by B.B. Pelletier

This report is specifically for Mannish, a reader from Mumbai. But I imagine we have many readers who might like to know the same things. How does a precharged pneumatic (PCP) airgun work?

First, let’s describe the differences between a PCP and a multi-pump pneumatic. A multi-pump is a gun that one pumps full of compressed air before taking a shot. The compressed air is mainly stored inside the gun’s firing valve. When you shoot, the valve exhausts all the air inside–if it is able.

Sometimes, we over-pump a gun, and the valve cannot open far enough or stay open long enough to exhaust all the air. That’s called valve lock, but you might think of that gun as a precharged pneumatic, because we charged the rifle and then shot it more than once before charging again. After that first shot, the gun was still charged with pressurized air for another shot, so, for that shot, the gun was pre-charged. See where the name came from?

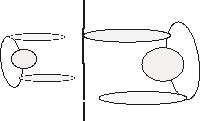

All you have to do is add a larger reservoir to this gun and you can store more compressed air. Instead of shooting just one extra shot, we might be able to get about 20 shots. And most of them will be at approximately the same velocity.

So, do we call that gun a precharged pneumatic? No, we don’t. By convention, we call all guns that have air pumps attached “multi-pumps,” unless they’re single-stroke pneumatics, which I don’t want to get into here.

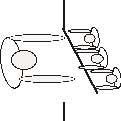

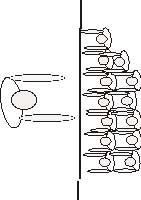

Precharged pneumatics or PCPs are, by accepted convention, those guns into which pressurized air has been added from a separate device like a scuba tank or hand pump. That air is stored in a reservoir in the gun until the firing valve allows some of it to exhaust during a shot. Their valves work just like those found in multi-pump pneumatics. And, since there is too much air in the PCP reservoir for the valve to exhaust all at once, the gun gets many shots per charge.

Too much air to exhaust. How does that work?

Well, there are many factors that determine the efficiency of a firing valve, and I only want to discuss two of them. A firing valve’s efficiency is controlled by the pressure in the reservoir behind the valve and by the amount of time the valve remains open. Now, I could go on for pages discussing things that control the amount of time that a firing valve remains open, because there are a lot of them. But for the sake of brevity, I will limit this discussion to just two things–the size of the valve and the strength of the hammer blow that opens it.

Size matters

If one person holds a door closed against you trying to open it, you may be able to get it open. Of course, the stronger the other person is, the harder it will be. So let’s make him a five-year-old, so that most of us will be able to open the door easily. Now, if we add a second child, the door will be a little harder to open, but no sweat, right? But what if there were 15 kids holding the door shut against you? Maybe then you’d find it difficult to open?

But 15 kids couldn’t push against a door unless it was very big. So let’s say that it’s now 10 feet wide. Maybe with a door that big 15 kids could all push against it at the same time. And if they could, you would have a hard time opening it.

In my analogy the kids are pressurized air. And the door is a valve. If the door is only three feet wide maybe only four or five kids could push against it at one time and you would find it easier to open than with all 15 kids pushing.

If kids run through the opening while the door is open, eventually there won’t be enough kids behind the door to matter to you. You’ll be able to push the door open and hold it there and they will all run out. When that happens, the size of the door ceases to matter.

As the number of kids behind the door decreases (because some are escaping every time it opens), you’ll eventually get to the point that no matter how large the door, there isn’t enough resistance to keep it closed against your push. That’s the point at which the valve drops off the power curve, more-or-less.

More pressure!

Let’s remove the kids and put people as strong as you behind that 10-foot door. It’s not going to open, is it? Nope, that door is valve-locked. So, putting more pressure inside the reservoir isn’t going to boost your gun’s power if the valve isn’t sized correctly for it.

When the Benjamin Discovery was designed, it was determined that lower air pressure (smaller kids) could do the same work, as long as enough of them made it through the firing valve. With a long barrel there was plenty of time for the lower-pressure air to push on the pellet. Sure, five-year-olds aren’t very strong, but get enough of them pushing and they can do the same work as a couple of strongmen.

A bigger hammer!

The other thing we can do to change the valve’s efficiency is to swap you for a real strong man to open the door. Then maybe he can open a 10-foot door with 15 kids pushing against the other side. And, we can make the room on the kids’ side large enough to hold hundreds of them, so now we have a more powerful “gun.” But we lose a lot more kids every time we open the door, so we don’t get as many “shots.” But our big “hammer” lets us open the door farther than if we used a wimpier hammer.

All we have to do is design a really big room for the kids to be in. Oh, but that makes the entire building bigger, doesn’t it? Well, what if we make the door smaller and fill a smaller room with stronger people? That would work, wouldn’t it? Maybe the strongman (bigger hammer) could open a three-foot door with a few grown men pushing against it. The few grown men that escaped through the door while it was open would be able to do a lot of work on the other side, wouldn’t they? Maybe as much as a lot of five-year-olds. We could have a smaller room for the grown men, yet we could get a lot of powerful “shots” from them this way.

Two things that can affect our valve are its size and the time it remains open. If we change the pressure inside the reservoir, that will also change the power of the gun, but very quickly it might get to the point where the valve doesn’t work very well. That’s because it was designed with a different hammer strength and a different valve/door size.

A PCP works by a balancing act of the valve size, hammer strength and the pressure inside the reservoir. As long as the pressure is within the design parameters of the valve, it works well. Once it goes outside those boundaries, the valve doesn’t work as well.

Goodmorning B.B.,

What a good analogy. How much of a part do computers play in designing our modern PCP's valving?

Gotta have alot of respect for the guys doing this stuff before Lewis and Clark.

Mr B.

The concept is very well explained.

Thanks

Manish

Mumbai, India

B.B.

Good job on the analogy!

It seems that the manufactures have been studying each other and the whole industry has improved greatly over the years. With Crosman leading the way to lower priced PCPs.

The advantages of no recoil, and high quality barrels manufactured in large runs for a low cost, and on the shrouded models, quiet shooting.. make it hard to choose a high power spring gun these days… at least for me!!

Today's PCP is a great deal ie the Marauder for example.. at $500

or Evanix Blizzard for a very powerful accurate PCP. at about $600

It will interesting to see the fate of the spring gun as we move forward in the industry.. I'm sure they will stay around, for the folks who don't want to be tied to a scuba tank or pump.. but when one gets into those items, they find it's not so bad… right Kevin? (I see your selling those pumps.. like I thought you might!!) 🙂

Wayne,

Ashland Air Rifle Range

BB.

Great post today!

One little question: Can a Talon SS hold enough air for 100 shots at 600 fps in .177"?

Julius

Wayne,

I'm sure there will always be a market for springers. Still something very attractive to me about a fully self contained gun.

Yep, I'm selling my last pump. Just don't use them anymore.

kevin

Kevin,

BTW, that was a great way to describe the issue of storing a loaded gun… It's been on my mind, so I really thank you (again) for the experience to bring to this blog!

It is very, very, tricky territory, and it seems it's up to the situation you find yourself in..

I guess I'm hearing the more uneducated one and ones' household are about gun safety and handling, the more locked up and unloaded the firearms need to be!!… and just forget it, if there are children around the house or come through it!!!

Wayne,

Ashland Air Rifle Range

Wayne,

Thanks for the acknowledgement.

Guns are tools. Dangerous tools. Especially if you don't know how to use them and don't respect them. Education and reinforcement where kids are concerned is my mantra.

I'm outta here. On my way to the mountains. Golf, poker and fishing tournament with the boys this weekend. I may not come back.

kevin

B.B.

Very interesting. I love those diagrams. I'm supposing that the trigger on a pcp releases a hammer that strikes the valve to knock it open. Then what closes the valve with sufficiently precise timing for the exact right amount of air to get through? Is it the pressure in the reservoir? I would expect this to decrease gradually over the course of the fill rather than towards the end where the power curve changes. But perhaps the pressure that closes the valve properly is the same pressure that powers the pellet.

And is there something about the pcp mechanism that makes them relatively high-priced? It doesn't seem particularly complicated.

Matt61

Julius,

The answer to your question is "yes," and you should look into a CO2 or hi-flow tank, or both.

You can get way over 200 shots at that power!!

– Dr. G.

Ha, great analogy, you just made my day.

Shadow Express dude

Julius..

The answer is no.

Talons are not regulated…you have a velocity curve when running on air. They will not hold velocity at any any given speed.

Only with CO2 can you maintain a constant velocity….it self regulates until the liquid component is used up.

twotalon

Something that B.B. said in the beginning caught my attention. Are there any modern airguns that combine a multi-pump system (integral to the gun) with a larger reservoir that allows several shots before "re-pumping"?

Brian

I actually found some 30-30 ammunition online. It is called Prvt Partizan and is from Serbia. Anyone heard of this brand? I figure if it's still available it must be bad. However, I'm just plinking with my Winchester 94, so as long as it doesn't damage my gun that's enough.

Matt61

Julius,

I think there is more than enough air in the tank to do what you ask–especially in .177 caliber–but I'm not sure the valve is balanced to do it.

The Talon and Talon SS change velocities dynamically as the pressure drops in the tank. The valve isn't tuned for consistent shots at that speed, but I could be. However, that would require taking the valve apart and it wouldn't work in the normal way after that.

B.B.

Matt,

Have you gone to Walmart? — mine has had .30-30 (Remington CoreLokts and Federals) pretty consistently. Make sure the Serbian ammo is round-nosed and non-corrosive — I don't know how popular lever-guns are in Serbia:).

Are PCPs truly recoilless, or is it just not enough to be an issue?

Matt, I believe most of the cost of PCPs comes from the tank/reservoir. Just compare the price of a Talon with the identical CO2 version.

Jake

My Fx Cyclone definitely moves more on high power than it does on low.

So though there is very little recoil, there is some.

Not enough to take you away from the sight picture.

BG_Farmer,

No access to a WalMart, but how about that. Midway USA cannot get stocked for 6 months while the ammo is on the shelf at WalMart. You're a lucky guy.

The Prvi Partizan ammo is "flat-nosed" and non-corrosive, so it should be okay.

Jake, that's a good point about the reservoir. I suppose all of the machining that goes into the valve must cost money.

Matt61

That's what I figured, because even paintball guns recoil a bit.

BG, thanks for that link, it seems to have fixed the problem. I skipped the distance marking part, because that seemed like a bit much to do to set up for plinking. And while it's still wierd shooting without a cheek-weld, at least it's shooting on target.

Jake

Epernoni?

Matt,

Sorry — didn't mean to gloat. You know we rednecks all have a super-Walmart nearby:). Even when I lived in California, there were Walmarts. People complained about them constantly "blighting" the cityscape and exploiting employees, etc., but they were always packed:).

Kiwi,

Glad to hear it helped. I don't blame you for not following the "3-4 hour procedure" entirely, its just the only page I found that had a good procedure when I had a similar problem (on mine, parallax was uncorrected at best focus):). You're right to try to correct the cheek weld problem also.

I'm going to pose a question to everyone for the weekend. What is your favorite small bore air gun caliber and why? I'm very interested to see what people prefer.

I'm currently trying to decide between .22 and .25 for my next rifle so advice there would also be appreciated.

Thanks,

Mike

Mike,

Definitely .22 ahead of .25. So much better, in fact, that you have just inspired a blog next week.

I am on the road right now, so it will be written on my laptop, but I feel passionate enough about the subject to give it a try.

Thanks!

B.B.

B.B. Have you done a write up on how a regulator works? If so, please post a link. If not, may I suggest one as a follow up to this series.

Mike,

I like .22 cal., but only shot one .25 cal BSA Lonestar.. the ammo costs more.. ( you can shoot long rifle rimfire for less.. or used too!) and I guess if hunting, one wants a larger hole in the prey, but hunting with air guns is not a high priority for me… I have room for the rimfire most times and when not.. I'll pick up my Air Arms .177 s410..

Mostly, I like just stocking fewer pellets…. .177 and .22 and a few .20 for the Sheridans

BTW.. since PA has finally added the Marauder to the dealer price page (I plan to add more for the rifle range next month when were totally setup)…. I put up the .177 Marauder with scope, extra mags and pellets on gunbroker, if anyone is interested.. pretty low price right now..

That's right me selling a gun!! There's a great old .22 lr Remington Targetmaster I want real, real bad at the pawnshop!!

Wayne,

Ashland Air Rifle Range

Mike,

An interesting, right on time question, at least for me cause I've been thinking about a .25 in my future for small game and varmit hunting.

The reason I'd go with a .25 Mike, is because I'm generally a member of a big slow moving bullet is better than a faster lighter one when it comes to killing game with a pellet gun.

Remember all of our pellets are shot subsonic because of accuracy issues when we go supersonic. Therefore, to put more energy on target requires heavier and heavier pellets. At some point in time you have to move up in bore size to support the pellet's weight.

Thus I'd choose a .25 for a strickly hunting gun over the .22.

Mike, what are your reasons for maybe looking at a .25 caliber gun?

B.B.,

If I could only have either a .22 or a .25 caliber gun, it would be the .22 everytime. The .22 is a very versable caliber with a tremendous choice of guns and pellets.

Mr. B

It's my opinion that if a .22 pcp is not big enough, then use something that will lay 1,500 ft.lb. on the target. If that isn't enough then get something that will lay out another 1,500 ft.lb.

If that isn't enough, then an ainti-tank gun or a nuke is in order.

twotalon

Would it be possible to design a pellet that is stable in supersonic flight? A spitzer shape and relatively heavy weight?

Kiwi,

Nothing to design, really, but you would have taken a pellet rifle that is almost certainly non-lethal at 200 yards and turned it into something that would be dangerous a mile or more away.

Kiwi

when you are talking about spitzer bullets as opposed to pellets, they will need to be jacketed, hard to load, barrel with a very fast twist, and pressures of 10's of thousands of psi to drive them. It has been tried many times with poor results.

The weapon must be designed to operate well and safely to shoot such projectiles.

This is simply not practical with air.

Even with a custom barrel with a fast twist, you do not have enough pressure to get any velocity or accuracy.

You would have a very loud muzzle blast and the bullet would be deadly for a VERY long range.

twotalon

I inferred that part. I was just wondering if there was an engineering hurdle to overcome, because I've read about how pellets tumble at transonic and supersonic speeds. Probably wouldn't get many shots off a reservoir, either, making it totally impractical.

Kiwi

Let's see now.

Let's take an example of a .22 rimfire barrel that has been modified to fit a pcp. Let's say we have some lead bullets that are of .22 rimfire design.

The barrel has been lapped at the breech end so you can insert the bullet without deforming it.

Airgun barrels have about the same twist rate as rimfire barrels. The bullet must be spun up by the rifling at rimfire velocities to stabilize by gyroscopic force only, since a bullet is not stabilized by shape and weight distribution like a diabolo pellet is..

So now how can you push a bullet fast enough with air to get the MV up for the right spin rpm of the bullet to stabilize it?

Certain problems here…..

When powder pushes a bullet, you have very sudden extreme pressure at the rear of the bullet that is fighting against the inertia of the soft lead bullet. This causes the bullet to expand into the bore to make the bullet seal in the bore. This will not happen with air….there is not enough pressure…not enough g-force.

Next look at friction to bore difference between a pellet with two very small contact points with the bore compared to the large contact area of a bullet….a great deal of friction to push a bullet through the bore as opposed to a pellet.

Next, the weight…A bullet is MUCH heavier than a pellet.

You end up with a projectile with a poor, leaky fit, increased bore friction, too low a velocity for the twist with a heavier bullet.

twotalon

Hello airgunners. I have a crosman spring piston air rifle and the front trigger guard screw doesn't appear to be holding the trigger guard steady. Why is this effecting my accuracy if it makes no contact with the action? Ive replaced the screw several times with a slightly large diameter screw which has solved the problem, but I need a larger one ever 2000 shots or so (which doesn't take long for me) Is there a better solution to my problem ?

Thank you, twotalon. I'm not very knowledgable in ballistics, so that helped to clarify things.

Anonymous with the loose trigger guard – which gun is it, and is it a plastic or wood stock?

Kiwi

I'm sure that BB could have explained better.

Best I could do at the moment.

Some of the large bore airguns do shoot bullets, but they are short and light compared to a full size spitzer of same cal.

They must be kept light for the sake of velocity available with air pressure. They usually have a hollow base too.

Large bore does not require as fast of a rotation rate either….more mass of a larger radius requires less spin to stabilize.

On top of that, any particular bullet design , cal, and weight dictate the proper rotation rate at any given velocity so that the bullet will not be over or under stabilized.

twotalon

For the person asking about regulators, here is a report:

/blog/2007/12/how-does-an-air-pressure-regulator-work/

Kiwi,

Others have already said it differently but I will also answer you. Yes, pellets can be designed to go supersonic, and you seem to understand what that entails, so no more discussion is needed.

However, you are making a classic turn in your interests that most airgunners make. You are getting caught up in the posibiloities of the technology and forgetting why we got into airguns to begin with. Firearms already shoot supersonic bullets, so there is no need for airguns to do so.

Please read this report. I think it will make you smile.:

/blog/2007/12/how-does-an-air-pressure-regulator-work/

It's a favorite of mine 😉

B.B.

Thanks for the reply.

You're absolutely right about my train of thought, but I've always been into technology that's possible but impracticle (railguns!) Also, you linked me to the regulator article, but since I love the 'techie' stuff and knowing how things work, I can't complain.

BB,

I'm guessing this one is the one to which you were referring:

/blog/2006/3/have-spring-piston-air-rifles-reached-their-limits/

Just a guess; am I right:)?

Vince, it is a wooden stocked quest 1000. The stock is mystery wood.

This comment has been removed by the author.

Repost with Edit:

Well, I can't find any one of those stages that fits me exactly. I'm more of a shoot-for-two-hours-straight-without-getting-sore-from-pumping-or-cocking person, so I'm content with gas guns. And I can shoot legally and safely in my own yard.

Though I do need to zero my scope in fully and work on my form. But I'm not buying a pellet scale. No way.

And it seems like the next stage in spring guns would be reducing or redirecting the kick. If I remember correctly, spring guns recoil forward, then back, correct? What would happen if the piston was flipped, and connected by a U-shape pipe to the breech? Would the recoil reverse, or would it be reduced?

Kiwi

recoil is backward then forward.

Rigging the thing backwards might present some cocking problems.

Running the port around would present more air space that would need to be pressurised. More high pressure air volume would be wasted filling the tube.

Recoil direction might be backwards compared to what we have now, but the same problems with springer recoil would remain.

twotalon

Mike,

.25 caliber is nice as a novelty if you already have an adequate selection of the lesser sizes. My experience with .25’s was limited to a Webley Patriot and a BSA Lightning XL. It is not a great all purpose round like the .22, but was entertaining to experiment with. If you take the plunge, you’ll find that the pellets and bores will vary, so don’t order a large quantity of any ammo until you’re sure it works with your rifle.

The .25 caliber pellet selection is limited, the rifles to pick from few and far between, and the trajectory is anything but flat – but I did enjoy shooting those chubby pellets downrange. Unimpressive across the Chrony, however when thy smacked a 1” pine board the results were notable.

Anonymous, if the gun is less than a year old give Crosman a call and tell them what happened. Believe it or not, they might be willing to send you a new stock free of charge.

Or you might want to consider an upgraded stock. The one for the Remmington Summit/Sierra Pro is only $30, if memory serves me right, and is much nicer than the original Quest stock.

Otherwise, an old trick is to mix a good wood glue with some sawdust, which (if necessary) you can generate with any scrap of wood and a hand saw. Make it into a thick paste, fill the hole in the wood almost to the top and put the screw in as far as it can go. Let it sit overnight and you should find that the screw is now secure.

Thank you Vince, I'll see about ordering one of those stocks. Should look quite sporting 😛

…..Browning 800 Mag vs. RWS LP8..

I have been shooting these 2 little beasts since last week, when PA mailed them to me. I was curious how they compared to my P1, which is a Standard to which other sporting spring pistols may be compared.

Since BB has started reporting on this, I will be not be expansive. Further, I am comparing two stock springers to each other, but also to a Slade tuned P1 with a lightened trigger, so this comparison is a bit skewed.

First, the chrony results using a pellet which I have found to be as accurate as JSBs in pistols…the Beretta "Target" 8.16-8.26 grain flatheads, and which I prefer for its superior paper punching ability. Beretta makes a lighter, 7 something grain pellet which is also very accurate, but this one is a bit better in my pistols.

This data from 10 meters. If you are interested in muzzle fps, then add about 35 fps to each number.

RWS LP8…467-476 fps = 4 ft./lbs.

Browning .. 560-586 fps = 6 ft./lbs.

Beeman P1.. 423-442 fps = 3 1/2 ft./lbs.

My P1 is a bit slow, but it is also unusually smooth.

Interestingly, the Browning not only is 50% stronger (ft./lbs.) then the RWS, it is also less harsh when fired.

The Browning is heavier, and to my hand it is more comfortable than the RWS. The trigger has way too much travel, and that is the only thing worse about the Browning than the RWS.

Both appear to be very accurate…around 1/2" or 3/4" at 10 meters for 6 shots CTC. I can not shoot spring guns more accurately than 1/2" at 10 meters at this point, so for me all 3 pistols are probably a bit more accurate than I am.

If the Browning's trigger can be improved by shortening the travel and making it more crisp, than it would be a pistol worth twice the price of the RWS, and not the other way 'round.

Rather than using open sights (similar on both), I used scopes of various power (2x through 12x), and rested my arms to get maximum accuracy from the pistols.

The safety is better placed on the Browning, although this is a small thing.

I duct taped the muzzle brake extension on the Browning to the barrel, as it is a silly thing to put on and take off and put on and take off. Once on, the cocking is easier than the cocking on the RWS, which started to hurt my hand. I am not put off by cocking my JW80 nor my Kodiak, but because this RWS has a sharp plastic point on the top front of the barrel (called the front sight), it kept hurting my hand…very off putting, I must say.

For me, both pistols needed some vinyl molding attached to various points along the handle in order to make the grip acceptably comfortable. Without the added cushioning, the RWS in particular has some very uncomfortable pressure points where plastic of different heights converge.

While the Browning groans/creaks when cocked, and while the overall feel/appearance of the RWS is one step up in fit and finish (how parts are put together), neither gun alone would stand out in any way as particularly well or poorly made. The P1 seems, on the other hand, particularly well made.

The conclusion is obvious…at this point, the Browning is a far, far better value than the RWS.

– Dr. G.

Dr. G.

Great little report!

Thanks very much, I was leaning towards the Browning, and now you've helped me step the right direction!… but I'll be waiting a while.. There is a Remington 541T .22lr I want to add to the collection at the pawn shop..

Wayne,

Ashland Air Rifle Range

Thanks for the comparison Dr G.

Now lets see if any of the manufactures are listening.

Dr G.,

Thank you for taking the time to do the testing and the posting of your observations. The Browning looks like the way to go for the springer pistol crowd.

derrick,

Did I read someplace that you've made a Discovery Pistol?

Wayne, why on earth do you want to add anything to the collection at the pawn shop? Let the owner take care of his own dang collection!

Wayne,

When you are ready for one or both of these spring pistols then I will be ready to sell/trade them to you.

The P1, because of its trigger, is my clear preference for a spring pistol. I also appreciate that it can be fired on low power for 10 meter shooting, as this also reduces the trigger pull and pistol kick.

Should I have a need for more power in a pistol in order to shoot squirrels beyond 15 yards, then the .22 Mac 1 LD on low power picks up where the P1 leaves off, and is easily capable of killing squirrels out to 30 yards (on low power).

Wayne, I have little doubt that should you send your new used spring pistols to Vince for a trigger evaluation and tune, that he can improve them significantly. He improved the trigger on my 54 when other "professional" tuners said that nothing further could be done.

As an addendum to my report, above, I would add that the pellets fit much more tightly into the Browning than into the RWS. This is usually a good sign, as you know.

I tried adjusting the trigger on the Browning and got it so that it is in the same ballpark as the mediocre trigger on the RWS. I would compare these triggers to the triggers on my bb pistols, in that they are the weak link to accuracy.

– Dr. G.

Wayne,

You're selling your Marauder and plan on adding more since they're now on the dealer page?

Did you get a bad Marauder?

Would you mind elaborating. I'm seriously thinking about buying a Marauder in .22 caliber. I saw the one you're selling is .177.

kevin

Wayne,

I wish I had the money to buy your Marauder and contribute to your Remington fund, but alas my own Marauder fund has been moving in the wrong direction lately. To tell the truth, my steadfastness is waning and I'm losing interest in saving for a Marauder. I'm enjoying the 92/94 so much and learning so much from shooting them that the Marauder will just have to wait a little longer.

You mentioned the long term fate of the springer earlier and there is at least one thing keeping it safe for right now. Price. $500 for just the rifle and then whatever charging mechanism you want on top gets expensive (at least to me.) From B.B.'s description, it does seem to be a relatively straightforward mechanism, so maybe the prices will continue to fall, So long term I agree with you.

A bit of a back-track to my scope issue. Does parallax have to be adjusted for different ranges and magnifications, or is it something that once it's set, it's set?

Jake

Jake,

I'm currently going through the learning curve of scopes as well. In fact, that's one of the reasons why my Marauder fund is depleted! I overpurchased on a scope and bought a Leapers 3-9×40 AO illuminated r/g reticle. Love it, but realized when I got it that it's more scope than I need. I was comparing it to the non-AO scope that I have on my 92 and I think that's where paralax is entering. Seems like the non-AO scope is more subject to paralax problems than the Leapers. On the non-AO the reticle definitely moves around when I move my head and when I placed the targets out to 20 yds instead of 10 the accuracy was off again. When I get my 94 back, I'm going to re-install the Leapers and shoot at 20 yds to see if re-focusing adjusts paralax like it should. It'll be interesting to see.

Sounds like the 3-9×40 might be more suited for your 94 than it is for my 2260. I got it for plinking, it is a lot more than I expected. The illuminated reticle is nice, but I'll probably never use it, and I tend to keep it in the 5-9x range. I also wish I could mount it a bit farther forward. (I need to photograph my gun….)

Kiwi90 (Jake),

Parallax is a phenomenon where an object apparently changes direction because the viewers position changes. In viewing a target through a scope, slight changes in head placement can result in parallax.

An Adjustable Objective (AO) is an option on some scopes. AO is a dial around the objective end of the scope, or a knob on the left side of the turret housing that allows you to adjust your scope's parallax to a certain distance by moving these adjustments until a clear picture is perceived, and/or the marked corresponding incremental yardages are approximated to your target distance. The correct setting of an adjustable objective minimizes the apparent movement between the reticle and the target when the shooter moves his head slightly off center of the rifle scope.

To directly answer your question, the AO on your scope must be adjusted for different distances to correct, as best as possible, for parallax.

Sorry to take the long way around the barn.

kevin

So setting it for say 10 meters will mean the parallax is off at 20?

Jake

Kiwi90 (Jake),

Depends on the scope but the answer is probably yes.

"Setting it" means adjusting the AO. Adusting the AO is simply focusing which is to mean turn a knob on the left side of the turret housing or the dial around the objective end of the scope (depending on the type of scope you choose). Very minor. It becomes second nature it very short order.

kevin

Jake,

"…becomes second nature in very short order."

sorry for the typo.

kevin

Ok, thanks. I was wondering why the parallax appeared off. The biggest challenge for me now will be finding a stable rest to adjust it on. Thank you for the information.

Dr, G.,

Thanks for your report on the Browning and RWS pistols. I will keep it in mind as I get back to the gun and also test the RWS

B.B.

Slightly off off-topic,

What would you guys recommend as a 'gear' box. I'm thinking something that can hold Allen wrenches, some screwdrivers, a box of pellets, and a few 12g Powerlets. I was looking at fishing tackle boxes, but I was wondering if there were other recommendations.

I wish I had more time to read and respond. I am currently in Fairbanks, Alaska. A friend and I have just ridden our motorcycles about 5,000 miles to get here and I must say it is a fantastic ride!!! It is not as difficult as you might think. It's like downhill skiing – you gotta dress for it. Lots of rain, lots of road construction, lots of road construction in the rain.

In regards to BB's PCP analogy … what a great way to get a point across!!!

Now, on to Denali, Halibut fishing off Homer, Ak. and ferry ride back to Bellingham, Wash. then 2,500 miles back home, so sad!

-Chuck

KiwiJake,

Since you did the AO->focus calibration, parallax should be corrected when the image is in focus. You just have to re-focus at different distances.

Also, if you trying to be precise (groups, etc), I would keep doing the "head bop" when you change range, just as a check; as you know focus does not always get you perfect parallax correction. Unless you are shooting field target and/or have re-calibrated and tested the distances on the AO dial for multiple temperatures, ignore them as much as possible — they are most likely wrong! I.e., don't just set the ring to 50 yards and expect either parallax error to be corrected or focus to be sharp:).

Vince,

Good one! Yes the idea is to lower the pawnshop inventory by at least one Remington .22lr 541-T (government issued target training rifle) and maybe another 511..

BG_Farmer,

Kevin, Fused..

Cashflow dance..The Raised Bed season has slowed down, so I'm trading to taste new things for awhile! I'm heavy in PCPs for now..and I'm really getting into the old .22 LR. Remington rifles..

.. and PA has finally made the Marauder available on the dealer price page, so I'll be replacing the one I just sold with 3 to 6 in a month, I hope.

No, there is nothing wrong with the Marauder that I know of.. I think it can compete with the best of my field target PCPs for 1/4 the price!!

I plan on the Marauder being the starter training field target gun at the Ashland Air Rifle Range.. and I have no doubt that it will be winning some contests.

Wayne

Wayne,

Thanks.

kevin

I have a Benjamin model "F" air rifle missing the trigger and trigger guard. Are these parts available?

Thanks Jack

Jack,

They are taken off parts guns. Contact this man:

B.B.

B.B. Thanks for your report!

I would really like to know how much air (in volume) a powerful, 3000psi, cal 22, pcp rifle uses each time you pull the trigger? Is there a mathematical formula(s) that i can use to figure out how much air a certain caliber need to achieve a certain velocity?

I'm also curious about how much that volume of 3000 psi air expands when it's released from the tank into the barrel? Is it around 204 times?

And finaly, can a low pressure 1000psi air rifle achieve the same velocity as the 3000psi using the same amount of air and a longer barrel? Does the 1000psi volume need 3 times as much space as the 3000psi under pressure (perhaps a silly q)?

Cheers,

Andy

Well, the analogy somewhat works, but would have preferred a more technical one. This was sort of ‘ARMY’ text-book smart where I guess for many this works, but it leads to more questions really. I am a break-barrel shooter (spring/gas ram), and although I am not ready to shovel out the dough for a setup of a PCP, I have been curious about them to maybe one day purchase. However, it seems no matter where I look there’s not much out there on the web as to the true functionality of one; the real ‘How Stuff Works’ without these very general, almost childish analogies. People are smart out there in the world, so a little more detail would be appreciated.

So after reading this, as many other articles, I am basically left with: Big reservoir+strong valve+trigger which is locking valve closed=HIGH PRESSURE. Pull trigger, valve opens, air goes whoosh, pellet flies! Did I miss something?

Your article was well written though.

Thanks

MrAirGunner,

Welcome to the blog.

I really don’t understand what you are asking. Can you please restate it?

B.B.

Not quite…

Trigger releases striker, striker hits end of valve, popping it open. How long it stays open depends on the pressure differential on the two sides (valve lock: too much pressure for striker to even open the valve), the valve return spring, and the valve inertia and travel distance.

Other than having a large, externally pumped, reservoir, not much different from a multi-stroke pneumatic.

Baron, now that made things much clearer.

I guess I am not good at analogies lol.

So is there a ‘regulator’ of some sort or is it the valve return spring which controls how much air is released per shot? I mean with any other rifle the entire reservoir is released upon trigger pull, so with a PCP I am assuming it is much akin to a CO2?

🙂 Thank you btw!!!!!!

It depends on the design of the gun.

AirForce (Condor/Talon/et al) are a straight-line striker with an adjustable pre-load on the striker spring. Light pre-load, and you get a short tap on the valve that rapidly closes again. Heavy pre-load, and the valve’s inertia will push it further into the tank before the valve spring can push it back closed.

Marauder’s have adjustments for both the striker preload, the striker stroke length, AND a side adjustment that controls how fast the air can flow into the chamber.

But yes — PCPs have self-closing valves, just as CO2 does. Spring guns don’t have valves, compression takes place when the piston itself is released. Most single-stroke pneumatics (at least, those that I’ve handled) have non-spring-loaded valves… When the trigger is pulled, it unlocks the valve and the air pressure blows it open (opposite of a PCP where pressure holds them shut) — dumping all the air. Opening the bolt is what closes the valve — otherwise cocking the pump just pushes air back and forth. Multi-stroke pneumatics could be “dump” valves or could be spring-loaded (if there is air left after firing a max-pump charge, it is spring-loaded).