This report covers:

- Know this

- Cheap BB

- No hole

- Loading the canister

- Table knife packer

- Drill out the tip

- Why do this?

- Summary

No this is not BB’s autobiography! Last Friday’s report that was titled What do you need?, caused me to look online for a grease gun that is smaller than the traditional 14-ounce canister type. I have several of those, but to dispense Tune in a Tube (Almagard 3752) after the plastic applicator stops working, a smaller grease gun is handier. Or how about that Red “N” Tacky grease that comes in a tub? There is no applicator for it.

I researched online to find such an applicator. Lo and behold there are several. But watch out, because they do have problems. The biggest is there is no hole in the tip for grease to come out — at least not in the one I bought! I will discuss that in depth today.

I read only the positive reviews — well I read the first one, and it sounded great. Then I got the thing and — no hole for the grease. Now that I know it and it’s all behind me I read several of the other reviews. No hole, no hole, no hole! They don’t hold back. And the strange thing is, even some of the 5-star reviews mentioned the lack of a hole. I guess it just takes more to bother some folks than it does me.

Know this

I also discovered that there are 3-ounce grease guns for 3-ounce canisters. Who knew? Not BB. But we aren’t talking about one of those.

What BB needed was a gun that he could just pack loose grease into and then get it working as a handy dispenser. Those also exist, so if you decide this tool is for you, know what you are looking for.

Cheap BB

I didn’t want to spend a bundle on this thing. So I bought the cheapest one, after determining from the first and only 5-star review I read that it was a good one. It cost $11.16, plus shipping.

The Astro Pneumatic 100 Mini Grease Gun.

BB’s grease gun.

No hole

At this point I didn’t know there wasn’t a hole in the tip of the nozzle. Who would make such a thing, anyway? Why, the Taiwanese, when not given enough money to drill the hole. I don’t have much of a problem with that — well, okay, I do have a problem with it. But why didn’t they at least tell me that in the pictograph instructions?

These are the only directions you get for the gun. They show how to fill the canister and to push up on the moveable plate inside, once the canister is filled.

There is a moveable plate inside the canister that moves up as the grease is dispensed. Although the tool’s title says it is a pneumatic tool, the grease actually flows hydraulically, and it sucks the bottom plate along with it as it goes. This replaces the spring-loaded plate and rod inside a regular canister-type grease gun, and according to the reviews, it works. We shall see.

The last picture in the directions shows pushing on the moveable plate through a hole in the bottom of the canister. Let’s look at that.

Push on the moveable plate to move it against the grease to get it flowing hydraulically. The label says Made in Taiwan.

Loading the canister

To load the canister you unscrew the top portion that contains the nozzle and the pump. The bottom of the canister does not come off. The diagrams show using the fingers to load it, but I used a spoon and knife. Before loading make sure the moveable plate inside the canister is all the way down.

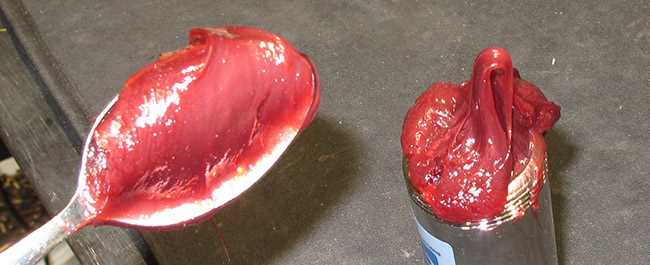

I loaded the canister with a spoon.

Loading went easy for the first couple spoonfuls, then it didn’t. The grease in the canister blocked any new grease from entering. It just squished out the sides when I tried to load more.

When there were a couple spoonfuls of grease in the canister, the grease became harder to load. If I tried, the excess just squished out to the sides.

Table knife packer

This is where the table knife came in. I used it to stir and pack the grease in the canister, to make more room. Loading became a slower process at this point. In the end I did use my fingers to pack the final bit of grease in more effectively. I estimate I filled the canister 3/4 full.

Now I pushed the moveable plate up from the bottom with a screwdriver. Of course the top was not yet screwed onto the canister so the column of grease went up. Then I screwed on the top and started to push the pump plunger. Nothing.

My neighbor Denny was sitting in my garage and he looked at the tip of the nozzle. He said he thought there wasn’t a hole in the tip. I thought surely not! Who would make a grease gun with no way for the grease to come out? Maybe it comes out through osmosis.

So I used the magnifier on my phone and looked with magnification. Nope, no hole! It looked like there was a hole, but it was just a divot in the metal of the tip.

Denny suggested hitting the tip with a fine file to see if we could uncover the hole. At this point in time he and I both thought there had to be a hole in the tip.

Before I did that I tried pushing a straightened paperclip through from the rear (I removed the tip from the spout). No dice!

So Denny hit the tip with a fine file several times and what looked like a hole opened up. So again I tried to pump the grease. Nope!

After Denny lightly filed the tip we looked and what appeared to be a small hole had opened up. But it wasn’t all the way through.

Drill out the tip

Denny and I played with this thing for 15-20 minutes until we both agreed that a 1/16th-inch drill (the smallest drill bit I have) might do the trick. So I chucked the bit in my hand drill and came in from the back side of the tip. I bet I had to go through one-eighth inch of metal before the bit broke through the tip. But then there was a clean hole!

I put the tip on the nozzle and pumped the plunger twice and grease came out! Now the grease gun works as advertised. According to all the reviews of people who have gotten the gun to work, it is sturdy and lasts a long time. It’s mostly used by bicyclists, from what the reviews say, but this one will be used on airguns.

Success! After the tip was drilled out the grease flows perfectly when the pump is pumped.

Why do this?

Did I need to do this — buy and fill this mini grease gun? Not really. If I bought Tune in a Tube, its applicator works fine. I have even reloaded the applicator after using all the grease and continued to use it a couple more times. But eventually the plastic plunger inside wears down and the grease comes out both ends.

Can I apply grease without an applicator? Sure. But I have to disassemble the gun farther to get at the mainspring. If I can find a needle injector that will fit the tip of this mini grease gun I will be in hog heaven. As it is, though, I have a clean way of storing my tacky red grease that is ready at a moment’s notice.

Summary

Today’s report is a case of BB researching something while he wrote a different report and seeing there was a better way for him to do things. So he did it, ran into a problem, solved it and recorded everything for all of you. I have to thank reader Alex2no for this. She got me to respond in the first place.

For all the guys who already knew everything I reported today, my apologies. But I didn’t know it, and I suspect there are others who might not know it as well. This one is for them.

B.B.

Suggest to to folks that make Tune in a Tube that they come up with usable packaging that also includes application. Or just tape a dozen Q-tips to the outside of the tube…

-Y

Yogi,

They do. It comes in a preloaded syringe.

BB,

Don’t those things have interchangeable tips?

Siraniko

PS: Section Summary 1st paragraph last sentence “She got me to respond in the fu=irst (first) place.”

Siraniko,

Fixed the typo. Thanks.

As for the interchangeable tips, I hope so. We shall see.

BB

B.B. and all

You may have mentioned it but I don’t remember if you have ever used spray grease. I used a well known company’s white lithium grease in a Weihrauch 30, just from the opening that reveals some of the spring. Well, I think just cocking it is as great a pleasure as shooting it.

In any case what do you think about applying grease, you pick the type and use, with a spray can to a springer?

Bill,

TIAT is extremely tacky. That is its claim to fame. Would a solvent that made it spray-able work?

BB

B.B.

That’s exactly what I would like to know.

Although it seems to have worked on the HW 30 I believe it’s up to you, our mentor, to run such a test. Lithium and some other grease, take your pick, in easy to apply spray form.

BB,

A company called LPS makes an aerosol grease called Red & Redi. I looked it up and it is an NLGI 2 grease, as is Almagard 3752. I used it at the company I retired from. It’s red and a little thin at first but apparently some evaporation takes place and it gets thicker. It’s plenty tacky and the can describes it as “Non-Sling” Lubrication.. If I’m remembering correctly, it even comes with one of those tubes that fit in the end of the nozzle for reaching tight spots.

Half

half,

There you go.

BB

BB,

The next time you fill your new grease gun, start with the floor plate at the top. Shove it down as you put in the grease and you shouldn’t get that air bubble underneath that was working against you. Depending on how tight it is, you may find it slides on its own or you may have to push a little with a skewer or butter knife.

as you add grease.

Half

Wonderful!! I had recently ordered this very grease gun from Amazon. I literally picked the order up from our Post Office in Keaau Hawaii this morning. I bought it for working on bicycles to pack the bearings, hubs, and cups (it’s bike lingo for bearing races). I’ll plan on drilling the tip as you did. This is a VERY timely piece, and you wrote it just for me!

Birdmove,

Of course I did! 😉

Did you not know that I am sometimes omniscient?

BB

BB,

I most often use a Q-Tip or a wood skewer. There are some sturdy basting syringes on the market. Some of these have screw on tips. I am certain you can find a tip that works better. Keep us posted.

BB and All-

Excellent blog about progressive problem solving. Before these were made offshore, I seem to remember that they were sold with a storage cap to keep the contents clean and that accessory applicator tips were sold separately. I guess by making the storage cap ‘universal’ (drill your own hole) simplified everything.

I would like to recommend the 3 oz. size pistol grip grease guns. Same operating principle of the 14 oz. size and they have the mechanical advantage over this plunger type gun when dealing with especially thick and stiff greases.

B.B.,

How about rhis?

https://www.grainger.com/product/LUBRIMATIC-Needle-Nose-Dispenser-3-4-41AA41?opr=PDPBRDSP&analytics=dsbrItems_41AA51

Michael

Michael,

I’ll look into it.

BB

For this: https://www.grainger.com/product/LUBRIMATIC-Mini-Grease-Gun-Pistol-Grip-41AA51

From Queen’s “I’m in Love with My Car”:

When I’m holding your wheel

Аll I hear is your gear

With my hand on your grease gun

Oooh, it’s like a disease, son

I’m in love with my car

Got a feel for my automobile.

Michael, that’s a great “blast-from-the-past”…I love it! 🙂

Check this out from 1981 in Montreal: I’m In Love With My Car https://www.youtube.com/watch?v=MAnYVt2xBCE

Today’s FM DA (DumbA–) questions/notions: assuming you do not have a proper applicator, except for maybe Q-Tips or wooden skewers, would it not help to heat the TIAT or whatever suitable grease you are using, to help it flow better? Also assuming Mrs. would not object to finding a strange concoction in the microwave or on the stove? Which might generate odors bringing on looks of disapproval – or worse – from one’s Better Half. See? FM is talking himself out of that idea already.

How about good old military-spec rifle grease for quieting springs? Only asking because FM still has about 3/4 of a container’s worth of the stuff. It’s got a few years on it, probably 50+, but still seems in good condition.

BB,

I bought a couple of large (40cc & 60cc) syringes from the vet and use them for oil and grease.

I fill the grease syringes about half full using a popsicle stick or something similar. Found that it wasn’t worth the bother (and mess) of trying to fill the whole syringe.

Cheers,

Hank

BB,

Before I forget it, when I want to post I have to log it twice. I log in, go back to the bottom and log in again and the second time I get a message box. Not a big deal but I thought you might want to know.

Thanks for the blog. I just ordered one of the little grease guns. I got mine off of e-Bay. It was $10 shipped. I had bought a big tube of Almagard 3752 grease and this will be a good way to dispense it. And, I can squirt it straight from the big tube into the little grease gun. I wouldn’t mind having a couple more of these little grease guns, one for white lithium grease and one for moly too. It would make it less messy in both cases.

David Enoch

Same here on the log in.

Seems to me that a short piece of flexible hose with a hollow needle at the end would make this tool, or the one Michael found above, just about perfect. Or perhaps one of those basting needles one uses to inject a turkey with marinade before frying it.

Off topic: Regarding the Crosman 362:

I finished (finally) my initial run through of my .22 pellet inventory through my new Crosman 362. I will go back and retest the best performers at different numbers of pumps, but the best ones at 8 pumps look like they will be RWS Meisterkugeln, Air Arms Diabolo Field Heavy, HN Baracuda Match, 5.52 mm head, HN Field Target Trophy, 5.53 mm head, JSB Match Diabolo Exact Jumbo Heavy, 5.52mm head, 18.1 grains, and two other pellets from the JSB pellet sampler that were surprising to me: JSB Match Diabolo Exact Jumbo Monster, 5.52mm head, 25.4 grains and the JSB Match Diabolo Straton Jumbo, 5.50mm head, 15.9 grains. So there are plenty of good options for pellets. I am going to go back and retest the cheaper pellets again now that the barrel is broken in, I would like to have a good (cheap) wadcutter for plinking and target shooting at low power and a good pellet for hunting and pests at higher power and longer ranges.

My initial conclusion is that this gun could benefit from better sights, especially if it proves to be accurate at longer ranges. I want to try reducing the size of the rear peep aperature and see if there is a significant difference in the groups. The stock rear peep seems enormous to me.. Also, I think it is worth it to invest in the steel breach and a red dot or scope.

Finally, I don’t want to gripe about a $100 gun, but the trigger has not improved with use, as I had hoped. I find that there are two points of creep, and the pull is relatively heavy, so there is sometimes a small jump to the left at the break when the hammer falls. If something could be done to lighten and smooth out the trigger, I think this could be a real gem.

All testing so far was done at 10 yards from a sandbag rest under the rifle’s balance point. I’ll keep you updated on further developments, and provide stats.

I look forward to B.B.’s next installment on this rifle. I am wondering if the Monsters would give this gun a jump in energy. I don’t have a chrony, yet, unfortunately.

I don’t have a 362, but do ave a 1322. I put on a steel breech, skeleton stock, and a 4×32 rifle scope. It makes a super handy little short carbine. It likes pointed pellets. Favorite one is the RWS Superpoints, followed by Crosman pointed hunter pellets.

Cool. I have seen different variations of the 1322. Is it hard to pump and how does accuracy and range compare to a full-size rifle?

I consider it an 8 to 15 yard airgun.

Any info regarding trigger mods or replacements for the 362 would be welcome. After shooting this gun for a while, I think it is a good, cheap gun that could be great!

B.B. and Readership,

“Do you need this tool?”

ONLY if you shoot coil spring powerplants that need some thick grease applied to the coil spring so your groups might get smaller! Lol!

Buy a PCP, CO2, Single or Multipumper, or a Gas Spring airgun and this messy tool will only be needed occasionally for your bicycles, boat trailers, or older motor vehicles! Of course those come with clean and easily loaded cartridges of the right grease/lubricant.

These coil spring powerplants seem so overwhelming! Just too much work for this guy from the simpler more accurate Dark Side! ;^)

shootski

Shootski,

I think a springer is easier to maintain that a PCP. There are three parts to maintain on a springer, a piston seal, a mainspring, and a breech seal, and that’s about it. Trying to figure out which of a half dozen o-rings is leaking or where a tiny piece of trash is blocking air is very frustrating. And, that does not even get into all the adjustments of hammer springs, valve open duration, valve bounce, and regulators. Each definitely has it’s issues.

David Enoch

DavidEnoch,

My post was 50% or more tongue-in-cheek; but you are certainly correct that each powerplant has a place. Some of my PCPs have but maybe four or five O-Rings, my Quackenbush come to mind, as an example of KISS PCP design that works in the field.

Yes I do drip a drop of NON PETROLEUM oil in the Foster Fitting (QD) on fills from time to time mostly to keep the Foster Fittings O-Ring lubricated.

shootski

Not at all, Shootski. All powerplants have their place. Try an R7 / HW 30s. Then forget the expense, your pumps and connections and tanks, and muscle fatigue from cocking the gas rams, and just enjoy unlimited shooting, until your pellets run out.

Do you NEED that tool? No, unless you have many springers or come across “new” ones on a regular basis that need a little love. In other words: B.B.

Don’t you have to lube the seals on PCPs all the time? Doesn’t a CO2 gun need pellgun oil on every cartridge? Most of the time, once you have applied the right amount of TIAT, you are good to go for a loooong while.

Someday, I’m sure I’ll dip my toe into the dark side, too, but until then, I’ll just shoot my sweet little R7.

“Someday, I’m sure I’ll dip my toe into the dark side, too, but until then, I’ll just shoot my sweet little R7.”

Ditto that! Amen! 🙂

Roamin,

I think either the grease gun or basting injecting system would cost more than $10 that I paid for the tool BB suggested. If you already had something that would work and was not using it, sure that would work. But, BB’s solution looks to be cheap and precise, which seems to be a good solution to me.

David Enoch

You are probably right. The comment about getting a syringe from the vet got me thinking. Everytime I buy a jar of marinate for a fried turkey, it seems like I end up with another syringe….But my tube of TIAT is still 90% full after 2 years, so I’ll bide my time.

“At this point I didn’t know there wasn’t a hole in the tip of the nozzle. Who would make such a thing, anyway? Why, the Taiwanese, when not given enough money to drill the hole.”

B.B.,

The wry humor you displayed here was my favorite part of the whole report; thank you! 🙂

Take care & God bless,

dave

thedavemyster,

A great many accessory kits and tips to include flexible hoses, rigid probes of various lengths and opening diameters. The cap that B.B. modified is likely a storage cap for when the other tips and fittings aren’t being used to stop leaks, grease drying out, and dirt/bugs getting in there.

shootski

“The cap that B.B. modified is likely a storage cap…”

Ah, I see; that makes more sense; thank you. 🙂

shootski,

Nope! It is the injector tip.

BB

Well, it certainly is now ;o)

B.B.,

Well now! BLESS their little hearts for manufacturing such a FUNCTIONAL product!

Made in the USA may become the norm once again after all!

shootski

Dave,

Mine, too! 🙂

BB

As expected! The Dark Side really isn’t as complex as some want to believe.

Pumps aren’t needed if you have a reliable place to get a bigger tank filled. The Carbon Fiber tanks are now rated as good for at least 30 years with a 15 year service life extension inspection along with the routine visual and hydrostatic inspections the dive shop i use does almost automatically. It isn’t THAT expensive with all the high air demand PCPs I have or if you shoot smaller air sippers a great deal. Ammo for any caliber airgun is the real expense over the long term. It actually always has been for high volume shooters and in the future it will get even more so; precision ammo costs!

I want new to airgunning folks that read this to know that IF you want to hunt mid and larger game or at ranges beyond 50 you will likely be using a PCP for the foreseeable future.

shootski

Shootski,

“These coil spring powerplants seem so overwhelming! Just too much work for this guy from the simpler more accurate Dark Side! ;^)”

With respect, and with tongue mostly in cheek, I can’t resist:

These precharched pneumatic powerplants seem so overwhelming! Carbon fiber, service life extensions, hydrostatic inspections, dive shops…Just too much work for this guy from the simpler more nostalgic Light Side! ;^)

Seriously, though, I find the adjustable power of some PCPs very interesting.

Bought this little fella at an auto parts or hardware store a long, long time ago. So long ago, it was still Made in USA. This may work well on FM’s sproinger. Yes, it came with a pierced tip. 🙂

FM,

I think you’ll find that doesn’t work with anything as thick as grease. It is for liquids and isn’t capable of sucking the grease into the intake of its pump mechanism.

Half

Yeah, wondered about that. Maybe best to use a regular grease gun with a needle tip – have one of those. FM’s ideas tend to be a bit “pie in the sky,” so thanks for pointing that out.