by B.B. Pelletier

Guest blogger

This is the second installment of Vince’s guest blog about the fabulous German Rekord trigger and the Chinese copy of it. If you’d like to write a guest post for this blog, please email me.

Bloggers must be proficient in the simple html that Blogger software uses, know how to take clear photos and size them for the internet (if their post requires them) and they must use proper English. We will edit each submission, but we won’t work on any submission that contains gross misspellings and/or grammatical errors.

Now, on to our guest blog!

by Vince

Machining

As expected, the stamping and machining is cleaner on the German original; but where there’s a sliding interface between two surfaces, the parts on the Chinese gun are smooth. Since my B20 is a fairly high-mileage gun, I think it’s safe to say that these areas were worn smooth rather than delivered that way from the factory. The German-made trigger also exhibits this same effect, although the smoother factory surfaces make it less obvious.

Rough-from-the-factory sliding surfaces translates into greater friction, which translates into greater trigger effort. But the only sliding surfaces that could affect trigger-pull are the interfaces between lever 4 (the trigger) and lever 3a, and between 3b and lever 2 (refer back to the first image in part 1).

Since the design of the trigger and the four levers works to reduce the sliding friction that the trigger blade feels, it turns out that those surfaces are lightly loaded. And where there’s little load, there will be relatively little friction. So, while the feel of a new BAM trigger tends to improve as the parts wear in, the improvement might not be as pronounced as it would on a cruder design. The two-lever affair (found on the old BSA Meteor and the Shanghai B3/B4 rifles) or the three-lever arangement (used in the Gamos, the Crosman Quest variants and the Remington Genesis) probably have more to gain through the break-in period than the B20/B26 trigger.

While the machining of individual parts in the BAM trigger group is not as good as it is on the much-more-expensive Rekord, any disadvantage here will likely be minimal and eventually go away. Of course, the tinkerer can always help matters along by disassembling the trigger and working those areas himself. Again, there might not be as much to gain as on some other guns.

Geometry

The third thing that needs to be compared between these two mechanisms is the exact geometry between the parts. Are the pivots located in the same relative positions, and are the lever moment arms the same length? This can be critical, as subtle changes in geometry can translate into significant changes in behavior.

To evaluate the geometry of levers 1 through 3, I measured the relative position of the pivots for those levers. Since the levers are almost identical to their Rekord counterparts, this should help complete the picture.

Without going into all the details, I can say that the pivots for levers 1 and 2 are in the same relative locations to each other. But there’s a difference in the pivots for 3 and 4. On the BAM unit, both pivots are closer to the front of the trigger by about .020″, which is a bit more than one would expect just from production tolerances. But the distance between the pivots, which is the more important dimension, remains about the same.

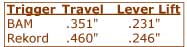

While I was playing around with the partially disassembled trigger units, I noticed that the seocond stage on the BAM assembly seemed to lift levers 3a/3b a lot quicker than on the Rekord. To confirm my suspicions, I measured total trigger travel (measured at the tip of the trigger lever) and compared it to the total lift imparted to lever 3a (measured at the forward engagement adjusting screw):

The lift/stroke ratio on the BAM trigger turns out to be .66, on the Rekord the same value works out to .53. So the BAM trigger is lifting the lever about 25% faster than the Rekord, which means it has less mechanical advantage and therefore is going to take more effort. That 25% is an average of both the first and second stages. Since the first stage seemed about the same, the percent increase in just the second stage is going to be even greater than that.

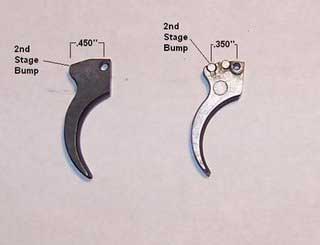

This led me to believe that the trigger profiles (where the triggers meet lever 3a) must be different. Unfortunately, this was one thing I couldn’t observe with the triggers still installed. Despite my earlier resolution not to undo any factory peening, I drifted out the trigger pins and pulled out the blades.

When compared side by side, it becomes obvious why they lifted at different rates (Chinese on the left, German on the right).

The nubs on the Rekord trigger for the first and second stages consist of steel pins set into the aluminum trigger blade, but on the BAM gun the nubs are part of the steel trigger. The first-stage nub is located in approximately the same position on both trigger blades, but notice how the second-stage bump on the BAM trigger is further away from the trigger pivot pin. It lifts faster but loses mechanical advantage, and that’s where the trade-off of greater trigger weight comes in. This situation is exacerbated because that second-stage bump then contacts lever 3a closer to its pivot pin, which further increases the lift rate and thus the pull weight.

This trigger profile seems to be THE culprit in making the BAM trigger operation inferior to the Rekord. Why the trigger was designed like this is anyone’s guess, and I’m not even gonna go there because, frankly, my dear, I don’t give a damn. I just want my trigger improved.

At this point, the rest is easy. How easy? About 5 minutes with a Dremel tool, and that’s because I didn’t feel like going out to my workshop to use the bench grinder (which would have done it in about a minute). I cut back the rear of the trigger to give me a new second-stage bump in pretty much the same place as the Rekord trigger.

About 5 minutes with a Dremel too, and my Chinese Rekord trigger looks like the German version.

Back together with the BAM trigger group to evaluate the results. I didn’t bother measuring the new lift-to-stroke’ratio because, well, I simply forgot! Besides, the proof’s in the pudding, as they say, and I wanted to try out that trigger. I was anxious to find out if the feel improved as much as I hoped it would and if the trigger would still fire the gun. Now that I got the mechanical advantage I wanted, the trigger has to move more. It was possible that the trigger would run out of travel before tripping the sear. But I didn’t think this should be a problem, and as it turns out…

I was right!

The trigger works great, and the difference in feel between the BAM trigger and the real Rekord has largely evaporated. The B20’s trigger has an ever-so-slightly softer transition into the second stage, probably because I should have dished the top of the trigger between the first- and second-stage nubs. And it’s still just a smidgen heavier in the second stage than the Rekord when set to the same first-stage tension (about 4 oz. or so). Realistically one can hardly feel the difference, but it did have me wondering until I remembered the stiffer trigger spring in the BAM unit. That’s probably the reason for it. No matter, as I said the difference is minimal. Realistically speaking, the B20’s trigger is pretty much as good as I’d want it.

As a side note, I’m going to mention a trigger issue I’ve seen on the BAM B26 model, which is supposed to be the improved and better-built version of the B20. And from BB’s latest test of that gun, I suspect that his gun suffered from the same problem. In both these guns, there was no discernable second stage in the trigger. Since the stock BAM geometry produces a rather drastic increase in pull-weight when the second stage is reached, this seems rather odd. As it turns out there WAS no second stage in the gun I was shooting, and for a very simple and fixable reason.

If you look at the diagram of the trigger mechanism (refer back to part 1), you’ll notice that there’s a metal tab sticking down that functions as a forward stop for the trigger (lever 4). Now, imagine what happens to the trigger blade if that tab is located further to the rear. The trigger starts moving through the first stage; if the tab is back far enough, the trigger is completely through the first stage and starting on the second. Well, that’s exactly what happened on my B26. Maufacturing tolerances, I guess, had that tab too far to the rear. A little grinding or bending (I don’t remember which I did) allowed the trigger blade to come forward more. Voila! My first stage was back.

There you have it. Did BAM really copy the Rekord trigger? The answer has to be a qualified yes. They did a fair job of it; and with a little massaging, you should be able to just about replicate a real Rekord’s excellent characteristics. Why on earth did BAM make it a little different? Who knows! Seems strange that they would come so close and then stop just short of delivering a very good airgun trigger. Fortunately, it isn’t that hard for the owner to take it the rest of the way.

There you go. Machine some blades and sell them.

I think you should get all your measurements exact and have a batch of these made. You could easily sell them at a very nice profit. Plus, if you don’t, someone else will. Excellent posts btw.

There’s a few reasons I’m not sure it’s practical to sell these:

1) In all probability the B26 trigger has all the same dimensions and the same issues, but since I don’t have one in front of me at the moment I can’t say for sure.

2) These triggers can suffer from other problems such as that front stop being out of position. Just popping in a new trigger blade ain’t gonna make that problem go away, but it might lead to dissatisfied customers who wonder why their triggers still don’t work right.

3) The trigger is peened in place, so you can’t make it a super-easy ‘pop-in/pop-out’ like the GRT. If an owner is willing to go so far as knocking out the peened trigger pin, he/she is also probably willing to spend a minute on a grinder to do it himself/herself.

I’m wondering if it’s possible to do an exchange service, though – a shooter orders a modified BAM trigger, and when he does the swap he sends his old one back in exchange. The entire trigger group itself is real easy to change.

Vince,

Wonderful articles, even though I’m not mechanically gifted enough to do such work.

Herb

Wos. says, “Why on earth did bam make it a little bit different?” Answer – ever hear of patents? Duh.

Wos.

Vince, thank you for both sharing your cure,and for helping others understand the process.that is truly the spirit of mentoring that makes this blog great!I’m certain BB is proud of you!{it’s no secret Wayne is}Kudos,FrankB

Vince,

Nice, thorough article. I think we both have the same affliction of having to make it better just because we can.

I’ve always found that sloppy fitting pins can throw major variability into multilink setups. Any major difference in pin and hole clearances between the original and the copy?

You said the Chinese trigger blade was steel. Could you tell if it might have been powdered metal, or stamped, or machined?

Thanks,

Lloyd

Wos, I don’t know enough about patent law to comment conclusively, but I believe that German patents are only in force for 20 years… and I believe the Rekord trigger is well older than that.

In any event, I don’t know if fudging a few dimensions here and there would have been enough to avoid an issue with patent infringement. The construction and operation of the trigger is obviously such a blatant copy of the Rekord that I can’t imagine that a relocated trigger bump would have given them much legal cover.

Wos.

Patent rights on the original Rekord design have expired. Patents for improvements on it may still be active. Also, actual dimensions are almost NEVER part of a patent’s claims so it is doubtful a dimensional change in the geometry would avoid an infringement situation. You would have to read and understand the patent claims to know.

Lloyd

Everyone,

Yes, B.B. is proud of Vince. He knocked this one out of the park!

B.B.

B.B,

Welcome back! It’s always good to be back home but you must be exhausted and on overload!

I agree with your comment about Vince. Getting to the root of the problem and finding a simple fix is personally rewarding, especially when you can share it with others.

Lloyd

Vince,

Fantastic job. Considering caliper measurements for the article, photo’s that were necessary so we could follow your progress, graphic manipulation, graphic re-manipulation (thanks for the replacement graphic in part 1) and writing a two part article, that was a enormous contribution of your time for all our benefit. At the end, you’ve given away one of your tuning secrets for free. A hearty Thank You doesn’t seem like enough.

Unfortunately, I’ve spent too much money on airguns recently so that’s all I can afford to give.

THANK YOU.

Reason #1,014 that this is the best airgun information source in the world. Unselfish sharing.

kevin

BB, thanks for the compliment but in retrospect there’s some weaknesses in the article.

First, I didn’t evaluate pin-to-hole clearances as Lloyd suggested… and he’s right, that can make a significant difference in the feel of a trigger mechanism.

Second, I never should have closed the article with ‘trigger finger’ impressions… I spent a fair bit of time tearing into these two mechanisms, so of COURSE I’m going to think that it feels so much better. When I was into road racing and car stuff, my buddies used to fall into that trap so many times – “I worked on it, so it’s GOTTA feel better!” – but the stopwatch never lies. I think I’m gonna get me a better trigger scale (I’ve got a crappy one) and try to better quantify trigger travel vs. effort rather than just say ‘it feels better!’

Third, I should have knocked out that remaining pin and taken a look at levers 3a and 3b.

Rest assured that barring anything unforeseen I’ll be tending to these issues and coming out with an addendum. Sorry for missing these things – I certainly know better than that. Just got lazy, I guess…

Vince,

You have the makings of a truly gifted airgun tuner. Mechanical background. You derive pleasure by making things better when possible and the common sense to ferret out what can be improved. Considering these enviable traits you obviously possess I believe that you must also have a sense of “feel” as well.

Appreciate you pointing out your perceived “weaknesses” in the article because you “Just got lazy”.

You’re fired.

Now go shoot and have some fun.

kevin

Kevin,

Well said!!

Vince, your too critical of yourself!!

The master was right, “You knocked it out of the park”

Bases loaded Home run!!

Very well written!!

Thanks for sharing your knowledge base with us…

Wayne,

Ashalnd Air Rifle Range

Vince !?!

RE: Just got lazy, I guess…

I think NOT!

The experiment is never finished. There will always be something else with which you can tinker.

I am absolutely awed by what you accomplished.

Herb

Addendum #1:

Levers 3a and 3b are virtually identical in profile and dimensions. 3a is formed from a stamping on the Rekord, and it is machined (albeit a bit roughly) from a solid block on the BAM.

I’ll take pictures if I can FIND MY CARMERA (sigh)…

Vince,

Why you LAZY BOY! What’s the matter with you, that you can’t give us a few simple dimensions like that? I’m beginning to think you are not worth all we are paying you.

Seriously — I understand completely the work you did to give us that report.

Don’t burn out!

B.B.

DB,

Re: Your search for a pellet mold

I seem to remember awhile back you were looking for a pellet mold to recycle your pellet trap refuse. I think B.B. said that there used to be pellet molds in europe but they were for solid pellets and never caught on.

Here's a link to a guy selling hand made pellets (spitzers) that look hollow. He may give you some insight for acquiring a pellet mold. His phone number and email address is at the top:

http://www.airguns.net/classifieds/show_ad.php?adNum=5016&adSort=&StartingAd=0&NumberOfPages=3

kevin

Vince,

Great blog today. Just out of curiosity, what else did you modify on the bam26 and 30? I was looking at buying the 26-2 and wondering how much damage control I needed. Were your experiences with the 26 any good? do you think it’s worth upgrading from a tuned Quest1000?

Shadow express dude

Vince,

Very interesting. Nice job. I know lazy, and that is not it. If I read right, you have a mechanical machining background from working with autos? That seems a common thread in many of the tuners. I’m sure your abilities and attention to detail far exceed what many of us not gifted in those fields boast. I assume that people without your skills will take caution before grinding away at any triggers.

Vince,

Since your such a Lazy Boy, maybe you want my “Wazyboy” recliner as part trade for all the work you’ve done on my air rifles.. If I try real hard, and took it apart, I could fit it in the box we have been sending the rifles back and forth in…

My wife would have you talking to your inner child about past experiences when you were never good enough!!

Wacky Wayne

Shadow express dude,

Hope you don’t mind me throwing in my two cents about the bam b 26. Based on many comments that I read, I passed on the bam b 26-2 primarily because of the very high comb on the stock. Everyone on the chinese forum (even B.B. in his review on this site) complained about how tough it was to get a sight picture. Most of what you read about the 26-2 on the chinese forum is about what modifications people had to make to their stocks to make the gun comfortable to shoot.

I bought two new, newly tuned b 26’s in .22 caliber several weeks ago as gifts for twin boys. Spent about two hours with both guns. Put mounts on them, scopes and shot about 50 pellets through them to sight the scopes and stop the dieseling.

I was very impressed with these guns. The tune I had done was by someone very knowledgable about this model with lots of experience. Undoubtedly, not on par with Vince but the tune was very nice. He did some trigger work and although the trigger’s weren’t as nice as the rekord in my R 7 I was impressed. Both guns shot around 641-644 fps (at my mile high elevation in Colorado) using rws superdomes which were amazingly accurate.

kevin

Wayne,

Time to be honest.

From what I read, I could park my truck in the box you’ve used to ship all those guns to Vince. Your lazy boy chair should fit easily.

kevin

Vince,

My B20’s trigger feels much much better. I filed the trigger to the point where it mimiced the silohuette of yours. I then de-burred it, and then polished it. Man, the diagram helped me me with reassembly alot. The 1st to 2nd stage transition is very smooth. I’m very impressed by your work Vince.

BB,

As posted before, I was considering a bam b26-2. But on second thought, maybe I should just get a gas spring for the quest1000. Do you NEED a gunsmith, this is a big issue for me as I don’t want to ship it and there are no air rifle smiths (are they, too called gunsmiths) in my area.

shadow express dude

Just got finished goin’ round with the trigger again, and I’m hoping that BB will let me put up a part 3. Still gotta get a good trigger pull scale, but I think I can now honestly tie up the loose ends. Oh, and I modified the trigger profile and it feels even better!!! But I’m still gonna check it with a gage…

Vince,

Once again, great job. Now that you’ve shown us, it seems like very little work to get a classy trigger. How does the first stage takeup feel, i.e. is there significant effort? And does the second stage break sharply or is there any creep? I’m not as sensitive to weight as some, but I don’t like to feel effort over a great distance, if that makes sense.

Kevin,

Honest…. what is that.. did you spell it write?

Wacky Wayne

Vince,

Thanks for the great post today and all the info off blog as well. I’m going to re-visit my B26-2’s trigger as well. I want that last 15% or so difference compared to the Rekords in my other guns.

Can you give us a guess in hours as to how long it took you to put the 2 blogs all together?

Derrick

b.b. a quick question to you or anyone.

'Competitive Shooting' by A.A. Yur'Yev…is it worth the 70bucks?

I've found some on the 'net who claim it's the 'bible', but these are all rimfire shooters…I imagine it would translate to air.

I've realized that becoming a decent pistol shooter is going to require some 'training'. I've picked up some weights (2&4 lbs) and have started some excercises described on an Olympic shooting site.

I find that, firstly, whoever coined the term 'Compact' for the Gamo was really stretching the term. After being on target anymore than a couple of seconds the front sight gives a fairly good impression of St. Vitas Dance, so I'm hoping doing some arm strengthing routines will help that.

CowBoyStar Dad

BG_Farmer, in both the Rekord and the BAM copy the ‘engagement adjustment’ screw can be used to take out some of the total trip-lever engagement. The amount of engagement taken up by the first stage is pretty much fixed, as you lessen the total engagement with that screw there’s less for the 2nd stage to take out. If you want, you can screw that trigger in to the point where the 2nd stage is right on the ‘razor’s edge’ and will go off with virtually no discernible creep. That’s cutting it a little too close for me – so I always leave a little creep in.

The overall trigger effort is determined by the tension adjusting screw, and can be set very light.

BTW – there’s another error in the diagram, I found it when I was going through the triggers again. I’ll send a correction to Edith, and if BB lets me do a third part I’ll explain how I made that boo-boo.

SED, the Quest is one of my favorite guns in terms of feel, weight, and power. And it’s easy to work on. The BAM B26 is more sophisticated, more complicated (because of that trigger) and heavier by about a pound. But as far as power goes, the Quest should be able to beat it since it has a larger powerplant.

And accuracy? Both barrels come out of the same factory. The lockup mechanism on the B26 is easier to keep tight, the Quest can be problematic in this area. So the B26, out-of-box, might tend to be more accurate. But if the Quest has been properly sorted out, my personal preference might be for the Crosman.

SED,

You don’t NEED a gunsmith if you are handy. If you can disassemble a springer, you should be able to install the gas spring.

Of course Pyramyd AIR is there if you need them.

B.B.

Vince,

Consider yourself pre-approved for parts 3 through 97.

B.B.

CowboyStarDad,.

I flat don’t know. This is a book I’m not familiar with.

Sorry,

B.B.

Finally got a chance to watch “Quigley Down Under” (caught it on TiVo, which turned out to be very helpful); fun movie. Unfortunately it only inflamed my obsession with the bucket shot. Anyone who wants to try to shoot like Quigley can try to wade through my tedious current draft/notes/formulation of scaling the feat to air rifle proportions. Feedback welcomed, especially criticisms and corrections.

I know there are already attempts out there, but they seem a bit indulgent to the shooter. I saw one writer proudly trumpet his Quigley-like prowess for hitting a 1.5″ field target hole at 50 yards, using an aperture sight, but, presumably (as pictured), seated in field target position. Wow! My old grandpappy could and did make the same shot offhand with an open-sighted Iver Johnson single shot he got in the teens or so (I don’t think it even accepted LR), and my 80 dollar chinese air rifle with fancy groove-mounted Mendoza aperture can do it from time to time, so I don’t think that its Matthew Quigley class shooting. Let’s see.

In online references to the bucket scene, I’ve seen distances from 500 to 900 yards. The one estimate I found on the size of the bucket is 17″, which I assume is the diameter of the upper rim. I will do little with regard to the size of the bucket, since that seems to be a reasonable estimate, except cut it down to 16″ just to be safe and also to account for the effect of the bucket’s taper on the angle subtended.

The real question is “how far away is the bucket?”. When I first saw the scene, my impression was 900 yards, but I know from previous experience to always subtract something from my initial estimate(of course, its also a film and the camera is tricky). It then occurred to me that there is a rather interesting alternative way to calculate and correlate that distance, namely by determining how long the horse (whose rider is carrying the bucket) is running and multiplying that by his velocity.

Timing the horse resulted in an estimate of 52 seconds, which I will round to 50 seconds, to account for uncertainty in the starting position of the horse and other variables (e.g., the horse does not get up to speed instantaneously). The horse shown is little more than a pony and the rider of average size, but I will grant him the average speed of Secratariat’s record in the Kentucky Derby (1.25 miles in 119.4 seconds), which I feel is more than generous. So, if he galloped for 50 seconds at 55.3 ft/s, he went 2765 ft. or 922 yards. We’ll round to 925 and take it as an upper limit. The angle subtended by the bucket at that distance is: 16/(9.25*1.047) or about 1.65moa. Keep in mind that the figures used to arrive at here are all pretty safe maxima. The likelihood of that horse carrying a full-grown man being as fast as Secretariat carrying a jockey is rather slim.

So, although I think the 500 yard estimate that I’ve seen online is too short, the bucket is almost certainly a good bit closer than 925 yards and may thus subtend a more substantial angle. Luckily, we not only hear the report of the rifle, we see the impact of the bullet on all three shots. By my timing, the three shots all get to the bucket in a bit less than 2 seconds.

This brings me to an examination of the .45-110 cartridge used in Quigley’s modified Sharps rifle. I do not have a general ballistics calculator or the data for the — no doubt special — 110/540 load used by Matthew Quigley, but I do have (thanks to Chuck Hawks) a likely initial velocity for the 550 gr. .45-110 buffalo cartridge: 1360 fps.

The best solution I have readily at hand is to find a modern approximation, which I believe I have in the current Remington .45-70 420 gr. soft point, for which the ballistics report is readily available. Its mv is 1330 and it will lose velocity a bit more quickly due to reduced weight, but I would be willing to bet its overall trajectory is probably not that far off. The .45-110 (along with the .45 -100 and other variants) is, after all, a version of the .45-70 with a longer case so that they could stuff in more black powder.

Given all that, a two second time of flight yields a distance around 650 yards, which we will take for the lower limit. At 650 yards, the angle subtended by the bucket is 16/(6.5*1.047) or almost 2.4moa.

Serious shooters in those days were probably more than capable of 2MOA shots offhand at ranges with which they were familiar (much shorter than the ones being discussed here). The often repeated rule of one inch at 50 yards tends to confirm this; remember these are shots offhand and with iron sights, usually open. Quigley is a professional long-range marksman, so we can reasonably assume that he is better than above average with his Creedmoor-style tang mounted vernier sight and long barrel (higher velocity and longer sight radius). In that light, the apparent target size minumum of 1.65MOA is not too crazy and the more likely 2.40MOA seems almost easy.

However, the distance adds the complications of wind and trajectory. I will dismiss trajectory, because the sights could be easily calibrated for any distance up to 1200 yards according to Quigley himself, although the drop, as we shall see, is not insginificant. The same sights are also capable of somewhat less precise adjustment for windage. It looks like a steady 5+ mph crosswind to me, but I don’t know what Quigley doped. Again, as a professional, Quigley should have this aspect well in hand, but it will not be negligible.

As for the fact that he, his rifle and sights have just spent months on a ship (BB himself raised this objection), we can assume there’s been time (not depicted in the film) for inspection and practice on the trip to the Marston Ranch, as he might well expect to be asked to prove his merit to his potential employer. We will return to trajectory and wind shortly for purposes of accuracy in re-creating the scene in miniature. For now, let’s give Matthew Quigley the benefit of a doubt and posit that the shot is in the realm of possibility.

If we consider only the angular dimensions of the target and place our analog at 50 yards, the scaled-down bucket should subtend between 1.65 and 2.4MOA’s, i.e. roughly 3/4″ to 1 1/4″. That, however, leaves us with an over-simplified scenario, since we don’t experience the true effects of distance that Quigley’s shots do, because the time of flight will be significantly less.

What I believe is more “authentic” is to try to manipulate the distance and the pellet selection so that time of flight and therefore resultant effects are similar. For example, positing a lower limit of 650 yards from the 2 second time of flight, the modern .45-70 drops 657 inches. The drift with a 5mph crosswind is roughly 47 inches. At 925 yards, the drop is 1514 inches with a 3 second time of flight and 89 inches of drift. Dealing with those types of issues is what constitutes real shooting and separates the good from the average.

We obviously need to go further than 50 yards to equal Quigley, even in miniature! Whether anyone could really make that shot (especially without any practice or ranging shots) is a matter of opinion…I’m skeptical. More precise ballistics data on the .45-110 might improve the situation somewhat, but even if it was 2x better than our (modern) .45-70 model, which is unlikely, it is still going to be an artillery-style shot, particularly at the 925 yard maximum.

To approximate the same “stunt” with an air rifle, we need to find some reasonable matches for the ballistics data. I believe that time of flight should be the primary consideration as it defines exposure to wind and gravity, so I will make that the determining factor in finding a match. To match the flight time for 650 yards, we need to launch a Superdome at 900 fps and hit a target at 210 yards. Or, for the truly competent, to match the maximum 925 yard shot, we need to hit a target at 245 yards with the same combination of mv and pellet. If we switch to a JSB exact (usually a better long-range pellet), the distances stretch to beyond 250 yards (Chairgun quits at 250).

Let’s just pick the “easy” one, assuming Quigley’s shot is 650 yards and placing our target at 210. The width of the target will need to be (2.4*2.1*1.047) ~= 5 1/4 inches wide; a small coffee can should be about right.

Alternately, if we put shoot the Superdome with a muzzle velocity of 430 fps from a 6 fpe rifle, for the “easy case” we can bring the target in to 127 yards, in which case we need a target size of (2.4*1.27*1.047) ~= 3 inches, about the size of a normal “pound” or “pint” can.

Now pick a day with a steady 5mph crosswind and hit the can three times in a row using peep sights from the offhand position. You can then say you did some extraordinary shooting like Matthew Quigley.

Vince,

Thanks. I’m sure its better than I’m used to, even with a little creep:), although I have really developed a liking for the single-stage trigger on my 36-2.

I left a post some time back on how to install the Williams Model 64 Peep Sight on the Benjamin/Sheridan multi-pump air rifles. I recently discovered a mistake in the instructions, so here is a re-post that includes additional information:

How to install the Crosman Model 64 Peep Sight on Benjamin C9, 397, or 392 model pellet guns:

Before installing the new sight, remove the OEM rear sight:

1. Make sure the rifle is unloaded and contains no air charge.

2. Measure the distance from the back of the rear sight to the front of the receiver [3.5”] in case you ever want to reinstall the sight.

3. Remove the sight, which is held by strong spring force to supports underneath it on either side of the barrel. Rest the butt of the rifle on the floor between your feet. Use a heavy wooden dowel 18” or so long on the front side of the rear sight. Use a soft-faced striking tool (plastic hammer or wooden mallet) and the dowel to drive the sight toward the receiver. NOTE: This operation will remove a little paint from the pressure tube and barrel, but it will not damage either one.

Note: I have read that a screwdriver can be used to remove the OEM sight, but I haven’t seen it done or tried it myself. I don’t know if using a screwdriver will damage the barrel or the gun’s paint, or destroy the OEM sight.

After removing the OEM sight DISASSEMBLE THE WILLIAMS DIOPTER SIGHT. Note that the windage base, containing the Diopter, has an index line on the front side of it. It is just barely visible because it is a shallow groove and there is no white paint in it. Carefully use a triangular jeweler’s file to deepen this groove to reveal the aluminum underneath. For even better visibility, apply white paint to the groove using a wooden cocktail toothpick; wipe off any excess before the paint dries.

Installing the Peep Sight:

1. Position the sight base over the two holes on the right rear of the receiver in the cutout behind the loading port. The SHORT SCREW goes in the front hole, and the LONGER SCREW goes in the rear hole.

2. Tighten both screws snugly.

3. Make sure the sight lock screw is loose (it is surrounded by a silver bushing). Back out the “grub screw” on the right-hand side of the sight assembly so that it won’t contact the sight base and then slide the dovetailed sight assembly in and ALL THE WAY DOWN. The uppermost mark on the sight assembly should be BELOW the single index mark on the sight base. Tighten the sight lock screw. Snug the “grub screw” down so that it won’t back out and become lost.

4. MAKE SURE THE APERTURE SIGHT IS SECURELY SCREWED INTO THE WINDAGE ASSEMBLY. I have installed three of these sights, and on EVERY ONE, the aperture was not screwed in all the way.

5. Adjust the windage by loosening the screws on the Diopter base and “zeroing” the index mark in the center of the sight base scale as a starting point. At this point you are ready to shoot the rifle and make the sight adjustments that are right for you.

NOTE: In my case, on all three guns, with the elevation all the way down and the windage set just to the left of center, the guns shoot slightly high at 25 feet.

–Witt

Any eta on the marauder?

Hi! to everybody,

I always will insist that this guy VINCE is a genius. For so many years shooters were contented shooting the 34 (.22) in around 650+- fps which I think is a little on the low side. I for one after reading Vince tips, my 34 now shoots in the high 750s fps with CPs and the Hobbys as advertised. Does anyone remember that called it the “Vince magic”?.

Hank

Vince,

Good writing, good info. Thanks for spending the time and effort.

-Chuck

Great article Vince! Very well written and very informative!

thanks much,

ben

Bg farmer,

Wouldn’t it be possible to shrink the target to correlate to the available distance and rifle?

250 yards puts a lot of us out of the game. I think authenticity should take a backseat to something more people could have chance at trying. Maybe we market a kit that includes different size Quigley buckets for use at different ranges? I’m guessing they are fine, but this would also make a nice show idea for American airgunner.

Anonymous: I heard spring/summer for the marauder. And for everyone else, I found a video on YouTube of the marauder. You won’t find too much about the rifle from it but it gives a good 360 view etc.

Volvo,

I like the idea of a “bucket set” that a shooter could work their way through. Can you sell it? I’ll design the buckets:).

In terms of angular size only for use at 100 (or 110 yards if that’s possible), the target should be approximately 2.4 inches for the 650 yard analog and 1.65 inches for the 925 yard one (1 3/4 and 2 1/2 are close enough). That is very close to my initial formulation after asking BB about the shot, but the flight times are much shorter than Quigley’s could have been (about .58 sec for a Superdome with mv=900fps).

I could very well be getting carried away with authenticity, but it involves so many things I like:).

TWO THINGS:

1) What CO2 pellet or steel BB pistol has the lightest trigger pull? And yes, this is very important.

2) FREEBEE!!! Courtesy of Wayne – he sent me a TF97 (QB36-1) to work on, but it turns out that it didn’t need any. It’s a .22 caliber that shoots 560-570 with Gamo Match pellets (which it seems to like, short range, anyway). I had it apart for a checkout, cleanup and lube, and I did a little to the trigger to get it a bit smoother. THE TAKER HAS TO PAY SHIPPING, and MUST BE 18 YEARS OLD OR OLDER!!!

NOTE!!! THIS IS A SLIDING CYLINDER GUN!!! And even though it has an anti-beartrap, all the standard warnings about sliding-cylinder guns still apply (they can mash your fingers REAL bad if there’s a massive failure while you’re loading the gun).

First one to respond gets it!!!

Bg-farmer,

I’m guessing that we could get Wayne’s cedar scraps for the buckets. I think if we would personalize them with a wood burn for PA or other venders with their name and e-mail address they will “sell themselves”

Oh, and the CO2 pistol has to be a repeater

Vince,

Rohm Twinmaster.

kevin

Volvo,

That’s what I was thinking, too. “The Matthew Quigley Port Orford Special Bucket sponsored by Pyramyd AIR and Natural Yards”. I’m still not sure I can aim at something that hasn’t contained food or drink, though:).

Vince,

While you have that 36-1, what breech seal do you think would fit (B3 kit?)? That’s about the only part I haven’t replaced on mine:).

BG_Farmer, I believe it is the same seal. I’ll check, since I’ve got a couple of them laying around. But according to Compasseco, the seal is the same.

Vince,

Thanks. That gun should be a nice one for somebody; they work well after all the factory features are completed or redone, and with your inspection the recipient won’t have to worry… I’m still hoping you’ll give the -2 a try, they’re only fingers!

since I’m trying not to be a packrat this year,even though this is a very generous offer and you’ve made me very curious about this line of airguns…..I’ve got to pass on that FREE airgun Vince.Someone is bound to give it a good home! FrankB

Vince,

I’m playing the guessing game.

My guess is the rohm twinmaster for best trigger, pellet pistol, co2, repeater (i know, the rohm is a 8 shot cylinder double action revolver/repeater). What’s your definition of repeater?

Do I win anything?

kevin

Vince,

Bravo… very nicely done.

Help needed!

Can someone help with a beeman P17 problem?

Jason posted a Beeman P17 question twice. His problem was re-written under the Friday, January 16th SHOT Show post and is currently the last comment.

I don’t have a clue about beeman p17’s. Can someone help him?

kevin

Vince,

I sure like to try the TF97. My notion would be to try it and pass it on…

Herb

Vince,

If Hank doesn’t take it I will.

Thanks,

DB

Vince & Herb,

Sorry I called Herb Hank.

DB

BG_Farmer & Volvo,

Cedar scraps abound….

I've actually designed a round tapered stave planter already.. They are not on the market yet.. but could be available for you in small amounts for field testing ( I can add "pellet tested" to the sales pitch when I release them)..

We've made them in 6" to 36" diameter…and 6" to 30" deep.

They are very strong and look nice too..

Vince,

Should we give a gun per month away? Just cheap stuff of course.. but you could tune it and send it off… and like Herb said, it could keep on "moving" until it really found someone to love it..

I'd like folks to feel the older ones… maybe one of the last three, the Czechoslovakia VZ3, IJ-22 Russian, or the pioner air gun European training rifle… for grounds hog day.. (my B-day).. I like to give a gift, cause I'm glad I was born!!

Maybe we will start a fun gun circle.. people could add their unused interesting ones too..

Wacky Wayne idea number… 975,385,224,994,661,001

All,

Thank you so much for the advise over the weekend concerning the FX Revolution.

I’ve not had the chance to do the reseach and offer a recommendation yet. But your comments were helpful.

DB

Kevin,

Those hand cast bullet style pellets look interesting. I might by a tin just to see them.

Thanks for the info,

DB

OK Herb – you got it. Email me your address vfblovesnancy@yahoo.com and I’ll let you know how much shipping is.

DB,

My yahoo account is hcacree.

If you’ll mail me your address I’ll pass it on for the postage after I play with it for a week or so.

Herb

Wayne,

That’s great about the planters — should be almost perfect profile and aspect ratio. I’m still hoping someone can find a major error in my calculations or offer a shorter range solution, because it would be nice to have a more accessible analog. It was, however, an incredible (and perhaps impossible) shot, even with a customized buffalo rifle, so perhaps it will have to stay that way. I’m still working my way toward 110 yards:).

Herb,

Be careful. If Vince says the gun works well, you might like it so much you end up wanting to keep it.