by B.B. Pelletier

Before we begin, I have an announcement. On Thursday I’ll start the Nitro Piston review.

Today’s report is for Bob from Oz, who asked for it long ago and has been more than patient. As we consider this operation, we must acknowledge that BB guns come in many different styles, and they don’t all come apart the same way. Therefore, this report will deal with those Daisy guns made from around 1915 to around 1970, which includes a large segment of what’s on the used market today.

Older and newer guns may vary a little or a lot from the ones shown with this procedure, and there are models within the same timeframe that vary because of their unique design. Also, non-Daisy guns may sometimes vary. However, fundamentally, most inexpensive BB guns are designed and assembled in pretty much the same way. If slight differences are encountered, it should be easy to adjust your methods to accommodate them.

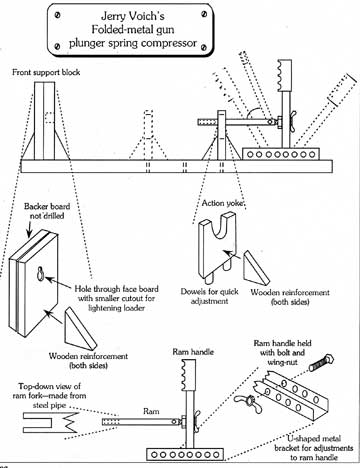

You will soon see that rather than a report on just how to disassemble BB guns, this is more a report on how to build a disassembly machine, because that’s what it takes to do the job. Without this machine, you need extra arms and hands at various times in the procedure.

The design of this machine was given to The Airgun Letter by the late Jerry Voich, who authored an article for us on BB gun disassembly. Let’s begin simply, shall we?

The powerplant of most Daisy BB guns is held in the gun by a spring anchor, which is a flat piece of steelplate that fits through the body of the gun. Find an easy way to remove this one piece, and the whole job of disassembly becomes easy.

The first step is to remove the shot tube. This is accomplished by simply unscrewing the tube and removing it from the gun. This is done on all guns. After this step, the guns become more specific, though the assembly of most of them remains the same.

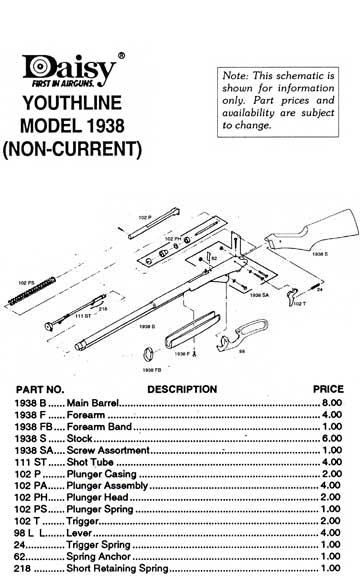

Taking as an example the Daisy model 1938, most commonly known as the Red Ryder, we can remove the buttstock and forearm by the removal of several obvious screws and bolts. The trigger and cocking lever are then removed by removing more obvious bolts. In the case of the trigger, there’s a return spring that also comes out with the blade.

That leaves us with the powerplant, which consists of the mainspring, the piston assembly and the spring guide. Daisy calls the piston a plunger and all the parts are plunger parts. When the gun is assembled, the plunger casing (mainspring guide) is pressing backward on the spring anchor, which holds it in place. On the front end of the plunger assembly, there’s a plate that’s swaged into the tinplate body of the gun. This plate forms the front of the compression cylinder of the gun. Its backside is what the plunger (piston) rests against; and in the front, it contains the screw threads that the shot tube screws into. This part does not come out of the gun.

One big secret!

The one big secret to BB gun disassembly/assembly is to take the pressure off the spring anchor so it can be removed by simply lifting it out of the gun. Then, the tension is relaxed on the mainspring, and the powerplant parts can be slid out the back.

The way to remove the anchor is to reach around either side of the anchor and put pressure on the mainspring, which is wrapped around the plunger casing (spring guide). Forcing the mainspring forward takes pressure off the anchor so it can be removed. The tension on the mainspring is relaxed, and all the powerplant parts can be removed from the back of the gun.

It takes a ram with forked legs to reach around the spring anchor and push the mainspring forward, and that’s what the disassembly/assembly machine provides.

The machine

Once again, the credit for this machine goes to the late Jerry Voich. He was a subscriber of The Airgun Letter who wanted to share this with all the folded-metal BB gun collectors in the world. This isn’t the only design that will work, of course, but it is simple to build and straightforward to use. Once you understand what you are dealing with, taking a BB gun apart is no more difficult than disassembling any spring-piston airgun.

One last bit of advice

I’ve disassembled several BB gun mechanisms without the benefit of a device like this, and it certainly is possible. One thing I learned while doing that is to work slowly. For example, once I remove the spring anchor, the next step would be to install it again. I would do that several times until I got the hang of working with those parts. This single step is the crucial one in the whole process, so whatever you can do to make that easier makes the entire job easier.

Fused,

here's that link I neglected to include in last night's comments section for SCUBA tanks.

/blog/2008/12/buying-a-high-pressure-air-tank-part-2-1000-posts/

Thanks Kiwi for pointing out my error.

Fred

Mr B.,

Re: AA S410 in .22 caliber. "Do you think that I can figure around 400fps with the JSB's?"

I'm sure with a combination of heavy pellet and adjusting the power lower than medium I can get 400 fps. Why is 400 fps your goal?

If you're hunting squirrels and are taking shots at 30 yards why not use full power? Do you have neighbors to worry about? If so, then medium power with a heavy pellet that won't over-penetrate seems the solution. What am I missing?

I think on medium power with the middle weight jsb's (15.8 gr.) the gun was shooting around 750 fps. I'll take the chrony to the mountains this weekend and I'll run a few pellets over a variety of power settings and quit trying to remember what the fps were. Give me some insight into what your goal is and I'll try to provide answers.

kevin

June 23, 2009 7:59 AM

Thanks for the link Fred.

I have some observations about shooting my new springer air rifles.

First with the 92, I noticed that I could not shoot with the open sights for the life of me. I was thinking that I must really be awful at this and was about to hang it up for good, but then figured why not just mount the scope that Vince sent me. Voila, my first single hole group (but still a pretty big single hole) at 10 yards! This was my first experience with fiber optic open sights. I was surprised because they are so easy to see, I thought this would make sighting easier. I read in one of B.B.'s posts that he does not like them, I guess now I know why although I don't understand why they are so inaccurate… Is it because there is too much separation between the dots and therefore too much play? The other thing I observed is that there really isn't much difference in the feeling of power between this and the 94. It's easier to cock, but the recoil and sound feel about the same. Maybe since it was tuned by Vince, it's a super powered 92 or maybe the 94 is just really smooth – I don't know. My last observation is that the 92 is too big for my 9 year old daughter. I originally thought it would be a good gun for teaching her to shoot, but it now seems obvious that it's too heavy especially with the scope. It will, however make a really nice cowbird and starling hunter!

For the 94, I haven't spent as much time with it because the 92 was the bigger challenge. Now that I have put that to rest though, the 94 is up to bat. I can tell you that the open sights on the 94 are much easier to use. No fiber optics, just plain plastic with click adjustments but they work!

Once I prove to myself that I can get them sighted in, I am going to stop shooting from the table and see if I can be accurate with them offhand. We'll see, does anyone have recommendations on how to hold them while your standing/kneeling or is sitting the best way?

First, tell the kiddo to wear safety gun glasses.

Make a mental note of where your front & end sites are lined up so you can make small changes for the next shot.

Make certain what is BEHIND your target!

Breathe deeply thru nose, exhale with a long, relaxing breath thru the mouth, if you can do this three times…lining up your shot while breath is out, take the shot. Seems to stabilize the upper body, it works!

Stance should be outside the width of the shoulders to give a good base. Mess around with foot positions that is comfortable for you/youngster.

Fused,

Because you are new to this blog, you have missed some homework assignments. One of these, watching the movie Patriot, would explain why fiberoptic sights are too sloppy for precision.

Mel Gibson says to his boys, "Aim small, miss small." and conveys in that phrase the fundamentals of sighting. With fiberoptics, you can't do that, because they have no precision. You cannot see exactly where you are holding them from shot to shot.

B.B.

B.B.

I have seen that movie and remember that scene. Good movie.

I am no fan of fiber optic sights! Amazing how old school things always seem to prove themselves over and over again.

Fused, I've found that the sights on the 92 seem to be harder to use than some other FO's I've tried. I find that I REALLY have to pay attention to make sure I have a consistent sight picture.

And I'm really sorry the gun is too large for your little girl… I did send you the shorter-stock version hoping that it would fit her better. I figured it might be marginal to start with (as it is for my 9-year-old girl) but that she would grow into it quickly enough. Perhaps I should have been more vocal about the possible mismatch.

The 94 is a lot more powerful than the 92. The one I sent you was doing about 14-14.5 ft-lbs as I recall, and the 92 was doing about 8-8.5. Up close you might not notice the difference, but if you start plinking at 50 yards or so the story will be different.

Vince,

No problem about the size, she'll grow into it. In the mean time I can have the pleasure of breaking it in for her.

Fused, what pellets did you try in the 92?

I like fiber optics for plinking cans indoors. It's allows for quick recognition in poorer lighting conditions, but you still need to look at the black parts of the sights for better accuracy.

Right now I only have fiber optics on the front sight of one of my BB guns and one of my pistols, which I hardly ever shoot over 10 to 15 yards.

BTW…did anyone notice that it's a little warm out today?

Maybe it's just the humidity.

Good afternoon all –

It sure is a scorcher here today in MI, I guess I can't complain though. Some of my contacts down in Bama said they've been up over a hundred degrees lately. (sorry JT)

I just picked up some 10.5 grain premiers at Gander, seems like everyone is out of the JSB's so I thought i'd try something I could find here locally. Do you guys think that 2 grains difference in pellet weight (10.5 premiers vs. 8.4 grain JSB)is enough to cause damage to a mainspring or seal? I know it's been discussed on here before, but I have a hard time believing 2 grains is enough to cause any damage or premature failure. Anybody have any thoughts?

-Aaron

Vince,

I am using CP hollow points. PA seems to be out of everything that has been recommended and that's all I could find locally. Once I use them all up, I'm planning on switching to CP's in the box or JSB exacts. Wayne recommends the JSB's so I'll try them first.

B.B.

PA is not answering the phone, so I guess they are still moving. The disassembly machine reminds me of the M1 Garand where apparently Garand was very innovative in creating machines that could mass produce his rifle.

Fused, actually I've had reasonable success with fiberoptics. I think that regular iron sights (not to mention a scope) are better where there is a defined target that is black on white, in other words formal target conditions. Where you don't have ideal background colors, the fiberoptics might be better.

Matt61

.177 I have good luck with:

JSB Exact and Heavy

RWS Hobby, Superdomes and Meisterkugeln Rifle 8.2gr

GAMO Hunter, Match and sometimes Raptors.

in .22 I like:

JSB Jumbo Express

BEEMAN Kodiak Extra Heavy

GAMO Magnum Points

Nowdays, I mostly shoot about 2/3 JSB and 1/3 RWS pellets.

BB,

Speaking of taking things apart, I know you said not to take a pump apart, but it quit working and the warranty had expired, soooo what the heck. It is a Benjamin pump I have been using to fill my S410 about once a per week for the last year. It got really hard to pull up and harder to push down, and fianlly wouldn't move at all when under pressure. When I got it open there were water droplets throughout the pump and rust on several of the parts.

I cleaned it up and put it back together, and you are right – it doesn't work. But then I wasn't being very careful because I have no intention of using it again. I will either go with a tank like Wayne suggested or a pump with an air trap. Please let Crosman they need to work on this.

MCA

MCA,

If you contact Crosman, they can get it fixed for you.

The secret in reassembly is to use all new o-rings and to use Parker Super o-ring lube on every seal. And cleanliness is above everything.

B.B.

"BTW…did anyone notice that it's a little warm out today? Maybe it's just the humidity."

AJ, I believe this is called Global warming…something we'll have to deal with ASAP if we want to survive and keep shooting airguns. Another interesting fact is that the mainland winds are beginning to die off…right at the time when we are investing heavily in wind powered electricity generation.

Fused, have you considered a Daisy Buck model BB gun for your 9 yr old? It's short, simple, inexpensive, holds a ton of BBs and it's a blast to plink with.

Edith,

I know, that Global Warming comment was probably too political for an airgun forum. Sorry. Please feel free to remove it, and this comment as well.

Aaron,

as no one has responded to your question about a 2 grain difference in pellet weight, I'll chime in. It appears you're going heavier so expect no damage to spring, piston or seal. The heavier weight will cause a slower acceleration of the pellet in the barrel allowing the required air cushion to still build up between the seal and the end of the compression chamber/orifice. The pellet should also travel a bit slower. You need to be careful of using extremely LIGHT pellets in high powered spring piston rifles – pellets down in the 6 grain category for .177 and even lighter, are what many companies use to obtain those 1,000 fps plus velocities they then stamp all over their ads and boxes. The lighter weight causes the pellet to travel that much faster and, if too light, will not allow an air cushion to build, allowing the piston seal to slam into the end of the compression chamber.

Be careful of those non-leaded pellets which can be very light and, surprise – word verification is "undleded". I kid you not. How does this thing work, anyhow?

Global Warming – Mr & Mrs BB have been tolerant of political commentary on this blog as long as everyone remains respectful. Obviously opinions will differ, but it is not a reason to be hateful to one another. However, if you are going to post something of a political nature, at least be man enough to sign your name to it.

-Aaron

ps – I agree with you on the global warming issues!

Fred – Thanks for the thought, that seems to make sense to me!!

-Aaron

I was just shootng the breeze about the weather, but global warming is definitely something to think about. Seems kind of strange how when the price of gasoline went up, people drove less and we had what seemed like a cooler or longer winter. But I guess "what goes up, must come down," and that it's "better to be safe than to be sorry" and responsibly plan for the future.

AND

NOW

FOR

SOMETHING

COMPLETELY

DIFFERENT:

A Parody of Don't Stop Believing – Journey

Just a small airgun

Livin' in fast on the run

It took the midnight train goin' anywhere

Just a man city bound

Livin in old Midtown

He took the midnight train goin' anywhere

A shooter in a target range

A smell of lead that heals the pain

For a while they can shoot all night

It goes on and on and on and on

Shooters waiting

Up and down the boulevard

Their shadows searching in the night

Airgun shooters

Living just to find emotion

Hiding somewhere in the night

Working hard to get my fill

Everybody wants a thrill

Payin' anything to shoot all night just one more time

Some will win, some will lose

Some were born to sing the blues

Oh, the fever never ends

It goes on and on and on and on

Shooters waiting

Up and down the boulevard

Their shadows searching in the night

Airgun shooters

Living just to find emotion

Hiding somewhere in the night

Don't stop believin'

Hold on to that feelin'

Airgun shooters

Don't stop believin'

Hold on

Airgun shooters

Don't stop believin'

Hold on to that feelin'

Airgun shooters

BB,

edge of seat till thursday.

Shadow express dude

I have thought about the Buck. Can't really explain why I'm not crazy about the idea. I guess I associated the Buck with the airsoft guns that are right next to them on the shelf at Walmart, and I'm conflicted on how I feel about those. Gets all muddled up in my head about airsoft – toy guns shooting real bullets (bbs) and teaching responsible handling of and respect for guns. I'm troubled when I see the neighborhood boys running around shooting each other with their airsoft, acting like gangsters and not wearing protection. What's wrong with that picture and what does that say about how would they approach a real gun? Like I said, muddled. Seems easier to instill a healthy respect from the get go, although maybe I haven't given the Buck a fair chance since it's not really an airsoft toy.

These are general questions for Marauder owners: 1.] Does the Crosman pump for the Discovery also work with the Marauder? 2.] If it does, are any special adaptors required, or does the pump come "ready to go?"

–Witt

Aaron thanks for reminding me:(

It's been like a sauna here for about a week,actually been cooler at my sisters

in Bush,LA.

Upper 90's with 100%humidity heat index

105 daily.Oh well at least we get very

little snow and ice to deal with:)

AJvenom

HOWL:) that song fits so well I can hear

it in my mind now.

Global warming ? Don't know about the rest of you but we're just a little ahead of schedule nothin unusual that I can tell.Long as we don't have another drought!that was bad and we just got caught up on rainfall here.

JTinAL

Fused – I have a Buck 105 or something. I like the fiber optic front sight. I just figure out the best sight picture at 7 to 10 yards and draw it out on the box for the kids to duplicate. They have a blast.

We've put a few thousands rounds through it and it still works pretty well. I ended up with a Mendoza 650 and Red Ryder for the older kids and adults (mainly me) to use. I like the fact that they self load and simple to use. To me they're the funnest pop can killers in the world.

On the daisy BB guns, I did flip a few bolts around on the receiver and store away the leather thing and possibly the metal ring on the red ryder. Those things were getting the way.

I don't own an airsoft gun. IMO, they just don't seem to be as satisfying to shoot as a BB gun.

JTinAL we finally got some rain today, it cooled off about 10 degrees. As for that song, I had it stuck in my head all day. Know what they say? Sharing is caring.

https://www.youtube.com/watch?v=ip1zsUIosoA

BTW….they're coming to take me away ha ha ho ho he heeeeee….

Not really, after tonight, I get the rest of the week off for a nice little vacation up north by all the big lakes, long rivers and giant woods. Fishing, camping and possible airgun shooting …..oh boy!!!!! Then again, we'll probably relax around the camp fire and drink beer, which is fine by me. Anything beats that growing honey-to-do list.

Witt,

The pump fits both guns and anything with a male Foster coupling, which is becoming more common all the time.

B.B.

On the subject of global warming, I heard that one plan was to build giant towers to suck all the CO2 out of the air. What a great source of cheap CO2 although they probably wouldn't be crazy about us shooting it into the air again.

And on the subject of songs, I just happened to be thinking of the old Christmas special with a character called the Heat Miser. He sings a song accompanied by a chorus of small creatures that goes something like this:

I'm Mister Green Christmas.

I'm Mister 101.

They call me Heat Miser.

Whatever I touch

Starts to melt at my clutch.

(Villainous laughter)

I'm too much. (Best line)

Anyway, you can find it easily enough on YouTube. All with kids will not want to miss this.

Matt61

Well after weeks of trying to remove the song "Be Mine today" from my brain from the old Here Comes Peter Cottontail Movie 1971, I am now stuck on:

https://www.youtube.com/watch?v=L6744Fxbu9M

Good evening folks,

Time for my two cents on global warming. The Finger Lakes in upstate New York were carved out by glaciers. Where did the glaciers go? They melted; without man's help! Fancy that, guess the climate goes in cycles with or without our help. Don't get shucked by the conmen, oops sorry, I mean politicians beating their global warming cash cow drum.

Mr B.

BB –

Thanks for today's blog topic. I've been meaning to spend some time looking more closely at my old Daisy Model 95. Purchased by me at age 12 some time ago. Still in the original box. Still shoots – but doesn't seem to have the guts it used to.

Today's post should give me the confidence to take it apart and make sure all is well internally.

OK… I'll contribute to the global warming patter…

1) What's the one thing we know for sure about the global-warming computer models? They are wrong. I believe none predicted the stable temperatures of the past 10 years. Oh, and predicting it now, after the fact – well, that doesn't really count.

2) If the weather feels hotter in any particular place, it's because it's hotter in that particular place. Local, short-term weather patterns are not going to be indicative of global warming, just as the cooler-than-average June we've had in NJ doesn't mean anything either.

3) If any in government really thought this was an important issue, they would start attacking it where they can do so immediately – in government operations. I've got 25 years working for the Navy, and trust me… nobody's trying very hard.

I sure hope it isn't a real and significant issue. Because our leadership is far more concerned with platitudes and feel-good-isms than tangible results. Look at gun control… if they pass legal restrictions on firearms, they've proven their compassion and humanity. Doesn't matter one iota if the laws work. Not one bit.

I'm not planning on disassembling a BB gun, but are there any specifications for the Plunger Spring Compressor, or is it a general guide?

Because I'm pretty good with interpreting how to build something from pictures, but I'm a little lost with this one.

Hi Aaron,

Thank you for replying to my post, although I was amused by your assumption that I was male.

I believe if I had it to do over I would have skipped making that political comment. Guess I hadn't had my morning coffee yet and wasn't thinking clearly.

Great forum. My love and respect to you all.

Donna

————————————–

However, if you are going to post something of a political nature, at least be man enough to sign your name to it.

-Aaron

Donna,

Hello and welcome. However, Aaron wasn't alone in his assumption. I'm guilty also. Political comments are made here from time to time so don't fret too much.

MCA,

I've had some bad luck with Crosman HPA pumps. They have replaced three for me at no charge. Follow B.B.'s advice and give them a call at 800-724-7486.

Perra Dog,

A welcome to this blog from another Marylander. Are you perhaps near the U of M @ College Park?

Mr B.

I understand this is completely unrelated to anything thus far, but I'm looking for some advice and information.

I'm interested in a

Walther Falcon Hunter

in .25 caliber. I'm curious about the differences between the regular spring rifle and the version with

the Air Venturi gas spring. What are the advantages and disadvantages of the gas spring?

Is it worth the extra $93 in this case?

Thanks,

-Mike

Mike, it's not the Walther Falcon, but BB reviewed the Gamo Whisper

with both a coil spring and a gas spring, and it should give you a general idea of the differences.

Here's the link:

/article/Gamo_Whisper_An_indepth_review_January_2009/55

Scroll down to the bottom for the Gas Spring portion.

Gas springs can be stored cocked,

so they may be more suitable for hunting purposes.

Admittedly, I have merely misplaced a half empty bottle of beer, but the resulting frustration is very distracting; however I cannot resist the urge to contribute a few tidbits.

Mr. B,

I was consumed by noise reduction for some time. I too am hemmed in by neighbors and choose to be pro active as you appear to be also. I think you will find that 12 ft in .22 caliber is a nice compromise. Depending on the weight of the pellet you will be in the 600 fps range. Used as such I actually found my .22 cal PCP on low quieter than my .177 FX Whisper which lacked a power adjustment.

Donna,

No worries, Love means never having to say you're sorry.

Bg farmer,

I’d probably cut a few inches off the barrel of that guide gun and drill out the extra wood in the butt. : )

I have the “heavy” JM tar and it seems appropriately named, but more so by color.

Kevin,

Tell us about summer in the mountains when you have time, and maybe link a picture if you can.

Wayne,

Any new favorites or still rating the S410 as number one?

Volvo

Mike,

I’ve only owned one gas spring rifle, and was not impressed. My particular example had a loud sharp crack that was very annoying and not present in a typical spring rifle.

I believe they are better in cold weather and can be left cocked longer.

Volvo

Volvo,

Did I ever tell you that my first car was a used 53 540 and the only new car I've ever bought was a 1969 144?

Aynway thanks for your comment. My go to yard gun is a Talon SS on CO2 with the PW at 3 and an AirHog shroud. She shoots around 600 fps. Works well.

Mr B.

Volvo,

Well, I'm still rating my Air Arms s410 .177 cal sidelever with power adjuster the best all around "only one gun in the closet airgun", assuming squirrels and starlings are you targets when hunting…

and you want to shoot field target (get the single shot tray)..

and you like to plink late at night without bothering the family…

and you like to get 200 accurate shots per one hour session … the easy to use side lever and 10 shot mag. keeps one shooting instead of cocking and loading)…

and about $1,000 fits into your airgun budget!!

if $500 fits, then my favorite is fast becoming the .177 Marauder..

I am very impressed with the used FX superswift in .177 cal. I just got… (after I got the barrel pushed back in line with the air tube! .. from shipping abuse I guess)..

I'm not a fan of the plastic stock, but it does fit well. The three different power modes is good, but not close to the full range of the AAs410 adjuster..

The sidelever is smooth and easy, but this one needs the lever almost slammed against the stock to set the trigger.

I like the way the 8 shot mag pops out when you pull back the spring loaded pin, but watch out to catch it!! I would hate to loose it to tall grass or something..

Of course accuracy it top of the line, as good as the AAs410.. but for the same price new.. I'd take a nice walnut stock AAs410 anytime or the FX superswift!

nope.. still selling the Air Arms S410 for free (as an unpaid salesman, that is!)

Wacky Wayne

Ashland Air Rifle Range

B.B. and All,

Did anyone see this first wire frame butt daisy on gunbroker.. looks very rough, rusty, no trigger, and the current bid is over $2,000..

..nope not me.. but I'm sure wondering how high it will go in the next days..

http://www.gunbroker.com/Auction/ViewItem.asp?Item=131695103

Wayne

Ashland Air Rifle Range

Donna,

I just hope that you will continue as a reader and as a commenter. We get precious few women's views on this blog and we would welcome one more. Actually, I know of only two others besides you. My wife, Edith, and a reader named Jane Hansen, who we have nicknamed "Rocket Jane," because she is a rocket scientist.

So please stay and talk–about airguns!

B.B.

Mike,

A regular Falcon Hunter feels loose and buzzy. One with a gas spring feels tight and quick–no buzz. The gas spring will feel much harder to cock, but it really isn't. It just resists your effort from the very beginning of the cocking stroke.

If you use the artillery hold, a gas spring is very pleasant to hold and shoot. If you grasp it tight it will loosen your fillings!

And you can leave the gas spring cocked for hours without spring fatigue. That's one of the major benefits.

B.B.

Wayne,

That is a VERY early Daisy first model and worth much more than the current bid. I predict it will top $4,000 before it sells. It could top $10,000.

B.B.

Kiwi90,

Blogger only allows graphics to be 5 inches wide. I could have run the diagram sideways, but I reckoned that those clever enough to disassemble BB guns would be able to understand this diagram. It all boils down to a pusher pipe that puts force on the mainspring so the spring anchor can be removed. After that, the gun comes apart easily.

B.B.

Mr. B,

Sounds like you have it covered. For some reason I thought you were having Kevin check on getting down to 400 fps with his S410? I’d guess I only picked up on only part of the dialog.

I had been tempted by the Talon’s but never pulled the trigger on one – I had often read they were difficult to rest your check on. Do you have any issues?

Volvo

Volvo,

I am basically a deeply blued metal in nice wood kinda guy, but I don't have any issues with the Talon. I bought a Wokbutt which is adjustable for height and cant. You can see them on TalonAir.com-index. I also cut the bottom out of a beer can holder and slid it over the tank for a cheek piece. No issues at all.

My Talon SS with an AirHog shroud is just incredable. No noise period. 15 minutes ago had a flock of grackles in the yard and shot three of them before the rest decided it was time to go–at 16 to 19 yards. That to me is quiet.

If I'm needing more power, I can just switch from the CO2 tank to the HPA tank or it only take 15 minutes to set up the 24" barrel with it's AirHog shroud and I'm good to go, again with the option of either CO2 or HPA.

Basically I feel about my SS the way Wayne does about his AA S410. Pull the trigger. You'll love it!

To answer your question about Kevin, his AA S410 and my comment about 400 fps is that I am looking at buying either the S410 or a Maurder. The ability to shoot on the low end of their power potential is important to me cause I don't need or want to shoot the "big boys" in my back yard.

I am still waiting for someone to tell me how the Maurder shoots on CO2!

Perra Dog,

A welcome to this blog from another Marylander. Are you perhaps near the U of M @ College Park?

Mr B.

Yup, just around the beltway towards the 270 split. I find myself going up to Damascus to shoot every week or so. I'm looking forward to September 15th, but have so many new guns that I'll never be able to decide which to bring !!!

Perra Dog

Perra Dog,

Hello neighbor. I've never gone to Damascus. What is happening on 9/15? Can you give me an address? Have you heard about the Berwyn Rod and Gun Club? They have a wonderful facility just outside Bowie. They allow any centerfire except the 50 cal BMG. You can also shoot Class Three guns and those with suppressors.

Mr B.

Many thanks PP. I have been on holidays and nearly missed it! Will let you know how I go after I make one of these jigs.

Cheers Bob

i wish to buy a trigger spring for a daisy air rifle model 25. please let me know. thank you.

George,

Welcome to the blog.

Pyramyd AIR does not sell parts for vintage airguns. Here is a place that may have what you need:

Baker Airguns @ (937) 660-9152 Email: info@bakerairguns.com

B.B.