by B.B. Pelletier

Announcement

Pyramyd AIR experienced trouble with its main server late Saturday and all Sunday. The backup server wasn’t up-to-date, so many images on the blog were temporarily lost and some orders may have been lost. Better check the status of your order if you ordered recently.

Guest blogger

Vince Brandolini’s first installment about calculating spring-gun energy [insert link after blog part 1 is published] has a few more steps to go, and today he finishes it up for us.

If you would like to write a post for this blog, please email me at blogger@pyramydair.com.

Bloggers must be proficient in the simple html that Blogger software uses, know how to take clear photos and size them for the internet (if their post requires them) and they must use proper English. We will edit each submission, but we won’t work on any submission that contains gross misspellings and/or grammatical errors.

Springtime! – Part 2

by Vince Brandolini

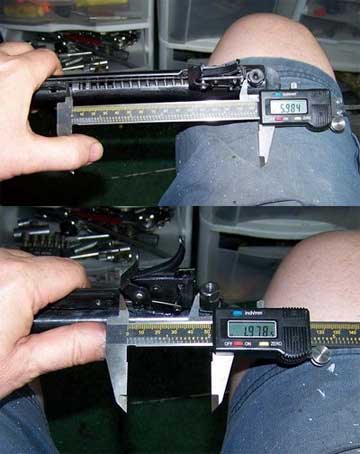

After you’ve followed all the steps in my previous blog, there’s one last step…measuring the piston stroke. You have to select an accessible datum point, such as the rear of the cocking shoe or a recognizable spot on the piston. Measure from that point to some other reference point (it doesn’t really matter where) with the gun cocked and uncocked. Subtract the lesser measurement from the greater and you’ll have the cocking stroke. On some rifles (like some from Gamo), you might have to cock the gun with the action in the stock, then separate it while it remains cocked. Take the upmost care while doing so!

At this point, a little number crunching and we’re done. First, calculate the preload in pounds. Multiply the preload distance measured above by the spring rate. This tells you how much pressure is on the spring when the gun is at rest. Multiply the stroke (in inches) by the spring rate and add it to the preload figure. This is your cocked pressure. Take the average of the cocked and preload pressures, multiply by the piston stroke, divide by 12, and you’re done. Here’s the formula:

- PL=preload measurement

- SR=spring rate

- ST=stroke

Now you have your powerplant energy.

What about efficiency? For that you need to know pellet weight and actual muzzle velocity. Use the following formula:

Divide the powerplant energy into muzzle energy, and you’ve got efficiency. Generally speaking, I’ve observed efficiencies in the range of 30% to 44% in .177 and 40% to 46% in .22.

There’s one big unknown I’ve left out of this entire discussion…the effect of dieseling (burning of lubricant) on velocity. Obviously, this would drive the efficiency artificially high. I’ve heard of the Cardew experiments that purported to show that a lot of a springer’s power comes from this effect, but personally I’m not convinced that this is always the case. I haven’t seen the details of that experiment, but I tried my own test some time back. I compared the velocity figures of a dry rifle (thoroughly degreased and relubed with only powdered moly) and wet (lubed sparingly with moly/oil) and found little difference.

I’ve seen some springers shoot with a very tight velocity spread of around 10 fps over 10 shots. If the rifle was dieseling, I’d think that the effect would not be that consistent, since there’s no mechanism to tightly regulate the amount of fuel introduced into the chamber. Lastly, there’s the matter of my most efficient .177 caliber springer; the one that showed up as over 44% efficient when every other .177 was between 30% and 39%. That gun happens to be a Crosman 795, an under-5-ft-lb gun that probably doesn’t have enough compression to really initiate any dieseling. And, my least efficient .177, a Walther Force 1000, has a loose seal, a large powerplant and a good-sized spring that should make it more inclined to diesel.

At this point, I’m just gonna stay out of THAT discussion. As I said before, this information can be very useful. I was always a little perplexed by the fact that my RWS Panther did about 875 fps with Crosman Premier 7.9-grain pellets, despite having a long and reasonably stout cocking stroke. When I calculated the efficiency, I found that it was well under 30% when every other springer I had was over. This told me that something was probably wrong, and I eventually discovered that the breech seal was leaking. It was recessed too far into the breech face. I shimmed it out, and now the rifle delivers over 940 fps with the same pellet.

Thank you Vince. Well written and very interesting. I liked the way you ended with the info being used to diagnose the problem with the RWS Panther.

Right on Vince!!! Excellent info to know and use. I’ll be setting up an excel spreadsheet soon so I can catargorize all my airguns.

–davee1

This really ticks me off, you couldn’t publish this before I had rebuilt several spring guns could you, NO. Now I have to go back and tear them all down again. Didnt anybody ever tell you not to plant ideas in curious peoples minds. Sheezz.

All Kidding aside great Blog and thanks for taking the time to tell us about it.

Sam

Vince,

I think it would be interesting to see how springs with different spring rates and preloads do efficiency-wise. My guess is that “soft” springs w/little preload are higher in efficiency by your system of measurement.

Vince,

So efficiency is based on the quotient of the muzzle and powerplant energies and not their difference. That makes sense. Are you sure that dieseling is the only factor that affects efficiency? I would expect that all of the things that go into tuning with the measuring, aligning, and lubing of different parts, not to mention making the gun quieter would also play a role although how much I couldn’t say.

Matt61

hi BB,

I asked you yesterday about the crosman custom shop carbine. I am still looking into into the gun. I am wondering about barrels. I would choose either the 18″ or 24″ barrel. i obviously want the highest velocity possible. Do you think i will see a significant increase for the 24″ barrel over the 18″? Also any idea how fast this would be? Thanks.

If anyone here has ordered a Crosman custom shop gun i would like to here from you. Comments on the guns and service from Crosman would be greatly appreciated.

Nate in Mass

Nate,

From the testing I have done with Crosman’s stock valves, the 18″ barrel will be faster than the 24″. My tests show that 16″ is about the optimum barrel length, but that will change from gun to gun because of small variations in the valve. However I would expect 18″ to always be faster than 24″.

This is CO2, and the gas expands slower than air. If it were air, the 24″ would be faster.

B.B.

Thanks BB

Im guessing the velocity would be around 600 fps with about 30 shots per powerlet. This is a rough estimate based on some other crosman guns. Would i be correct in assuming these numbers?

Nate in Mass

BB

I know your answer to Nate in Mass is in reference to a .177 cal barrel. What would your answer be to the same question, but for a .22 cal. barrel? Thanks, JR.

Tom and Vince

Off topic question here. Can you damage an airgun by over-cleaning it?

I have a Crosman 1377 w/ Walnut grips from RBGrips.net. I enjoy the ritual of cleaning it after I shoot. I use a plastic line (bore worm?, patch worm?), and soak the 1st cotton patch with Beemans Metalophillic oil. The rest are dry patches. I use a scant amount of the oil on the metal parts and then dry it with a cotton cloth. I then polish the entire pistol with silicon cloth.

Of course, I use pelgun oil as recommended by Crosman on the pump cap and hinges. Again, just a scant amount every 250 pellets or so.

I know the gun does not need as much cleaning as I give it. However, I enjoy the quiet time, handling the pistol and the way it looks when I am done. To me it is part of the ritual of shooting.

Thanks

Vince and B.B.,

Okay, how about this as another energy sink in the firing process. I read somewhere, perhaps this blog, that the compression chamber of a spring gun attains up to 2000 degrees F during the firing cycle. Incredible. I suppose the intention is to convert all of this heat energy to the mechanical energy of pushing a pellet out the barrel. However, I expect that a good deal of this heat is lost. Where could it go? Airguns, in my experience, don’t heat up anything like firearms. Does the excess heat somehow dissipate in the metal parts?

Matt61

Nate,

Six hundred f.p.s. or a little better in .177.

J.R.,

In .22, something above 500 f.p.s., I would think.

B.B.

Marc,

It is very easy to damage an airgun, not by over-cleaning it, but by cleaning it in the first place. That’s why I never recommend cleaning unless the accuracy has fallen off.

Airgun barrels are made from either dead-soft steel or brass. Both are susceptible to damage from erosive forces. Line cleaners have been known to cut grooves in the muzzle of the gun from abrasive grit embedded in the line. An abrasive monofiliment line is one way Jade is carved.

A metal cleaning rod flexes in the bore and hammers the rifling. If it does that at the muzzle, the accuracy will be affected.

B.B.

Matt61,

The air temperature during spring-gun firing is adiabatic. It dissipates with the air going out the muzzle and is so quick it doesn’t have a chance to heat the metal of the gun.

Yes, it is one source of energy loss.

B.B.

BB, I’ve been shooting the 1377 pistol I bought last week and noticed that it continually shoots high. I’ve lowered the rear sight and still shoots high. I read in the blogs about fileing the groove deeper, so what kind of file would you recomend? One thing I’ve tried with some decent results is to align the from sight with the bottom of the groove (like a semi-peep sight. The trigger is getting smoother with use too!! Thomas

Thomas,

Filing the rear sight groove deeper doesn’t lower the shot, and more than dredging the rifle lowers the surface. You need to add height to the front sight.

B.B.

“Dredging the rifle lowers the surface”,…not sure I understand what you mean BB. How is it possible to add height to the front plastic sight? Another question; I think I read something in the 1377 blog/comments about “3 to 7 pumps for better accuracy. Does the full 10 pumps send the projectile too fast to where it loses stability in flight? Thomas

Thomas,

Ha! You caught me. I meant to say the river, not the rifle. You can lower the bottom of the river, but not affect where the surface is.

The full 10 pumps doesn’t destabilize the pellet at all. It may turn out to be the most accurate fill level with some pellets. I don’t know where the 3-7 pumps comment came from.

B.B.

LOL’s!!! Had a few Coronas already?!?!? I get your point. Yeah there was something written about pumping it a certain # of times, but the blog had over 200 comments in it and I probably would never find it again if I tried. But I have read somewhere about hyper velocity pellets losing accuracy during super-sonic flight, so I figured the same would happen on a smaller scale in regards to a pistol. Don’t ask me where I read it thought, because I don’t remember. Guess I’ll just have to test it at different power settings (pumps) and experiment with differrent pellet types. Our local Wal-mart has Crosman Premiers in hollow point, but i wish they had the regular diabolos instead. The Destroyers ( my fav’s) are the ones I get the best groups in, but they don’t last long,….not enough in the tins. Maybe it’s me and my style of shoting, but the regular Crosman field hunting pointed pellets never seem to shoot consistant groups. Have you experienced any similar results with them as I have? How would you raise the front sight on one of these 1377’s??? Thomas

Thomas,

I would build the front sight up with JB Weld and file it to shape.

Swiss files are what you want for that. They are much smaller and easier to use on small projects.

Crosman pellets are usually the best in Crosman guns, but I don’t like any pointed pellets, as a general rule. Only RWS Superpoints are useful in Hakims.

B.B.

That’s a big ten-four. Not crazy about pointers either. When you build up the front sight, do you layer several coats on the blade edge like paint, or do you form it with masking tape to make a ‘mold’? Got the JB Weld and files!!! Thomas

Thomas,

My approach would be tape as a form.

B.B.

BB.

My question yesterday was extremely unclear (sorry). Let me try again. You told Nate in Mass that his .177 cal. CO2 airgun would get higher velocity with an 18″ bbl. than a 24″ bbl.(with stock valve). I have a 2260SE, which has all the same internal parts as Nates’ gun, but with a .22 cal. bbl. Will I gain velocity by cutting and recrowning my 24″ bbl. to 18″ or even 16″? Thanks, JR.

JR,

Yes, my testing says that it will increase in velocity. BUT DON”T TAKE MY WORD!

I want you to dgo on the Crosman forum and ask them the same question. The testing I did was years ago with a Quackenbush XL. It gained velocity to the 16-inch point, then started losing it again.

http://www.network54.com/Forum/275684/

We are only talking about 30 f.p.s. or so here.

That was with a .22, as I recall.

B.B.

Matt61, I don’t think I said that dieseling is the only factor affecting efficiency. In any case it’s not… efficiency is going to be determined by an interplay between friction, bore, stroke, piston mass, transfer port size, sealing, barrel length, and so on.

Tuning should, at the very least, improve sealing and friction which should then improve efficiency.

As for the heat of compression, you have to remember that the air in the compression tube is compressed very, very briefly. There’s not much time to loose a lot of heat through the walls of the chamber. Also remember that once the air expands back to atmospheric pressure, it cools back down.

BTW – I strongly suspect that this is one reason pump type pneumatics are very inefficient when you compare the energy you put in vs. the energy you get out of the pellet. In those guns the air heats up, but it has a LOT more time to cool down before you pull the trigger. When it cools down the pressure drops.

Was the problem with your RWS 34 Panther unique to your rifle or is the problem a design or manufacturing flaw common to all Panters?

I’m way off topic here, but would appreciate some advice. I’ve borrowed my dad’s old Sheridan Blue Streak (I believe made in the mid 60’s) for dispatching rats in my backyard. It’s awesome, and I plan on buying either a 392 or a Blue Streak. I like the idea of a .22 pellet, but wondered if I would be at all dissapointed with the 392 compared to the Blue Streak that I know I really like. Is there any apreciable difference in these two rifles other than the .5 mm difference in pellet size? Also I’m considering having Mac 1 do a steroid job to it. I don’t plan on generally exceeding the standard 8 pump factory max, but like the idea of a little more juice in the tank if I want it. Is that something that you reccomend against? I have also read that on newer Benjamin/Sheridans that you should not put oil in the air inlet hole. This seems to me to suggest that it’s not a bad idea for the older ones. My dad has had this rifle since his childhood, and I want to do my part to maintain it properly while it is in my care. Thanks in advance for the help!

Aggie_00,

Always store the rifle with a pump of air in the reservoir. That keeps the seals closed to airborn dirt.

Oil the pump head with Crosman Pellgunoil. Flip the gun on its back and open the pump handle all the way. The pump head is just visible in the pump slot (away from the muzzle) Drop 3-5 drops of Pellgunoil on the head every 6 months.

There is no appreciable difference between the Blue Streak and the 392. Get the .22 for more plentiful pellets.

I have owned a Steroid. It makes pumping harder, which I don’t care for. It is a more powerful gun, however.

You might enjoy reading these old reports:

/blog/2008/1/the-pump-assist-benjamin-392-part-5/

/blog/2005/9/the-benjamin-392397-60-years-later/

/blog/2005/6/my-early-silver-streak/

/blog/2006/1/three-principal-sheridan-variations/

B.B.

Thanks so much for the info.! The old posts are very helpful. We’ll have to get the “Know your SHERIDAN Rifles and Pistols” book to see if we can get a more precise date on my dad’s rifle (definately 1963 or later because of the rocker safety). It’s still a great shooting gun after all these years, and that’s a big part of why I want my own. I want something that will be around for my kids to enjoy when they’re in their 30’s (I’m sure my dad’s old blue streak will still be shooting great right beside my 392)!