by B.B. Pelletier

Before I start on changing the barrel, I need to clear up some things I said about the top hat adjustments in the last segment. I had mentioned that one Talon SS owner adjusted his top hat to a clearance of 0.068″, but what I didn’t tell you is that he also had rubber bands around the cocking knob, pulling it back into tight contact with the top hat. If he didn’t do that, the velocity would have fluctuated wildly.

AirForce now fits the top hat to each rifle they ship, so the cocking knob is in tight contact when it’s rotated into the notch on one side. In fact, sometimes the cocking knob may only rotate to one side because this fitting is so tight. They take this extra step to ensure greater shot-to-shot consistency. Leave it where they put it, and you won’t have any dud shots.

Forget the chronograph!

One more comment. Some owners don’t even shoot their rifles at anything. They just chronograph all their rounds to see if they like the gun or not. That is not the way to shoot these rifles. Get away from the chronograph and start punching holes in targets. Find out what you can do downrange before you look at the numbers. I can’t even tell you what velocity my Condor produces with the pellet and power setting I use, but I have long-range groups to prove it does the job. Putting holes in targets are what these rifles are all about – not producing graphs in spreadsheets!

Changing the barrel

I suspect the reader who asked me to show the barrel change doesn’t own an AirForce rifle, yet, because the procedure is pretty simple. Owners will have figured it out within minutes of handling their new rifle, but I think this reader wanted to see if he could do it, so I’m showing all the details.

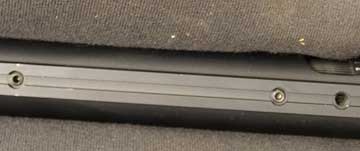

The barrel in any AirForce air rifle is held in the frame by two bushings. They have been made of Delrin in the past, but today they are made of aluminum. The following applies to all AirForce rifles. Early guns had two screws per bushing, but then AirForce went to a four-screw system. Whether you have two or four screws holding the barrel in place, the accuracy is exactly the same (I’ve tested it hundreds of times!).

I always remove the air tank, to make the rifle easier to handle. I also make sure the rifle is uncocked. The forearm comes off first with one Allen screw.

Next comes the muzzle cap. Another single screw that doesn’t have to be removed – just loosened. The cap slips out easily.

With the forearm off, you can see both barrel screws in the bottom channel of the frame. Remove both, then flip the rifle on its side and remove the other two screws. My Condor is very early, so the two side screws are very short. They’re 1/8″ long and just touch the barrel bushing. Current guns (all models) have longer screws that go all the way through the bushings to touch the barrel. Either way, remove them both. The barrel now slides out the front of the gun. Total time? About five minutes.

Once the barrel is out, that’s a perfect time to clean it. Most people will want to replace it with either a different caliber or a different length. AirForce sells Lothar Walther barrels in .177, .20 and .22 calibers in the 24″ Condor length. If you install a shorter barrel, the power will drop, however that’s what I’m going to show you because it’s a trifle more difficult.

Installing a short barrel

The 24″ barrel sticks out of the frame in front, making a convenient handle for positioning the barrel bushing screw holes when installing a barrel. What if you want to install a 12″ barrel? That shorter barrel will be recessed about 4″ inside the frame when the bushings are aligned with the screw holes, so you’ll need a dowel rod or broom handle to push it into place.

One alignment tip. The thin end of the barrel is the breech, and it has to pass through the sliding breech cover attached to the cocking knob. If that cover isn’t aligned, the barrel will stick and refuse to go all the way to the point that holes in the bushings are aligned. The solution is to move the breech cover until it aligns with the barrel. Here’s a maintenance tip: The rear of the barrel holds the breech cover in alignment. Two o-rings are inside the cover to seal the barrel during firing. When installing a barrel, it is an excellent idea to apply some silicone grease to the breech (the thin portion of the barrel) so those two o-rings get lubed. They’re lubed at the factory with a long-lasting o-ring lube as the rifle is assembled, but don’t miss a chance to lube these two o-rings when you can.

Has the zero changed?

The zero changes every time the barrel is removed. However, the AirForce concentric bushing design pretty much guarantees that each new barrel will be close to where the old one was. They don’t make as big a deal of that as they should, but I make dozens of barrel changes a year and notice how close it is to zero each time. I also slide the scope on and off the mount on the gun and it’s easy to zero, as well.

Hey BB, I have a question about the breech locking lever on the HW55 rifle from yesterdays blog. Did this assist in tightenning the breech seal with a cam type of system? And did it help to lessen the barrel droop at all? If so, I wish Crosman would have integrated this into their quest rifles. Even better, have a U-shaped lever that would make it ambidextrious for lefty’s. Kind of like the safeties on certain models of .45 pistols. Thanks, Thomas

Thomas,

The breech lever made the lockup more positive. It came at the time when Weihrauch had to compete with Feinwerkbau and Walther who both had fixed-barrel target rifles on the market. In 1969 an HW55 CM won the world championship – the last time a breakbarrel did so.

To put a latch on a gun that doesn’t have one would add a lot of money to the price and many who don’t appreciate it would object.

B.B.

BB. My condor is about a year old and

cocking knob does not contact the top

hat. Should I send it back to Airforce factory for An Alignment.

Sam.

Sam,

It is physically impossible for the cocking knob to EVER contact the tophat. Are you saying there is play when you rotate the cocking knob into the notch, or are you saying you cannot rotate the coking knob into the notch?

B.BN.

BB, I understand about the cost increase hindering sales. Like they say, everything comes down to the almighty $. I would appreciate it though. It makes sence to me for having them, and perhaps this is why a break-barrels haven’t won a world championship since. Then again they do seem archaic in todays comp shooting with all the advancements in PCP rifles. Like taking a chariot to the Indy 500!! LOL’s Thomas

bb

for the first time since reading your blog (over 1 year now) i am going to have to totally disagree with your opinions about the Condor. For some reason you show huge favoritism for this gun (maybe because you worked for Airforce??) and i can highlight one point here (there are many others i wont bother to mention…yet). You state clearly that with the Condor you should leave the Chrono alone, amd that they produce great groups what ever the chorno results show. What you are really saying here (and i agree) is that the shot to shot consistency of the Condor is poor, and a chrono proves this. Well, all firearms, regardless of calibre, or powersource, simply need to be consistent or the accuracy will suffer. Simply as that. With large difference in velocity, the pellet/buller will take a different trajectory and ultimately land in a different place, thats physics. Condors look cool, they are awsomely powerful and they make .22LR type moise, but they are shoddily made with huge error tolerances and thats why they look bad on a chrono. I own one and have shot it (till it broke…twice) and have chronoed it. I own 14 airguns and 8 firearms, its by far the least accurate of any.

John

Thomas,

I posted a long message to you, but accidentally placed it on yesterday’s comments.

Sorry ’bout that.

Derrick

B.B.

Not that I would not have figured it out but I am glad you showed the dissassmebly of the AirForce. My new SS should be ariving next week from pyramid (if they get the pumps in) and I am soaking up everything you have written.

Unlike the pessimist above I am looking foward to an awesome new shooter. I don’t have a chronograph anyhow so I am going to be looking at how it dusts a grackle compared to my benji.

jw

John,

I’m sorry we disagree about chrono-ing the Condor. I said that because many people only do that and little else. Now I shoot mine at distance. I have shot many half-inch groups at 50 yards, though I will admit the average is more like three-quarters. But if that is the least accurate airgun you own, then you own some fine guns.

B.B.

JW,

An SS and a Discovery are very close in power. The SS will shade the Disco for accuracy, but not by much. However, the trigger is better and the way your hold the rifle is completely different, so your impressions will be interesting.

B.B.

B.B.

I should have been specific I don’t own a disco. I have a 392. It will be a fun comparison because I sure like the benji, but it may not be a comparison if that makes sense.

jw

JW,

Oh, there is a world of difference between a 392 and an SS!

B.B.

B.B.

That is what I am hoping for. Why doesnt AirForce install an airgage in their tanks? Is it really not that important? Is it fairly easy to see the power drop to know it’s time to refill?

jw

Derrick, No problem, I’m usually a day late, and a dollar short! I read you comments and will agree with you about better built rifles. This one is the most expensive I’ve ever had, and the first springer too. After you had the modifications done to your rifle (Quest???) did it improve the FPS, accuracy, etc. Did you do it yourself, or did you send it off to be worked on? I have an old Spanish made Marksman (Norica-Laurona) that is better in group consistancy than the Sierra, and I do believe it’s a much better design. Although it’s only shoots around the mid 600’s, I’ve never had to adjust the scope (Powerline from Wally-World) near as much as the Sierra. Pretty much aim, fire, and viola,……target hit. Now being a hunter/plinker, I site in my scopes at ten yards in the kneeling position just to get it close, after that I drop back to 20 yards and scope them in shooting from a standing position. So far I’ve had good results with this method. I did have a problem with barrel droop on both Sierras I’ve had, and the mount was not that great to compensate it with the scope stop/rear elevation screw, and I ended up shimming the rear ring with a peice of paper. The blades of the dove-tail clamps were crossing over the dove-tail grooves cut into the action. Didn’t really look good, and somehow I didn’t have that secure feeling that it would stay. Did you have this similar experience? BB mentionned some adjustable B-Square rings, but I’d rather use a one piece mount. This weekend I used a spare set of rings with the Crosman Scope to see how it would work, but the recoil was too much and the rings were bending back over the scope stop. Got a little damage to the scope, but not sure if it’s dented beyond useable service. Probably put it back on my Benji 397. Worked better on it anyways!!! Thomas

JW,

Any time a tested pressure vessel is penetrated, it has to be tested all over again. The AirForce design doesn’t lend itself to installing a manometer.

The guns that have them mostly have untested pressure vessels. The U.S. DOT requires testing for any vessel with an exterior diameter greater than two inches.

The gun makers choose material with many times the working pressure and then they install gauges without any requirement to test.

It would be nice to have a gauge, but experience can also serve to let you know when to charge again.

B.B.

B.B.,

can the power-adjuster removed as easily?

This Talon barrel looks huge. What is the diameter of it, what is the diameter of the breech section?

Markus

B.B.

That really cracks me up about people only shooting their guns at a wall to measure the velocity. Can’t say that I’ve felt this impulse yet.

Matt61

The IZH-Baikal MP-514K by IZH-Baikal looks quite interesting.

This is the only bullpup airrifle abalable here in the states that i know of. Would you be willing to do a review of this rifle any time soon. It looks like a quarky and fun can killer.

Thanks Chase.

Thomas,

I’ve got a Remington Summit. I did all the work on it, but I have a spring compressor and I’m comfortable taking things apart. I also put a Charlie da Tuna GRTIII trigger in it and I drilled a deeper hole into the receiver tube for a larger scope stop pin.–could tell right away it was going to be trouble. I’m using a two-piece mount, as I like the flexibility in ring positioning, No problem with one-piece, but on some guns the built in scope stop pin will need relocating in a one-piece mount.

I did have to shim the rear scope ring to get on target.

After the work, the fps stayed about the same, but the rifle is very smooth now with no spring twang. There are no flyers anymore. It’s a one-hole gun now at 10m. The trigger swap was a no-brainer. The stock trigger is abysmal. I can’t overemphasize what a better trigger will do for your shooting ability.

Oh, if you haven’t, you might want to clean the barrel with some JB non-embedding paste. Mine was absolutely nasty. Sludge, rust, gross.

Derrick

Matt61,

Nice riffle! from what i have read, it’s equal to an ed brown in terms of accuracy! Sweet! Congrats!

I have owned a Talon for five months and fired 2,400 rounds through it. I have had 3 or 4 shots that sound weak and impact lower than the others. Are these dud shots?

You said you have shot many half inch groups at 50 yards and the average is around three-quarters of an inch. If these are not 10 shot groups,have you ever shot 10shot groups? If so what were your results.

Derrick, I’ve been looking at those triggers, and I’m thinking about getting one too. The barrel in mine wasn’t too bad as far as cleanliness, I do swab it with a mop and a dab of Kleen-Bore gun cleanner periodically to remove the lead build-up. But when you clean the barrel, do you clean it from the breech, or the muzzle. I usually clean mine from the muzzle end so the last stoke with a patch goes in the same direction as the pellet. Is the JB-Paste abrasive?? Luckily my Norica isn’t strong enough to warrant a scope stop, and I’ve used separate 4-piece rings on it. Two that grad the dove tails on either side (open to go to iron sights if needed), and two upper (separate) ring tops per ring,….make sense?!? Makes it easier to torque them down without uneven tightenning. Uncle Bucks (?!?) from Wal-mart. Haven’t had the first problem with them so far. I do get a kick from shooting the rifle because it feels like the pellet is in ‘slow-motion’. Yet it hits the target 9 times out of 10 if I’m on point. Just that longer pause. I read the blog on shimming the breech seal a few weeks ago, tried it, and may have gotten a tad more speed, but nothing over welming. And I whole-heartedly agree with you about the stock triggers,…..they are junk!! Thomas

Will Crosman Silicone Chamber oil work for oiling Condor breech?

Markus,

The Talon and Condors have 16 mm barrels. The Talon SS has a 12 mm barrel. Both barrels are ground as much as 0.010″ to remove surface hardness before bluing. The breech is approximately 0.310″ to 0.314″.

An owner cannot remove the power adjuster and retain the warranty, and yes, the adjuster comes out easily.

B.B.

Chase,

I did test the MP 514, but I found it clunky and difficult to use. If enough readers want a review I can order another one.

B.B.

Where can you find a breach seal for a gamo shadow express. I plan on blogging about it. better than the viper express.

Dud shots,

They may be. If you have any slop in the sliding bolt cover with the bolt handle turned into the notch you might try adjusting the top hat to get rid of it.

B.B.

10-shot groups,

No, my groups were all five-shot groups. You are correct to ask about the number. I haven’t done any testing of the Condor with 10-shot groups.

I talk a good story, but when you see what I really do, there’s fuzz around the edges.

However, I do five-shot groups for almost all my other tests in this blog, as well, so at least I’m consistent.

B.B.

Gamo Shadow breech seal,

Why not contact Gamo USA?

B.B.

B.B.

I’m a little amused by your answer to the question regarding ten shot groups, I suspect you intended that.

I’ve always thought that the nuber of shots in a group ought to correspond in some way to the use of the gun as any other reason for one number over another is arbitrary. For instance; if a gun can manage 4000 shots on one fil, then maybe a 4000 shot group is called for. But if a gun can only muster 2 shots on a fill, then maybe a 2 shot group is reasonable? Or what about 2000 2 shot groups?

Those numbers are silly by design. There is no specific number of shots in a group that prove anything. I’ve seen guns that get 3 shots off a fill shoot fantastic groups of 3 off one fill just to be panned for only shooting 3 shot groups and other guns that can’t get shot 1 and 2 within 2″ get rave reviews. Other guns that shoot .5″ groups of 5 at 50 yards are considered average while a similar gun shooting 1″ groups of 10 at 50 yards is “special.”

On top of that; the more shots in a group, the more operator error influences the result as every shot is an opportunity for the shooter to mess up. Here’s an example: I was doing some slug testing to see if the latest design was as good as it needed to be… I decided to take 15 slugs and see how they grouped out of a rifle tethered to a regulator. The first shot was dead center, the second was pulled to the left and I knew it was my fault, the third shot was a little right but felt perfect, the next 12 shots went through the same hole as the first shot. Measuring everything at the end shows a group of about 3/4″ including shot 2, about 1/2″ including shot 3 but not shot 2, and if shot 2 and 3 are both ignored the group is 13 shots into less than a 1/4″ at 41 yards.

What have we proved?

Jerry

one thing i think that was not talked about is i got a condor in .22 cal and also a .177 barrel also to go with it. but air force never mentioned that the springs in the valve are diffrent and you just can’t change down a cal. the problem i had is the valve would dump around 2500 psi. unless i am missing something you can’t just change down to any cal. but to the people that say the gun is not accurate shot eun jins, i do and can keep a 1 1/4 inch group at 70 yards. this is the gun i shot the most

B.B. In part one you left off saying in part two you were going to talk about filling the tank….Did I miss something??? I’m wondering if I should send my gun back to A.F. because it won’t give full power until well after 20-30 shots. Then once it “comes on cam” (a little racer lingo there) the P.W. seems to do nothing till it’s alomost to its lowest setting. What it likes is 2500 psi max and will blaze all the way down to 1000. From SavageSam

Thomas,

Yep, that GRT III trigger was something like 32 dollars shipped. Didn’t seem like much money for today’s weak dollar. I always clean from brreach to muzzle. Don’t think it matters as long as you’re careful around that muzzle crown. Are you really gettong leading? Or maybe it’s just atomized lube from the mainspring/piston collecting in the barrel?

The JB bore cleaner IS mildly abrasive. You don’t use much and you don’t use it very often. BB says only once. I can go years without cleaning an airgun barrel.

Derrick

Grouping and chronographs are the most fun shooting sports…especially if done scoped from a benchrest. My idea for a hot seller is a a scope with 80mm objective and display overlay that can calculate group size and shot velocity/variance. Imagine the fun as you shoot (even a blank piece of paper is fine) and get all this information in real time. Oh yeah, there’ll also be an accelerometer (to quantify tuning improvements) and gyrocopic orientation feedback. The next step is a computer controlled clamp/rest that removes shooter error from the equation and optimizes shot placement based on feedback from the optical system. Imagine how easy it will be to proudly display a 1u (micron) group from a “smart-rested” rifle with borg-vision scope.

Resistance is futile, although I prefer to fight the future.

Hi Henry. Yes, I waded through reams of discussion comparing the Savage 10fp to the Remington 700. (Blogging outside of the kindly influence of the PA blog is interesting. One guy asked if another guy wanted him to hold his wee-wee!?) What got me is that the Savages are good out of the box. No technical wizardry required. In fact, the ultimate sniper Carlos Hathcock is quoted somewhere as saying that your “Savage is your most accurate stick off the shelf.” AND, they’re (relatively) cheap. That did it. Snagging a good deal for me is akin to what must be the feeling of the hunt.

So, now I am on the tenterhooks of anticipation waiting for it although I’ve fired many hundreds of rounds in my mind. I’ll let you know how it goes.

Matt61

bg_farmer

Wow, this is very imaginative and goes way beyond just filming the image through a scope. The scary part is that I suspect this technology is not that far off if someone really had the will to assemble it.

This reminds me, though, that I think one reason that I’m holding out against PCPs and enjoying my springers–besides their simplicity–is that the recoil makes me feel like I’m riding the shot and participating in it. I guess it’s like the reason that some drivers say the prefer the stick to an automatic. Plenty of recoil with the firearms though….

Matt61

Jerry,

No, the number of shots in a group is not arbitrary. A three-shot group is close to meaningless. Statistically, it represents less than a 50 percent representation of the true group size.

A 5-shot group is indicative of the final true size, but it isn’t perfect. A 10-shot group is very close to the size that 30 shots will give. A 30-shot group is so close to what the gun is capable of that in 1,000 30-shot groups, only three will be larger.

So the guy was correct – a 10-shot group is considered to be a true representation of the accuracy of which a gun is capable.

B.B.

>22 and .177,

I will address the valve situation with these two calibers. It has been resolved and you can get your tank rebuilt by AirForce if you contact them and explain your problem.

B.B.

Savage Sam,

I guess I missed that! Sorry.

You don’t have to send your rifle back, but I will explain in detail in the next installment.

B.B.

Hey B.B.,

Would chaning for the 12″ barrel, now that its full in the shroud, quiet it as much as say a Talon SS? Thanks,

Brody

Brody,

If you also put the SS end cap on the end of the frame the gun would be quieter than a Condor. But it would be louder than a Talon SS. It would have about the power of a Talon.

B.B.

Matt,

Sadly, I think those things would do well in the market and not be too advanced for current technology. Matter of time:(. I’m with you on simple springers…as long as I’m as accurate as the gun I’m using, who cares if its the “most accurate” type or model. Of course, I do want a 10M gun and a PCP eventually, too:).

hey bb,

This is way off subject, but do you or any one know of a 88 gram air source adapter for the Crosman 2260?

Thanks again,

Ike

Shadow express dude

What is the purpose of a barrel crown. I’m still working on the report.Over the 3 days I’ve had it, I have put 300rnds in it, got 2 starlings, a grackel, and with a scope at 50yrds with a pellet came the pidgeon. The breach seal is a disappointment but I cronied the first 10 pellets and the highest was 647fps with crosman wadcutters. I also cronied the shells at 608. The accuracy of pellets has been about .25 inches at 15 yrds. The one thing that really bugs me(not the trigger) is the vibration. I might put some money aside for a gas spring or a tune.

Hi Ike,

Not sure if these guys have an 88 gram air source adapter for the 2260 – but they might.

http://www.airgunartisans.com/AABioBulking1.htm