by B.B. Pelletier

Happy birthday, USA! I’m at the NRA Junior Airgun Championships today through Saturday, but thanks to laptops and modems, I’m here with you, too.

Yesterday we looked at how the B-Square adjustable scope mounts are made. Today we’ll learn how to install them.

Installation

These mounts install just like other scope mounts, but because they are adjustable, there are some extra things to do. First, let’s loosen the locking screws that hold the windage adjustment screws. After that, loosen all four windage adjustment screws a little. Whether you use one-piece or two-piece mounts doesn’t matter. Both types are clamped to the dovetail and the stop screw (if required) is positioned at the rear of the vertical scope stop hole. If you have a different kind of airgun, such as the Webley Patriot, use the appropriate scope stop mechanism.

These setscrews must be loosened on each ring before the windage adjustment screws on the side of the rings can be loosened.

Now, before you put the scope in the rings, it’s time to do some preliminary elevation adjustment. Screw each ring as far down as it will go, then back it out, at least a half-turn in front and whatever you need in back. For Diana spring rifles, the back ring gets two full turns. For most spring rifles other than breakbarrels, the back ring gets one full turn. Breakbarrels other than Dianas get 1.5 turns. All CO2 and pneumatic rifles get a half turn, the same as the front. This won’t always be perfect, but it’s a good starting point. Let’s get the elevation right before we start on windage.

Install the scope

I assume you have the scope adjusted where you want it before you put it in the rings, but if not, you can either optically center the reticle which takes at least an hour, or you can just count the clicks, stop to stop and set each knob in the middle. That way after we have adjusted the mount you will have the greatest latitude to adjust the scope knobs. I wrote a blog about optically centering the scope, so read that if you are curious. And here’s another post that is an index of all the scope-mounting blogs I did in the past. You might find them of interest.

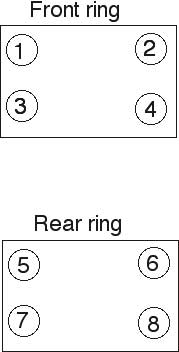

Tighten the screws in this order:

1, 4, 5, 8, 2, 3, 6, 7.

Tighten with the small leg of the Allen wrench or use very little torque as you go around this pattern repeatedly. When each screw feels tight, stop.

After tightening the caps, the scope will still be loose!

Yep, remember those adjustment screws you loosened? Well, the scope won’t tighten up until they are tight, but forget about that for now. Let’s shoot at 10 feet, 10 yards and finally 20 yards to verify we have the two rings correctly elevated. If not we must remove the scope from the rings and adjust the rings up or down. We are not looking for good groups yet – just want to see where we are in terms of elevation.

IMPORTANT!!

Always have a half-turn of elevation on the front ring for every two turns of the rear ring. That’s what allows the front ring to tip forward when the rear ring is elevated. Without it, the front ring cannot move freely and you will dent the scope tube when you tighten the caps. So if you need to elevate the rear ring at this point, the front goes up another half-turn, too. If not, you can leave the front ring alone. Obviously when the front goes up by a half-turn, you have to add an extra half-turn at the rear to compensate, so any more elevation is on top of that.

Once you have your scope hitting at the correct elevation, it’s time to adjust the windage. I’ll cover that tomorrow.

bb,

so, when talking about spring rifles, since they have the most droop, you like the b-square mount better?

Have fun atthe junior airgun championships!!

Dave

Dave,

I use B-Square adjustables almost exclusively on breakbarrels.

B.B.

hi BB.Just wanted to wish you a happy 4th of july.Have fun at the airgun chanpionships

^^^^^Sorry forgot to sign

Hernan(CF-X guy)

Hernan,

Thanks.

Good to hear from you.

B.B.

BB

Happy Independence Day to you. Question about a scope base: I’m considering a purchase of a big bore, and one of the manufacturers I’ve in mind is Mr. Quackenbush due to the more custom approach. His rifles use the Weaver scope base, so could this mount or a different be used on such a rifle. JP

everyone,

i know last week(or maybe the week before) some ppl were talking about daystate airguns, and some were not too great…which ones are good? i am looking into the air ranger, and i really like it, but i dont want to spend a lot of money on crap.

Dave

bb,

im looking for a short, accurate hunting spring rifle, and ive been looking at the bsa lightening series…are they worth the few hundred that websites charge for them?(around $450) do you have any other guns in mind for me?

JP,

I happen to own a .457 Quackenbush Bandit and you can use a B-Square AA Weaver mount on it – but you don’t have to. Quackenbush makes his rifles without droop.

B.B.

Dave,

The DayState AirRanger looks like a fine air rifle now. When they were first introduced, they only shot a .223 lead bullet that was hard to obtain, but it looks like they now use conventional pellets.

B.B.

BSA Lightning,

BSA is a fine air rifle maker. They are unfortunately not well-represented in the U.S. (by that I mean there are not very many dealers) but the guns are fine.

If that’s what you want, get it.

B.B.

HELLO B.B. IS GAMO DISCONTINUING THE MAXIMA?

why are the biodegradeable airsoft bbs more expenxive than plastic ones, i mean arent they alot cheaper and easier to produce? and which ones are better

CAPSLOCK,

I don’t know. What makes yoiu ask?

B.B.

Biodegradable airsoft BBs cost MORE to produce and they have a limited sales appeal. They are not made from recycled product. They are made from material that degrades over time.

They are not used more because they are not among the most accurate BBs.

B.B.

I am looking at the Beeman® SS1000S Dual Caliber Air Rifle Combo. I won’t be doing a lot of hunting, but will go out occasionally with my son and liked the flexibility of the dual barrels. I am a bit concerned, though, about the wear and tear of switchingthe barrels. Any thoughts would be appreciated.