by B.B. Pelletier

So, I was on the range with a couple buddies day before yesterday and one of the guns I wanted to try was a new (to me) M1 Garand. Garands have always been reliable in my experience, so imagine my surprise and disappointment when this one failed to allow the bolt to come all the way back when I cocked it! And when I finally succeeded to get it all the way back, I was stunned that the rifle would not accept an enbloc clip of ammunition. I couldn’t load it!

For a moment, I thought about Matt61 and the guy he sent his Garand to for accurization. And then it hit me. This is a Garand! And I was taught to field strip one blindfolded and how to care for each part that came out! At one time, I could do that while being yelled at by a drunken fat man. Later on I became the fat man.

This should have been no challenge at all!

After that awakening, I did what I knew how to do so well–I field-stripped the rifle in less than a minute right there on the range. After that, I could see more clearly what the problem was. The rifle was entirely dry!

The term “light coat of oil” was ingrained in me during my misspent youth. Dress blues, tennis shoes and a light coat of oil was the joke uniform of the day in my ROTC unit. And this rifle was dry. So I went to my range box and looked. Did I have any oil? Of course not! It wouldn’t be much of a story if I had oil.

Then, I did something that quietly amazed my two shooting buddies–both of whom are my age and both have served in the military. I pulled the dipstick from my truck’s engine and proceeded to oil the contact surfaces of the moving parts with the little bit of oil that remains on the bottom of the stick. I had to pull the stick out twice to get enough oil for all I needed to do. How did I know to do that? Because when I taught Maintenance Management at the Armor School, that was one of a thousand little gems we passed along to our students.

It’s a trick right out of McGuyver’s notebook, but one that works and one that was presented to students as they slumbered in classrooms with their eyes open on lazy summer afternoons, waiting for the final bell to dismiss them to a better life. Tricks like using a jeep wheel as a powered windlass to winch vehicles out of trouble. How to tear a web belt in two with your bare hands. That last one is also a bar bet.

After assembling the rifle again, the bolt operated perfectly, and I loaded a clip. The rifle then fired two clips without fault. That got me thinking about all those little problems we airgunners have. I was reading PurcHawk’s plea about the failure to eject the last round of his Marlin model 60 autoloader. My model 60 started doing things like that when it got dirty, so that’s what I told him.

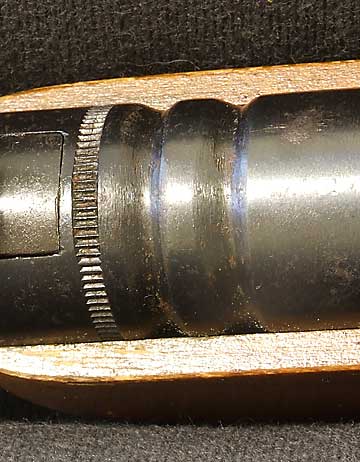

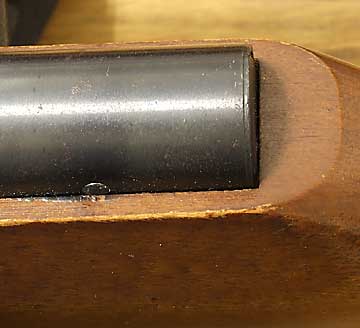

Okay, a Marlin 60 isn’t an airgun, but here are two that are. They’re both Slavia 622s and both in .22 caliber, but they’re not identical guns. The one that I believe is earlier has a serial number of R27887E stamped into the underside of the wooden buttstock (!), instead of on the metal anywhere. The one I believe to be the later gun has the number 93353 stamped on the left flat of the baseblock. There are small differences between the rifles, but they share a common problem. Low velocity!

How low, you ask? Well, I chronographed them shooting RWS Hobby pellets. The earlier one averaged 295 f.p.s. for 10 shots after a three-shot warmup and the later one averaged 274 f.p.s. after three warmup shots. The earlier gun had a spread from 290 to 301, while the later gun went from 266 to 281.

The early gun was a little harsh on firing, though only in comparison to the later gun that was incredibly smooth. The early trigger is creepy, while the later trigger is better. Neither trigger would win an award, though, because these are economy guns at best.

What am I leading up to? Just this–in this blog, we’ve learned many lessons about the performance of spring-piston airguns. We learned about cleaning the barrels, we learned what tightening the stock screws does to velocity and we learned the all-important relationship of the breech seal to velocity.

The rest of the airgun world doesn’t know what we know about springers. They know how to over-oil their compression chambers and how to put too-strong springs into their guns to make them harsh and objectionable, but they don’t know the subtleties we know. Let’s see if any of this stuff means anything, shall we?

I traded for these two rifles from my buddy, Mac, who said he did everything he could think of, yet they still don’t shoot very well. We know from testing the Haenel Model 1 that .22 caliber spring guns of small proportions are never very powerful, and I don’t look for these to get any great boost from whatever we might do. But let’s just see what can be done with a few simple tricks we’ve learned from working on other spring guns. It should be an interesting time!

Mornin everbody

Ok BB you've got my attention. Like I've said I love the lower powered classics.

Here's one for those who can't decide

between a Bow and Arrow setup or an

Airgun.

https://www.youtube.com/watch?v=c7kFTTH7Szw&feature=related

By the way would that contraption in the above link qualify as a springer?

JTinAL

As I recall the Slavia 622 I did for Wayne was shooting (Gamo Match) in the low-to-mid 300’s, so yes, these guns are probably a bit slow.

I’m still praying to see a single pump pneumatic in .22 with at least 500 FPS. My order is waiting.

B.B.,

Great article. I live for those “McGuyver Moments”. Brilliant story about the M1 Garand. Tearing a web belt in two with bare hands? That’s a new one for me.

Anxious to hear the next part in this series.

kevin

BB, (off topic)

I took my RIA 1911 to the range again yesterday. It jammed almost every last shot of the clip when I used PMC .38super ammo (what mine likes). I had also tried Winchester White Box and Magtech, both jammed even more than the PMC. The only reliable ammo I could find was Remington UMC, which never jammed once, but it shoots groups that are about an inch and half wider than the PMC. This certainly doesn’t like wadcutters and hollow points. I took it to my smith to ask what was wrong, he fired 5 shots in the back room (PMC again)and said it was fine. Ejected brass from the winchester has a huge gash in the mouth, which says to me it doesn’t have the same dimensions as the other loads. The PMC has streaks across the case, they kind of look like stretch marks. Magtechs brass had the same problem as Winchester. The magazine spring is really weak too. This pistol has feeding and ejecting issues. Should I get a throat job done and polish the feed ramp?

Shadow express dude

SED,

Let me guess that your “smith” also sold you that gun? I’d get another smith–one with a repuitation for 1911s.

Are you limp-wristing the pistol? That can cause feeding problems.

I would also suspect both the magazines and the extractor. If the mags all worked with Rem. hardball, it might be the extractor. A Wilson Combat extractor solved the last of my Taurus feed problems.

B.B.

SED,

I would hold off on the throat job and the ramp polishing. That can cause kaboom accidents like the Glocks have.

B.B.

MacGyver always boasted about how he despised guns, though. So I guess it’s ok to electrocute people and blow them up, but not shoot them.(?)

Why does anyone even make a low power 22? What’s the point?

I’ve wondered about the point of a low-powered .22 myself. Not sure I can answer it, except to say that sometimes ya just wanna make bigger holes in things, or get more action out of reactive targets. There is the advantage, of course, of the larger pellets being easier to handle for those who are fumble-fingered by nature or from age.

Fortunately there are enough budget-priced .22’s out there of decent enough quality so that it might not be much more expensive than shooting .177’s.

B.B.:

Thanks for a GREAT post on improvising and showing how to actually THINK through a problem. That’s inspiring.

I’m going to tackle cleaning my Marlin 60 after all this encouragement.

PurcHawk

BB,

There may still be a few wondering how you knew there was oil in the truck for sure, and a couple of others thinking you might have shortened the service life of that M1 by 2.34 rounds due to oil and additive differences:).

PurchHawk,

I tore down my 60 night before last, just so I wouldn’t seem hypocritical and would have it fresh on my mind if you had problems. The only halfway tricky thing is the recoil spring in/behind the bolt, but the manual (which I look at afterwards:)) is pretty clear on how to do it.

SED,

A feed ramp polish won’t cause any ka-booms. Use a dremel tool, felt cone and some polishing compound. It’ll take you 15 minutes. It should help the feeding with wadcutters (you DO mean semi-wadcutters–right?) and hollowpoints.

The gashes in the case mouths you’re seeing are not necessarily indicative of case length discrepancies either. It’s more likely produced by a faster cycling speed of the slide. Try a slightly softer recoil spring. Go down about 1.5 to 2 pounds from the stock recoil spring. This should slow down the cycle of the gun and allow more time for the fired case to eject.

You may have an extractor problem as well, but I think you need to look at the recoil spring first.

I take that back. The VERY first thing you need to do is get a good magazine and eliminate the magazine from the equation. If you have several of the same mags, mark them so you can track and attribute feed issues to specific mags.

Thoughts BB? Anyone?

Derrick

Purchawk – Cleaning the model 60 is a piece of cake. If you google “marlin 60 cleaning” it takes you to a power point on the high raod website I believe. I have the link on my computer at home, I’ll post it on here tonight if you haven’t already found it. I tore my old one down many times. As a matter of fact, before I sold it, I was using graphite (pencil lead) for lubrication. This seemed to work okay as it didn’t have a tendancy to attract powder residue like oil/grease does. When you get it apart you’ll be able to see where the wear marks are on the moving pieces. I just loaded em up real good with graphite from a fat carpenters pencil. I’m not sure if this is the best thing to do in the world, but it seemed to work for me and might be worth a try.

-Aaron

B.B.

295 fps is pretty slow. I thought I was working at the rock bottom of velocity. So, we’ve found something that will stop an M1 Garand from functioning. My infantry weapons book said that the rifle functioned flawlessly in the mud of the ETO, -40 temperatures in Korea, and according to Douglas MacArthur, a week of uninterrupted combat on the Bataan peninsula without maintenance.

Good job with the dipstick. It brings to mind my panicked call to Clint when the safety on the rebuilt gun did not appear to work. After disassembling the trigger group over the phone under his direction, it turned out that I was not pushing on the safety hard enough. Well, I’m glad to make someone’s day.

I had another moment over in Hawaii when for some reason a clip would not load. Time to panic, especially since I couldn’t use my favorite remedy of calling someone or sending the gun off for service. However, I finally realized that the rounds were not stacked properly in the clip; restacking solved the problem. Odd that the rifle knew what the problem was. Anyway I take comfort in Clint Fowler’s statement to me: “My friend, there’s very little you can do to hurt that rifle.”

Matt61

Matt,

And here is another tidbit. Mud is both a lubricant and an abrasive.

B.B.

BG: You are going to some lengths for me–I appreciate it!

Aaron: Thanks a bunch. I should have thought of Google, but you are right, there’s a lot of instruction. I looked at the YouTube video from Chris B27 (a Brit) and the even better step-by-step illustrated description on http://www.castbullet.

It does look simpler than I thought it might, so here goes.

PurcHawk

Everyone,

This just came up for sale:

http://www.gunbroker.com/Auction/ViewItem.asp?Item=128552514

kevin

Kevin,

Thanks for the link. He has a .20 and .22 that he was going to use for field target? Strange!

That’s a low price for a Whiscombe with two barrels. I would expect the price to rise to 5K or more. I’ve bookmarked it to watch it.

Thanks,

B.B.

Nice post B.B.,

I really like it. Maybe one day i will take my storm apart, and tune it. But right now, im just going to keep shooting. I can take apart my daisy 880 in like 2 minutes. I have done it so many times. I can put it back together without even thinking. Although i do end up with extra parts…..

So, OK, B.B., how DO you tear a web belt in half with your bare hands?

Joe,

It’s a leverage trick. Impossible to tell without pictures. Maybe one day we’ll meet and I’ll tear your belt in half. That’s how the story is told.

B.B.

BB,

Thanks, that’s exactly what I was worried about with such a high pressure round. I’ll just replace the magazine and maybe look at the extractor.

Shadow express dude

BB, In your report on the model 34 panther you mentioned that the action must be different then an older model 34, Do you know if you can put a model 34 premium stock on this rifle?

Derrick,

Thanks, I think it came from the factory at 22lbs or something, it’s a lot heavier than the 18lbs one on my Sigma. Yes I meant to say semi wadcutters. How can you tell that the problem is the extractor, I get stovepipes and sometimes the brass is left idle over top of the magazine, but the tension feels ok in the extractor.

Shadow express dude

Red,

What is an RWS Diana 34 Premium? I looked for that model on the Pyramyd website but couldn’t find it.

Do you just mean a wood stock? If so, the answer is yes–but why bother, since the metal parts are the same. Or are you trying to save the fiberoptic sights or something?

B.B.

SED,

Extractor tension has nothing to do with it. It’s the angle of the entrance to the extractor claw that’s the problem.

The approach to the claw must match the rim of the cartridge you are trying to load, or there will be a problem. The feed lips of the mag must position the next cartridge so it pops into the extractor claw as it escapes the lips. The rear of the cartridge is moving in an arc when that happens.

Stovepipes are caused by poor extraction (a claw that lets go too early) or by not enough of a tap from the ejector. A too-strong mainspring can play into that.

B.B.

Extractor problems, feeding problems, some rounds don’t work right.. hhhhmmmm..

This is why I like revolvers!!

I’m a simple type guy!

Wayne

“noing” was the word verification..

very interesting spelling.. I know where I’m going:))

Aaron

You are a brave man,I wouldn’t have

admitted to using pencil lead as a

lube:O (works good though don’t it:))ssshhhhh

JTinAL

SED,

I found this interesting:

http://www.gunshopfinder.com/articles/1911recoilspring.html

Some good points in that article about the balance between the recoil spring and the mainspring.

The good news is that 1911 stuff is just about everywhere so there’s lots of different parts to play with.

The bad news is that 1911 stuff is just about everywhere…

There was a review of an RIA 1911

http://www.m1911.org/ezine/RIATactical.htm

He mentioned extractor problems also about midway through the article.

Those RIAs seem to be really nice guns for the money.

Derrick

B.B.,

I’ve bookmarked it too. This is only the 3rd JW I’ve seen for sale in 6 months and the only one with more than one barrel.

Seller sure set a low reserve amount and doesn’t have any feedback on gunbroker???!!! I’ve never owned a .20 cal but if this JW 70 doesn’t go too high I may.

kevin

A model 34 premuim is a wooden stocked model 34 however its laminated, checkered and has a rubber recoil pad. Pyramyd air doesn’t carry this stock or gun. Yes, I’m doing this to keep the fiber optic sights. If you look on Diana’s website you will see the model 34 premium. I know a place which sells these stocks, not the gun so I need to change the stock.

Red, the Panther and regular ’34 stocks interchange. The action isn’t really any different, but the factory might be paying more attention to details such as the clearance between the spring guide and the spring OD. That will make the gun shoot smoother.

Red,

Thanks for the explanation. I understand.

B.B.

Wayne, regarding revolvers versus semi-autos, we are of a like mind. I have some semi-autos, but I use them only at the range. I have a CWP and carry a S&W Bodyguard.

–Witt

B.B.

That’s interesting. Perhaps that means a muddy rifle will work okay while getting worn out faster. It doesn’t seem to have worked for the M16A1 in Vietnam, though.

Matt61

JT – I got the idea from my dad. Apparently it was popular way to lube your M-16 in Nam?

-Aaron

BB,

Sir Yes Sir…we like those MacGyver tricks for airguns though Mac never used a gun). They certainly are a blog in itself. Thanks for all the learning here.

Abe

B.B.,

Thanks for the tip about Divers silicone grease on air fittings that you gave to someone a while back, after they tore an “O” ring on a new PCP. It also works on quick disconnect air line fittings on regular air compressors for slow leaks.

No leaks after using Dielectric connector compound, which is 100% silicone grease. No Divers shops here in N LA. Thanks again.

Boyd

Matt,

The M16 is one of the worst designs ever to succeed in battle. It succeeded only though the persistence of the U.S. Army, who refused to admit defeat.

The twist rate of the original gun was wrong, the rifle is ineffective with a bayonet, accuracy is poor and it soils itself as it shoots. It requires far more care and attention than any rifle the U.S. has ever used since the Trapdoor Springfield.

It’s one of the most complex designs on the battlefield–nearly as complex as the Garand, and far more flimsy.

But it is light, and has little recoil so it’s easier to train troops with. It does work well on rock-n-roll.

In my opinion, the M16 is a successful failure–similar to Apollo 13, only it lasted longer. Fortunately we are doing something about it today, but we should have gotten rid of it following Vietnam.

B.B.

BB,

I got to see both the M16 and the M14. For “tactical” training, the M16 was great – light weight, fun to play with. We only used the M14 for parades. I seem to remember an older NCO telling me that for the two-way rifle range, he preferred the M14.

[Word verification – “dingin”]

Gettin behind…gotta catch up..

Love the McGuyver stuff.

-Chuck

B. B.,

Alright, a CZ 622. I picked up one of these neat little air rifles at an auction, $35. I was willing to pay that, since I'd never seen one before. Anyway, here are two links where I wrote a little bit about it over at RFC.

http://www.rimfirecentral.com/forums/showthread.php?t=234820&highlight=CZ+Slavia

http://www.rimfirecentral.com/forums/showthread.php?t=234821&highlight=N-Tea+Trio

E in V,

Thanks for the links. I read them both. It seems like a lot of people have rifles like these.

B.B.

What a great blog! It is a pity that I can not find RRS address. If RRS offers a subscription service, I can easily follow your blog!

Air Jordan,

It's the standard blogger rss location, rss.xml. Here's the link for you.

/blog//feed/

Welcome to the blog 🙂

Air Jordan,

I may have misread your request. Did you mean RSS? I've never heard of RRS, what is it?

Bobby Nations,

What a fantastic asset you are to this blog.

kevin