by B.B. Pelletier

Good morning! I’m attending the Airgun Breakfast at the 2009 SHOT Show in Orlando, where the airgun community is being shown a trailer video of American Airgunner–the first television program devoted entirely to airgunning! Remember the big bore hunt I went on, back in November of last year? We were filming the pilot episode, from which the teaser was made.

I’ll get a link to the trailer for you shortly.

American Airgunner is a half-hour video magazine that explores all aspects of airgunning. We chose big bore hunting for the pilot for several reasons. One, because it’s so amazing that such airguns exist (the wow factor) and that they are capable hunting arms. Another reason is because the outdoor networks will recognize big game hunting, even if they’ve never heard of airguns that can do it.

We are meeting with potential sponsors at the SHOT Show and hope to have the bulk of the first season budget nailed down by the show’s end on Sunday. This will be a prime-time broadcast of 13 episodes the first season. We have not finalized which network we’ll sign with, so I can’t tell you where to watch for it, yet.

I write the show, and Paul Capello is the host. We have secured Heather Parcells as our co-host, and I can tell you she is a dynamic and attractive young lady, as well as being very polished on camera.

There will be a website, and we’ll be in-tune with our viewers. So, there’s the possibility of another airgunning website on the horizon.

Guest blogger

Vince wrote today’s guest blog. If you’d like to write a guest post for this blog, please email me.

Bloggers must be proficient in the simple html that Blogger software uses, know how to take clear photos and size them for the internet (if their post requires them) and they must use proper English. We will edit each submission, but we won’t work on any submission that contains gross misspellings and/or grammatical errors.

Now, on to our guest blog!

by Vince

When Weihrauch developed the 4-lever Rekord trigger system a few decades ago, a new standard in airgun triggers was set. Here was a trigger with a genuine 2-stage action that could be adjusted to give a very light and crisp second stage and be safe while doing so. If you pulled the trigger though the first stage and released it, the internal mechanism would reset itself to the just-cocked position. There are quite a few trigger designs that can’t do that; and if you released the trigger after pulling it part way, the internal mechanism would stay right where you left it. This could be right on the edge of the second stage and very close to firing. Since the trigger blade will probably return to its normal position (it usually uses a separate return spring), the shooter might not even know he or she is handling a gun that might be unstable and could go off if bumped or jarred.

The Rekord trigger, installed on several Weihrauch guns (and the Beeman-badged variants), quickly established itself as the one to beat. But as the old saying goes–if you can’t beat ’em, join ’em–and that’s where the Chinese come in.

China had been making low-quality airguns for quite some time, but BAM (Best Airgun Manufacturer) was genuinely trying to produce a better product. They produced close copies (not clones, mind you, the guns were never identical) of Gamo and Diana rifles and of the Beeman R9 (Weihrauch 95). The R9 Chinese copy was called the B-20. The later (and slightly revised) version was the B-26. They sold for approximately one-third of what the R9 sold for and was supposedly equipped with the same fabulous Rekord trigger.

Of course, it didn’t have a REAL Rekord despite what the ad copy always suggested. It was understood that it was a Chinese COPY of a Rekord, and exactly how good a copy was always a matter of debate. Some shooters claimed it was very good, others that it was horribly unsafe. Personally, I exchanged a B20 after it went off unexpectedly upon closing the breech and punched a hole in a wall, although I eventually learned what caused that mishap and how to prevent it. I did get the trigger on the second one adjusted and found it to be pleasant and reliable once I figured out how to keep the tensioner from backing out during use.

Still, I always wondered–if the B20’s trigger was nice, how much better would the real Rekord be? I thought I’d never own a real R-series Beeman or the Weihrauch equivalent, being the cheapskate that I am, but I found a gun shop that had a used R10 sitting on the shelf. I thought the asking price was a steal, so I jumped on it.

Turns out that the price was, well, so-so, and the gun had a bad piston seal to boot. But it DID have a real Rekord, and I’ll be darned if it didn’t feel nicer than the trigger on my B20. With a smoother and lighter second stage, the real Rekord certainly lived up to its billing. When I looked at the mechanisms side by side, I sure as heck couldn’t see what the difference was. I don’t like mechanical mysteries, so I decided to find out the differences.

I removed both triggers from their respective rifles (which does not require pulling the spring), dismantled them, and compared the parts and construction. There were three general categories of comparison I was looking at: overall trigger design, quality of machining and lever geometry. I wanted to find out–for the Rekord (sorry!)–exactly what was the same and what was different between these two triggers.

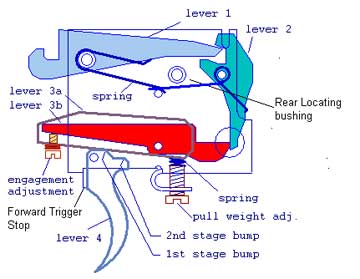

This is a clear, functional diagram of the workings of the Rekord trigger. We’ll use this as a reference for the rest of this article.

Overall Design

I dismantled the triggers as far as I could take them easily. I wasn’t looking to grind off any factory rivets, welds or peening. As it turns out, both triggers had 2 pins peened in place, so I initially left those alone. Besides, I believed I could find out what I wanted to find out without disturbing those pins.

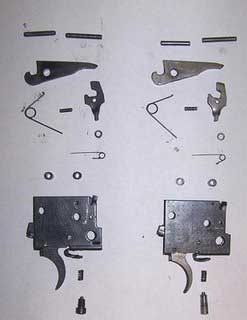

This is what I found when I laid out all the parts side by side (German Rekord is on the right).

As for levers 3a and 3b, which remained inside the trigger group, this is what they look like from the top.

It’s pretty obvious that BAM had copied the design of the trigger–lever-for-lever, screw-for-screw, spring-for-spring and pivot-for-pivot. With the trigger assemblies apart, there are few detail differences visible to the naked eye that distinguish one from the other. The outer shell is dimpled on the Rekord, smooth on the BAM. BAM uses a black finish on levers 1 and 2, the Rekord has a bright (probably nickel) finish. The Rekord trigger blade is made out of aluminum, steel on the BAM. The forward face of the Rekord is grooved, while the BAM trigger is smooth. The head on the tension-adjuster screw is larger on the BAM trigger and the screw itself is shorter. The rear triggerguard screw fits into a threaded hole on the Rekord but into a semi-captive nut on the BAM unit.

So far, it doesn’t look like there should be any functional differences between the two.

When I started measuring everything, I found that the exact dimensions of most of the parts vary a few thousandths here and there (and pin diameters vary), but certainly not enough to seriously impact trigger performance. The two hairclip springs were virtually identical, although the trigger-return springs were not quite the same. The Rekord spring was made from a slightly thinner wire and had one more coil, which means that it is softer than the BAM spring by about one-third. Since this spring operates directly on levers 3a and 3b, which in turn are lifted directly by the trigger, this tells me that the BAM trigger effort will rise faster than the trigger effort for the Rekord. So I’ve got at least part of my answer, but I’m thinking there might be more to it than that.

There was one other significant difference I found at this stage of the comparison. The rear locating bushing on the BAM trigger was located about .035″ further forward than on the Rekord. This has no bearing whatsoever on trigger operation, but it does insure that the trigger assemblies cannot be easily interchanged.

Unfortunately, I had no way of quantifying the relative hardness of the steel used in either trigger. I would expect the German original to be harder, but I have no way of knowing for sure. But the well-used B20 trigger parts betray no sign of excessive wear, so I don’t believe the Chinese copy is particularly deficient it this respect.

Read the second part of Vince’s guest blog on Monday, Jan. 19.

So that’s what it was a new TV show. Cool. From SavageSam

Yeah. So hey, did you all see the Marauder and Challenger PCP at AoA?

Yes I did. From SavageSam

If tv is the BIG announcement, then I guess Edith and Tom can go back and watch the tv an be proud.

Probably channell 568 or something like that, 200 viewers on Saturday morning at 6.

Wos.

Am I missing something, or is the Rekord diagram wrong? As shown, “lever 2” (rear sear?) has a spring that is providing no tension on the lever. Shouldn’t the long leg of the spring be on top of the pin?

I hope the episodes will be available on the web because we don’t have access to all of the american chanels here.

J-F

B.B.,

That is huge news! A TV show that you star in. Hope the programming successfully walks the line between informing the non airgunning public that these aren’t toys but at the same time shouldn’t be catagorized as firearms. A concern that’s probably unwarranted since the segment of the populace that’s afraid of everything and wants the government to step in and regulate it won’t be watching this program about dangerous BB guns. They wouldn’t be able to sleep that night.

This explains why we haven’t heard from Paul Capello in awhile.

Well we can all say we knew B.B. before he got his star on Hollywood Blvd.

kevin

Dito Kevin!

*Cheers* to continued success!

Vince,

Great article. When did you find time? Read about the truckload of guns you’ve been tuning for Wayne.

Bought two B-26’s in .22 caliber a few weeks ago and had them tuned by a reputable tuner very familiar with these chinese copies of the R-9. Among other things he replaced the factory sear engagement screw with an allen sccrew and nut so you can adjust the sear engagement to your liking. Still not as crisp as the trigger on my R-7 but I must say I was very impressed with the guns.

Mounted scopes on both, ran 50 pellets through them to stop the dieseling and gave them to twin boys as birthday presents.

Looking forward to part 2 of your series. Thanks for the effort.

kevin

Joe B.,

Thanks for the response and your understanding about my moving your comment from an old post to the “active” comment section the other day.

To answer your question, yes, you posted under part 1. of the 3 part series that B.B. did on the walther lever action (June 4, 2008).

Since you were having trouble with the scope I asked:

Your scope problems are curious. I now have bad eyes and fight focus too. Are you adjusting the ocular (eyepiece) for your eyes or adjusting the objective (AO)?

kevin

Tom and Edith,

Congratulations.

THAT IS HUGE.

A couple days ago I was wowed by a two-page airgun spread in Outdoor Life. The sad part is those reviews are often not written by air gunners.

The information is usually sketchy at best. To have an expert representing us to the rest of the world will be nice.

Those that don’t comprehend the importance have not been around long enough to understand how little recognition our sport gets in the States. I’ve waited 30 years for this. Can’t wait to have my buddies that only shoot “real guns” watch an episode.

My suggestion would be to try and offer both technical information along with the “last page” of the magazine story line. Educating and entertaining combined would be great.

Best of Luck,

Volvo

Anonymous – great catch! You are halfway correct, the leg of the spring for lever 2 does not bear upwards against that pin. It actually bears downward against the pin for levers 3a/3b

Volvo,

Did you just buy another HW (weirauch)?

kevin

Vince,

If the graphic is incorrect, do you have a correct one? If so, please forward it to my email, & I'll get it online right away.

Edith (Mrs. B.B.)

CONGRATULATIONS B.B.!!!!!!

Looking forward to seeing the TV show and all the new airguns and equipment from the SHOT Show.

Nice blog Vince and good job to all the Guest Bloggers.

Did I hear a Brady Bunch Parody?

Here’s one from the Sound of Music:

My Favorite Things

Raindrops on bushes and whiskers on bunnies

Bright tins of pellets that didn’t cost much money

Brown paper lunches tied up with strings

These are a few of my favorite things

Camo colored clothing and crisp morning air

Springers and pneumatics

And tanks filled with care

Wild game a running around in a ring

These are a few of my favorite things

Air rifles kitted and carefully zeroed

Targets with groupings hung like a mural

Collecting an armory that would rival a king

These are a few of my favorite things

When the dog bites

When the bee stings

When I’m feeling sad

I simply remember my favorite things

And then I don’t feel…so bad

Pyramid Air,

In my younger days I spent some time in the restaurant industry. A Managing Partner for a little known restaurant known as Chili’s Grill and Bar that was located mostly in Texas.

The point is the first time they were on TV an explosion in sales occurred. You should be tooling up for at least a 50 % increase.

BB,

Congratulations! A major coup for the entire airgun world. What a great way to broaden the entire spectrum of the sport.

Derrick

Vince,

Fantastic blog! How did you construct the graphic?

If you have a second, shoot me an email.

dwk164@sbcglobal.net

Derrick

Kevin,

No new HW rifle for me. However, I have already owned most of them and remain a big fan.

Why do you ask?

I did make a recommendation for the care of the AA S410 stock.

Mr. & Mrs Gaylord,

This Heather Parcells??

http://www.heatherparcells.com/

Herb

Volvo,

I forwarded your email to the owners of Pyramyd AIR, however they're pretty savvy & nothing gets by them.

Managing Partner for Chili's? I have a nice story about them.

On a crisp, sunny Saturday in October 2007, Tom and I were having lunch at Chili's. During the meal, Tom said he was giving some thought to a gun he'd like for Xmas (I told him weeks before that he needed to give me a heads up of his choices). He mentioned a rifle (firearm), but he was concerned that it was kind of pricey…about $400. He would lead me to the right place to find it used because a new one was going to be too expensive.

I told him, "I can get that for you if that's what you really want, but I wanted to buy you a Wilson Combat 1911." He looked at me as though he'd just won the lottery! I could see tears welling up in his eyes.

He said, "I didn't think I had that kind of buying power."

To which I said…"You don't, but I do."

That afternoon, I bought the gun. The rest is history.

Edith (Mrs. B.B.)

Bravo BB, may this year be more rewarding than you can imagine….look foreward to you next year on an episode of MTV CRIBS,or maybe an episode w/ Robin Leach! Vince,great job on the blog.very interesting reading. Wayne,karma is rewarding you with success.you deserve a new LAZYBOY…can I have your old one?LOL FrankB

Derrick, I didn’t construct the graphic (although I did modify it). That graphic is floating around on a couple different websites (sometimes labelled ‘Rekord Trigger’, and sometimes ‘B20 Trigge’), and I couldn’t nail down a source so that I could properly credit it. I’ll email you when I git home form work.

Edith, I’ll try to get it done this evening. Please accept my apologies for the error.

Volvo,

Confused you with another Chris.

Saw your response. Now you’ve got one.

You “hit the target” on my choice even before I posted on the other forum. Think you had it figured out awhile ago.

Now if I could just get the gun. Sigh. Re-read your first time experience with a pcp the other night just to be prepared. Great article you wrote.

kevin

Al in CT,

Along with Tom Gaylords “The Beeman R1” I used this article to adjust my rekord:

http://www.gatewaytoairguns.com/RekordTrigger.pdf

kevin

An airgun TV show really fits all of Edith's adjectives. And, I had my seat belt on. I hope Kevin had his on, too.

As most of you realize, this is big in many ways. My hope is that it will eventually become available to the general public and not only to those that subscribe to a specific channel.

Can we wean a shooter from his or her collection of powder rifles to start a collection of airguns? Maybe, if they realizes the cost/performance and quality of an airgun and the ability to practice in the basement.

The real biggie, to us airgunners specifically, is that, hopefully, because of this increased exposure to potential buyers the airgun manufacturing community will increase their R&D budgets and we'll begin to see some really eye popping features on our guns.

-Chuck

Edith,

Thanks for sharing the Chili’s story. I’m sure that the PA folks are sharp. I just did not want them to underestimate the impact. I believe at the time Chili’s had less than 80 units total compared to the 1500 stores now. Lead by Norman Brinker they were an intelligent group of guys too, but still were blind-sided by the positive effect.

Anyone remember the Baby Back Rib song?

P.S. – Tom: following Man Law, we guys will pretend we missed reading the tearing up part. No worries.

Mrs. Gaylord,

Great story about the 1911. My wife makes me cry too but for completely different reasons. Long stories.

Herb,

Thanks for the link to Heather Parcells website. She just doesn’t do it for me. I vote for Edith.

kevin

Vince,

Vince, geessees dude, is their anything you can't do? You write as well as the best.. Lucky for Tom and Edith, (and us too), they have one more person to call on for guest blogs..

Tom & Edith,

A very big WOW!!!

This for sure is a milestone of great importance!!

You two have had a large role in the growth of the "Air Gun World", and now your taking it to new heights.. built on a solid foundation.. very good work… but don't forget to keep it fun.. that will grow your viewer base faster, and bring new people to the hobby.

When have you got Southern Oregon scheduled? I'm sure the Governor will change the hunting season if it doesn't fit your shooting times.. but we will need time to reprint the rule book..

I hope you cover some of the FT contests. I know that it could be boring watching someone focusing and adjusting themselves for the POI, but to some of us that would be very important info. If you had a close up camera on the target, especially that small steel hole, and explain the difficulty of 12 or 20 foot lb. air rifles in the wind.. It for sure is a challenge for the shooter.. but conveying that to the viewer is a larger challenge..

Maybe keeping it to very short snipits at first, and see how the viewers respond.. In that way, if it's tied to a blog, you could get instant feedback for future shows..

Well, time is up for me, I've got to give up my computer now..

Wayne,

Ashland Air Rifle Range

Vince,

Sounds like you have some very impressive skills. I am a huge fan of the record trigger. Three of my keepers were HW rifles tuned by PW with the trigger being a major factor in their ranking. Speaking of which, PA has the HW50S again. Not crazy about the new front sight, but great all around rifles.

I still have two of the three tuned HW’s, but one was sacrificed for a PCP.

Tom & Edith,

Wow! Congratulations! I'll have to get my in-laws to tape it for me (we don't have cable or satellite).

Vince,

Great article! Looking forward to part 2 even though I don't have anything that resembles a Rekord.

.22 multi-shot

Dang… no cable TV in the DB home.

We watch no TV programs… just select movies and vintage (clean) TV shows on DVD. Nor do we watch the TV news… you can not trust it so what is the point.

Hopefully there will be an internet viewing option.

Congrats to BB and Paul C. I expect this will be another “must see” TV show for me along with the military history channel.

Cjr. – no offense taken but I am excited about the Challenger PCP. I thought everyone else would be. Like I said, this is a tough crowd – and knowledgeable!

I’m also glad I didn’t ruin the surprise.

Anyone ever replace their rekord trigger unit with a venom mach I or mach II.

Please share your opinion.

kevin

Kevin,

Tom replaced his Beeman R1 Rekord trigger with a Venom Mach II. He wrote about it in the “Beeman R1” book, pp 141-145. It’s in the section he calls “Dream Guns and Special Things.”

He called the Mach II trigger a “jewel of a trigger.”

Edith (Mrs. B.B.)

Mrs. B.B.,

Read about you allowing Tom to buy the last venom mach II trigger from Trooper Walsh.

Now I want one but I need more endorsements in order to convince my wife I need one.

Not all of us are lucky enough to be married to Edith’s.

kevin

B.B. and Mrs,

Great news, and a great way to spread the word about the versatility and variety in airguns. I had no idea what was out there until I found this blog a few years ago and started digging. There will be lots of folks tuning in to the program who are just like I was.

Congrats and good luck!!

Lloyd

BB,

That is a big surprise, and Paul will finally have some company in the Air Lodge:). My favorite factual program is AgPHD, but that may change soon.

Vince,

Great job. I would like to try one of those copies someday. Seems like the “copy” just needs some finish work to be very good.

Fred,

I share your enthusiasm for the Challenger PCP — basically my dream air rifle (we’ll see about the price); looks like Crosman reads this blog. That’s why I though it so crappy that someone else (company and blogger permanently deleted from Santa’s good-list) pre-empted the announcement.

Wayne,

I keep forgetting to congratulate you on your award. I look forward to seeing your raised beds on “Gardening by the Yard” or similar…now that BB has gone Hollywood, you should too:).

How about a show called “AirBusters – exploding airgun myths”?

Edith, Tom,

Wow! Why not do a segment on Wayne and the Ashland Air Rifle Range? This could also be a great introduction to all the different airgun types, as I believe he has almost every air rifle ever made (OK, so I exaggerate). Do it in the Fall, when the leaves turn…Ashland is so extraordinarily beautiful then.

Joe B.,

The first season is filled with wonderful episodes, spectacular variety and things that will excite the imagination of anyone interested in the shooting sports (regardless of discipline).

Edith (Mrs. B.B.)

Lots of possible show ideas. I picture an ongoing competition of .22 rimfires vs. air rifles at 30 meters. They would need to be the same price point. Just don’t let Wayne represent the air rifles. Those S410 groups look like someone patterning a shotgun. If he gets an FX then let him have a go at it. : )

Hi Kevin,

Ah, so THAT’s where I left that post. Thanks again for rescuing it from obscurity.

“Since you were having trouble with the scope I asked:

“Your scope problems are curious. I now have bad eyes and fight focus too. Are you adjusting the ocular (eyepiece) for your eyes or adjusting the objective (AO)?”

I wasn’t aware that a cheapie Tasco Rimfire scope had AO. The instruction sheet didn’t mention it. I’ll go have look today; thanks for the suggestion.

My 2250 review got sidetracked a bit…yesterday I bought a Daisy Red Ryder (my first BB gun as a kid), so now I’m up to my neck in nostalgia. (“Gosh, Doctor, I…I didn’t realize it was possible to love t-two airguns at the same time!”)

Vince,

Great job. I’ve always been impressed with the depth of knowledge your questions and responses in the blog have shown, especially about interchangeability and “blood lines.”

I was getting panicky as I got near the end of your blog until I saw you were going to have a part two.

I couldn’t believe you were going to give up and say you didn’t find the reason for the performance differences. Looking forward to more!

Lloyd

http://www.americanairgunner.com/index2.html

not sure if this was posted yet?

Just what we airgunners need is more fodder for the Antis.

Airguns will thereafter be called ‘weapons’ and as they are not protected by the 2nd amendment you will unwittingly volunteer for regulations and controls as found in Europe.

This while well intentioned is foolish unwarranted grandstanding.

Displaying what airguns are capable of will not garner favour with those already positioned against us.

Unwise move as I see it. Walter…

Volvo–That's it. Thanks for posting it!

Walter Glover,

I believe the opposite. I refuse to live in fear. I refuse to cower.

Increase usage along with education and pretty soon you have a large number of people who will stand together. Americans are not Europeans. If they want to confiscate guns, they will have to get rid of every lathe in the country and every piece of metal tubing at Home Depot, because you can use them to make firearms & airguns.

Americans are different. We don't give up.

Edith (Mrs. B.B.)

Volvo,

Now you’ve done it. Slander Waynes “special” AA S410??!! Watch out. I know he’s coming at ya.

Thanks for the link to the new airgun shows trailer. Glad to see sponsorship by pyramyd air. You probably read on the other forum about all the speculation about a gamo sponsorship and commercials taking elephants with a gamo and the negative ramifications and the sky is falling and the sun won’t rise, etc. etc. Seems too common in human nature that before seeing anything first hand that the assumption has to be that it is bad. Very sad that we all can’t wait and see then pass judgement.

kevin

Joe B.,

Good to hear from you. Your “cheapie Tasco Rimfire scope” probably doesn’t have a side knob or adjustment on the bell/objective to correct for parallax (AO). But, if parallax is your problem, you may still be able to adjust for it at the range you shoot.

Many fixed power rimfire scopes don’t have AO. They’re adjusted to shoot at a certain distance (50-100 yards is most common on my fixed power firearm scopes). But some are adjustable. If you examine the front end of your tasco see if you notice a thin joint line a short distance back from the rim.

If there is I can try to help you adjust the scope for the distance you’re shooting.

kevin

Fred,

I’m glad you’re not offended because I’ve never intentionally sent an offending comment to any member of this blog. No one on this blog ever speaks with malice towards another reader. I’ve found the nature of this blogging beast as well as emails is that one loses voice inflections and facial expressions that usually convey the actual intent of ones point. I’m smiling away behind my keyboard thinking I’m being humorous or helpful but the reader sometimes hears something else totally not intended.

Thanks for not dropping out for a week. We need good readers like you.

-Chuck

Mrs. Gaylord,

Re: Walter Glover

Amen.

I’ll also add that I am in favor of any format, especially TV (even if it’s on channel 668 at 3:00AM), that teaches, among other things, responsible handling of guns, be they firearms, pellet guns or bb guns. This is a learned trait that must be re-introduced and re-enforced if we are to remain the great country that we are.

kevin

Edith, all,

Thank you for posting my comment and allowing me the freedom of a differing opinion.

I am with you and hope for the good and proper understanding of those that view this program. Part of my thinking is influenced by the Gamo pig shooting airgun video. That will be a part of teh challenge ahead of you with the TV broadcast. To dispell and reject foolishness such as Gamo’s grandstanding.

I am also of course influenced by the society in which I live where as far as guns and shooting of any kind is concerned it is best to fly under the radar.

Thank you again

Will watch with great interest the outcome of the first broadcast.

Walter….

yes, fly under the radar and note as you do so the names and addresses of your opponents, the descriptions of their cars, etc … for future reference … always best to know more about your adversary than they think u do, or that they know about u

That’s a great announcement about the TV show. Unfortunately, I don’t have a TV! I get enough entertainment from the blog. But I’m sure I’ll get to see parts of the show somehow or other.

Heather Parcells is very nice-looking. Does she shoot airguns too?

Vince, how very interesting about the Rekord trigger imitations. I would never have guessed this about the BAM triggers and neither would the people who complain about BAM triggers on the web. Initially, they seem to come very heavy although this may be for legal reasons. I was able to adjust mine to around 4 pounds, and Rich from Mich did a modification which made it crisper although maybe a little heavier–I don’t have a scale. It works well enough, but I wouldn’t associate it with the greatest trigger design of all. It is inferior to the IZH 61 trigger which is supposed to be inferior to the Mendoza RM200.

That’s interesting to hear the enthusiasm for the new Challenger rifle. My understanding is that the old Challenger, while decent, was distinctly inferior to the Daisy 853, so I’m not sure why expectations are so high for the new one. For target rifles, the gun to beat seems to be the Air Force Edge with its great sights, trigger, and Air Force workmanship. The trigger is the only criticism I’ve heard of the Air Force rifles, and that appears to have been fixed. A comparison of the Edge and the Challenger would be interesting, perhaps something for a future blog.

Matt61

Walter,

I respect your point of view but would like you to hear from someone on the “other side”. I am a moderate-to-liberal democrat who is also a STRONG believer in the 2nd amendment, and believe it or not, there are lots more just like me out there.

I recently joined our local rifle and pistol club because of the great facilities. But the ideology expressed at the meetings did not make me feel comfortable expressing my POV. And still, at the same time, the club officers were saying that they wanted to attract more members from the general public. But if you limit your pool of members to those that already openly support you, you only further deepen the divide. Go out there and find the Democrats that appreciate the 2nd amendment and pretty soon you have us breaking party ranks and voting AGAINST gun control measures. Lots of folks are willing to vote conservative on one issue and liberal on another.

This can definitely help at the local level (shooting range noise ordinances??)if you get a few well know moderates or liberals on your side. But if you never search out that hidden support, and just continue to vilify the “other side”, you will always be stuck with the “you’re either for me or against me” mentality.

Just my two cents,

Lloyd

P.S. Walter, I just read your follow-up post about the Gamo pig shoot and agree that is not a positive for our cause.

In general, I oppose any government taking of rights from the people, but my viewpoint assumes that citizens take responsibility. I’m often left dazed by proud tales of squirrel-baiting, poaching, and kids shooting each other. If I’m not amused, I assume there is a large part of the population that is or would be considerably more upset, and they haven’t seen much yet. My recommendation is to throw Airsoft under the bus, try to integrate airguns into state hunter education programs, work with the NRA very closely to see what they need to take air rifles and the use of them seriously, etc. In general put adults in charge of the airgun scene. As I say this, I know it will never happen, although a few good people like BB will try.

High powered (relatively) repeating PCP’s available to minors or the weak of mind is liable to be the straw that breaks the camel’s back. I think we should treat them like firearms, before the decision gets made for us. Right now, there just seems to be a communal whine about our right to bear airguns — what amendment is that, unless we classify them as arms? Anyway, I don’t really have any answers, but I don’t think Walter is a bad guy for his opinion.

Matt,

LW barrel. Ergonomics had to be superior to the 853, it was accuracy that was lacking. Adjustable power is great, too. Allows use at 10M or 50M for different applications.

Uh,…part of Walter’s first comment spoke of potential “regulations and controls as found in Europe”,… not necessarily “confiscation”…

Those who live in a handful of states in the union are already impacted by regulations. I for one would hate to see this type of “action” infiltrating other states. I would hate to now need a FAC or license to possess my meager 30+ air rifles that deliver greater than 12 fpe.

The timeliness of the story concerning “the NJ man that accidentally killed is wife” is reverberating not just through the airgun/firearm community, but also through our collective community. There are members of the Legislative that have been waiting for such an unfortunate event to spear-head their own agenda. Show them a .50cal Dragonslayer and its capabilities, and beware of their pens and signatures being drawn. Laws are not passed or readily influenced by “people standing together”,…they are passed by the small number of elected officials looking out for and protecting the well-being of the collective.

I for one am excited about being able to see and experience my beloved hobby played out through the TV screen, but please do not dispell or discount Walter’s words. An educated individual attempts to weigh the outcomes of their actions as best they can.

Everything is speculation until it comes to pass,…and No, do not “cower”,…but definitely don’t stick your head in the sand either.

B.B.,

A very cool and huge announcement indeed. I think it will be really nice that there will be A Tv show dedicated to Air Guns only. With you and Paul being in the forefront I hope that the show is A great success. I will certainly watch it when it airs.

As huge as that announcement was, the announcement about the new Benji Marauder is the bigger news for me.

An American made PCP, A choked free floating Lothar Walter barrel WITH an Internal shroud That shoots .22 caliber pellets at 1000 fps. That's big to me..

It is EXACTLY what I and several other bloggers had said we wanted the new Discovery to be, and it just looks good.

I know that there are other PCP's that offer equal or better specs ,features price and performance.

But other then the Career and the Sumatra PCP's, what other PCP's offer the same performance in that same price range?

B.B., how come AoA got to be the first to announce the Marauder and not PA? It isn't even on the Benjamin or the Crosman websites.

Walter Glover,

In responce your post, I agree with what you wrote. But, I also understand the points that Edith made. I remember A Tv show on ABC called Thr American Sportsman which was hosted by Curt Gowdy. In the first few episodes they showed the actual shooting of the big game that were being hunted. There was such a protest from A large block of American Citizenry that there were no further showings of the game animals being hit by bullets. They did continue to show bird hunting though.

All I'm saying is that I want the show to go slow with thier reporting on the sport/hobby of shooting Air Guns. Like Walter said, "stay under the radar". I would not like any town, city, county or state to have gun laws like we have hear in New Jersey.

Lloyd & Walter,

I to am A moderate-to-liberal democrat, Very well said.

BobC NJ

Kevin,

Nope. No hairline near the front of the Tasco. I looked at where the scope gets ‘sharp’ and you’re right about rimfire scopes…this one becomes sharp at about 50′. I’ll look into a Bug Buster.

Walter,

I agree with you. “Big bore” hunting, while exotic, portrays air guns as weapons not toys. Let’s be honest, the notion that airguns are toys is what has kept the regulations low. Nobody thinks of a BB gun as a “real” weapon.

I can’t shoot a firearm with city limits. Period end of discussion. Didn’t buy a hunting license to whack squirrels causing me a problem. Can’t hunt in city limits either. Note all the consternation over “silencers” vs. “shrouds.” So more regulation is on the horizon.

Unfortunately our representatives vote on perception not reality. There are already regulations on owning handguns and machine guns. I can’t carry around a ninja sword any more than I can carry a handgun. My local city council has even debated making “baggy pants” illegal. The idiots never asked the two pertinent question in the “debate.” (1) Will this make our streets safer? (2) How much will this new law cost to be effectively enforced?

Of course lots of things in a house can be used incorrectly to hurt someone. Knives, screwdrivers, hammers, baseball bats, and on and on. I’m sure more people were killed in the past year with kitchen knives than air guns, but that won’t stop the regulations. Every house has kitchen knives, but “guns” are owned by a minority, a vocal minority, but a minority.

I can only hope that significant time is spent talking about how to SAFELY enjoy the hobby. For example, how you can safely setup a range, and field targets. What a range safety officer needs to consider. The time to thing about safety is before you do something, not after.

The faster that some one comes out with a commercially sold 0.22 machine air gun shooting 2,000 fps the faster the whole hobby will get regulated out of existence.

Herb

Joe B.,

Sorry to hear that. Many of the old Tasco fixed power rimfire scopes had locking rings that could be unscrewed and taken off the front of the scope. This would give you access to tiny slots inside the end of the scope but ahead of the lens. These slots accomodated a spanner engagement tool that could adjust the factory setting of the objective lens/glass. The joint line is very fine, like a piece of hair.

If it’s not there it’s not there. Pity.

Good luck with your new bug buster. Will your rifle with your mounts provide the eye relief the small bug buster requires? Might check with PA.

kevin

wouldn’t that just be “ironic”, if the impetus for airgun regulations across un-regulated states, derived from what some legislator saw presented by some well-meaning airgun enthusiasts on tv that love and want the best for their hobby. and in the minutes and legal documents the name of the show and its participants are referenced.

i would just hate to be “those” guys.

for some reason the saying “pride goeth before the fall” seems apropos.

Kevin,

I am guessing Wayne will enjoy the controversy. If he still has time for us. How boring would it be if we all drove Volvo’s, liked poodle mixes, and loved the S410? I’m afraid that would overload my harmony circuit.

Anyone,

Speaking of controversy, the big bore subject has been a concern of mine for a while. I understand not hiding, but flaunting is something else indeed. Some of you may recall the add-on for the Ruger 10/22. All was fine until the designer made a video in which it appeared to make the rifle a full auto. He may as well sent invitations to the BATF.

My biggest concern would be the elimination of direct delivery by mail order for airguns. In 2008 I made about a dozen buying and selling transactions. If this were not possible via Post Office and UPS, I would guess that would be just two. This should be a concern for PA.

BG_Farmer,

I’d overlooked that about the LW barrel. Even the Marauder doesn’t have that. And for the Challenger to also have the 2000 fps fill pressure is awfully good. But based on the pricing of the original, I’m not hopeful about the successor.

I also have to agree with your point about gun safety. I think everyone should have a right to the marvelous enjoyment of airguns and firearms too. However, safe and responsible handling is an equal imperative. And the endless stories about stupid and irresponsible behavior are just unacceptable. I understand that Plaxico Burress took a loaded unregistered handgun into a nightclub tucked into the waistband of his sweatpants. When it, inevitably, slipped down his leg, he made a grab and touched off the trigger, shooting himelf. And then there was the one about the guy shooting his ex-wife in the chest while having sex with with her….

Matt61

Walter and others,

Cudos for being strong enough to voice your opinions and raise questions about this “new” and supposedly exciting direction. I personally am kringing a little bit.

What is the answer to 99 out of 100 questions? Money.

This show is obviously and most likely a marketing ploy to generate business, of course. You have to generate “new” interest in order to generate, maintain, and spike new revenues. What better tool than TV, and what is more American than Greed.

But the wrong kind of, and even too much, interest is never good. If (and I know its “IF”) requlations insue, watch the revenues fall. Watch used airguns flood the classifieds. Listen to people excuse themselves by saying “hind-sight is 20/20”.

I myself enjoy my hobby as quietly as my muzzle report allows.

I also do not appreciate individuals that have the audacity to flippantly pull me into a fight that I never was interested in fighting. Alot of laws are passed because of the bonehead actions of a few.

A “large number of people who will stand together” singing “we are the world” won’t wish the regulations away if they come.

I want to take the barrel from my 2260, and put it on my 2240. I do not know anything about gunsmithing. How would I go about removing the barrel? I can’t figure it out -_- Thanks

I am stunned. We have an opportunity to have a show about our hobby, and lot of you are cringing.

The pilot episode has hunting in it, but it’s a small part of a 30-minute show (actually, 22 minutes). There’s a lot more to airgunning than hunting, and there’s a lot more to American Airgunner than hunting.

Tom just called and was surprised that things had turned ugly (I had to delete a comment) over a TV show about one of your favorite topics.

Edith (Mrs. B.B.)

Matt61, what BAM model are you trying to improve the trigger on?

Vince provided a corrected graphic of the Rekord trigger, which I just uploaded. The previous discussion about the wrong graphic no longer applies.

Thanks,

Edith (Mrs. B.B.)

Tom and Edith,

This is your blog, and therefore you have inherent permission to oversee it as you see fit. One thing I have liked about it in the past is the ability for individuals to honestly express their opinions about issues that are brought forth, as long as the conduct is acceptable.

If certain individuals, like myself, are apprehensive we may feel a need to voice our apprehension also on how “our” hobby may be portrayed or perceived. There are alot of adults here, and from what I have read there are alot of adult ideas and concerns being eloquently offerred.

I have never experience either of you being closed minded to what others have shared or voiced. We hope you are listening to us, and taking our concerns into account. Notice I say we hope, because you may do as you wish, but please forsee the impacts as best you can. We have no clue as to what the format of your shows will be. This is your vision…

Its not just your hobby,…its also ours…and I can only speak for myself.

This surprise was a surprise to me…well duh! I would like to pass my best of wishes toward to you and tom. Unfortunately, I am stuck in the stone age and do not have cable (this might be a reason to get it!).

Good luck Mr. and Mrs. Gaylord!

John from jersey

Edith(Mrs.B.B.), we are a group with alot of view points. Lots of people with differing opinions freely and respectfully exchanging ideas says nothing but good things about this blog.

Personally, I think it’s a good idea to get our points out the way we want to present them rather than having to respond to attacks by the anti”s. Just some thoughts Mr B.

I also am concerned about the rights of airgun owners. However, knowing Tom from this blog, he will do his best with “American Airgunner” to educate. He has told it straight on the blog so I expect him to do that for the show. That should help the sport.

Black powder shooters also enjoy a lot of freedom and there have been shows on black powder shooting (perhaps not a series). Airguns also have a historic heritage like black powder which I think is great!

The problem is that some people see guns as “evil” and nothing can change their mind.

.22 multi-shot

Edith,and Tom our HERO…I for one will not imagine rain for your parade.I also will not overlook your tireless WORK done on behalf of us,the airgunning community.I think there is alot to be thankful for on our plates right now…lets just revel in the moment.It’s truly the beginning of something we love being shared with the world.I for one look foreward to a day when others can appreciate what consumes the rest of us…Instead of the blank stares I usually get when airguns are mentioned in any context other than toys for ten year olds. my two cents…FrankB

I’ve deleted 2 comments. Please don’t cast aspersions on the intelligence or character of others.

Edith (Mrs. B.B.)

Though it is most definitely b.b.’s and Edith’s blog, I think there are genuine concerns being expressed.

I’m from up yonder…Canada.

A mere 15 years ago I could own a long gun with no problem…well unless it was fully auto…that was a no-no. And of course handguns have always been heavily regulated here.

But since the liberal government brought in the FAC requirements I now cannot even own an airgun without regulation if it is over 500fps.

And hunt with a handgun…not on your life…not in Canada.

The amazing thing was that, though a hue and cry against the FAC erupted upon it’s announcement, at at time when the talk of gang shootings and such started to really hit the new here…the laws got passed quickly.

Even the Association of Canadian Police Chiefs said they were against it.

Didn’t matter.

There’s an old saying…there’s no such thing as bad publicity.

I think there is.

I would only hope the TV show in question, if it does show hunting, makes it clear it is done with humane kills, and that they don’t play up too strongly the fact that some airguns are capable of killing fairly large game.

CowBoyStar Dada

I’ve never seen posts like this here… whenever politics are involved huh.

I live in Canada where regulations are pretty hard on airguns (everything above 500fps is considered a firearm) it’s not impossible or that hard to get these airguns you just need a firearm puchasing permit.

I’m very happy to get a TV show about airguns and I can’t wait to get the first season on DVD (I wish we still had airguns illustrated too), even if the regulations come I still think it’s a good idea and a really cool project.

I think the important thing is getting more people to love and respect the hobby and the more fun we’re going to have.

J-F

2260 barrel,

Probably the first thing to do is download the 2260 and 2240 exploded views from Crosman. There is a “download a manual” in the Customer Service section of their home page https://www.crosman.com/airguns/. Follow that to the correct section and look for your model. Download the manual with the EVP suffix for the exploded view.

You will find that you have to lift the breech and underneath there is a metal sleeve that goes between the CO2 tube and barrel. This is probably what is keeping you from removing the barrel. Don’t lose the little rubber gasket that sits under the sleeve.

The 2240 is very similar to the 2260, so it shouldn’t be too hard.

Hope this helps.

.22 multi-shot

2260 barrel,

That rubber gasket actually sits in the CO2 tube, so you might not notice it if you don’t look for it.

.22 multi-shot

Vince,

It’s the BAM B30.

On the subject of the TV show, there may be reason for due caution. But I think a well-turned out program with B.B. in charge is a great development. We’ll get good coverage of field target. We’ll get to see Heather.

Matt61

Some people think of airguns and BB guns as ‘toys’. I have been guilty of using phrase, “real gun”, in regards to firearms and am working on that. The toy gun attitude is probably why some (most?) airgun stupidents happen.

Matt61, not all BAM triggers are the same. The B20/B26 trigger is completely different from the trigger on any other model. The BAM-made Quest has a poorly made copy of the Gamo, the B12 has (I understand) a direct sear, and B25 has something similar to the Diana T05. I’m not sure about the B30’s trigger, but I do know that it isn’t the same as the one I examined in this blog.

Vince, that makes more sense. I understand that the B30 trigger is complicated and not easy to modify. It works well enough, though.

Matt61

Vince,

I have a B40, and although it is beautiful, and beautifully made, the accuracy seems to be a bit spotty. I’ve never seen a real TX200 except at a show, so I’m wondering if you have any comments on the B40 vs TX200, trigger, or otherwise.

Thanks,

Lloyd

Kevin,

Well doggone! I was target shooting with the 2250 today and found that screw-on piece about 1/32nd inch back from the front of the objective lens (I had thought it was window dressing for the scope). Looks like I’ll be able to adjust focus closer than 50′ after all.

Thanks, Kevin.

The key with any show, documentary or educational program is how the writers present the topic(s). As a lifelong motorcyclist, I hate it when TV or movie stars are shown riding with no helmet, eye protection, leathers or other riding suit. It gives a terrible rep to the sport that I love and I love bikes even more than airguns. Forget about those shows where the motorcyclist is always the bad guy or villan(s). Just terrible. Stanley Kramer did more damage to my sport with the public with “Wild One” than any gang of Angels or Bandidos ever did

We are most fortunate that the writer(s) and lecturer(s) fo this forthcoming airgun show are two people who love the airgun sport (I’m talking about BB Tom and Paul C). Everyone here should rest assured that our sport will be presented in the best possible light, with safety at the forefront. I look forward to the show and to continue my learning curve on this fabulous sport.

One last thing, I NEVER was going to stop reviewing the blog for a week, just stop posting for a week. But since all is forgiven, you folks will now have to continue to put up with me….

Fred from NJ where everything appears to be considered a firearm. Even slingshots.

Lloyd, I’m sorry but I’ve got no experience with either. BB does, though:

/blog/2006/10/bam-b40-part-3-accuracy/

(with links to parts 1 and 2)

and

/blog/2006/10/bam-b40-in-22-caliber-part-4/

(with links to parts 1,2,and 3)

Joe B.,

That’s great news about finding the forward lens locking ring! You have a chance at adjusting for your favorite range of shooting. You’ve got a little work to do. Here are details about what you could do to adjust your non-adjustable scope:

http://fuzzylimey.net/projects/parallax.html

Let me know if you have any questions.

kevin

Observation and Opinion,

Just returned to the blog after an afternoon of meetings.

Deeply disappointed to read that todays discussion deteriorated into bitterness to the point that comments were deleted. A first for me on this wonderful blog.

I understand the passion from both sides but would encourage that we all keep the dialogue civil.

I for one would like to see this site remain as a venue to exchange ideas and experiences about airguns.

There are plenty of other options available to express your political opinions and even debate your political ideology other than here.

Again, my opinion and my desire.

kevin

Kevin,

I looked at the fuzzylimey article. It talks about parallax adjustment. Will moving the lens holder (counter-clockwise probably, judging from the article and the fact that both his and my scopes are Tascos) also bring the focus in closer? Currently my targets are fuzzy until they get out to 40-50 feet away.

I’m more concerned about sharpness than I am about parallax at this point.

Thanks,

Joe

To all,

American gun owners are hardly a minority. And generally seldom volcal. Wish they were though.

If you fear the worst could happen… act now and join the NRA. Join in the fight. It is a worthy cause.

History teaches what happens after the people are disarmed.

DB

I just read the winter edition of the Illinois Shooter, the quarterly journal of the Illinois State Rifle Association. There is a full page article by James E. House about using pellet pistols for practicing handgun hunting.

He wrote a sizable column on the S&W 586 & 686 ($200-$250). He claims, "Smith & Wesson CO2 guns have the best sights." He also covered the Model 3576 from Crosman ($50)as a "…good practice gun for shooters who want economy." And, he describes how to set up a suitable range for practicing using a bag of newspapers.

James is the author of "American Air Rifles and CO2 Pistols & Rifles", and "The Gun Digest Book of .22 Rimfire", and co-authored "Customize the Ruger 10/22" with his wife Kathleen.

My point being, Airguns are showing up everywhere. Prepare for and enjoy the good. Resist or ignore the bad.

-Chuck

Joe B.,

Unscrewing the lens holder by itself will not improve or unimprove the clarity of your sight picture. The lens holder merely holds the lens. Once you have removed the outside ring completely you now have access to the inner locking ring. There are detailed instructions about adjustment that I sent in the link but your goal is to actually move the front lens of the scope.

Before doing this can you tell me if your eyepiece is adjustable. Please try to turn/unscrew the outside of your eyepiece counterclockwise. It may be stiff. If it is adjustable try this first to improve your focus at short distance before you dive into the adjustment for the lens in the objective/rear of the scope. Get back to me.

kevin

Volvo,

Concerning your concern about direct delivery of airguns. You are lucky to live in a state where you can still do that. In Illinois I can’t take delivery of an airgun over .178 or an air gun of any kind over 700fps. However, I can buy one from a dealer in this state. I’m sure things are worse in other states.

Recently I bought a scope from Pyramyd that I found wouldn’t fit my gun so I boxed it up and tried to ship it back through UPS. I had marked it as a scope and they said they will not ship any gun parts from an individual and a scope is a gun part. How about that! So, I have to be extra careful what I buy through the mail because I may be able to get it but I may not be able to send it back even if it is defective.

-Chuck

Chuck,

Ouch. Can’t see how they can refuse a scope. USPS would have shipped it for you. As far as UPS I have developed a relationship with one of the local stores. They now ship my air rifles with no questions. They were “gun shy” at first. I will admit to making a point of befriending the owner and flirting with the clerks. Just don’t ever have UPS pack anything for you. The charges are incredible.

Just finished my nightly shoot.

Looking at the current PA survey, I have to ask where do people live that 70% shoot outdoors in the winter?

I think the high here today was 3 degrees. I only went out twice, once to fill the bird feeder and then again for my weekly visit to my Mother’s. I can’t imagine leisurely shooting outside right now. Hats off to the folks that do.

Good to see that the sport of airgunning is now big enough in the US to warrant a TV show, and here’s hoping for success for all those involved in the project.

Here in Britain airgunning is going from strength to strength, as it is one of the few forms of shooting which is available to us. The restrictions our government has placed on firearms means that it’s no longer worth the bother you need to go through to own one.

I just hope the people deciding the content for the show don’t shoot themselves, and other airgun lovers, in the foot by focussing on aspects of the sport that the anti-shooting brigade can use as a reason for a ban. Shots of high powered guns maiming large animals and features showing airguns which look like tactical automatic weapons are guaranteed to be counter-productive to your cause. I was a bit concerned regarding the trailer for the first show, which seems to focus on big bore guns and tactical rapid fire pistols.

If the new TV show fails to demonstrate airguns being used responsibly and doesn’t emphasise the safety aspects essential to our sport, then I’m afraid the worst is more likely to happen.

A TV program which brings the right sort of people into the sport, which is respectable enough to be featured in the Olympics, can only help avoid future interference from oppressive government legislation. Would whoever has editorial control please make sure this is considered.

As a European (Belgian) I resent the comment about us cowering in fear.

The current gun laws in our regions have nothing to do with us hiding away while our evil governments take away all our rights, they are the result of a complicated period of war and turmoil, destruction and rebuilding, usually with Belgium cought in the middle. I can still see the bulletholes in my grandfather’s barn where some British tanks were hidden, and still sound the Last Post every year for the victims and the ever decreasing group of veterans at our memorial, which every town has. Granted, I wasn’t around yet to witness it, but the effects remain long after.

Therefor, I can’t blame people for wanting to ban weapons, I can, however, respectfully disagree.

That being said, I’m not the kind of person that will hold a grudge against you for it.

I don’t really know how to phrase this without disrespecting anyone, so I’ll just say in advance, I respect everyone posting here, even the ones with other opinions than mine.

Now that that’s out of the way, you can keep telling yourself you’re not going to cower and you’re going to stand up for your rights, fact is, laws and regulations are not made by the people, they are made by politicians, the media, interest groups and the likes, and they are more than happy to jump on anything that will get them some publicity.

The bigbore hunting thing (as much as I like reading stories about it and would love to one day do some myself) may only be a few minutes out of the show, but those few minutes WILL be the parts that will be used against you, that’s what they do, they single out the ‘bad’ things about you and only show just that.

They will use your own words against you to prove their point and make your life harder.

It would be foolish to think they won’t.

Ofcourse, you are free to put whatever you want in the show, as obviously it doesn’t affect me.

That being said, I do hope that your show gains great success, and I do hope the airgun world will flourish for it.

I wish you both the best of luck.

Bart,

I think you may have misunderstood my comment. I never said Europeans were cowering in fear. I said that I would not cower and that I would not live in fear.

Please reread Walter’s statement. He said that making an airgun show was grandstanding…which means they are making the TV show just to get attention. Nothing of the sort. I can’t imagine Tom or Paul being involved in a TV show to grandstand. The show is a way to educate people about airguns. They’re sharing the sport along with all its pleasures. It is an opportunity to shoot more guns and do so in places you never knew you could shoot.

My parents escaped from Nazi Germany…just barely (other relatives were not so lucky). If only they had had guns.

Unfortunately, they escaped to China, which was partially occupied by Japan and also embroiled in a brutal civil war (while being simultaneously invaded by aggressive neighboring countries). They lived in China in constant fear of their lives for 10 years. My brother and I were born there. If only they had had guns.

Because of my parents’ experience, I have become rather aggressive when it comes to gun rights. I refuse to sit idly when legislators try to pass laws that infringe my rights. I’m a life member of the NRA, and Tom is an endowment member. If Americans want to protect what is rightfully theirs, they must be willing to aggressively defend it.

Thanks for reading.

Regards,

Edith (Mrs. B.B.)

Mrs. BB,

did your family live in Shanghai or Manchukuo? If so, then you are the first person I’ve ever communicated with that was a participant in the Japanese’ Fugu Plan! Very few people know about this. Rather than take up space here, anyone who is interested can do a search on Google. The Wikipedia entry offers a fairly detailed and accurate assessment of this mostly unknown historical event. Mrs.BB, if I’ve brought up an unpleasant period in your life, my sincere apologies.

Fred in NJ

Fred,

My father worked for the Japanese occupiers in Manchukuo (until they were forced out). After that, he worked for several steel plants. He had a Ph.D. in extractive metallurgy.

My brother was born in Mukden (now Shenyang), and I was born in Shanghai.

My brother and I wrote a 40-page book about our parents’ escape from despotism and their journey to America.

I buy vintage books about that era (as the rewriting of history has distorted some facts in modern books). I also continue to do weekly internet research, have found some very distant relatives through some genealogy sites and have corresponded with the Actives Museum in Germany.

Edith (Mrs. B.B.)

Tom & Edith –

First of all, a sincere and heartfelt congratulations on the announcement of your new and grand project. I look forward to watching the episodes over and over again, as I have with Paul's Airgun Reporter segments. In my view, the timing couldn't be better. Thank you.

Secondly… Hang in there. The naysayers remind me so much of similar circumstances in the past. Remember when people swore that videotapes would bring about the demise of the movie industry? After all, who would go to a theatre when they could just stay home? If I were you, I would continue to trust your own insticts. They have served you (and us) quite well. Again, thank you.

I recently added the Outdoor Channel and the Sportsman's Channel to my cable TV service, and I just can't take my eyes off of them. At 50+ years of age, I've been reading about shooting for four decades. At last I get to see and hear not only the authors of my favorite columns and articles, but demonstrations of guns that I will never see any other way, shooting competitions that I will never attend, and exhibitions of skill that I never knew existed.

One last comment to the readers of this blog… Please don't make the mistake of thinking that keeping a low profile will protect airgunning in any way. To those who would take away our second amendment rights, next Tuesday is Christmas, and Santa Claus is coming to town. Expect outrageous proposals of new gun control legislation. Keep in mind that congressmen listen to public opinion, and the public only hears those who are making themselves heard. If you really want to protect airgunning, then take a stand to protect your constitutional right to bear any type of arms. Join the NRA. Make sure your congressmen know where you stand. Now is the time to be proud of your involvement with shooting sports. Stand up and be counted.

– Jim in KS

In support of Walter, in your comment you mention to strategically placed points…

– Americans are not Europeans.

– Americans are different. We don’t give up.

How could he and other Europeans not be offended. I am American, and I was also offended. I am also offended with the idea that “guns are the answer”,…If only they had had guns.

This is a sad day for me, for though I have quietly enjoyed reading this blog from day to day, I can no longer stomach the agenda of the individuals involved. I know no one will notice me go, for I have been a lurker. Do know for every one person like myself that speaks up, there are a handful of other quiet lurkers with similar feelings.

I will most likely spend my hard earned dollars elsewhere.

Thank you

Inner Voice,

I don’t know why you would stop reading the blog and buying stuff at PA because people with a different opinions than yours (and mine) are posting here…

They have the right to their views and we have the right to ours.

We have a common interest that is airguns and there is no way everybody is going to agree on everything.

J-F

Inner Voice,

Sorry you feel offended by the idea of guns as a solution to oppression. I truly believe it is the very foundation of America's continued freedoms.

Americans really are different. It's the reason people come here. It's why my family came here.

I believe the removal of guns from the hands of most Europeans is vastly different from what will happen if they attempt to remove guns from Americans.

We have each stated our opinion, and so it is with most sites that allow comments. When you tell people they can voice their opinions, you will always find people who will disagree with you.

If something is a sticking point, then we can agree to disagree & move on. Therefore, this is my last comment on this subject.

Edith (Mrs. B.B.)

Inner Voice,

Pyramyd AIR just provides the forum. They don’t write the comments. To take a stand and make a statement that you’re not going to support Pyramyd financially because you don’t happen to agree with what a few people out of the 6.7 billion on the planet have posted here is well within your rights. But I don’t understand the point you’re making. How does your disagreement with a comment here make Pyramyd at fault?

Ironic.

History teaches that without unity and guns oppression is inevitable. Revolution was necessary for the founding of America. In many moments in history since our founding we have been forced to protect our freedom. The only reason we have survived is because of unity and guns.

Our freedom of speech that allows us to disagree and the freedom to take our business elsewhere (capitalism) were hard fought battles. With guns. Historical facts.

The only “agenda” I observe is jealously guarding our hard won rights since history has taught us the consequences of apathy.

kevin

Kevin,

You’ve pretty much summed up the entire history of the world. The world still lives by the way of the gun. Only those who have them are in charge. If you have even the slightest inclination to doubt that, take a 10 second tour of Africa, the middle east, Asia, Korea, China, Western Europe, America… It’s even how we got America. With guns.

How could one of the greatest news in airguns history have come to this…

We’re getting A TV SHOW ABOUT AIRGUNS HELLO!!!

No one is going to solve the world problems here today, let’s enjoy our hobby and have fun.

Now stop arguing and be nice.

Now, Now folks..

I can see both points of view as probably the most liberal/Jeffersonion (rights to the people, not big corporations) in the group..

I for one want to keep my guns, and buy more… My favorite model for a country is where at least 1/2 of the citizens volunteer or are required to keep rifles, and attend a safety/training class each year. An on call citizen army, is what our founding fathers had in mind.. at least that’s how I see it.. But what good does that do when the government army is so much more well armed…

It will be hard to get people to face facts.. Like my friend Kevin said to me, most people like to eat steak, but don’t like to see animals get killed…

The land and people would be much healthier if people had to kill their own meat, or at least hire someone to do it for them.. and that meat was harvested from wild lands, instead of “feedlots”..

As a compromise, how about if the hunting was for “Dirty Rats” and mice.. not many Americans care if they get killed on TV..

I would start off with lower power air rifles like the Red Ryder, R-7, gamo Delta, crossman 2240 and Vince’s custom 499, if Jane ever sends the rest of the formula, so Vince can keep the b.b.s from orbiting:):)…

Then, because noise is probably the most important factor in acceptance by the “other side”, add quiet rifles under 20 ft lbs like the FX Whisper and the new AAs410 shotgun:):)… shooting field target.. hunting steel holes won’t bother anyone..

How’s this for the first show.. Jonnie Appleseed is practicing punching paper, with her Red Ryder.. the night before the Wedding of her older sister.. A mouse shows up and eats some of and poops on the top of the wedding cake… and as it’s running back to the hole he chewed in the $8.00 per lin ft. base moulding…Jonnie nails him.

Next show is hunting rats that are spreading disease to people somewhere..

just my 2 cents.. try to build bridges, not burn them..

Wayne,

Ashland Air Rifle Range

I’d like to build the world a range

And furnish it with things

FT critters next to honey jars

and targets with vivid rings

I’d like to teach the world to shoot

In perfect harmony

I’d like to hold my arms up high

And keep them company.

I’d like to see the world for once

All standing hand in hand

And hear shots echo through the hills

For peace throughout the land

(I’d like to teach the world to shoot)

Like the world to shoot today

(In perfect harmony)

A song of peace that echoes on

And never goes away.

https://www.youtube.com/watch?v=wVa0WPVuEOI

PEACE

-AJ

All of a sudden I want to reach for a Coke.

BTW…I’m not prejudice…I tease everyone equally.

Hey,

I was born in 1950 and grew up in the 1970’s in Southern California …. what can I say…

Wacky Wayne

to those in NJ, Canada, maybe Europe … do you have to show a permit to buy paper clips, since they could be launched by a rubber band as a makeshift slingshot ? Like I said yesterday, agreeing with the writer who used the phrase “fly under the radar”, it is often necessary to find unorthodox ways to persuade the well-meaning politicos that their passing of new, more restrictive regulations, is an unwise agenda for them … as a military veteran, I learned the value of intelligence data about the enemy, and the best intel to have is how to hit him where it will hurt the most without him knowing that you know that … and patience to wait for the appropriate time to strike … remember in the Bible where it says sins of the father will be paid for by the future generations ? nobody wants to have their children used against them, but it sure does get their attention

wow? now this has become an NRA membership drive?

Wayne,

It sure took you a long time to grow up:).

BG_Farmer,

I’m still working on it!!.. but not too hard.. I just pretend to.

Just ask my Wife, Son and Daughter…

They think I’m going the other way… and their right.. as fast as I can!!

How did that one go? “I’d never be a member of any club that would have the likes of me!!”

Wacky Wayne

CJr – the best group I had with the 953 5 rounds 10M with Leaper 4x32AO scope and JSB exact heavy was .040″ (1mm) c-t-c. Nowhere near that at 40 yards like BBs. Still waiting for target sight to come. I hope it works out good.

I don’t have time to get out much now that it’s been so cold. Hit around -17 this last week here. Windchill about -35 to -45.

On the Uk airgun forums the BSA lightning is popular. I’ve learned a lot about airguns from reading their forums too. I also, play guitar and write songs. So every once in a while I like to joke around so for what it’s worth:

(Set to music of Grease Ligntnin’)

BSA Lightnin’

Well this air rifle is systematic, hyerpnuematic, ultramatic

Why, it could be BSA Lightnin’!

We’ll get some super seals and a four system spring, oh yeah

Keep talkin’, whoah keep talkin’!

Nitrous oxide injection cut off they safety vavles, oh yeah

I’ll get her ready, I need to get her ready!

With lasers on the switch and bunnies in the ditch

You know that suckers lit when we’ll be gettin’ lots of hits

BSA Lightnin’

(Chorus:)

Go, BSA Lightnin’

You’re burnin’ up the quarter mile

BSA Lightnin’, go BSA Lightnin’

Go BSA Lightnin’

You’re flying through the chrono trials

BSA Lightnin’, go BSA Lightnin’

You are supreme

The chicks’ll scream

For BSA Lightnin’

Go go go go go go go go

AJ,

Let us know when you post on YouTube.

-Chuck

I’m excited about the Marauder that Crosman is going to be offering in several months. It’s going to do a lot for the air gun community. I’m less excited about the new show coming out. In fact, I guess I’m one of the people that are cringing. Right now, the majority of the non shooting public and for that matter most of the powder burning crowd, perceives air guns to be little more than toys. That’s fine with me. Toys equals no regulation. I’m afraid that once it becomes general knowledge that there are air guns capable of taking big game, that perception will change. When people realize that anyone 18 years of age or older can buy a rifle capable of downing an animal the size of a deer with no questions asked, they will start to ask for regulation. Frankly, I can easily see airgunning in the good ole USA heading in the same direction as it is in the UK or Canada. Low power only. And don’t look for help from the NRA. That’s mainly a firearms group. Also, the constitution doesn’t cover air guns. So yeah, I think this new show will do more harm than good.

To the TV show haters,

don't you think that by having a tv show about airguns it will bring more people to the hobby and that in case of bad legislations MORE people is exactly what you need?

If we follow what keith is saying maybe we should also close the websites about airguns, maybe someone could find it and make airguns illegal.

Also if we stay a relatively small group there is no point for the manufacturers to grow and put more money in R&D.

Bring the tv show and bring back the magazine too.

The more people we are going to get interested in the hobby/sport the better.

John

B.B.,

Why don’t I see the Rekord trigger system on any PCPs? Thanks.

Alan

Alan,

For the same reason you don’t see a Ferguson three-point hitch on the back of a Corvette. The trigger on an PCP only has to hold a few pounds of spring and can be much lighter and more refined than a Rekord.

B.B.