Air Venturi G9 high-pressure hand pump.

This report covers:

- History — again

- The Brigand

- Splatology

- Let’s test

- Dennis the rapper

- Siraniko was correct

- Single-stage pump?

- Back to the old big bores

- Summary

I’m writing about high pressure hand pumps again today for several reasons. First, there was a lot of interest in this subject and It will take at least today’s report to get through the historical data so we can switch over to the modern hand pumps you are all interested in. We can’t bypass today’s information or you will miss some very important stuff.

The second reason I’m writing about this subject so soon is because Pyramyd AIR has donated a G9 hand pump to the blog for extended testing. What I mean is they gave it to me. And I intend to test the heck out of it — just as I am testing the RovAir Portable air compressor for an extended period of time. I bought that compressor for the test, so I’m grateful to Pyramyd AIR for donating the G9 hand pump that will also be tested a LOT.

The third reason I’m writing about this subject so soon is because reader Elmer Fudd asked several basic questions about hand pumps and today I hope to start answering some of them. Reader Siraniko also made a prediction in his comments to Part 1 that I will address today.

The fourth reason I’m writing about this subject is because Crosman has come out with the 3622 and the 3677 is soon to follow. These rifles that fill to a maximum of 2000 psi are created to be filled from a hand pump! And I will soon have a G9 to do just that. Many shooters have stayed out of precharged airguns because of the cost of the high-pressure air. Crosman and Pyramyd AIR have solved that. So, Elmer and everyone, there are four compelling reasons for this second report so soon after the first one.

History — again

Today, we are going back into history again. I told you in Part 1 that the velocity and power of antique big bore airguns was unknown as recently as 1997. We simply had no clue how fast they shot. But when Dennis Quackenbush made his .375-caliber Brigand in 1996, we certainly had the equipment to know how fast it shot — and that made comparisons with the big bores of history possible.

The Brigand

The Brigand operated on bulk CO2. A fill was good for 10-12 powerful shots as I recall. And the velocity for an 84-grain .375-caliber lead ball was 600-650 f.p.s. That’s your first big bore velocity and my first teaching point. But the big bore airguns of the past were not filled with CO2 — excepting the Giffard, of course.

After I experimented with my Brigand awhile, I wondered how it would perform on air. Dennis made it strong enough to hold more pressure, so after checking with him I filled mine to 1,200 psi from a hand pump and got that same lead ball up to over 800 f.p.s. That’s my second data point/teaching point. CO2 may have the same pressure as the air was compressed in the antique airguns, but the CO2 molecule is larger than the separate atoms in air, and therefore it flows slower through a valve. So — more velocity on air at the same pressure. And there, Elmer Fudd, is a partial answer to your question. No, air does not flow slower as the pressure rises, making the pump harder to operate. But when air has to flow into a reservoir that already has pressurized air inside, it does have to overcome that pressure to flow — AT ALL!

Yes, I do know that 1,200 psi is more pressure than CO2 commonly reaches. That would be 850 psi at 70 degrees F. But there wasn’t that much difference in velocity from air compressed to the two pressures (1,200 psi and 850 psi). You see — I also tested that. As long as it was always air, the bullet went faster than it did on CO2.

Splatology

In Part 1 we learned about the science of splatology, which is the phenomenon where a lead ball of any size flattens the same amount when hitting a hard target at the same speed. So a .375 lead ball that hits an anvil at 350 f.p.s. flattens just as much as a .60 caliber lead ball doing the same thing. The splat that the larger ball leaves behind is wider across, of course, but the lead splats from the two different calibers appear identical. That means we can determine the impact velocity of a lead ball that that has struck a hard target just by examining the splat it left behind. In turn that means we can know how fast a lead ball was traveling two centuries ago, just by examining a drawing of the splat it left behind.

Gary Barnes was instrumental in developing this observation. He tested all of the big bores he made and created a set of flattened “splats” that he knew the exact velocities of. You can see his splat boards in the report I linked to above.

There isn’t a lot of historical splatology data to examine, but what we do have points to many antique big bore airguns shooting in the 500-650 f.p.s. range. Curious, isn’t it? No matter how we look at this, the velocity of antique big bore airguns always seems to fall within a narrow range. And that is another teaching point.

Let’s test

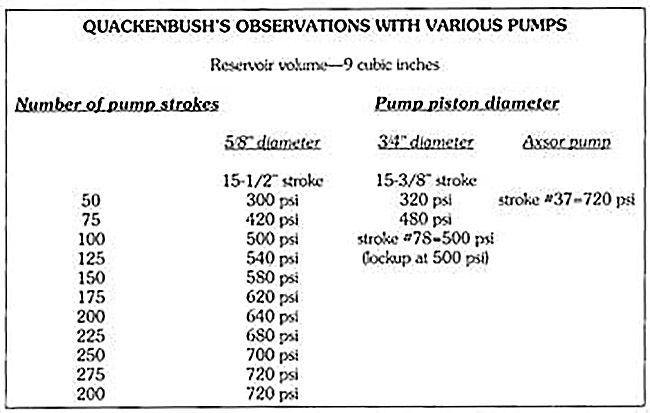

The antique hand pumps were single stage, like bicycle pumps are today. Remember I told you that Dennis Quackenbush built two single-stage hand pumps and a test fixture to test them? He connected both pumps to to the nine-cubic-inch test reservoir that had a pressure gauge. He then pumped up the reservoir with each pump and counted the strokes required to get to certain pressure levels. He repeated this experiment three times to verify his figures, which is in the box below.

And Elmer, Dennis also tested a modern three-stage Axsor hand pump, whose results are on the right in that test box.

There is an incorrect number in the chart above. In the left-hand column the last number should read 300, not 200. It shows that more pump strokes did not increase the pressure in the test reservoir.

Next, he made another 5/8″ diameter pump without a seal to test the effectiveness of something truly vintage. I felt sure he would not be able to reach the same pressure as a pump with a synthetic seal. This one had only a tightly-fitted piston with a thin film of oil to seal it. The results were quite surprising! The pump with no seal went all the way up to the same pressure as the pump with the synthetic seal, proving, once again, that we aren’t as smart as we think. You may remember in Part One I told you that we had assumed that a single-stage hand pump with a synthetic seal would be more effective and we discovered we were wrong? This was the test that proved it.

Dennis the rapper

On a suggestion from one of his airgunning friends, he tried “rapping” the air into the reservoir — similar to the method that was used with the Korean-built Yewah Triple B Dynamite shotgun (a .25-caliber air shotgun from years ago). Rapping means imparting extra momentum to the pump through inertia — basically jumping up and down on the pump handle. With this method, Dennis raised the pressure ceiling of the 5/8″ plain piston pump to about 810 psi, but at a high cost to his personal well-being. He said his wrists hurt so much from doing the rapping just once that he had to recuperate for several days thereafter. So, rapping, while possible, is not a practical way to fill vintage reservoirs to higher pressures, and it’s doubtful that anyone ever did it more than once.

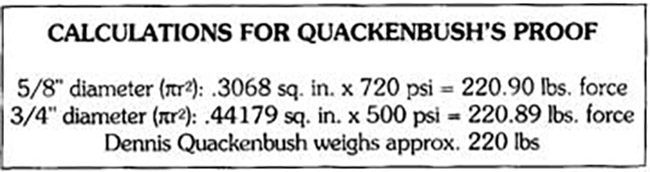

One additional thing he did benefits this study even more than these test results. He noticed that the piston diameter relates directly to the total pressure achieved. Yeah, you guys discussed it in the comments to Part 1, but when these tests were conducted, none of this was known. What Quackenbush did for us was remove the complex mathematical formulae from the work and substitute simple equations in their place.

The data show that it’s possible to calculate the maximum pressure for any single-stage air pump by simply dividing the weight of the pump operator by the area of the piston head. There should be some loss of efficiency due to friction in the pump, but this is most probably offset by some imprecision in determining the person’s body weight:

220 lbs. divided by .3068 = 717.08 psi

This allows us to build a “theoretical pump” that can generate whatever pressure we desire within the limits of physical laws. For example:

250-lb. operator using a pump with a 1/2″ piston

250 lbs. divided by .19635 = 1,273.24 psi

150-lb. operator using a pump with a 1/2″ piston

150 lbs. divided by .19635 = 763.94 psi

Notice that the stroke length of the piston does not enter into this calculation. That’s because the length of the stroke determines only how much air is being compressed. It doesn’t affect the highest pressure that can be achieved. A longer stroke will compress a greater volume of air; a small-diameter piston will allow it to build to higher pressure.

Siraniko was correct

Reader Siraniko made the following comment to Part 1, “I’m really going to be interested in the outcome of the single-stage pump because those are what powers multi-stroke pump airguns after all. Based on a local experiment I believe you will get around 800-900 psi maximum.” He was spot-on!

Single-stage pump?

Up to this point, the term single stage has been used when referring to the pumps of old. Single stage simply means that the pump is compressing air in one direction rather than on both strokes. In all cases, the direction for compression of a single-stage pump is the down stroke. The upward stroke sucks in more air for the next downward compression stroke.

If a single-stage pump were made with a very small piston–perhaps 3/8″, what sort of pressure might be possible from a 150 lb. operator?

150 lbs divided by .110446 = 1,358.13 psi

Of course, this small-piston pump would take a lot longer to fill a reservoir, so we might increase its stroke to help matters. That gives us a long, thin pump that would eventually become too long to carry conveniently. Also, the thinner the pump piston, the thinner the piston rod; although the piston HEAD might be able to compress very high pressures, the rod that connects it to a source of force will eventually become too thin to bear up under the strain.

Back to the old big bores

The large valve contact surfaces of vintage big bores constrain them to use lower-pressure air. With the state-of-the-art technology available to 17th-century airgun makers, it was all they could do to seal valves against pressures ranging from 400 psi up to 650 psi. They used horn and leather to accomplish as much as they did. Today’s use of hard synthetic valve heads bearing on thin areas of contact on precisely machined steel seats is simply beyond anything they could achieve.

Also, they lacked the homogenous materials from which to make reservoirs to contain the higher air pressures. Even if they’d been able to make the valves and pumps to work at higher pressures, the reservoirs would have held them back.

Summary

I think that’s it for single-stage pumps. The information you now have sets us up very well to understand modern multi-stage hand pumps.

B.B.

How about asking newbies who might be interested, how many pump strokes they are happy to do do fill their airgun? 10-15-30, any predictions?

-Yogi

Yogi,

When I started out with PCPs, all I had was a hand pump. It was just fine for filling my Talon SS and my Edge.

It was not until I started shooting Lloyd’s .357 Rogue that I realized that if I was going to go big bore, I was going to need more than a hand pump. It was not the pressure, but the volume of air it used that wore this old, fat, balding geezer out.

Yes, it will take far more than 30 strokes to fill a PCP. The number of strokes will increase with the higher pressures.

With the super-duper high-pressure PCPs that are hitting the market these days, forget about it. Hand pumps are not really designed to achieve the high pressures of these new airguns. They will likely go that high, but golly gee whiz, that is a lot of hard pumping. 2000 PSI, no problem. 3000 PSI, achievable. 4500 PSI, are you kidding me?

This is why Yogi does not shoot PCPs. He is looking at this all wrong. He will purchase a very expensive sproinger, but will not put out the bucks for a PCP and a way to fill it. One way or another, you pay for what you get.

One of the reasons FM has grown fond of his Maximi is the relative ease of pumping them up to 2000 PSI; 20-25 shots are plenty on one fill, for this shooter at least. With Gunfun’s Hatsan pump, can get to 2000 PSI starting from about 1000 with 75-80 strokes of the pump. If the gauge on the rifle indicates the pressure has dropped into the yellow CO2 range, then it might take 100 pumps to get to the 2000 PSI maximus for Maximus.

Now need to order a replacement gauge for that pump and get that little problem sorted out. One thing to consider about a compressor is that it would make it easier for FM to pressurize multiple guns at a time.

RR

I do not have very much space to store/harbor STUFF. STUFF accumulates are you get older.

PCP’s make it very hard to live by the KISS motto. If I had a 5,000 square foot McMansion and a three car garage, maybe…

-Y

Yogi,

This is where you learn to set your priorities concerning what STUFF you accumulate. No, I do not have a McMansion or a 3 car garage. Mrs. RR has taught me to get rid of STUFF, despite my best efforts. 😉

Yogi

This 62 years old guy finds that 50 pump strokes is a good point, for him and the pump.

OK,

So you live in Texas, 90 degree days, 90 % humidity, how many strokes until you are dripping with sweat?

And that is just for one fill. Now you have to clean your gun after shooting because all that sweat will cause rust. And then you need to shower. One thing snowballs into 25 other things….KISS.

-Y

That’s why I exactly said “this 62 years guy”; In the region of Athens (Greece) humidity and temperature are quite different from Texas. As RR usually says “to each his own”.

After all you just asked for opinions.

Yogi,

You already know most of my thoughts on the benefits of PCPs; but there will be new readers for whom your blast of negatives need to be balanced by the voice of experience.

Newbies to the world of PCPs this is for you from more than three decades of experience shooting on the Dark Side. I started buying a 10 Meter PCP and a hand pump. It was easy to pump up that small cylinder that screwed right on to the pump outlet; it certainly beat a Single Stroke Pneumatic (SSP) pumping during a shooting session. But i also had SCUBA tanks from my diving so the pump was just a backup from the beginning. Some will complain that you can’t get full pressure fills after the first fill on a 200 BAR SCUBA cylinder and that is true. So i used my 3,600 PSI (250 BAR) steel 100s…plenty of fills using a CASCADE from those two big tanks. Later i upgraded to the much lighter 4,500 PSI (310 BAR) Carbon FIBER (CF) cylinders and never looked back with my two pumps just collecting dust.

WARNING

You must be certain you have a convenient fill source that will fill your cylinder(s) to their maximum pressure. It will be cheaper in the long run than a compressor(s) dryer air, faster fills (just not too fast to keep heat buildup under control) and far less time down spent on maintenance. CF cylinders are good for 15 years and now can be extended in the USA another 15 years with a special inspection; i think they will become unlimited in service life with proper testing in the next few years.

So yogi you could stop sweating and only need to give up say, 6 square feet of your obviously cramped living space…unless you did a wall or ceiling/rafter bay (SAFER) for your cylinder(s) when you (KISS) hardly notice them.

shootski

Tom,

Thanks for the mention but I did say that came from somebody local who determined that by experiment. Another point is that our brass single stage pumps filling brass reservoirs surely could not contain excessive pressures. Attached is our local Multi Stroke Pneumatic that acts like a PCP. The lower tube is the integral single stage hand pump, the middle tube is the reservoir naturally the top tube is the barrel. It takes around 70 strokes from empty giving a .22 caliber pellet around 650fps velocity for around 5 consistent shots. The efficiency could be improved though as that I can hear the valve being held open by the overpowered spring longer than needed.

Siraniko

PS Section Splatology 2nd paragraph 3rd sentence: “I showed you his splat board in (a link in) Part 1.” No picture was included only the link.

Siraniko,

Ooops! Boy, did I mess THAT ONE up!

Sorry!

It was actually TWO splat boards and it wasn’t in Part One ofd this series; it is in the link to Splatology in this same paragraph!

Siraniko, that’s a pretty cool rifle!

Are they only sold locally?

That looks like it would make a dandy hunting rig. 🙂

Blessings to you,

dave

thedavemyster,

To my knowledge they are only sold locally but I do know that there were a few sold overseas by collectors.

Siraniko

Siraniko, thank you; I think they would sell well here; they look really cool. 🙂

Siraniko,

wow, congratulations on your multipump, precharged pneumatic, air rifle! 🙂

Although you already gave a lot of information in just a few sentences and one picture, would you tell us / me even more about this airgun please: for example, though it reminds me a little of an Armscor product, is “Mainland Metalcraft” the actual company that manufactured this airgun, how is the integral pump operated, is it a single loader, etc… ?

hihihi,

The integral pump works like your run of the mill old time bicycle pump but upside down. There is a small metal stirrup your foot steps on while you lift the gun before bringing it down to compress the air. It is a single shot bolt action rifle. Armscor never made a multi stroke pneumatic to my knowledge, they only made a local version of the Crosman 160 bulk filled CO2 rifle.

Siraniko

Siraniko,

ah, I think I can imagine the pump you describe. 🙂

Sounds like some vintage systems I can’t quite remember the details of. I think Giffard made a similar pneumatic multipumper, but that was no repeater. Anyway, thanks!

Would you, next time you use it, confirm the pump operation with a picture please?

You see, going by the kind of bicycle pump I used 40 or 50 years ago, there is a good chance that a reader might have misunderstood the description and yes, I’m including myself! Thanks. 🙂

So, without markings to indicate the maker, how do you know it’s made locally to you – are you yourself a bit of a gunsmith?

hihihi,

No I’m not a gunsmith. Although I do know enough to be a danger to my airguns. This is a locally manufactured air rifle made of brass with the tubes and barrel soldered together. Attached is a picture with the pump at full extension. You step on the stirrup and press on the butt with both hands to compress air.

Siraniko

Siraniko,

hehe, the words of wisdom of a SIRang mekANIKO, ” – thanks for making me chuckle! 🙂

Also, thanks for your reply, and that picture! 🙂

I am happy to report, that is also how I imagined your airgun’s pump to work. I wonder how many strokes it takes to replenish those “… 5 consistent shots…”? I guess about six pumps per shot?

Sounds like a guest blog in the making!

BB,

I am so glad that PAIR sent you a G9 to test as I have one in my Wish List to replace the Hill two-stage that I had given to my grandson.

Thanks for the interesting and well-done report. This helps us to understand the basic background better. I too am grateful for the donated pump by PA. I hope you will be careful using it. Hernias and handpumps might not like each other. Please enlist a helper (if needed) before injuring yourself further.

Elmer,

Believe me — I am considering that!

BB

Whenever I have any doubts as to whether or not I should do or say something, I have concluded that the best thing for me to do is to NOT do or say whatever it is. If I lived near you I would certainly volunteer to help out. I would guess that there are some readers who have that same G9 hand pump that could remotely perform some of the experiments for you that require a lot of pumping.

Overheard a trainer at the gym FM frequents comment that “40% of our muscle mass in in our legs” – that is why it is essential to keep them fit thru walking and other exercise. The question is, in terms of airgun hand pumps, why are there no foot-operated airgun pumps or why are they scarce? Is it because of cost or engineering difficulties, impracticality, all of the preceding? You would think the old legs would provide more pumping force and a lower pump handle more leverage.

Disclaimer: FM is no engineer and/or genius inventor and is also an airgun newbie so excuse him if the above questions are amusing to the experts. Bring on amusement!

Basil,

Umarex was working on a prototype foot-operated air pump but it never made it to market. Or perhaps it hasn’t made it yet.

BB

A stair master airgun pump would be interesting.

David Enoch

What about small pumps in the heels of one’s boots? One could tether one’s gun and never run out of air just by walking in the woods. I always imagined that.

For a preface, almost all of my airguns are used. I just can’t justify spending too much on my hobby.

But I do have a Marauder and a “Kral Puncher Breaker Marine Silent” (who named that thing?). I have a cheap Barska pump and an older Crosman pump. Those are all that I use for those two because I haven’t yet found a compressor that is both in the price range that I am willing to pay, and I felt would last any time. I have hand pumped a 90 cubic inch bottle up to 4500psi with that Barska 50 pumps at a time, 2 to 3 seconds per stroke. Not the most fun I’ve ever had, but not as bad as I thought it would be. I am sure that I don’t shoot my PCPs as much as I would if I had a compressor, but I do shoot them just on my hand pumps.

Point being, hand pumps are viable if your determined. Or stupid. One or the other.

CB

Speaking of being stupid. I have often thought about filling a scuba tank with a hand pump. I like Captain Bravo would shoot more if I had a compressor. But the hand pump works great on my marauder pistol, but gets a little tiring with my Marauder rifle.

From Captain Bravo’s 50 pumps on a 90″ in tank. I calculated 76,777 pumps to do a 4500psi 80 foot scuba tank. Am I doing that correctly if so It could take years.

Speakski

All very interesting. I was especially curious about splatology, which I first encountered in a book recommended by BB some years in this blog: The Practical Guide to Man-Powered Weapons And Ammunition by Richard Middleton. I bought it and the book contains a section on splatology.

So a .375 lead ball traveling at 375 fps deforms identically to a .60 lead ball traveling at the same speed. But the energy delivered by the .60 lead ball would be much higher. I never studied physics in school (too hard!), so I can’t do the calculations, but I bet the amount of foot-pounds energy delivered by the larger ball would be impressive. Now that fact is useful to me when considering the weight of the pellets I shoot in my .22 break-barrel Crosman.

Great post BB.

MiTurn

MiTurn,

Given you wrote: “I never studied physics in school (too hard!), so I can’t do the calculations, but I bet the amount of foot-pounds energy delivered by the larger ball would be impressive.”

You might like this calculator and information:

https://www.ctmuzzleloaders.com/ctml_experiments/rbballistics/rbballistics.html

Scroll down to “NEW – A Web Application For Direct Calculations!!” For the Round-ball Ballistic Calculator

Enter your information and press FIRE for your answer!

e.g., .375 at 375 FPS = 26 FPE at the muzzle and a .60 @ 375 = 101 FPE

the calculator will give you a bunch more information if you play with it; like trajectory and fall off of energy.

shootski

Thanks shootski. I’ll play with the calculators.

MiTurn

BB,

That was a most fascinating history lesson; thank you! 🙂

Blessings to you,

dave

B.B. and Readership,

I was looking for the article about the crank operated pump on a wheeled cart that the military used to pump up and transport the folded and riveted buttstock of the Giraradoni rifles but found this instead.

Slightly off topic: The TRUE “why” behind the Girardoni Windbüchse (Air Rifle) rejection by the Austrian military!

“Weitere Modelle und Abarten waren vorhanden, darunter auch so ein Exot wie die Österreichische Windbüchse, das erste Druckluftgewehr seiner Zeit. Wurde aber auf Grund seiner Eigenschaften sehr schnell verpönt. Es zischte nirgends, es machte nicht Bumm und das war ja Unsoldatisch.”

From the writings of the, Herzoglich Braunschweigisches Feldcorps e.V. (a reenactment group) in present day Germany.

The last sentence above says it all: It doesn’t WHOOSH anywhere, it doesn’t make a BOOM and it was (not befitting a warrior) UNSOLDIERLY.

shootski

the new way this site is set up is horrible.

BB,

Under “Dennis the Rapper” you said, “Yeah, you guys discussed it in the comments to Part 1, but when these tests were conducted, none of this was known. What Quackenbush did for us was remove the complex mathematical formulae from the work and substitute simple equations in their place.” and I’m not sure that I haven’t misunderstood you.

In 1996 I CERTAINLY KNEW about the relationship between the piston diameter and area and how it is intertwined with the force required to achieve a given pressure. I learned it in my High School Physics class in 1973 in the Fluid Dynamics part of the Mechanics section of the course. I also learned in the same class that the principles involved where discovered in the early 15th century by a French Mathematician and Physicist named Blaise Pascal. As for “the complex mathematical formulae”, are you saying that a simple geometry formula for finding the area of a circle of a known diameter, something I learned in the 10th grade, and a little multiplying or dividing, is “complex”?

Respectfully, have I misunderstood you about what things weren’t known or who didn’t know them?

Half

I read that they used a pump mounted to a wagon wheel to fill reservoirs on the Girandoni rifles.

David Enoch

DavidEnoch,

It was actually a pump mounted ON a wheeled cart; icm still searching for the drawing i found years ago from a technical military manual. For now this may be of interest to you and other readers: https://pistolplace.wordpress.com/2020/08/20/classic-air-guns-the-girandoni-repeating-rifle/

shootski

PS: Still no drawing but: https://www.beemans.net/lewis-assault-rifle.htm

Footnote 9 from the above monograph

“Girandoni reported that the wheeled pumps actually were a bit slower than the long hand pumps, but even though the filling of an air bottle would require the same amount of energy input from a wheeled pump as from a hand pump, the wheeled pump must have been enormously easier to use. It is staggering to think of the amount of manpower that would have necessary to keep those transporter wagons full of hundreds of fully charged air bottles, plus shunting them to the shooters. This alone could have been a key reason for the decline of the airgun as a regular military weapon.”

shootski,

I’ve often wondered why they didn’t use actual “horsepower” to fill the tanks in the field. Get a horse or ox (just a specially trained bull cow) to walk in a circle while an axle turns a radial piston pump of multiple cylinders. For that matter, set up a pumping station at the local grist mill to service the needs of the locals (rich ones, anyway) who needed air for their hunting guns. I see a missed business opportunity! 😉

Half

Half,

I can tell you never had to deal directly with a Military Comptroller and you are thinking like a Capitalist to boot! ;^) Plus the Cavalry wanted nothing to do with the infantry/sniper types…still the same story today in most militaries.

But it is fun to think about Time Travel back to see IF you could have an impact on battle outcomes…without getting burned at the stake!

shootski

Maybe something along the lines of a railroad handcar with that seesaw lever to work a pump might have worked. Then again, it might not have.

FawltyManuel,

you would be amazed how close you are to what I seem to remember that they used. 🙂

Like shootski, I have yet to find confirmation online.

Since BB introduced the idea of interchanging air and CO2, I wanted to comment on the pressure of CO2, in case anyone wants to experiment with it in a gun of their own design.

Steven Archer has published that, according to a producer of CO2 guns (Sig Saur, I believe) and his own experimentation, the pressure in a CO2 tank goes up approx. 2 psi for every 1 degree F rise in temperature. I saw somewhere that the max storage temperature for 88gr. CO2 cartridges is 122 degrees F. If 850 psi is the pressure at 70 degrees then the pressure in a tank at 122 degrees would be as high as 954 psi. That would, no doubt, lock up any production gun’s valve, but you could design around that when inventing your own gun. Just don’t say I told you it was safe and okay to do! LOL (post photos)

Half

halfstep,

Wondered about that at the theory level too; but Quackenbush’s work proves what could be done back then at the practical level. That’s how i read it…

For those readers interested: https://www.engineeringtoolbox.com/pneumatic-cylinder-force-d_1273.html

This is a great site for calculators and formulas if you want on many areas of interest to air gunners.

shootski

I finally put the Quackenbush 5/8 inch diameter piston pump geometry into my spreadsheet to compare the calculated results with the measured results.

The input included the following:

Pump diameter 5/8 Inch

Pump stroke 15 3/8 inches

Reservoir volume 9 cubic inches

I used an equivalent dead space to achieve a maximum fill pressure of 750 psi. That is a volume of 0.0924 cubic inches or the volume of 0.301 inches of the 5/8 inch pump tube. This seemed a reasonable assumption and gave a good correlation with the measured data.

Note: I also start with the reservoir at atmospheric pressure so there is air for the pump and elevation can be included in the calculations. The pump starts at that pressure for each pump stroke. For these calculations I used 14.7 psi as the initial reservoir pressure and then subtracted it from the results for the plot.

I think this is the first time I had data to test against my spreadsheet. I seems to do very well.

Don

Benji-Don,

Perfect Proof for my statement: “Quackenbush’s work proves what could be done back then at the practical level. That’s how i read it…”

And you did it all without exposing the Mathematics to the Readership…or is that exposing the Readership to the Mathematical pain and suffering ;^)

Thank you!

shootski

Shootski,

I should have also mentioned that the maximum force for pump number 300 was 219.25 pounds.

I also assumed a constant temperature. That easily may not have been the case in the real world testing.

shootski,

I’ll bet Dennis didn’t pump too fast to keep the heat from causing problems with metal expansion rates and messing up any seals used. Also, the heat buildup really seems to accelerate only above 1,500 psi.

shootski

I generally agree but 300 pumps and what does 10 deg do to the pressure? Did he take a break especially near the last 100 pumps approaching his body weight. Just wondering.

Maybe B.B., has some first hand knowledge and will chime in.

Think about the advances in the compound bow leverages in the last 30 years can the dragonfly gen2 be significantly improved on?

Benji-Don and anyone else,

I (still) think ‘jet’:

Think about what a pressure washer or sand blaster can shift. Hydraulic pumps can achieve very powerful movements.

I have heard that tiny but very fast jets of gas or liquid can cut through sheets of steel. 🙂

When pumping power is limited by one’s body weight, then, I believe, the achievable pressure will be higher, the less air volume is transferred per pump stroke.

I think of this as, concentrating the available power by reducing the exit hole, ie the less- but faster the escaping air, the higher the air pressure achievable outside the pump. : )

That’s my theory while the reality involves time, ie I would want to get the job done reasonably fast and therein, I think, lies the realistic pressure limit. 🙂

edit: I have repeated and elaborated on my thoughts from Part One in case they had been misunderstood

hihihi,

Nice try but the Gas Laws say no.

Bernoulli’s principle gets into the way as well with the jet or restriction idea.

Pneumatics is a really complex area of science and there are many assumptions (bad word) that are made even in the basic “LAW” that should disqualify them from even being called laws. It really messes with your mind when you are taught them in High School (USA) and then in University courses you find out they are actually fantasies that don’t apply to reality or current theoretical knowledge and computational power.

This isn’t just my opinion this is based on current understanding of the science.

shootski

PS: This is a good place to start if interested…https://www.engineeringtoolbox.com/technical-terms-fluid-mechanics-d_181.html

shootski,

ah, it looks like I may have succeeded in making myself understood. Thanks.

Also, if I am indeed fantasizing, then, I still like my fantasy! 🙂

hihihi,

Me too!

On the fantasies ;^)

shootski

hihihi,

You are onto the idea of a spring piston airgun. They involve leverage to compress the spring. That act stores potential energy in the spring. When the trigger is released the strong spring pushes on the piston with a force much greater than the force the shooter used to cock the spring. The force on the end of the barrel is over a couple of feet the spring is compressed a couple of inches from the barrel leverage. When the spring is released it compresses the air in the compression tube and at the same time is giving the mass of the piston momentum. At the end of the firing cycle the spring is still pushing on the piston and the stopping piston is taking the momentum of the piston to add more force than just the force from the spring.

To do what you suggested is similar to what Dennis was doing by rapping jumping on the pump. He was forcing a high speed jet into the reservoir by converting momentum to force. Stopping his mass in a hurry was damaging to him.

Maybe more along the lines of your reasoning:

The jet/venturi concept has some merit but has not proven to be significant in airguns. I have tried to use a venturi in my low pressure airgun to speed up the air between the valve and the barrel. It does not seem to make much difference in the pellet velocity. Maybe I just haven’t perfected the geometry of my venturi yet.

Good food for thought.

Don

Benji-Don,

thanks for your response!

What an interesting take on this air pump pressure thing to which I couldn’t add… 🙂

Benji-Don,

As if pneumatics weren’t complex enough to figure out we airgun types have thrown in a closed system reservoir/valve (added recently regulators) that we turn into a flow system, however long/briefly, and back to a closed system (the barrel with a projectile in the chamber) then we go and allow/expect the projectile to change the volume of the containment vessel as our projectile travels down the bore (at varying rate, and finally when we don’t care anymore at muzzle exit we have a few folks that think it still somehow effects our projectile!

Talk about complexities to shoot an airgun.

It was much easier to work on flow in an automotive/aircraft intake manifold’s Venturi numbers since it was a comparatively simple flow system. After seeing a propellent based increasing pressure photograph or video show the hot gas cloud quickly following and occasionally overtaking the projectile… doesn’t work that way with a falling pressure cold gas flow system.

I believe you will find that the venturi effect is mostly killed in the closed bore system that disrupts flow velocity in a number of ways even in your very low pressure design. But keep trying, don’t

let my ramblings stop you!

You may just make a breakthrough!

shootski

hihihi,

I used to work with an abrasive waterjet machine. At 30,000 psi, with a “jet stream” width of about 0.030” (plus abrasive garnet (sand) in the water stream) it is supposed to be capable of cutting up to a 7” thick piece of steel. The pressure is high but the volume is quite low. The pump was a three cylinder, with three (ceramic) pistons being about 1/2” in diameter and a refrigeration unit to keep the pump and water cool.

Hydraulics is an amazing area of study, but I am reminded of what one engineer said about it: “the first rule of hydraulics is that everything gets worse, under pressure.”

I suppose a similar thing could be said about high pressure air.

Bill

billj,

what amazing machines we humans have and use! Was there much training involved before being let loose on one of those powerful cutting machines? And were the resulting parts used to assemble anything specific?

I remember the very first time I was told about water cutting through metal and my reply: “What, you really think I’m that stupid and gullible?!” 🙂

Interesting to read about those ceramic pistons. You see, I had this idea of experimenting with some fine sand in my pressure washer water, but, I guess, along the lines of that engineer’s “…first rule of hydraulics…”, the pump wouldn’t last long. 🙂

hihihi,

I think I understand where your going with this, but the unfortunate thing is that the increased or highest pressure will be in the pump. If it was the other way around the air would flow out of the gun and into the pump. We care about the pressures achieved in our guns.

Half

halfstep,

thanks for sharing your perfectly logical thoughts. 🙂

Regretfully I have expressed what I think happens, differently, which made me feel misunderstood. Now, I wish I hadn’t kept going on about it.

We all know what an air pump does and I’m happy to leave it at that. 🙂

No room to reply below. I think you are correct on the venturi in the closed system. I am devising some tests to see if transitial/intermediate ballistics are effecting accuracy in my low pressure airgun. I don’t think it is but I’m running out of ideas.

B.B.,

I bought a Benjamin Marauder shortly after they were introduced, along with the consensus best (everywhere on the ‘net, including here) hand pump of the era, a Hill (2nd variant, I believe).

I should point out at that time I was still able to bench press in the neighborhood of 230 pounds. In my 20s I had a personal best of over 250 pounds. (As a teen I sometimes worked out in the weight room with former Olympic Shot-Putter Brian Oldfield, so I learned about moving weight.) At the time I bought the Marauder and Hill pump, I weighed about 330 pounds.

It was extremely difficult to pump the Hill pump just once, using leverage and my considerable weight to best advantage. My guess was that it required in the neighborhood of 200-210 pounds per pump. That is why I shot my Marauder no more than two magazines’ worth, and put it away. I glanced at it in my basement yesterday. It has been collecting dust in the same spot ever since.

That experience taught me all I ever needed to know about PCPs, and my often retelling my story has dissuaded at least two co-workers and two family members from buying PCPs (including mine).

Michael

Michael,

Did you ever look into whether your pump was defective or not. My first PCP was a Gamo Coyote with a G6 pump. I was 60 and scrawny and didn’t have much trouble filling to 2500 psi. I think I actually went as high as 3000 on occasion. Have you tried filling the gun with a different pump? On my pump, the first bunch of strokes feel like filling a bicycle tire.

Half

Half,

I do not know if it was defective or not, and nope, I didn’t try another pump. The Hill was the best reviewed everywhere at that time, so I did not bother fussing with it or throwing out good money after bad for some other, lesser brand pump.

My philosophy regarding expensive non-essentials is that something new has just one chance to make a first impression.

One of those I dissuaded from buying a PCP and pump instead bought a very high powered springer in .22, I recall, and commented to me that one “pump” at forty-ish pounds was much easier than 100 pumps, each at greater effort than that magnum springer’s cocking stroke. I had shown him the basics of an artillery hold, and apparently that did the pesting trick for him.

Michael

Michael,

I guess that’s fair enough, but I still think it’s a bit of a shame that that one bad experience with what I think most would predict was a defective pump has kept you so negative towards PCPs. They can just be soooo accurate and easy to shoot. I guess your case proves the need for companies to achieve their best level of quality control. They lost you as a repeat customer and your sharing of that experience has no doubt lost them many additional customers, over time.

I don’t want to beat a dead horse here, but I can’t help it. It’s the lifetime of making my living repairing all sorts of stuff that makes me ask, did you at least try to pump the pump without it being connected to a gun at all, just to see if it was still hard to pump? If it isn’t, then the problem may be in the gun and you have a perfectly good pump that you could use on other guns or sell (or just give to a blog buddy that won’t just drop the matter, LOL)

Just tryin’ ta help, Half