big factor but keeping things on the quiet side is always a consideration.

I was 90% in favor of purchasing the Condor based partly upon your statements drawing a correlation between both black powder shooting and hand reloading. Not to give my age away but my favorite teething tool was a Lyman tong tool set up to reload .22 Hornets and I was making .22 -.250’s from .300 Savage casing when it was still a wild cat. My favorite coyote killer was a Pre War 70 built and barreled by P.O. Ackley. Enough of the past.. back to air guns.

I’m a fairly quick study when it comes to problem solving and I think I would enjoy all the options availed in the Condor. I like the idea of the different barrel and calibers. For certain it would be fun to play with a .25 caliber gun. I would bet that 90% of our shooting would be spent poking holes in paper and seeking bragging rights on the tightest group. 10% of the time bunny hunting would be about the only hunting activity Arizona has to offer.

Down time from shooting in terms of factory required repairs would not be something the Grand Son’s would tolerated as easily as I would. So, not putting you on the spot, how about the pros and cons of Condor vs Talon SS. In terms of “problems” do you think the Talon SS is less problematic than the Condor? And Logan asks, “How many refills does the Condor tank get from a scuba tank?”

Thank You for your time,

Pete Peterson

Logan Peterson

Ethan Peterson

Mesa, Az.

PS. If anyone asks, it takes 4 reams of paper and 7 1/2 ink cartridges in an HP DeskJet 4740 to print all your archives from March 2005 till today.

Grandpa Pete, Logan and Ethan,

Well, you made my day, week, month and year! What a nice surprise your comment was!

When I write the blog I try to keep an image of my readers in mind. From now on it will be the three of you!

Now to the question at hand. I own both the Talon SS and the Condor, but I also worked at AirForce for three years and can get them repaired and upgraded at the drop of a hat, so I’ll try to think like a real customer.

I answered all the phoned-in technical questions while I was at AirForce, and when this question came up I always answered the same. My pick is a Talon SS with an optional 24-inch .22-caliber barrel. The reason is because of Logan’s question. A Condor gets 10-20 full-power shots per fill, depending on what you are doing. If you are shooting tight groups at 50 yards, then it gets 10-15 shots. If you are popping pigeons at 25 yards it can get up over 30 shots. It depends on the range and precision you want.

But the Talon SS always gets 1.5 to 2 times the number of shots the Condor gets with the same air. So, no matter how many shots a Condor gets from a scuba tank, the SS will always get more.

The reason I’m waffling on the number of fills is because you didn’t mention the size scuba tank. A Condor or SS will get 2-3 full (3,000 psi) fills from an 80-cubic-foot tank, The next fill will be 2950 and so on down the gauge until you get to 2200 psi and need to get the scuba tank refilled. You’ll get maybe 15 partial fills, and each will have fewer full-power shots than the last.

A 100-cubic-foot steel tank will get 5 times as many fills as an 80 cu. ft. tank and an 88 cubic foot carbon fiber tank that goes to 4500 psi will get 9 times as many full fills and 45 times as many total fills. But regardless of the tank, the SS will always get more shots per fill than the Condor.

The 24-inch barrel DOUBLES the power of the SS – to about 45 foot-pounds. The Condor is still at least 20 foot-pounds more than that, but how many times will you need that extra power?

However, I own both rifles, so take what I say with a grain of salt.

Please tell me what you decide to get and I want to hear how you like it.

B.B.