by B.B. Pelletier

I got a request for this article last week from Manish in India and then another request to explain what is meant by the term valve lock, so I’ll deal with both subjects today.

There’s very little difference between the valve in a multi-pump pneumatic and a precharged pneumatic. Add air volume to a multi-pump reservoir and you can make the gun capable of multiple shots on a single fill of air. Then the only difference between that and a precharged gun would be the presence of the onboard pump. Therefore, the valve I will discuss applies equally to both types of pneumatics.

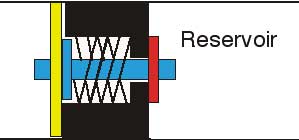

First, let’s look at a closed valve (graphic below). The reservoir is filled with compressed air that wants to get out, but the valve is blocking its way. Air pressure on the valve (red) presses it against the valve seat, which is a part of the valve body (black). The walls of the reservoir tube are also shown in black. A valve return spring inside the valve body also holds the valve shut, but with far less pressure than the air itself. The purpose of the return spring will be obvious in a moment.

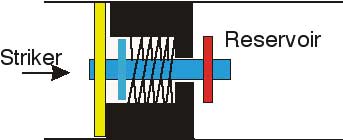

When the gun fires, a weight called a striker or hammer is driven forward by spring pressure. It strikes the end of the valve stem (blue), driving it forward. When it goes, it takes the valve with it, opening small air passages around the valve stem that allow the pressurized air to escape.

What is “valve lock”?

Because the air in the reservoir exerts force on the valve, holding it closed, the higher the pressure, the more force it exerts. That force is balanced against the size of the valve, the weight of the striker and the strength of the striker spring. There’s a range of reservoir pressure in which the valve remains open long enough to pass the same amount of air, despite the fact that the air pressure inside the reservoir declines with every shot. When the air pressure is at the high end of the range, the valve remains open for a shorter time, but the higher pressure forces more air through the valve. When the air pressure drops, the valve remains open longer, allowing a greater length of time for air at lower pressure to flow through the valve. The same volume of air flows through the valve in both circumstances.

The result for a precharged pneumatic that gets many shots per charge is that even though the air pressure is dropping, the velocity remains more or less constant throughout this pressure range. For a multi-pump pneumatic, the pressure range doesn’t mean as much, except when the pressure goes too high. Then the valve cannot remain open long enough to exhaust all the air in the gun and there will still be air remaining for a second shot. Also, the shot the gun fires will be slower than normal, because less air is behind it.

The velocity will drop for both precharged pneumatics and multi-pumps when the air pressure goes above the range for which the valve was designed. The reason should be obvious – the valve closes before all the air needed for the shot can get out. This marks the beginning of valve lock. If the air pressure goes too high, the combined force of the striker and its spring will not be able to open the valve at all and there will be no shot. Now the gun is locked down by its own air pressure. The only remedy is to remove some of the pressure to drop the internal pressure down to a level at which the valve can open. Continued firing will drop the air pressure back down into the optimum operating range.

The performance curve

For this reason, using a chronograph with a precharged pneumatic allows the shooter to discover the exact pressure at which the valve operates best. And this decision can be left up to the shooter. If he wants more shots, he accepts a lower initial velocity (that comes from a higher initial pressure) and allows the rifle to climb in velocity, then fall back down to his established parameter. If he wants his shots to be as close in velocity as possible, he starts at a lower air pressure that gives him an initial velocity higher and closer to the highest velocity of which the rifle is capable. This is called the performance curve, and every non-regulated pneumatic rifle and pistol has it.

Some airguns, most notably those of Korean manufacture, are designed with sheer power in mind. Their valves are set to open at very high pressures, very close to valve lock. These guns will lock up if over-pressurized just a little, and they tend to have a steadily declining velocity instead of the curve described above. They can be modified to give longer strings of consistent shots, but the velocity at which they do it has to drop. So, a .22-caliber Career 707 might give the first five shots with .22-caliber Crosman Premiers that look like this:

1,175

1,160

1,139

1,107

1,075

If the rifle were tuned for more shots, the same first five Premiers might look like this:

930

945

939

936

941

This is what makes the AirForce Condor so remarkable. Not only does it deliver smashing power in the 60+ foot-pound range – it does so for the first 10 shots. And, if you’ll accept a velocity loss of 75 f.p.s., the first 20 shots are usable. No other smallbore air rifle has that kind of performance curve.

The Benjamin Discovery, which needs only 2,000 psi air to get identical performance to other rifles shooting with 3,000 psi, teaches us that air pressure, alone, doesn’t make velocity. The timing of the valve has far more to do with it than what’s inside the reservoir.

Those are the basics of pneumatic valves. They govern the gun’s performance, and they dictate the parameters under which the air pressure must be managed.

Mornin’ B.B.,

Nice report. I was wondering. How many guns do you own. And about how many do you have on loan to test at one time? It seemas to me like youd have a house full of guns, because i know you own a few, and your constantly testing a few. And one more quick question. Do you know anything about crosmans new PCP there coming out with?

Thanks,

Brody

The other amazing thing about the Air Force Condor is it’s accuracy. See Paul Capello’s video review of the CO2 version. Air Force has a winner.

Nice article as alway, B.B. But it makes me ask more questions:

I heard that on precision precharged guns there are pressure regulators. So do those guns still use the kind of valves you described? (Presumably the reservoir in your illustration will be regulated and have a fairly constant pressure over a wide range of air pressure in the cylinder.) Also, do you know how those regulators work?

I believe my IZH-46M has a different type of valve as seen here (http://www.pilkguns.com/tenp/spizh46.htm). There is no hammer, only a couple sears. When the trigger is pressed, the valve sear releases the valve, and the valve opens under spring force and air pressure to let all the air out at once. So, the performance curve is not an issue for the IZH, neither is valve-lock. Is my understanding correct? Is this kind of mechanism typical for most (all) single-stroke pneumatic guns?

Thanks.

Nick

Brody,

I own about 100 airguns and have about 50 on loan at any time.

Crosman hasn’t told me anything about their new gun, but I believe it will be a shrouded repeater with adjustable power.

B.B.

Nick,

Yes, regulated guns use the same kind of valves described here.

I have done a report on regulators:

/blog/2007/12/how-does-an-air-pressure-regulator-work/

Not all “precision” PCPs use regs. The USFT that won the World Championships last year doesn’t. Regs break down, so makers avoid them when possible.

A single-stroke pneumatic is different than a multi-pump. The performance curve isn’t an issue because the gun uses all the air it has. Same for most multi-pumps made today.

B.B.

B.B.

Roanoke Airgun Expo –

I spoke to Fred Liady last night and he said the 18th Annual International Aigun Exposition in Roanoke VA will be

October 24 and 25 (Fri and Sat).

He emailed me a flyer with the particulars.

Hope to see you there,

Lloyd

WOW,

B.B., you have more guns, than i will ever dream of having. If you had to pick yur all time favorite gun for anything what would it be? My gun has to be my 880, because i can take it out hunting wth me, or i can enjoy an afternoon of plinking. You should do a blog about that, you favorite guns of all time, and people could chime in about theres.

Thanks,

Brody

Lloyd,

Thanks for that update.

B.B.

Brody,

Though I wrote a book about the R1, my favorite air rifle is probably the Diana 27. But I don’t get to shoot it that often.

My “go-to” guns are as Blue Streak and a Talon SS.

I know a lot of people love the 880. Maybe I will do one, though I’ve done the Remongton AirMaster 77 and the 22SG that seem quite similar.

B.B.

B.B.

BB,

Where can I find This report on the Remington 77? The 880 is nothing special, you get what you pay for (I think the 760 beats it hand down). I’ve past that 1000 round marker and I just realized I need to oil my gun. I have a tube of crosman chamber oil. How many drops? Also, how do you oil the spring, I have an unopened bottle of RWS spring cylender oil. It is combustable.

Thanks, Shadow express dude

B.B.,

I meant a blog, on your favorite gun, but that would be good too. Have you done a report on the 953 target pro?

Thanks,

Brody

Shadow express dude ,

Three or four drops should do it. I am confused about the spring, though. The 880 has no mainspring.

Here is the AirMaster 77 report:

/blog/2005/12/remington-airmaster-77-just-right-for-christmas/

You can find old reports by searching for them with the search function on the current page of the blog.

B.B.

Brody,

I have reported on the Diana 27. Look here:

/blog/2005/11/diana-27-a-golden-oldie/

I haven’t tested the 953 yet.

B.B.

B.B.

Very interesting. Does the cheap and easy to use pump that comes with the Discovery work on other PCPs too like the S200 or the S410? Great news about the new Crosman PCP; those are just the features I’m looking for.

Matt61

BB,

I was talking about my shadow express. My 880 shoots an inch grouping at 12 yards. I bought mine used. The pellet clip design on the 760 is much better but the accuracy is about the same. The 880 is a bit easier to pump and seems to have a bit more power. Mine is an older model (metal trigger) that has a 6lbs trigger that has a very crisp single stage.

Shadow express dude

Matt61,

With the right adapters the Discovery hand pump works for all PCPs – the same as every other pump.

B.B.

B.B. & All

I just ran a crony test on my S410 .177 10 shot repeater..

I filled to 195 bar, about 3,000 lbs. and ran it down to just under 50 bar with JBS exact and Beeman Kodiak extra heavy….on the first 30 shots with the kodiak the high was 1027 the low 1006 – avg 1014. the bar at 160 now. The next 30 avg was 952 with the bar at 120..then the last 30 avg. 805 ending the bar at 60, I said I would go to 50 bar so I shot 15 more ending at 731fps.

The JBS exact starting at 195 bar were 1081fps with a high of 1092 and avg 1074 on the first 30 shots. They were about the same progression with the 95th shot registering 755fps at just under 50 bar on the guns gauge.

Both the JBS and Kodiaks are very accurate, but now I think the Kodiaks are best for the gun, might as well shoot the heavier pellet since it's so close on fps. to the JBS, don't you think?

I have been shooting at targets down to 50 bar as well. I've got my 6-24×50 leapers set for 50yrds so I have to start aiming high after 40 or 50 shots.

I get my best groups sometimes at 60 or 70 bar, although I'm aiming one mil dot high at the 50 yrds, and at 50 bar 1.5 mil dots high.

Will any other gun give so many shots at that fps?

I also think that there is no valve lock, the fps just keep going down pretty steady and even…so that means no valve lock right? I don't have to change my aim point until after 40 or 50 shots and then only a little high.

Wayne,

Ashland Air Rifle Range & Rentals

Wayne,

Valve lock occurs ABOVE the standard fill pressure. Fill the gun to 230 bar and see what it does. Your Kodiaks will be coming out in the 500s somewhere I bet.

As for your lengthy “string” many shooters would not accept anything past the first 30 shots. They like to keep the groups all small, consistent and hitting in the same place. Remember, these guys want a half-inch or less and always at the same place.

I had a Career 707 that was tuned to 30 foot-pounds with a regulator. It came off the reg at around the 40th shot, but I started adjusting the power wheel after than and got 100 good shots very similar to how you have done it.

If you only shoot one gun you can learn its operation to a very fine degree and do things that other shooters find impossible.

B.B.

B.B.

If I use the bench rest, I can get the 1/2″ groups at 50 yrds for 50 shots without loss of POI. starting at the 190 bar. I can’t get to 230 bar with my scuba tanks, 200 bar is tops until I get the carbon tank. But I guess I won’t want to if that is where the valve lock would happen.

The longer I own this S410 the more I like it….

Wayne,

Welp, after a year of searching my bookstores for airsoft magazines, and getting nothing but small references to it in paintball magazines, yesterday at Borders Books yielded Airsoft International magazine. I was plenty excited until I realized it was from England, and concentrated, for my tastes, too much on battles. I doubt that England will ever tire of kicking German butt (there was an article on Waffen SS Infantry).

It did have a nice article on my WE 1911A1 GBB pistol, although I thought their grading system was a bit harsh. But hey, the WE is my first GBB, and I may be overly touchy.

I know from looking online that there are Japanese airsoft magazines. They look complicated though. It was nice to find something in English language. [I do need a "pounds sterling to US dollars" converter though!]

I was struck by the complete absence of orange tip markers on the British guns. They look so much better than ours. BB, or anyone, can you give me a good reason why the US requires the orange tips on our guns when it doesn't on BB & pellet airguns? This seems so useless to me. A bank robber could easily glue the orange circle on a real gun. If confronted with a kid with a gun, I'd still hesitate to shoot, no matter what the tip of the gun was wearing.

–Joe B, perplexed on Maui

Joe B,

Federal law requires that toy guns or imitations to have an orange tip.

I guess airsoft guns are considered “toy guns” or “imitations”. BB guns and pellet guns are not toy guns or imitations.

Joe,

B.,

The orange tip or orange slide marking is a concession the government made in the 1980s when it was trying to outlaw airsoft guns altogether.

Airsoft guns are made for people to shoot at one another. Argue that if you like – that is one big use for them. BB guns and pellet guns are never meant to be shot at people.

So the use of the gun, shooting at people, is what made the legislators anxious. I believe they are right to be concerned, but I think their solution is poor. Mandatory firearms safety training would be a better approach, then making people responsible for their actions if they screw up. But that debate will never end.

At any rate, the orange tip is just the start. Airsoft guns are not allowed to be carried open in many communities. And they may not be used in other than sanctioned areas.

The risk is not to you or me, Joe. It’s to the rookie inner-city cop who has a kid draw down on him and returns fire with effect. Everyone expects you and I to hold our fire, because we shouldn’t be in threatening situations most of the time, anyway. But irresponsible young adults a reckless kids do things from which there is no second chance.

By the way – you think airsoft is the only one in this mess? Guess again! Umarex guns have been used in crimes, and return lethal fire was justified. In fact, a common suicide in big cities is to pull a lookalike airgun on a cop.

B.B.

As a failed writer I envy your ability, BB.

Thanks for the article. SO much of what I have read is so poorly written that I bring very little away from it. I strongly suggest that those interested in regulated airguns read the article referenced above.

This stuff is not so intuitive to me and these peices are very valuable.

I read some tuning articles in the very fine Airgun Hobby mag and finish knowing less than when I started…

Bruce,

That’s what got me started as a writer – articles I couldn’t understand, written about subjects I did understand.

My first article was written freelance for Robert Beeman about what I discovered when shooting my Beeman C1 carbine. I discovered that a light hold – not the heavy hold described in his catalog, was what the gun needed to shoot.

Beeman never published that article, but I did – in my R1 book! I called it the artillery hold.

Beeman was a good sport and wrote a chapter about the R1’s history for me. We’ve been friends ever since.

Frustration is often the greatest motivator of all.

B.B.

BB and all,

Following is just my opinion.

I assume that there must be a place for air guns (airsoft or pellet) that look like ‘real’ guns. I perfer purpose built air guns and have no desire for replica guns.

If I want a gun that looks like a firearm I’ll use a firearm. I have both pellet and ‘real’ guns and find them to be quite different hobbies.

My only point is for folks who like replica guns to be extremely carefull. My several friends and a couple of relatives in law enforcement hate replica guns for the dangers they carry when used by those who do not know the risks.

Please, if you have replica guns be extremely careful how and when you use them.

Al Pellet

BB ,

Can I ask you to do a similar article on a more specific part of a PCP …. the valve … ?

Tophat, valve stem, return spring etc. etc. … effects of changing their dimensions to tailor airflow (more/less) … hammer weight, hammer spring …. you get the picture?

Thanks

RT

Probably a rhetorical question, but has anyone ever employed a “slider” valve in an air rifle? This particular design would eliminate valve lock, but MIGHT be a bit maintenance intensive if not built correctly. Anyway, if I’ve thought of it, then someone’s done it and/or found it useful or lacking. Let me know what you know about it though. JP

Many thanks B.B. I really appreciate your attention.

Manish

RT,

That WAS a pcp valve! A tophat only exists on an AirForce valve, as far as I know.

The information you asked for – spring strength, valve stem diameter, hammer weight etc. – are all tied to one another. Change one thing and you have to change the others (usually) to make the thing work. So it would make no sense if I were to give you that information. It’s like saying Exodus is a great book. On page 410, it says “Then…”

The spring rate of a standard AirForce valve return spring is adjusted to 17-17.5 pounds. But it can be adjusted from a low below 10 pounds to a high above 20.

B.B.

JP,

Slider valves have been used in CO2 guns, I’m pretty sure. And a Crosman 130/140/1400 valve is a blow-off type, where the sear holds the valve closed. But I can’t think of any pneumatics that have used a trumpet-type slider valve. Probably the air sealing is too poor.

B.B.

What oil/lube should i use on a chinese made Sharp Innova and what part’s should i oil/lube. Thanks

MattNZ,

Use Pellgunoil if you can get it. If not, use a silicone chamber oil.

Oil the pump head, as shown in this blog:

/blog/2008/09/what-to-oil-part-1-a-guide-to-sealing-pneumatics-and-co2-guns/

B.B.

BB,

Thanks a lot mate.

“Great blog”, hugh source of info.

cheers,

Matt (New Zealand)