by B.B. Pelletier

Before I begin, I’m going to Pyramyd AIR today and won’t be back until Friday. I’d like to ask the old-timers to watch the blog and help the new folks. Thanks.

I’m testing the Hammerli Razor on a request from at least one reader. I must have balked at the idea because I already reviewed the TF Contender 89 in .177, a derivative of the Chinese AR1000. However, this Hammerli is made in Spain. So, this is a brand new rifle to me. I see the family resemblance to the AR1000, but coming out of Spain, this must be from the line of the sire. How strange to have more familiarity with the copy than the original. This is the original, which Vince once said was probably related to the Norica GS1000.

Overall

The Razor is a large breakbarrel. It weighs 7.5 lbs. and is 45.5 inches long. That’s lighter (though slightly longer) than a Beeman R1, but still larger and heavier than an R9. It has a ball-bearing detent holding the barrel closed, so you don’t have to karate-chop the muzzle to start breaking the barrel for cocking and loading.

The finish is impeccable! The bluing is deep and even, and the woodwork is as good as the best that Europe offers on a production gun, with the possible exception of the Air Arms TX200. The metal is not polished to a high shine like a TX, but rather to a more satin finish like the RWS Diana guns.

New cleaning product

Birchwood Casey’s Barricade is a rust preventative that smells a lot like their Sheath that I’ve used for years. It says no harm to synthetics, so I’m testing it on airguns. It cleans oil and grease very well and leaves a protective film that stands up to prolonged salt spray. Pyramyd AIR doesn’t carry it, yet. If I find that it works well on airguns, I’ll recommend that they stock it. It cleaned the Razor quickly and left a nice shine.

Have you noticed that I haven’t yet fired a shot? I’m gushing all over the gun, and the test hasn’t begun. What does that tell you about the fit and finish of the rifle?

Plastic parts

The trigger, triggerguard, end cap and the two screw covers of the forearm screws that look like spanner heads are plastic. Other than that, the rest of the gun is metal and wood.

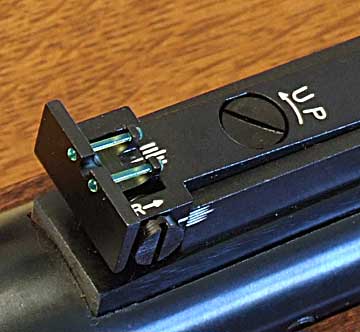

Fiberoptic sights

Both front and rear sights are fiberoptic, but the light is very subdued, so they don’t get in the way of precise aiming. The front red dot is all but invisible and acts just like a metal bead. It lights up only in strong daylight.

The rear sight is all-metal and has scales for both windage and elevation adjustments. This is the kind of quality rear sight some shooters will love, because it really works. Of course, there’s an 11mm dovetail and a proper scope stop at the back of the rail, so scope users are properly set up. I plan on doing something a bit different with this rifle–at least at first. I plan to test a new BKL mount to see whether it can hold its position with clamping force, alone. Back when I wrote The Airgun Letter, the BKL mounts I tested all failed the holding test, but the six-screw model 260 was not yet available and none of the mounts were being made on modern CNC machinery. You may be interested in following this test.

I got the rifle in .22 caliber, because at this power level it is better-suited than .177. The max velocity advertised is 820 f.p.s., and of course that’s the highest velocity with the lightest pellets, so I’m hoping to get Crosman Premiers running in the 720-750 f.p.s. region. That would make the power equivalent to the stock Beeman R1.

The cocking effort measures 33 lbs., so this rifle is for adults. I fired one shot and had a detonation, but the action feels smooth and solid. I’ll know more after velocity testing.

The bottom line is that this is a rifle worth considering. We’ll have some fun with it.

BB,

Joy to my ears! Those Beeman AR1000 guns can look like (specificly the rear end of the barrel shroud) they were put together then chewed on by beavers. That and they are way tho heavy. The wood and blueing looks great.

Shadow express dude

Hey B.B.

Is there anything that u can attach to a weaver base that allows u to mount a scope with dovetail rings?

B.B.

Some possibilities here…

Good looking, has open sights, easy break, and NOT chinese.

Please comment on how the open sights will work with this rifle. I had to grind a lot off the stock of an RS2 that I have before I could get my eye over and down to the sights.

twotalon

Anonymous,

Since B.B. has already left for the airport, you're stuck with me answering your question.

It looks like Pyramyd AIR does not carry any adapters that will let you switch from a Weaver dovetail to either a 3/8" or 11mm dovetail. They have several for going the other way, though. You might find something through a Google search. But, I'm curious. Why would you want to switch from a Weaver to either 3/8" or 11mm?

If you find the adapter you need, I'd be curious to know who makes it.

Edith

twotalon,

B.B. has left for the airport. It might take a day or so before he answers this.

Edith

SED, I don't think you'll find the Razor much lighter than the AR1000 variants (if at all). I believe the S1 I had may have been a bit lighter, but that gun had a slightly smaller powerplant.

Edith

Thanks. I figured he was on the road. No hurry.

Tom will almost be in my neighborhood. I'm a little closer to Toledo than Cleveland.

twotalon

yeah the designers of these Spanish Hammerli guns must have been paying close attention to the [higher quality] Chinese line. this rifle looks like it has identical mechanics to my Beeman RS3, but with a different stock, sights, and finish on the trigger. (the triggers look identical except for the fact that my trigger has a chrome finish and that one is as plain as concrete.) my gun has the same scope stop, safety, receiver, about the same blueing (the Hammerli is darker) and i'm gonna guess same powerplant, because everything that i see that surrounds the powerplant looks similar. i have seen pictures of the old Beeman GS1000 and i'm shocked at the similarity. only differences i see in THOSE guns are sights, and that the Hammerli doesn't have that gold Beeman logo on the side. these things seem to be coming from one central company that provides all this stuff. would be nice to know who is actually MAKING the mechanics, instead of always finding out who's ORDERING them.

John W.

Thanks B.B. I really appreciate your review of this rifle. I can already tell it's going to lead to a lot of interesting comments relating to the variants and lineage of the rifle.

Weaver to Dovetail,

I can see why you'd want a converter if all you have is dovetail rings. I'm talking off the top of my head here, but you might find that buying a new set of weaver rings will not cost that much more than buying something to convert, and adding a converter may cause the scope to mount higher on the gun, which you might not like.

-Chuck

John W, it's no secret that Norica makes the Hammerli Razor and they made the Beeman GS1000. Before that they also made the Beeman S1 which was a very similar design.

Make no mistake about it, the Spanish Norica came first. The Chinese gun is the copy, not the other way around.

Nice gun. But why so many breakbarrels and so few with fixed barrel geometry? I think that the sidelever is much easier to cock and load. Maybe it's because of the lighter weight.

Jake, the magic number of shots you are looking for to establish accuracy is 30. B.B. mentioned that a long time ago.

As for why two five shot groups are smaller than one 10 shot group, I've wondered the same thing myself. I figured if a rifle shot a two inch 30 shot group at 100 yards, any five shot group would be scattered randomly within the two inches. Such is not the case. Group size is tied to number of shots up to 30. Vince gave good visualizations about why that should be. But I've been trying to find a statistical explanation and have come up with the following.

I think it has to do with the standard distribution of a bell-shaped curve. In any statistical sampling, most of the points will cluster at a central value (apex of the bell), then spread out to either side. 66% will fall within one standard deviation of the central value. The number decreases as you walk further and further away until it goes down to zero.

Since nobody shoots every shot exactly the same place, their shot pattern can be described with what David Tubb terms a "call radius." It can be large or it can be small, like his. Regardless, the distribution of shots within that radius will follow a standard distribution with most in the center and getting sparser as you go to the edge.

The key point is that for any given number of shots you fire, the distribution of shots remains the same but the absolute number differs. So, by shooting a fewer number of shots, you reduce the chance of an outlying shot which can open up the group. These are not fliers; they are a legitimate part of the group. With five shot or, better yet, three shot groups, you can have quite a few without any of the severe outliers. When one shows up, you can dismiss it as a bad group as we often do. I have not worked out the equivalency between six five shot groups and one 30 shot group. You would think that they are the same, but I don't believe they are. I think it's because somehow the five shot group wipes the slate clean of outliers so that each time you are shooting from scratch. Anyway, I think this is why as B.B. says a three or a five shot group is a good predictor of a three or five shot group but to approach statistical certainty you need 30 shots.

Jake B. those hunting stories are crazy. For every person injured or killed by a wild animal, you probably find 20 doing something stupid to provoke them. Kids on the back of a black bear? And how close do you have to be to shoot wild animals with paintballs? I pictured their range as being very limited, like airsoft.

Your man with the holstered .44 magnum is scary. I can see why most ranges don't allow drawing from a holster, and I'm glad although it would be a lot of fun to practice.

Matt61

aah ok thanks for explaining Vince. i know a lot of Tech Force and other brands would use that Norica design. now i know who made it first. thanks!

John W.

Here's a question I hope someone can answer.

A friend of mine has tried the Kenco Stingers in his low powered Gamo pistol. (for those who don't know they are a lead free plastic skirted pellet)

He is using them to shoot in the basement and he has young children…so the lead concern.

Anyhoo he noticed that they really foul the barrel. A sub 500fps gun that shouldn't really require cleaning…felt pads come out very dirty, and what's more disturbing in my mind is that there will be minute plastic swirls.

What I wonder is if the friction generated could be high enough to slightly melt the plastic skirts…and if this material could eventually fill up the lands of the rifling and decrease accuracy.

CowBoyStar Dad

John W, over the years 'Tech Force' sold a lot of guns mostly from Shanghai, but some from BAM as well.

Those two factories have based their guns on designs from Gamo, Norica, Diana, and Weihrach, sometimes in piecemeal fashion and often with modifications. But the AR1000's seem to be virtually identical to the Norica original. I've not gone over them side-by-side with a micrometer, so I don't know this for sure.

There have also been a few original models from the Chinese. I believe the QB36 and QB36-2 (TF97 and 99, respectively) aren't copies of anything. I think the same holds true for the QB57.

Norica, Gamo and Cometa oh my, the Spanish and their airguns.

I thought Beeman GS1000 were Gamo and S models Chinese. Also, there is a different manufacture in China for SMK, QB and BAM? I believe Mendoza 600 is based off of RWS. Ouch, my feebile little brain is hurting again.

Industry, Hatsan, Norica, Diana, and Mendoza sold through Crosman, Daisy, RWS and Hammerli….perhaps BB can draw us a giant family tree/time line of……….who made who?

https://www.youtube.com/watch?v=Kz3kJJJ6Txw

Actually is it GH Gamo and SS chinese?

About the adapter–

I would use it for putting a scope with irremovable dovetail wings on an airsoft rifle with a weaver mount.

CSD,

AirForce experienced such accumulation of plastic in the bore that they specifically say in the owner's manual not to use synthetic pellets.

B.B.

BB,

I think the Hammerli "division" of Umarex, though the brand has been diluted, does hold their products and contractors to a bit higher standard than some of the other importers. Its interesting that they choose to sell the Spanish original at a higher price rather than the IB copy, which I think they briefly sold as the Hammerli Titan and later Walther (Force?).

AJ,

QB series is Industry Brand, imported and sold directly or re-labeled as Tech Force (most are IB), BAM is a the product of a different manufacturer, imported by Xisico(?) or something like that. I think SMK (1000?) was an importer's brand or model name for B20? To add to the confusion, there are other Chinese manufacturers of air rifles, and some of the designs seem to be shared commune style:).

Vince,

I thought QB57 was the same action as QB88, except for the trigger and linkages required for a bull-pup, and further, that QB88 was a close copy of something else (FWB 300 without recoil reduction)?

Actually the QB57 and QB88 both use a knockoff of the Gamo trigger. The one on the '57 does have the remote linkage, but it is indeed the same basic trigger. Not sure about the basic powerplant, but they do have different anti-beartraps.

BAM and Shanghai are different manufacturers, and both have produced guns sold under the TF label.

I believe a variety of guns had been sold under the SMK label, and I also believe most of those were Shanghai.

The only Shanghai product I ever really took a liking to is the AR1000. Tried a bunch of others, all were disappointing.

Vince(s)?,

I'm seeing two identifiers. One is Vincent.Brandolini and the other is Vince. Are you one in the same?

kevin

Weaver to dovetail,

Do a google on weaver to dovetail. I got a few hits. One was:

https://www.amazon.com/Weaver-Dovetail-Adapter-Scope-Adaptor/dp/B000MH129O

-Chuck

Weaver to dovetail,

The one Amazon has are really short so you might need two and they only have two left. Hurry !!! Hurry!!!

-Chuck

Vince,

You're definitely right about the Gamo trigger, which puts a screw in my theory:).

I forgot to mention that for me the most interesting aspect of the Hammerli Titan (copy of the Norica designed Razor) was that the trigger was 2-stage adjustable and got quite a few good reviews, whereas the original (Razor) has a a heavy (direct sear?) trigger, despite its higher price.

I thought you like the 490 and QB88, too?

Twotalon,

My denim was too thick for patching, but just by being really tedious and going to 60 gr. Pyrodex, I got hints of much better groups today with the cleaning (t-shirt) patches. I could handle everything pretty well, except keeping the seating pressure perfectly consistent — I would get down close to my "loaded" mark (on the ramrod) and inevitably hit something that required a smack:). I'm going to wipe the bore b/t each shot next time.

Hi all,

Here is the post I put up on the field target forum. it wouldn't fit in blogger, so I edited it down a little.

Oregon State Match Results Aug 22nd and 23th

The weather was about perfect, 60 at 8am and about 75 at start time both days. Wind flags on the oak trees said 5-10 with occasional swirling gusts of 12-15 mph.

This part of our course is mostly uphill. We had a 60 shot course that averaged 28 on the Troyer scale on Saturday with one lane each standing, kneeling and prone.

On Sunday we added more lanes, and made 5 more standing. Sunday we had a 74 shot course that was 26 on the Troyer scale.

All shooters were shooting 12 ft lb or less. Terry shot his 8 ft. lb 10 meter gun. Rick and Terry were the only shooters who used shooting jackets. No one used a harness. So this was a WFT contest.

I found tail light repair tape and placed it on the inside of the target plate, not the KZ paddle.

So when two or three of us first through the course, saw our pellet holes in the tape, and the target didn’t fall, we called for a question mark, so at the end, if others had a complaint, we could adjust.. We adjusted the targets lighter for Sunday.

The tape was also useful for seeing where you hit the KZ. Even used tape was still very helpful. THANKS!!! TIM M.

Rick Knowles and Terry Cooke came all the way down from Tacoma Wa. This is the second time Rick has traveled down here to help us set up the Ashland Air Rifle Range, and show us the fine points in shooting field target.

They were the only out of state folks at the meet. Only four locals showed up, Larry Rodrigues, Randy Moore, Chris Knutsen, and myself. Two others on our team Josh and Nate had caught the flu bug, which might be what hit Terry late Saturday night, and caused him to leave for home early on Sunday.

This was Larry’s first time shooting air rifles, let alone field target, about half way through the first contest, he figure out his eye relief!

Randy has shot air rifles for a year now, but this is his first attempt at field target also.

Chris has only two practice field target sessions under his belt.

I’ve been practicing indoors and getting in shape for the sitting position for almost a year now, but this is only my second FT event.

I want to say thanks again to Rick and Terry for coming so far, and Rick for coming on Friday and helping with the setup, and all the advice he and Terry gave us was so welcome and needed!

Results:

Rick Knowles 52/60, 55/60, 71/74 AAEV2

Wayne Burns, 46/60, 46/60, 59/74 USFT #44

Chris Knutsen 34/60, 39/60 N/A AAs400

Terry Cooke, 31/60, 33/60, N/A FWB 300

Randy Moore 28/60, N/A, 36/74 Marauder

Larry Rodrigues 18/60, N/A, 29/74 AAs400

So, for the few Oregonians there.. I shot the best… but I can’t call myself the Oregon Champ just yet.. Rick let us know only three weeks before our first event, that he would like it to be a State Championship Match, to fit into the tight North West schedule. So it was way too little notice for folks to show up.

With all that in mind, I’ll be available for the rest of the year for any Oregonian to whip my butt and take the Oregon State Champ title in a WFT class event.

Wacky Wayne – Ashland Air Rifle Range

Wayne,

Congratulations. At your next meet if you could do a little video and post it on you tube? I’m sure many of us would like to see the layout and such.

Kevin,

Do you have a Walther on the way?

Volvo

G'day BB

Where can I get a couple of fore end screws for my son's Beeman R9 as he has lost one. The order must be too small for Lewis as I can't get a reply.

Or if you can tell me what thread it is…is it metric fine?

Cheers Bob

Bob,

What about going directly to the source? From what I here, Weihrauch is very cooperative in helping customers. They certainly know all the answers to your questions, which I, unfortunately, don't.

B.B.

to those out there

would like to know if they make or made a snubnose airpistol,would also like to know anybodys take on the crosman model 400

thanks vinny

Vinny,

Go here and post your question. You will reach more readers:

/blog//

This will always take you to the most current day's posting. Don't worry about it being off topic. We don't care.

-Chuck

thanks chuck

vinny