by B.B. Pelletier

Guest blogger

This is Paul’s first guest blog, and he’s reviewing one of my favorite airgun brands–Haenel. His review of the 303 model shows it’s an accurate gun, as you’ll soon see. The gun belongs to his friend, so he’s got only temporary ownership.

If you’d like to write a guest post for this blog, please email me.

Bloggers must be proficient in the simple html that Blogger software uses, know how to take clear photos and size them for the internet (if their post requires them) and they must use proper English. We will edit each submission, but we won’t work on any submission that contains gross misspellings and/or grammatical errors.

by Paul

The rifle above is a Haenel model 303. Made in East Germany, it looks to be a refinement of the model 284 reviewed by B.B. last year. It was purchased in East Berlin in the early 1980s and is a conventional breakbarrel rifle in .177 caliber, similar in size to an R7 and identical in power. It weighs about 6.5 lbs. and has a pull of 14 inches, so it doesn’t feel like a toy. The overall length is 42.75 inches with a 17.5-inch barrel.

The cocking effort starts out very light and builds to 22 lbs. just before the end of the stroke. The gun can be easily cocked with two fingers. The wood stock looks like beech and is not stained; there’s no buttplate–just ribs cut into the end of the stock. The stock finish on this particular rifle has a few nicks but is excellent otherwise. Unlike the earlier 284, there are no finger grooves on the forearm.

The stylized Haenel name is stamped at the end of the receiver. The safety button projects from the end of the tube.

The blueing is very good–black and even over the entire gun, even the parts not normally visible. The Haenel logo and country of manufacture (German Democratic Republic) are stamped on the end of the receiver. The safety button projects from the end cap and automatically sets when the gun is cocked; it and the receiver end cap are the only two plastic parts on the gun. The safety is a bit noisy but operates positively and can be reset after being placed on fire. Depressing the safety and pulling the trigger while holding the barrel fully open releases the mainspring without firing.

The model number is stamped midway on the receiver.

The trigger is stamped metal and blued; it has a solid block sear at the top that engages the hook at the rear of the piston to hold the action in the cocked position. The screw at the front of the triggerguard controls the sear engagement; I did not adjust the screw since the second stage was consistent at about 5 lbs. When the second stage is reached and the trigger is pulled a small amount further, the pull becomes slightly lighter and finally breaks. Once a few shots have been fired, the trigger becomes easy to control.

Rear sight is adjustable for elevation and windage.

Unlike the earlier 284, the rear sight on the 303 is adjustable for windage. A spring-loaded ball backs the adjustment knob to produce clicks and to lock the position. The V-groove rear sight works well with the front sight for precise aiming. The comb of the stock is also the perfect height so the sights are in very close alignment when the gun is shouldered. The barrel pivot bolt is locked in place with a small set screw that fits into a notch of the bolt head. No washers are used between the baseblock and the forks of the receiver. Instead of the usual plunger ball or wedge in the baseblock, the wedge is in the front of the receiver. A matching V-notch in the baseblock provides a positive lockup. The cocking link is a two-piece arrangement enabling a very short slot in the forearm. A spring-loaded button that presses the straight part of the link against the bottom of the receiver is in the forearm. This part of the link is an open box stamping with a plastic block inside that contacts the lower part of the receiver to prevent wear.

Front sight is a hooded peppercorn design.

Firing the 303

The Haenel exhibits moderate vibration upon firing. Some pellets caused noticably more vibration and were not tested further. Due to the power level, recoil is minimal and the rifle seems to be fairly hold-insensitive. I was able to get good groups supporting the forearm on a bag rest or using my left hand. The point of impact didn’t seem to be affected either way.

Only a few hundred pellets have been put through the rifle; it also hadn’t fired for about three years due to a lack of ammo. Because of the age of the rifle and the leather breech seal, I guessed that it had a leather piston seal (it did) so I chronographed it before oiling and after. The results were interesting. Before oiling, velocities would vary as much as 54 feet per second for a 5-shot string. Two shots would be within a couple of fps of each other and the next would drop by 40 fps and then come back up the round after that. After oiling, the average velocity was unchanged but the variation was reduced to as little as 8 fps for five shots.

Suspecting that the original lube had dried and hardened, I disassembled the Haenel for a cleaning and relube. It took about four hours to tear down the gun, clean and lubricate the internals, and put it back together. The spring was under about three-quarters of an inch of preload; it was .75 inches in diameter, 7.25 inches long and perfectly straight. Due to the lack of wear, it’s evident that this gun has seen little use the last 25 years. Fortunately, the leather piston seal was in perfect shape. Once the gun was reassembled, it took about 20 shots to get consistent velocities.

For the most part, velocities increased about 21 fps after tuning. Beeman Kodiak pellets were unchanged, but the Beeman Crow Magnums picked up 35 fps and the gun seemed to shoot smoother with those pellets.

Something that struck me was the level of finish inside the gun. It was obviously built with care. The only sharp edge I found was in the slot in the bottom of the piston; it was only rough enough to scratch a finger. The slot in the bottom of the receiver was very smooth. Chamfers were added to the edges of the rear sping guide and the block that retained the trigger for easy insertion into the receiver. All of the other small parts were cleanly finished. This was an inexpensive gun, but it was not cheaply made. A nicer stock would be a fine compliment to the excellent metal work.

Velocity and accuracy

A number of different pellets were tested at 10 meters. Five-shot groups were used due to time constraints. The sights were never adjusted and groups varied from centered to about a half inch to the left.

Beeman Lasers

The 6.5 grain Beeman Lasers were a bust. They averaged 621 fps but ranged from 595 fps to 657 fps and strung out horizontally. No other pellets displayed this behavior.

7.7-grain Beeman Coated Wadcutters

Beeman Coated Wadcutters averaged 609 fps with a high of 615 and a low of 602 fps. They gave a .53-inch group.

Beeman Coated Hollowpoints

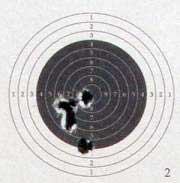

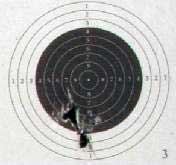

7.2-grain Beeman Coated Hollowpoints shot with less vibration than most. They averaged 663 fps, varying from 654 to 677 fps. The group below has four shots in .40 inches with one flyer (my fault), opening it to a full half inch.

Crosman Premier Lights

7.9 grain Crosman Premier Lights fit loosely in the Haenel’s breech, dropping about 1/16 inch in. They averaged 627 fps, varied by only 14 fps (620 to 634), didn’t want to group any tighter than half an inch and produced wider groups than most.

RWS Super-H-Points

The 6.9 grain RWS Super-H-Points averaged 652 fps, varying from 643 fps to 669 fps, and produced a .39-inch group.

Beeman Crow Magnums

For a heavier pellet, I tried the 8.8-grain Beeman Crow Magnums. The Haenel seemed to like these. It fired with little vibration, averaging 590 fps and varying from 586 fps to 596 fps. Groups around .37 inches were easy.

RWS Superdomes

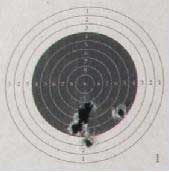

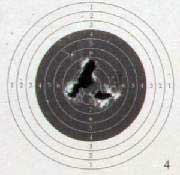

The 8.3-grain RWS Superdomes were a standout. They averaged 608 fps with a low of 599 fps and a high of 621 fps. The .29-inch group was a little hard to measure since these pellets do not cut a clean hole at all.

Crosman Premier Hollowpoints

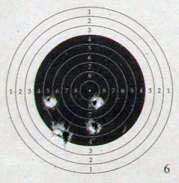

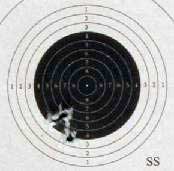

Last up were the 7.9-grain Crosman Premier Hollowpoints; they also gave one-hole groups. Their velocity varied from 620 fps to 654 fps for an average of 633 fps. Groups were .37 inches (below) and .34 inches.

I also shot at some cut pieces of 2×4 blocks at 35 yards. With a little hold over, it was simple to topple them nearly every time. I didn’t attempt groups past 10 meters due to my nearsighted, 45-year-old eyes.

I was quite pleased with the accuracy of this gun. For a low-priced rifle it shoots beautifully with the right ammunition. I only wish it were possible to install a scope; a glass sight would be a great help at longer ranges. I did tell my friend if he ever wants to part with the rifle and his son does not want it that I want first dibs! It’s an excellent plinker.

Paul, a nicely written and very informative article. I especially enjoyed seeing how well the RWS Superdomes performed. They are a superb pellet! Hope we hear from you again.

Paul,

Real nice write up!

Very good breakdown on the rifle inside and out!

Thanks for all the effort.. now you know how hard B.B. works for us!!

To me, that is the perfect sptringer, just the right power plant! Shootable, without special holds, easy to cock, easy to carry, built to last! What else could one ask for? … certainly not more power and the hold sensitivity that comes with it!

I just wish mine looked so good! That's a real beauty..

Wacky Wayne,

Ashland Air Rifle Range

Paul,

Well written and very interesting. Your knowledge of subtle differances in the exteriors of airgun designs gives great insight into your passion. Four hours to tear into, lube and put it back together also tells me you know your way around the inside of these springers as well.

Sure don't see many of these 30 year old beauties as well preserved as this one.

kevin

Paul,

Thanks for your review of this Haenal 303. You comments about how well the metal was finished inside the gun were appreciated. Looks to me that the wood to metal fit was also excellent.

Mr B.

Great post, Paul. I only wish I knew how to get my pictures to look that good!

blowgunner62,

B.B. did a 5 part article on taking pictures of airguns, pellets, etc. Here's the link to part 5. At the top are the live links to take you to parts 1-4 so you can read them in order. Great series:

/blog/2008/9/photographing-airguns-part-5/

kevin

Thanks for all of the compliments – I was nervous about writing an article for this blog considering its readership. Being able to take a couple of weeks helped. I saw lots of things to fix after leaving it alone for a few days.

It was also work! – probably about eight hours worth. I would definitely not want to have to write five a week. I also have to thank Mrs. B.B. for removing the background from the photos. All of the gun pictures were taken outside on a bright, sunny day under some trees near the house so I had a good amount of indirect light. Some were taken multiple times to get a usable image. The targets were shot in direct sunlight and just cropped using MS paint.

BB, thanks again for the opportunity and I am glad that it was well received.

Paul

Paul,

So when will you do your AK-47 bb gun review?

Hi B.B. Pelletier

Last week you said you could look at a Walther 1250 Dominator this week end. If you could test one (.177) it would be great. could u plz check the accuracy and if it has any feature derived from LG300 as the ad says or it is just a converted 850, may be compare the action and barrel.

Thank you

Paul,

Great job on the review. Overall, it sounds and looks like a good rifle of the type everyone should have.

The stock, however, is "interesting" to say the least, perhaps designed by a committee of workers who all liked different styles:)?

1250,

Thank you for reminding me. I will order the gun for the test.

It takes several weeks, you know.

What ad says this rifle has any feature borrowed from the LG300? I'm not familiar with that. Of course the firing valve might be used, but other than that I think this is an 850 running on air.

B.B.

Paul,

You done very good! This was a report worth reading.

Let's see more!

B.B.

That's a pretty gun. I guess some good things did come from the Commies 😀

It's interesting to me that Premier Lights did horrible, and the Premier Hollowpoints did excellent.

Jake,

I was wondering about that also. The particular CPLs I have are very loose in the bore; the hollow points are not. Both groups with the CPLs were spread out and both with the hollow points were one hole. Maybe a slightly undersize lot of one and oversize of the other? Time to break out the micrometer, I think.

Paul

Where do pellets typically headspace off of?

Jake,

Only cartridges have headspace–not bullets. A pellet is a type of bullet. Hence, no headspace.

B.B.

I measured a few Premier Lights and Premier Hollowpoints. The HPs have a skirt diameter just one thousandth of an inch larger – .181 vs .182 inches. The head diameter on both was .177in. I did notice that the CPL's fit more loosely – they would drop about 1/16th of an inch into the barrel – the rear edge of the pellet would be below the breech. The HPs did not do that.

Not much of a difference but the grouping was repeatable. Just lot variations? Maybe the HPs just work better in the 303. Who knows.

This rifle seems to have a larger bore than my HW30S. I tried the Beeman Perfect Rounds. They gave 100 fps less than the HW30 and the firing was harsh. Only tried one shot with those. Maybe the larger bore makes it pickier.

To me it's one of those things that make testing various ammo interesting – you cant just tell by looking.

Paul

I'm off-topic a bit, but does Wayne or anyone else have any more experience with the new Evanix Blizzard?

Does it deliver anywhere near the results reported in PA, (very consistent velocities in that data). Also curious if they hold air or bleed down over days, (pumping is realy a pain for me – I need one of those cheap compressors).

Now that I'm hooked on PCP, (and still have my budget), I'm anxious to add to my collection of 1….

Jane

I think Wayne knows a lot about the Blizzard. But as far as I know, a PCP should hold air in its reservoir, otherwise somethings wrong.

Paul,

Thank you for taking your time and thanks to your friend for allowing you to report on his airgun.

DB

All,

Emailed Daisy for their recommendation on grease for the 953 innards. They recommended, "… sylicone grease or any machine grease should work fine." So looks like Ajvenom's suggestion was on target.

Will be doing the trigger mod and then retesting next week. Also considering doing a power mod. It is simple just fill in the head space on the plunger. Supposed to add about 60fps. I'm hopping for just simply giving more consistant shot to shot speeds. Time will tell.

Right now I'm pondering how to fill that space and still be able to undo it if needed.

DB

Jane,

Each Korean gun is unique on the holding air issue. The Blizzard that I am testing was last filled in June and it's still holding fine.

And I just realized I didn't do part 2 yet, to say nothing of part 3.

Monday, I think. These trips every three weeks are throwing me off schedule.

B.B.

BB,

Thinking back to your recent article on CO2, how does the Beretta compare to the Nightstalker? I'm not asking you to do a full review, I was just wondering what you thought about it.

Jake,

Well the NightStalker is cheaper but only a 12-shot compared to 30. Both use the 88 gram cartridge, so no problems there.

Use optical sights on either one.

B.B.

Jane,

Here's a teaser and comparison with the gun that B.B. is testing:

This is from a thumbhole .22 cal with 18gr. JSB starting with a 225 bar fill.. (dry pellets by the way)

1089fps, 1088, 1076, 1076, 1068, 1065, 1060, 1047, 1048, 1043, 1036, 1034, 1033, 1025, 1019, 1016, 1007, 1004, 1000, 995, 992, 982, 977. 160bar.. 973, 966, 958, 953, 949, 939, 932, 924, 914, 911, 904, 898, 899, 891, 130bar… 875, 871, 849, 849, 847, 845, 832 110 bar…

I kept shooting long after B.B. would… only cause you hate pumping, and I believe that there are some nice strings in the 160 bar area.. and 900fps with an 18gr JSB that carries it's ft lbs out to 50 yards about as good as any… ain't nothing to skip over lightly.. too fast and you might find accuracy suffer… check it out!

There is a power adjuster on it, but I haven't play with it yet.

Mine holds air for weeks as well.

Wacky Wayne,

Ashland Air Rifle Range

DB

Be very careful making the cuts for the trigger mod.Make the cut too small then

grind to fit is better than cutting too

much and making an unuseable trigger.

Also if adding the adjustment screw mod,

superglue the screw in place before soldering or alignment will be a pain.

Just not too much glue or you'll

really have to tork the driver to break

the screw loose to adjust:)

For filling the piston cheap you can use slugs.the knockouts from an electrical box like square D are pretty close to size and can be epoxied in

lightly for later removal if you want.

if you can't find just the right size

they can be sized with a dremel and stone tip fairly easily.Remember to remove any paint before gluing:)

Hope this may help a little.

JTinAL

JTinAL,

Thanks for the tips on the 953 mods.

Was going to do the screw in the trigger guard not the one soldered to the sear. Is the putting one on the sear much better?

DB

DB

I can't really say which is better,but the screw in the guard seems easier.I

Hadn't tried the one in the guard and had forgot about it.From what I've read it works just as well:)I haven't even modded mine yet but it broke in so well I wasn't gonna go into it.Now i've got a cocking problem so I may do the mods while checking that out (suspect a loose spring or lever)when it won't cock I can tap the butt with my hand and it works for a while.The rifle I

modded for my nephew seems to be working

pretty well.Haven't got to see him or

the rifle lately:(

Don't forget to let us know how yours

works out and good luck cause these are

great shooters out to 60'.Even try mine

at 90'pretty often but holdover isn't

easy with my cheap powerline scope.

JTinAL

JTinAL,

This 953 is going to my great nephew too. Guess it is just an Uncle thing.

I'm going to do the trigger guard screw mod. Can always add the other screw too later if it seems to be needed. Like you I think the trigger is pretty nice out of the box though. Just hoping to make it better.

I'll let you know how it turns out.

DB

B.B

Thanks for considering to test Walther 1250 Dominator.

Few sites including pyramydair says the following so I have asked if there is any relation with LG300

"The Walther 1250 dominator implements the proven engineering of the successful Walther LG300 Dominator in a compressed-air repeating system with 8-shot rotary clip."

Thanks

Yep,

The only relation is the pressure level. The guns are unrelated.

B.B.

Wayne:

That's a pretty impressive set of numbers for a Korean hunting rifle. What do you think you AA S410 do if you used the same pellets?

The guns are not that far apart in price – I just wonder if the AA gets into the same power range…

Best regards,

Jane

Jane,

The AAS410. in .22 cal on full power with JSB 18gr. would probably do about 80% of the feet per second, (have to ask Kevin to test it for you, I don't have a .22 cal anymore)..

and the AAs410 would get twice the shots per fill, and you could instantly power down for quiet indoor shooting.. The Blizzard is 25% more loud than the AAs410.. but still backyard friendly.. sort of.. only 1/3 as loud as the AR6!!!

I was very impressed with the quality of this Korean gun.. the stock is superb! The bluing very good, and the smoothness of the magazine almost as good as the AAs410.. And Accuracy was very close between the two.. both can do 1/2"- 5 shots at 50 yards on a good day, in a good benchrest. 1" was easy!

Really it comes down to number of shots per fill vs 20% more power. The Blizzard is almost like shooting a .22 lr rimfire out to 50 yards!!

Wacky Wayne,

Ashland Air Rifle Range

Jane,

Would you please share with us the reasoning behind the purchase of your next PCP. By the way an early congradulations on shortly doubling your "collection" of PCP's.

I am stuck between a Marauder, an AAs410, or a Blizzard. One and two meet my requirments for quiet as purchased. The Blizzard would need an after market shroud/LCD which will add $150 or $200 to its price. A plus for the s410 is its adjustable power feature for my back yard shooting.

Wayne, one do it all gun, AAs410, Marauder, or Blizzard?

Mr B.

and now for something completely different…

https://www.youtube.com/watch?v=D2FX9rviEhw

ajvenom,

I don't know who enjoyed "something different" more the kids or I. Thanks!

Mr B.

BB sorry I am a little late with this question, does your v350 have any markings on it? I have a gun that looks identical with none I can find,my brother said my dad bought it in the early 60s at Montgomery Wards while I was in Germany.

shakey,

Your dad's gun certainly could be a re-badged crosman v350 marketed by Montgomery Wards.

According to my research, not first hand knowledge, Crosman manufactured the V350 for Montgomery Wards/Hawthorne Brand as the model 1414A.

Are you sure you can't find any markings on the gun?

kevin

Mr. B.

Well, I still say it's the AAs410 if it fits your budget.. because of the ease of adjusting the power, and the side lever makes it so easy to stay on target while cocking the gun..

That's no small thing to someone who wants to make the most of their practice time. I pre-load 12 – ten shot mags, (get RCMachine aftermarket extra ones), and with the super smooth side lever, I can stay in my sitting FT position and do all 120 shots in 10 mins. with amazing accuracy.. loading the 12 mags and filling the gun takes about 10 mins. so I can easily get 360 shots in an hours practice..

Then when a 20 ft lb. contest is happening I put in the single shot mag… and.. I feel I am one with the position, the trigger, and the timing of the shot..

..practice, is the name of the game… the contest is short. and for meeting and visiting with new friends. But at least I'll be comfortable in the position.

My AAs410 SL XTRA FAC .177 has the larger air tank and I think a larger tank somehow adds to the control of a slightly more steady air supply for the valve… Just a theory on my part.. I noticed the USFT has a very large air tank, and Tim put two dots on the gauge, 1,800 and 1,300. There are 60 good shots in that range. And 30 more with a little loss of POI..

But loss of POI is practice too. Isn't that like shooting at a 50 yard target..

I shoot the AAs410 a lot less now though, because I'm really trying hard to master the 12 ft lb no harness game with the USFT.. ..that's a very slow process for me.

But for getting the most shots in a practice session, and have those shots go where your pointing the gun.. to me.. It's still the AAs410.

The Marauder is second (even if the price was higher), if you want quiet and accuracy. The straight pull bolt slows you down a little, but not much.

The Blizzard is second if you hunt and noise is not an issue and power is! .. It's not noisy, but it's twice as loud as my AAS410 and three times as loud as the Marauder.

And the smooth side lever, (round nose pellets only!.. it likes JSB 18gr), let's you stay on target for a quicker second shot. .. but only 20 or so good ones!..

So there you have it.. sorry it took so long.. I ramble.. hey it's Sunday night, and I still want to shoot a little with the USFT..

nightie nite

Wacky Wayne

Ashland Air Rifle Range..

Where the OREGON STATE CHAMPIONSHIP CONTEST will be held on Aug 22 & 23Th.. Rick and I just set the date… he said we might as well.. the season is almost over.. crazy huh!

Wayne,

Thank you for your most eloquent, learned and thoughtful reply. I thought that you would have said more positive things about the Marauder.

Good Luck with OSCC on 8/22 & 23. Why we already know that it'll be very successful!

Mr B.

I have another scope question. I'm nearsighted, and anything past 3 feet or so starts to get blurry. Could I shoot without my glasses if I dialed in the parallax and focused while not wearing them, and just use the scope as a corrective lens?

Mr. B,

my son likes that video too….he's been watching Charlotte's Web a lot lately, the old and the new version.

what is the difference between Air Arms S400H Classic Bolt-Action and Air Arms S400 Sidelever

Shakey,

The marks on a V350 are extremely hard to see, especially if the bluing is still deep. The letters are tall and the lines are thin.

You can rub chalk over them to bring them out or go into the sun and hold the barrel until the sun reveals them. They should be on either side of the barrel. Sometimes you can feel them first.

B.B.

Jake,

I have astigmatism and wear bifocals and I use a scope that way, sometimes.

B.B.

The Air Arms S400H is a bolt-action single shot rifle. The S400 Sidelever uses a sidelever to retract the bolt. It's also single shot. The sidelever has adjustable power, while the bolt action does not.

B.B.

Mr. B,

Don't get me wrong! The Marauder is great. If it had a side lever, and a better quality stock, it would be a close tie with the AAs410 FAC.. just needs the easy to adjust power adjuster… If one considers that the cost is about half the AAS410, then it's a tie out of the box!!!

I'm having a field target stock made for a .177 Marauder now… and I've got single shot trays on the way too.. so, we plan on using them for field target here at the Ashland Air Rifle Range!

That's how good I think they are!!..

You asked what I thought was the "Best all around" air rifle.. again, if you have the money for one, It's the AAs410 SL Xtra FAC side lever.. is it.. IMHO! Small game hunting, indoor quiet shooting, and field target winner.. The large difference for the Marauder, is just the number of practice shots one can get in a session.. so if that's not important to you or you can take more time in your practice sessions.. then the Marauder is number one, if you take in consideration of the price difference!

Wayne,

Ashland Air Rifle Range

Hi! I have a heanel 303 and I would like to know how to lubricate the leather piston seal and what kind of lubricant I have to use. Thanks a lot. Matias.

Matias,

Stand the gun on its butt and drop 10 drops of household oil down the inside of the barrel. Wait a day, then shoot the gun 20 times with pellets. Be careful, as it will spew oil when it shoots.

B.B.,

Hi I got this model when I was a kid and I mounted a basic scope to it no problems there are two mounting grooves.

wilk,

Welcome to the blog.

Some 303s may have dovetail grooves, but not all. The one on the report doesn’t.

B.B.

Right that makes sense very impressive report thanks.

If anyone is interested I would like to sell mine it’s based in Felixstowe Suffolk.