by B.B. Pelletier

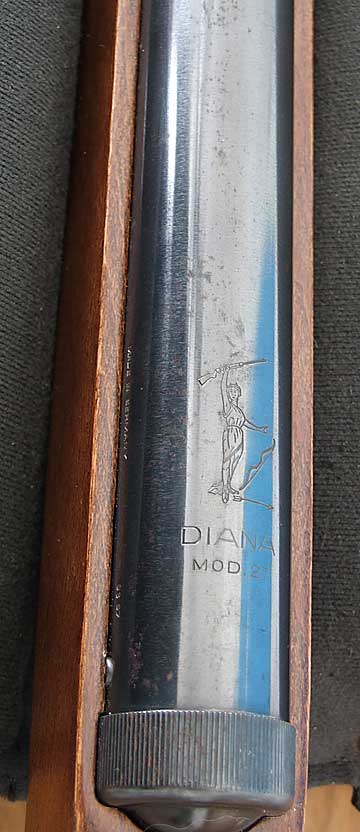

Diana model 27 is a classic breakbarrel. My new one is a .177.

Kevin prompted this report by asking me about the Diana 27 I bought at this year’s Roanoke airgun show. Then he surprised me with the gift of a very nice peep sight made for the Diana model 75. It also works great on the little Diana 27 rifles, and Kevin wanted me to see that so he sent one.

What I plan to do is test my new .177-caliber model 27 and then install the peep sight and test that for you. Unfortunately, the 27 I got in Roanoke doesn’t have a rear sight base for this sight; I’ll install it on my other 27, which is a Hy-Score 807 in .22 caliber. For those who are fascinated by coincidences, the .22 caliber Hy-Score was purchased from the same dealer from whom I bought the .177 15 years before. It was made in August of 1967, while the new gun was made in March of that same year. Spooky, no?

The new Diana came without a rear sight rail. The presence of the Diana logo indicates there never was one.

Many Diana 27 rifles, including this Hy-Score 807, have a rear rail like this for mounting a peep sight.

The top of the rail is textured with cross-slots that assist the peep sight by providing a solid anchoring surface.

I’ll test the new rifle before lubricating the piston seal and again after a good oil soak. The oil will be applied through the air transfer port, so no disassembly is required.

However, I thought this new rifle would also be the perfect one to tune for you so I can show you the inside parts and how I tune it. That’s coming some time in the future.

Before oiling

But right now, we’ll test the rifle as I got it. The 27 is a low-powered spring-piston breakbarrel that was considered medium-powered in its day. The rifle had a long life, starting in 1910 and running off and on until 1986. However, all those model 27 rifles were not the same model. In fact, you can’t really call them the same gun. The model 27 we’re examining here started some time after World War II and finished in ’86. That said, the final pre-war 27 rifle was quite similar in appearance to the post-war gun and differed only in the trigger and a few small details. This particular rifle I’m testing was manufactured in March 1967 (from the date stamp on the spring tube).

Eley Wasps

Kevin also sent along a tin of .177 Eley Wasps for me to test. He says they’re very accurate in his 27, and he wanted me to try them in mine. The .177 Wasp is a domed pellet that weighs 8.1 grains on average. It’s a pure lead pellet. In .22 caliber, the Wasp is also sold in an oversized 5.6mm, but in .177 the head diameter is 0.174″ and the skirt is approximately 0.181″ to 0.183″. I say approximately because these pellets vary a lot. Being pure lead, they deform when handled.

They fit the breech of this rifle very tight and had to be pushed into the bore with a Bic pen to avoid damage to the skirt when the breech was closed. If I didn’t seat them, the velocity was 278 f.p.s. Seated they had a velocity of 444, but it was sharply bi-modal with the lower average at 436 and the high at 460. There was no shot recorded between the velocities of 439 f.p.s. and 456 f.p.s. I suspect an extremely dry piston and breech seal.

RWS Diabolo Basic

RWS Diabolo Basic pellets were even more sharply bi-modal than the Wasps, with a low average of 457 f.p.s. and a high average of 512 f.p.s. No shot was recorded between 460 f.p.s. and 505 f.p.s. These pellets were also tight in the breech and had to be pushed into the bore with a Bic.

RWS Superdome

The RWS Superdome was not bi-modal and averaged 412 f.p.s. The high was 425 and the low was 395. They were also tight and seated in the bore with the pen.

Crosman Premier 7.9-grain

Crosman Premier 7.9-grain pellets could be seated by finger pressure alone. And they averaged 580 f.p.s., with a spread from 560 to 593. On paper, they appear to be a promising pellet, but the target will tell.

I had the feeling after this testing that the leather piston seal and breech seal need copious amounts of oil. So, I oiled the piston seal through the transfer port and the breech seal topically. I’ll repeat this process one more time and give the rifle a couple days to soak it all in. Then, I expect the results to be faster and more uniform.

We shall see!

BB, I recently went through a Winchester 425 (Diana 25) that seems to have many similarities to this gun.

The one I’ve got had a REALLY bad spring, not busted but short. It was shooting about 190fps (in .22). I suspect that the gun was left cocked for a long time – years perhaps.

Yours has a leather breech seal? Mine (made in Aug 71) has an O-ring, the standard Diana breech seal that is still used on the ’34 variants and the 350. A standard #109 O-ring is virtually the same size. The machined grove is about .34″ID and .51″OD. I don’t know if it originally had a leather breech seal.

It has the 3 ball-bearing sear, which really isn’t that hard to service. I really like the simplicity of the design and the fact that the wear parts (the ball bearings) are so easily replaced.

I got it running pretty well and gave it to a friend’s son for when he comes over. It is really a pleasant older-youth rifle, with only about 15lbs of cocking force.

When you go through yours I’m hoping that you tell us about the gun’s bore, stroke, and spring specs. I’d be curious to see how much different it is from the ’25.

Hi, guys i have a daina model27 airgun and it is in very good condition in spain if any one want to BUY it .call me on This num=0468-37429098

My price is 1700$

b.b. Love this kind of report. A good quality airgun with acceptable power for plinking that will last a lifetime with little maintenance.

Just like my Slavia 🙂

But, a little off topic, and something that may help someone in the future.

About two weeks ago I started to have the much reported slide jams on my Walther PPK/S. About every 3rd or 4th shot the slide would hang and need a little nudge to return it to it’s full forward position before it could be fired again.

There are a lot of cures on the net, many of which entail field stripping the gun and filing or sanding the inside of the slide, of course voiding the warranty.

The fine folks in the Umarex service dept told me that if I patiently say and worked the slide back and forth, back and forth for 1/2 and hour or so it would likely cure the problem.

So I patiently sat working the slide back and forth for two consecutive eventings (who said sit coms wern’t good for something) and darned if it didn’t do the trick.

Last night fired about 200 rounds (do they call bb’s/ammo/pellets rounds?) through the thing without a hiccup.

Anyhoo…I’ll take this chance to wish b.b. and everyone here a very Merry Christmas. I don’t have the ‘net at home (yup, I’m a proud luddite) and after work today I’ll be off line for a few days.

The Red Ryder (for the 5 year old) and the Marksman 1010 (for the 7 year old) are all wrapped and under the tree, and I’m looking forward to a very pleasant Christmas break with the family.

Cheers to all!

CowBoyStar Dad

Vince,

There were two grades of model 25s and you had the higher one. As far as I understand it, only the stroke was shorter than the 27, but the bore was the same.

The clue is the ball-bearing trigger. Only the top grade of 25 had it, while all the 27s of that era had it.

I think your seals may have been replaced. I thought they all had leather. The breech seal on this rifle I have has deteriorated and has pits in it, so I’ll have to do something about it.

I will try to remember to give you those dimensions, buy prod me if I forget. It will probably be a few weeks before I get into tearing the rifle down.

B.B.

BB, what has happened to Pyramyd?? Did they get bought out by someone?? Their service is awful all of a sudden. They lied to me about an order yesterday and talked down to me. What has happened??? They have seen the last of me. Too bad, I liked Pyramyd.

CowboyStar Dad,

I wish you and your family a Merry Christmas, too. And in Canada, don’t you also celebrate Boxing Day? I have never understood the fascination with a boxing match on the day after Christmas, but I suppose that’s what traditions are for.

Anyway, we want a full report on those youngins and how they accept their special gifts this year!

B.B.

Lee,

I’m sorry you had a bad experience. I do know Pyramyd AIR is overwhelmed by orders this year, but that’s no excuse for treating a customer poorly.

I hope you have a very Merry Christmas,

B.B.

Gee Lee, that’s what everyone likes to hear in retail…a scathing complaint with absolutely no details.

Kinda pointless to even post in my mind.

B.B.

Good morning. Happy holidays all..

Now your talkin.. just my style of springer. “Oldie but Goodie” and 400 to 750fps… I look forward to your future report.

Your oil trick really helped the .22 cal 27 you helped me find a few months ago. The next day it was shooting the 11.9 hobby at lo 465, hi 487, avg 478fps.. up from the 300s… I think it will even out more as the oil soaks in, and the seals fit better.. I should check it again.. very easy fix, thanks a lot!

Wayne,

John from Puyallop,

John, if you can get past the CO2 cartridge issue, the bolt action, single shot Crosman 2260 rifles and model 2250 carbines offer boat loads of accuracy for way cheap money. They are also the basis for many customizations should you so desire. It’s typical to get 40 good shots from a CO2 cartridge from either gun. The cartridges are steel, so in that sense, they are recyclable. I’ve said this before on this forum, for under $100, there are no other airguns that have this level of potential accuracy, power and aftermarket options. They’re also made in the USA.

I talk about these Crosmans like our man Wayne talks about AA S410s and UFT rifles…

Wayne’s Tempest is scheduled for delivery today.

Have a great holiday everybody!

Derrick

Wayne,

I sure hope this one goes the same way. I’m concerned bout the breech seal though. It seems to be disintegrating.

B.B.

B.B.

You said “So I oiled the piston seal through the transfer port…”

What type of oil did you used?

Will this oil (inside the chamber) detonate when you shoot the gun?

Also, What type of piston seal does the Model 27 has?

Just wanted to be clear.

Thanks,

Joe

Cowboystar Dad,

thank you for posting that cure for the PPK/S. My college age son is getting into air guns and fell in love with that CO2 pistol and ordered it from PA the other day. I’ll remember this if he starts suffering jambs. And for the rest of you Wyatt Earps, happy holidays to all and remember Ralphie – please don’t shoot your eye out. Be safe.

Fred

BB,

Nice, looks great for the age. Are they really accurate enough for a peep sight? I finished engraving my Remington 77 with the walnut thumb hole stock. I did some scroll work from the Smith and Wesson catalog. When do the seals need replacing in a pump gun? some days it’s a breeze to pump, but seems slow, and other days it takes some real force and shoots faster than my shadow express.

Shadow express dude

BB,

I saw a really nice custom RWS320 at springgunning.com, it kind of looks like those savage varmint guns. Is the 320 any good or is it chinese?

shadow express dude

(From yesterday)

Kevin,

If when out in the field you shoot less than 40-50 shots, you will not have any need to bring a pump. The Chrony is only needed at home to learn the rifle. Alternatively, just fill and shoot until POI changes, that is the number of shots your rifle is good for. You only need to learn this once.

As far as the Webley, they borrowed the technology from FX so they share many similarities. A small bonus is both rifles use the same fill probe. Once assembled the pump, hose and probe need not be messed with. The two shot feature on the Raider is silly, but it does make it the easiest single shot to load – ever.

I’m confident you’ll own a PCP soon. Single best advice I can offer is to make sure a fill will give you at least 30 full power shots. More is better. Once again, my FX will give 48 in .177 and over 60 shots in .22 on a single fill. Also make sure your rifle is a “FAC” version. Usually 18 – 30 ft lbs, which is fine for most pellet gun work.

Wayne,

Don’t apologize for your unbridled enthusiasm for the S410. The passion that you show is often the key to success.

Bg-farmer,

I have been shaking the long box under the tree on a regular basis. As long as the kids or wife supply the CO2 I will be in business X-mas day to test the QB78.

Derrick,

How are the QB78 copies different from the Crosman? (Other then being made in China)

I went with the QB because it was available tune and tweaked.

B.B.

Thanks for the positive feedback.

All,

Happy Holidays.

God bless us all.

Joe,

The b27 has a leather piston seal and since the power is low I use petroleum oil as a lube. No detonations or dieseling to worry about.

B.B.

SED,

Yes, the 27 is quite accurate. Kevin who gave me the peep sight wanted me to try it because of how accurate they are.

Replace pump seals when you don’t have 90 percent of original power. You need a chronograph!

And oil that pump cup!

B.B.

Vince,

Do you have any experience with the RWS 320 for SED? I have none.

B.B./

BB,

I like the looks of those 27’s, with no extra frills. I’ve gained a preference for the straight (in this case meaning non “Monte-Carlo”) comb style lately, in particular. It almost seems, however, like the forearm is missing a finger groove, or was that an HW or other company’s trademark? I never liked the looks of a finger groove in particular, but it does work and is easier and more practical for airguns than making a (semi-)beavertail. Probably my terms are incorrect; if so, ignore me:).

Volvo,

Pick yourself up a pack of CO2 cartridges, just in case. Shooting on holidays (Easter excepted) is a tradition, at least in my family:). You got it tuned for accuracy and shot count, right?

b.b. Boxing day got it’s start hundreds of years ago in Britian and was originally known as St. Stephens day.

Christmas day was a day of celebration and giving between families and equals. The day after Christmas (St. Stephens or ‘Boxing Day’) was the day that you would go out and give food/clothing to the poor.

It’s great how much I enjoy Christmas now that I have the little guys. As much fun as I am having with the CP99 (my early Christmas gift), I know it doesn’t approach how happy the boys will be when they open their respective BB guns.

CowBoyStar Dad

B.B.,

Beautiful gun you found. Great condition. Didn’t know this was going to turn into a multi-report.

Volvo,

Appreciate the advice. Need to drag all the contraptions for a pcp from one home to the other since I shoot at both. Pulled the trigger on a pcp purchase this morning. Leaving town for the holidays in a few hours. I’ll let you know what it is and how I like it when I get back after the holidays. Here’s a clue, Wayne Burns was instrumental in the purchase (no it isn’t one of his guns). So why a webley raider and a fx whisper if the guns are so similar? What am I missing?

Shadow Express Dude,

The 27 is amazingly accurate with the right hold, right pellet, etc. I can shoot clovers with mine at 20 yards with the rear diopter fitted with a gehmann magnified iris and an aftermarket diana globe sight with clear inserts. Incredible gun in ordinary clothing.

kevin

B.B.

If an airgun has a synthetic seal, does it needs to be oiled? If so, what oil to use?

Thanks,

Joe

Going out on a limb with the RWS 320, I’ve never known Paul to work on the Chinese guns.

/product/diana-rws-320?m=621#productDescription

https://www.reviewcentre.com/review25848.html

Kevin,

Glad I can still spot buying signals. If you went the AA S410 I’ll expect you and Wayne to wear matching outfits. : )

The Webley Raider and FX Whisper only share family resemblances but are worlds apart.

Have a safe trip.

Bg farmer,

I had a Model 25 Diana from 1934. Smooth as butter. Only issue was no provision for a scope or peep and it would be wrong to modify a 70-year-old rifle, so it went to a new home.

I’ve got 28 relatives coming for Christmas, so if no CO2 I will make it an extra day. Darn IrishItalian heritage makes for huge families.

Volvo

BG_Farmer,

Some of the Dianas had finger grooves and some did not. I don’t know which ones, but I think the earlier ones had them.

B.B.

Joe,

Synthetic seals need much less oil that leather. And the newer formulations need almost none,

Always lube synthetics with silicone oil having a high flashpoint.

B.B.

Anonymous,

The QB78 guns are excellent copies of the long discontinued Crosman 160–a gun many hold as one of the finest CO2 guns ever made. They use 2 CO2 cartridges at a time as opposed to a single cartridge like the newer models. Also great guns for the money.

Derrick

B.B. (and all)..

While I'm patiently waiting to decide on my first PCP, I've read comments on poor magazine quality and lever-action issues with the AA offerings, (Wayne mentioned he returned several), o-ring & seal problems with FX rifles, cracked and defective stocks on new Evanix rifles, and now I suspect you are waiting to resolve an air leak on your Career Infinity.

Are all new PCPs so problematic? The air guns I own, (Gamo, RWS, Umarex, and Crosman), all worked flawlessly from Day 1 and still do.

Should I expect these problems when I try PCP..?

Jane Hansen

My first and only PCP was an Airforce Talon .22. I got it for Christmas last year so I have had it for about a year now. The only problem I have had in 4,700+ shots is a plastic bushing on the cocking knob wearing out once. I emailed Airforce and they mailed me two new ones. Other than that it has worked perfect in below 0 degree temps. and high 90s and every thing in between. I don’t think every AA, FX, Career, or Evanix will have problems.

Jeff

BB,

Thanks. I was thinking the finger groove was an feature on several brands at one time, and you still see it on some current Chinese copies.

Volvo,

That 25 sounds good. You know I would have kept it and used the open sights:).

Looking forward to the QB78 report.

Jane,

So good to hear from you again….

Let me explain why I returned two Air Arms S410 side levers, one a .22 carbine and one a .177 beech stock. I got them one month after I got the first walnut stock .177 AAs410 side lever, which I still have and love bunches and bunches.

It has always been smooth as silk loading the pellets from the 10 shot mag…but, after 3,000 shots or so the thin brass advance bar, broke..

Because I couldn’t stop shooting it long enough to send it in, I advanced the mag by hand, (which was not much of a problem). Finally, I got the confidence to repair it with the kits that PA sent me for FREE!.. It took like ten mins… And after another 6,000 or so shots.. it’s still smooth as silk.

What I’m learned is that it’s the magazines themselves that are the problem, and the oiling I did on the pellets, that collects dust and the like and makes it hard for the mag to advance… I oil less now, and they work fine.

But the .22 cal mags are worse..

The better solution is an aftermarket mag that is sold somewhere else.. I can look it up for you… I got one with a used straight pull bolt AAs410 without power adjuster. I bought to see if the problem was in the side lever, and it’s not!!!.. wow what a difference the after market magazine made over the plastic mags, that come with the rifle..

The .22 cal advances perfectly with the after market mag, and has to be helped by the bolt with the factory shipped plastic one.. It works, but not up to par with the rest of the rifle.. something you would expect with the $109 IZH61.. not a $1,000 master piece…. like the rest of the rifle is…

So… I’ve gone back to the side lever newer model, which is SSOOO easy to cock, and allows you to keep the rifle in eye relief, while you cock the rifle.. The straight bolt is very hard to cock, and one has to firmly hold the rifle with one hand and pull the bolt with the other. It’s very difficult for a small/med women like my wife.

And, I decided to sell the .22 cal used, straight pull bolt action .22 cal S410 and S310… (on the yellow now.. I’m in a make offer mode now).. in favor of the super easy 1-2 lb cocking side lever, .177 with power adjuster, like the one I have now, (which is suitable for field target, if one changes mags after each lane), for the basic rifle at the range.. PA will soon get a nice order from me..

Wayne

Ashland Air Rifle Range

On the RWS 320, It is the B-20 rebadged and sold by RWS back 7-8 years ago , before they re-organized and moved. Copy of the R-9, the B26 is the newer version of this and is better. I have one and it was rough. Broke it’s spring early ,and wouldn’t stay cocked because of trigger issues. Very buzzy firing cycle. Took a JM kit and a lot of work to get it right. JM doesn’t sell the kit anymore. Mine does 850 fps with cpls now and isn’t bad in regards to accuracy. Stay away unless you like projects and are comfortable working on springers. Hope this helps. Robert

Shadow Express Dude, as Robert says the RWS320 was a rebadged B20. And yes, the same basic rifle does live on in the B26.

But they are not all as rough as Robert’s version. Mine (a B20) had a few problems – the main one was that I didn’t realize that the trigger tension screw tended to back out on its own. When that happens the trigger can become unsafe and the gun can fire when you close the barrel. My first solution was to make a little locking wire that fit in the screw slot and was secured under the trigger guard. My second solution was Vibra-Tite VC3, a threadlocker that you brush on a bolt and let dry. When you reinstall the bolt it doesn’t glue it in place, but it fills the threads and results in a friction fit that still lets you adjust the screw.

Another problem mine had was a tiny bur on the muzzle. After that was removed the gun became a very nice shooter.

The B26 is supposed to be better, but I’ve seen signs that this is not always true. The B26 stock is fitted better and it has a better way of anchoring the action to the stock (mine beat out the front stock screws from recoil). The B26 also has a nice FO sight which can be fitted to the B20/RWS320, but the earlier non-FO sight is still pretty good. The two B26’s I had – one in each caliber – could not match my B20’s accuracy. And on one gun the trigger machining was so poor it wouldn’t function as a 2-stage trigger until I did some selective grinding.

I could be wrong, but I believe that the tolerances on the compression tube started getting a little wild. BAM used to advertise that the B26 had a larger diameter, but it didn’t in actuality. I’ve read that some later tubes started coming out bigger than others, I don’t know if this was because they finally started changing over the tube size – I never saw a straight answer to that question.

Mine also broke a spring, but they are still available as replacements from Xisico (same spring as the B26). In general, I don’t know that the B20/RWS320 tends to be any more of a project than any other Chinese airgun. Of all the ones I had – B19, B20, B21, several Quest variants, Several AR1000 variants, QB18, QB88, B1, B2, B4-2, a few KL3B Fast Deer’s and some others I think only one AR1000 (a Walther Force 1000) never really gave me a reason to take it apart. I don’t know that overall the B20 was really any worse than anything else.

Of course a lot of people bought them with the expectation that they were getting something comparable in out-of-the-box quality to a model 93, 94, or 34. Perhaps some did, but a great many didn’t. It’s a classic case of representing something as being better than it really is.

Thanks all

for the thorough feedback. It’s just I thought the gun on springgunning.com looked like serious voltage.

BB,

I shot my Rock Island Armory 1911 in .38super today for the first time. Shoots like a .380acp. Hardly any rearward recoil, the muzzle does rise 2 inches. At 10 yards, I was getting sub 1.5inch groups, at 30 was getting 4inches. I had TONS of jams, in fact, the very first shot was a stovepipe. I think its the winchester ammo’s fault as the magtech worked almost perfectly. 10 yard rapid fire was easy, drawing was fast (I have a Grip Clip mounted on my kimber grips), and groups were around 3-4inches. THIS IS NO ORDINARY 1911, was reiterated with each shot. MUCH louder than any other gun at the range, even the .38spcl and the Thompson .45. Overall a great (exept the jams) way to put a hundred through your new heirloom.

Happy Chrisanuka,

Shadow express dude

Thanks Vince,

I hate to make you choose, but which do you like better as an all around gun (hunting, enjoyment, target,power), the Quest varients (yours were crosmans right, not umarex) or the AR1000 varients.

Shadow express dude

B.B. and All,

Thanks for another great year of air gun blogging.

ALL of you have A very Merry Christmas and the best of A New Years. Enjoy your toys guys (:>)

SED, I don’t think Umarex has any Quest (actually B18/B19) variants in this country. Stoeger does.

Frankly, I’ve had trouble shooting the Quests very well… it’s kinda frustrating because I had one that I couldn’t shoot worth a darn – and the guy I sold it to (for $45) was doing dimes at 30 yards with it. That’s a shame, because I really like the size and feel of the Quest – light, handy, easy to shoulder. I can live with the roughish trigger (a little deburring does wonders) and the better ones I’ve had in .177 would do 15 ft-lbs.

The AR1000, although it has a better trigger, well – I just don’t like shooting it as much. It’s also harder to work on. But I can hit my targets a lot more consistently with it in either caliber than I can with the Quest.

If I could shoot the Quest as well as many others seem to be able to, that’d be my favorite between the two, hands down. But I can’t, so it’s not.

i am sorry to interrupt this conversation to ask my question , but i have not found any other up to date talks by all you pro’s on here si i thought i would just jump in and ask some questions .so here the deal , a few months back i picked up a pellet gun for plinking in the back yard and to handle the pesty rodents in the trash etc. at night, within the first 3 months i had been through over 10 new guns ( many got returned ) and ended up with things like Gamo whisper , walther force 1000 , crossman nightstalker , , and yet was still not happy or having any real fun plinking pine cones or anything else , so i then bought a rws 850 in .22 cal , i like it a lot compared to the rest , but wish it had the pwer of my Whisper or force 1000 , even though it shoots a heavier load it lacks enough that they come out delivering more power , and as i am not yet ready to spend $1,000 to $1,500+ ( as i would then be thinking and asking you guys if im better off with a s410 or hw100 ) but i do think i am ready to soon buy another gun another step up from the rws 850 , and i have narrowed my likes down to Career infinity , walther 1250 dominator , or a AR6 , i really though i wanted the 1250 cause i like my rws 850 , and i like the help of the reduced muzzle report , and the blacked out look and the way it looks with a good scope and a varmint hunter kit with that umarex compensator , and yes i think personal appeal is good quality too . but as i read on all these , i find that it seems no one buys or reviews the 1250 dominator , i think that cant be good , and it cost more than either of the other 2 that both come with good reviews etc. , then the other problem is that once i start looking at taking that next step i start bringing into play the idea of the infinity in .25 , and all that i have read states the .25 would be better for knocking down varmints , and my regimen of plinking pine cones off the tree , as my rws 850 only takes out the dry and dead ones , but i feel if it had more fps ( power ) it would give me a better impact result , and even better again i would think in .25 cal …. please unload on me the responses and personal knowledge you have on these questions of mine .

also my personal email is rarebreed29@sbcglobal.net

Robert,

Thank you for that information on the RWS 320! I learned something.

B.B.

SED,

Thanks for the update on your new .38 Super 1911. I would have thought the gun would feed flawlessly, so the jams were surprising. After fixing the Taurus, I have some experience with fixing 1911 jams, but not in .38 Supers. I would look at the extractor.

Keep me informed.

B.B.

Jason,

I haven’t tested the Dominator 1250 yet, but that doesn’t mean I can’t. I have tested the 850 AirMagnum, but you already know what that one is like. The 1250 will have the same barrel, so expect the same accuracy.

As for all the other guns you are considering, I say go slow. Read about all of them before you make a selection. As many have noticed, these guns often do not live up to the advertising, but an honest test will show you how they really work.

Have you considered the Renegade? I have reviewed both the rifle and the pistol, thus far.

B.B.

Jane,

PCPs are more problematic than spring guns, but once you sort them out, they are just as reliable, in my opinion. Here is an example. A Condor may be a little touchy about fill pressure, but once you discover the pressure it likes you have no more problems. Of course there are airgunners who cannot live with a gun that doesn’t fill to EXACTLY 3,000 psi. These people go nuts when faced with a rifle that needs a fill to 2650 psi. They should stick to springers.

On the Career Infinity, you and others asked me for so long to test the gun that I wanted to show all of you EXACTLY what it’s like to work through a problem like I am having. That will turn a lot of buyers off, but it will also give others the confidence they need to work through a problem.

My job is easier when people know as much about a new gun as they can before they take the plunge. That’s what I would advise you to do.

B.B.

B.B. ,

i actually like my 850 as i stated ( handling , looks , general accuracy of a new still not broke in gun ) , but i really am un satisfied with the weak power output , i can literally see my pellets drop off by the end of my short backyard , and when i put in a heavier pellet ( .25 eun jin ) i can really see the decline and in a rather short distance , also it can shoot bottles on still new 88 grams co2 tanks and not break them , when that would never happen with even a .177 Walther force 1000 or Gamo whisper , so i just want more out of that .22 , and since it seemed like trying to convert it would cost near as much as being well on my way to one of these other guns , i decided to just be happy with the 850 as a possible in door plinker etc. and accept it for what it is , with all of your handling of these different guns what would you go with in the $400 to $600 range ? and do you think the renegade better than the infinity or the ar6 ? also what do you think of the more expensive fx guns ? i like the looks of the black rifle they have . also sorry for so many questions but i have another , once looking at all these guns i am for my next step up . then what is your opinion on considering the .25 over the .22 ? or will i just be happy once i get the right .22 ?

Volvo,

Thanks for:

“Don’t apologize for your unbridled enthusiasm for the S410. The passion that you show is often the key to success.”

I get that way. If I like something, I’m usually in with both feet.. arms too, ah hell, I just jump in!!

But, if I try something and don’t like it, I’m high and dry with it..

I love to play “comment tennis” with you.. Someday you’ll shoot my AAs410 and we’ll see if you get unbridled enthusiasm for it as well..

Special Blessings on you and yours!! If you think IrishItalian heritage makes for huge families, try Southern Baptist and Italian.. My Dad, from Alabama, was one of 13 children..

But that’s what makes for great family gatherings.. Enjoy yours..

As far as success goes, it’s hard to measure.. but like I told Tom, I’m a “very happy camper”.

Yes, the best idea ever is:

God Bless us All!!!

Merry Christmas Everyone,

Wayne,

Ashland Air Rifle Range

Jason,

In that $400-600 price point, you can’t go wrong with a Condor or Talon. If you like that design, over a wood stock. Power, accuracy, adjustable power, barrel changes, aftermarket goodies, extra air tanks for hunting trips.. hard to beat..

They better built in my opinion, and are for sure, more accurate than the Korean guns, but the Korean guns are multi-shot, and pretty accurate for hunting..

I think you would find in the reviews that the Condor or Talon will have less problems over time, if you don’t fool around with it, and just shoot it..

Wayne,

Ashland Air Rifle Range

Jason,

Stick with .22 caliber, .25 caliber pellets are to find, limited in selection, and generally lack the ballistic coefficient of their .22 counter parts.

Your RWS is probably putting out about 12 ft lbs. any .22 cal PCP will double that.

Wayne and all,

A toast:

May you live as long as you want,

And never want as long as you live.

Merry Christmas

Volvo

Jason,

Slow down and watch me test the Infinity. I’ve already tested the Renegade, so read those reports now.

Do you know how to use the Search function to find old reports?

B.B.

yes i read everything i could find that you or anyone else of any intelligence wrote and or experienced or tested . it seemed to me that you found the renegade rifle and pistol both to be of decent quality and good power .

when do you plan to finish the report on the infinity ?

when do you think we could get you to test that walther 1250 ?

and what is your opinion on the .25 infinity ?

Jason,

I have the new inlet valve for the Infinity. All I need to do is say goodbye to my house guests so I can test the rifle for velocity indoors without scaring a bunch of old people with the noise and I’m ready to move on with that test. I expect next week sometime.

The Infinity has enough power for a .25 caliber pellet. Even though the rifle I am testing is a .22, you should be able to draw some good conclusions about a .25 from the results.

As for testing the Walther 1250, it will probably not happen before February, if that early. I still have a .25 caliber Sumatra to test for you before that.

Merry Christmas.

B.B.

B.B. , thanks for all the help and info , your the man , i do appreciate all the tips etc. as i do not want to just waste all my time and money searching for the true goods , i am interested in the sumatra findings , and do want to know what you think of that gun as well , even in .22 , i looked at it as well . but decided that i think it looked kinds too much like a classic old gun , thats not my style etc, i think i like more of the sniper cool look . but thats just me , i like the look of the fx blaccked out gun , and do like the look of my rws 850 , would love it if it wasnt so weak , its really just like for plinking cans , anything tougher , and you will be unhappy … Merry X-Mas to all in this fine airgunning forum ttyl JLP

Hi B.B.,

Thank you for this very interesting post.

I am currently trying to learn my seven year old son to shoot with my trusty Diana 27. He is clearly on the right track, but the rifle is still a bit heavy for him. Would he better of with something like a Weihrauch 25?

Best wishes,

Jannik Lindquist

Jannik,

Yes, the smaller, less-powerful HW 25 would be a better airgun to use with your son. But do you have access to the rifle we know of as the Hammerli 490, here in the U.S.? It would be an even better gun to use if you can get it.

It is called the QB 15 by the Chinese factory that makes it.

B.B.

BB and Jannik, I think you'll find that the Hammerli 490 is actually a bit larger and heavier than the Diana 27. The weight of the 490 I had was a little over 6lbs, while my Diana 27 weighs around 5.5lbs. Overall length of the 490 is a couple of inches longer, the pull length (trigger-to-butt) is about 1/2" longer.

While the QB15 is indeed a 'youth rifle', the Hammerli 490 is a rebadged QB18, not a QB15. To the best of my knowledge the only gun out there which IS a rebadged QB15 is the TF39.

The Gamo Delta might be a good one to consider. It weighs in at about 4 lbs and has a 1" shorter pull length. I believe it is the same action as the Recon, and is quite capable of good short and mid-range accuracy. The main differences are the stock and the fact that the Recon doesn't have the open sights that the Delta does. Actually – the 'Lady Recon' DOES have open sights, but I don't know if a boy wants a gun with a pink stock!

Vince,

Thank you.

B.B.

Vince, B.B. – thank you both. QB-rifles doesn't seem to be available here in Denmark. The Gamo Delta is easy to get, though – at half the price of the HW 25. I'll give it some thought.

Thanks again,

Jannik