by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- The first airgun rifling

- Important points

- Choked barrels

- Rifling twist rate

- Other twist rates

- Smooth Twist

- Summary

Today we will look at airgun rifling as it has evolved over the past century. For many years airguns were not rifled, but in 1905 the BSA company built what many consider to be the first modern air rifle and it was rifled — as the name implies.

The first airgun rifling

The first underlever air rifles made by BSA were taploaders. A pellet was loaded into the open tap, nose-first, then the tap was rotated closed and the gun was fired.The pellet expanded inside the tap and was driven into the rifled barrel at high velocity — well, high for airguns at the time. Maybe 500 f.p.s. for a .177 pellet and 325 f.p.s. for a .25-caliber pellet.

The rifling had to be aggressive enough to catch the pellet and not let it slip through the bore out of control, but it also couldn’t be so aggressive that the pellet was slowed by excessive friction. So the question arises — how did “they” know what to do?

Of course they didn’t know. Not until they began shooting pellets did the developers know for sure how the rifling would react with the lead pellet.

Important points

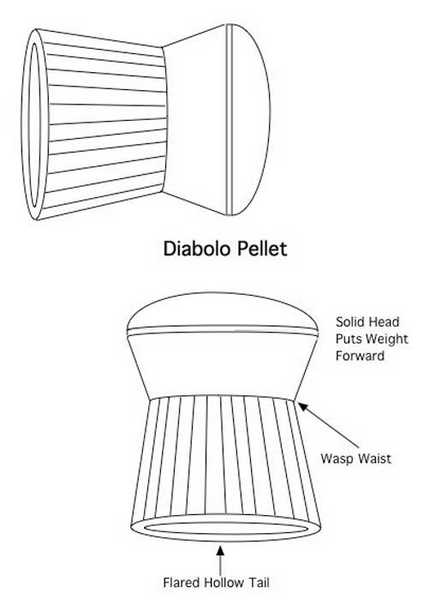

Pellets were also evolving at this time. First, the diabolo pellet had either just been invented or was about to be invented because the rifled barrel needed it so much. I believe the former to be the case.

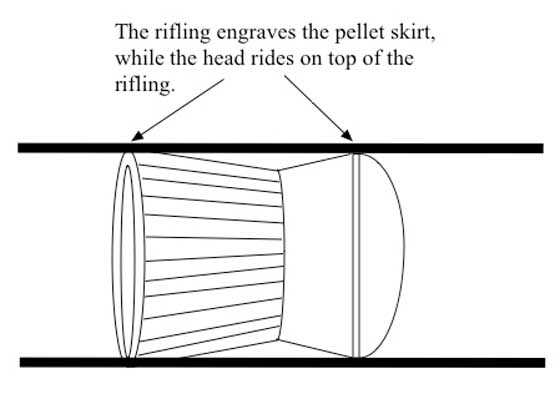

Diabolo pellets contact the inside of the barrel at two points along their axis. Their heads are small enough to ride on top of the rifling sticking up, or if they are engraved, it’s only slightly. The skirts stick out farther and are engraved by the rifling. They are what makes the pellet spin in accordance with the twist rate of the rifling as they travel down the bore.

It turned out that shallow rifling and narrow lands were all that was needed to properly guide the diabolo pellet. If you recall from Part 1 of the rifling series, Ballard rifling was invented in the late 19th century and was considerably shallower than the rifling that preceded it. But in 1905 the first airgun barrels were rifled with lands only about half as high as traditional Ballard lands. Instead of 0.005-inches high, the airgun lands were around 0.0025-inches high. This proved to be enough to catch and hold the pellet at the velocities it was traveling.

Next you’re going to want me to tell you how many lands and grooves they used. I wish I could. But in researching this topic I was struck by the fact that the writers of the day got away with phrases like “finely rifled” and “polygroove rifling” to obfuscate the fact that they either did not know the number of lands and grooves or they didn’t care. I have personally encountered vintage barrels that had 12 lands and grooves and a few (much fewer, in fact) with just 6 of each. There may have been different numbers, but there isn’t enough information to go by.

The point is, the BSA designers understood very well that the airgun they were building didn’t have a lot of energy to spare. Anything they could do to lower the pellet’s friction with the barrel was a plus. Apparently lots of low lands was the solution to lower friction.

Choked barrels

I’m about to launch into the largest part of this report, but before I do I would like to say a few things about choked barrels. We hear about them a lot and perhaps you have wondered if choking the barrel is all it’s cracked up to be.

First of all, what is a choked barrel? Rifle bores are meant to be the same diameter from one end to the other. The military used to gauge their barrels and they marked those that were the most uniform with a star at the muzzle. These are called star-gauged barrels.

But barrel makers like Harry Pope discovered that if there is a slight taper — a choke — near the muzzle of the barrel, that barrel will be more accurate. Even his barrels that were loaded from the muzzle responded to a choke because when the black powder went off it obturated (squashed out) the base of the bullet out into the rifling. So, when it arrived at the choke, the bullet got squeezed down even farther.

Airgun barrels are not typically choked, but sometimes spring gun barrels that have dovetails for the front sight get squeezed down inside a little and it feels like a choke what a pellet is pushed through. The only airgun barrels that are usually choked intentionally are those found on precharged guns. The makers say the choke helps size all the pellets the same before they leave the muzzle. Spring guns size their pellets by squashing the skirts out into the rifling when they fire, so a choke isn’t necessary.

Rifling twist rate

If the number of lands and grooves in a vintage airgun barrel is a mystery, the twist rate of the rifling is as open as a book. It was always one turn in 16 inches of travel. I would like to say something at this point about twist rate. The pellet doesn’t “spin up” to its rotational speed as it travels down the barrel. It’s spinning just as fast at one inch down the bore as it will be when it leaves the muzzle. The length of the barrel has very little to do with how fast the pellet spins. All it can do is increase the pellet’s velocity, which does make it spin faster. But it is the rate of rifling’s twist that determines how fast the pellet spins.

You may recall that I did a huge 13-part test to see what affect the twist rate has on a pellet’s velocity and accuracy. Dennis Quackenbush made special barrels for my Talon SS with twist rates both slower and faster than the standard. I gathered lots of data in the test, but the bottom line was the 1: 16″ twist rate was the best — not back in 1905, but in 2013. Read the series if you haven’t already, because it will help you will understand airgun barrels better.

Other twist rates

Have other twist rates been tried? Yes, they have. I have heard of a 1:14″ rate and a 1:18″ rate. Both of these, though, are so close to the 1:16″ rate that there really isn’t enough of a difference to sort things out. But there is another barrel with a twist rate that’s vastly different.

Smooth Twist

The Smooth Twist barrel is a proprietary rifling system employed by FX Airguns. The bore is smooth until the final few inches, then the pellet reaches the rifled portion and the rifling takes over. The rifling is pressed in from the outside of the barrel (hammer-forged?) If you read the internet comments about Smooth Twist you get opinions that range from it doesn’t work (not too many of those) to it’s the greatest way to rifle an airgun barrel.

Some of the claims for the benefits of the Smooth Twist barrel are:

Higher velocity

Less cleaning required

Superior accuracy — particularly at long range.

They like any domed pellet

Some of the detractors will say:

They cost too much (this is a universal response to anything that’s not free)

They are very picky about which pellets they shoot (one popular claim is they were made to only shoot JSB pellets)

They only shoot well in a narrow velocity band

I have investigated the twist rate reports for the Smooth Twist barrels and found rates that range from 1:45″ to 1:96″. However, these same people who measured their Smooth Twist barrels are measuring other airgun barrels and finding twists of 1:16.798″ and so on! So I suspect they are not measuring the Smooth Twist barrel twist correctly.

It would appear that the Smooth Twist barrel does have a slower twist rate than a conventional barrel. And it also appears that these barrels do favor domed pellets over other shapes. And perhaps they perform best within a certain velocity range, but so do all conventionally rifled barrels.

The Smooth Twist barrel is a different kind of rifling for the 21st century. Who knows where it will go?

The one thing we can say for certain about airgun rifling is, “It ain’t over yet!”

BB

What gets my attention is that statement about smooth twist barrel twist rates and domed pellets.

So maybe some research needs done to be done to see if twist rates do make a difference with wadcutters, pointed or dome pellets. And also that shape of the JSB 10.34’s. What is that shape called anyway?

That even makes me think more about the idea I had about taking the smooth twist barrel to the next level.

Have different screw on tips that have a different twist rate. And I said this before. How do we know if FX has different twist rates for different calibers. Now we need to find if that’s the case for the shape of the pellet.

GF,

I’ve seen one good report on smooth twist barrels, where the rifle was fired with a variety of pellets. At 10m, the wadcutters were making single holes, and at 50m the domed pellets were grouping better. Not rocket science. I plan to wring out the wildcat when it gets here, maybe I’ll know more around the end of the year.

BenT

I had 2 of the FX Monsoons and they were very accurate guns. I was shooting domed pellets with them. Never tryed wadcutters or pointed pellets. Did try some hollow points and they were just as good as the domes.

Like to hear what happens with your gun when you try them out. Post your results when you get them.

will do.

That smooth twist thingy sounds like an attempt to do gain twist rifling on the cheap. Well proportioned gain twist would probably be optimal even for spring guns, but I don’t think one can hammer forge that. Are the other methods to make rifling competitive these days especially in the air gun industry?

Monophonic,

Welcome to the blog.

The smooth twist is not a gain twist, unless you consider going from no spin to some spin a gain. It is an entirely different way of rifling a barrel.

As for the way it is done, hammer forging rifling in from the outside of the barrel is currently the number one way of rifling a barrel. As long as you are making a lot of barrels to pay for the $750,000 hammer forge machine, it is the cheapest way to go.

You are right — a gain twist can’t be hammer forged.

Another method of rifling is through electronic discharge — where an electrode beats away the barrel steel. But that costs too much and is a slow operation, relatively speaking. No airgun barrels are rifled this way yet.

B.B.

Thank you,

I have been reading for a couple of years and wrote a comment or two using a different nick before you had to make registration mandatory. This subject finally had me interested enough to take that step.

I meant to compare the gain and smooth twist in the regard that they are both after the same benefit. Less friction between the barrel and the projectile at the start of the acceleration while still giving a good spin at the muzzle. With the smooth twist the rifling starts when the pellet is already going at a high velocity. Will there be a lot of leading at this spot?

Of course gain twist is also unpatentable thanks to some 150 years of prior art.

That electronic method sounds interesting – similar in principle to the old buttoning process but without the problems with the barrel’s inside surface, I guess? Maybe that could be more competitive if used to cut just the short rifling used in smooth twist but then one could add gain to that?

For historical curiosity has anyone ever tried casting a rifling? Although one would still have to smooth the result so why not just cut the rifling at that time.

I better stop here, I’m asking questions as fast as my 7 year old kid…

-m

Monophonic,

Cast rifling? That’s one I never heard of before. I suppose it might be possible with a bronze barrel for a pellet gun, but what are the advantages? Unless they are there, no one will ever do it.

B.B.

BB,

Lloyd and I had a great time at the show Saturday. I even was allowed the opportunity to hold a bellows gun AND a Girodoni rifle! I also saw a BSA and a Diana from the 20’s also.

BSA may have been the first manufacturer to put rifling in air rifle barrels, but Lincoln Jeffries and other gun smiths were rifling German air guns and reselling them in the late 1800’s and early 1900’s. That led to his designing his air rifle that BSA manufactured.

RidgeRunner,

It sounds like a great show! Maybe you could do a guest blog on it.

Jim

Jim,

I am afraid I lack the skills for such. I have tried to compose a couple in the past, but they just did not come together. I will have to give it another try.

As for the show, it is not yet up to what the Roanoke show used to be, but it is headed there. What is really needed though is attendees. If the vendors know there will be a good turnout, more of them will show up to sell there wares. Also, every show is different. You will see something new every time.

By the way, next year’s airgun show in Hickory, NC is scheduled for October 14th and 15th. You guys need to plan on attending and bring your wallets full of cash!

BB,

I do not know about how the BSA originally performed as the spring in mine is a replacement, however my 1906 BSA shoots 8 grain RWS Superdomes at a hair over 600 FPS.

Would i be correct in thinking that the smooth twist barrel is an FX patent at the moment and like the patent on the Theoben gas ram system will eventually be open to all airgun manufacturers to produce after a certain amount of time?

If so imagine how cheap Gamo or Hatsan will be making them for, Eeeek, think of the quality.

Best wishes Wing Commander Sir Nigel Tetlington-Smythe.

Sir Nigel,

I am sure the Smooth Twist is patented. By whom or for how long I don’t know, but it probably has at least 12 more years to run, if not more.

Yes, I believe you are right. Other makers will copy it after the patent expires. The really smart ones may license it from FX now and get a head start.

B.B.

Hi BB,

Did you make it to Hickory for the airgun show? I hope you did and will have a few good post about it.

David Enoch

David,

No, I didn’t. Too many things happening here for me to leave right now.

Maybe next year.

B.B.

First sentence of the third paragraph, “It turned out that shallow rifling and narrow lands were all that was needed to properly guide the diabolo pellet. If you recall from Part 1 of the rifling series, Ballard rifling was invented in the lath 19th century and was considerably shallower than the rifling that preceded it.”

“lath 19th century” probably should be late 19th century unless you are dictating this article with a lisp BB.

Can the shape of the .177 JSB 10.34gr be called cylindrical or is it semi diabolo or semi cylidrical?

Siraniko,

Fixed. Thanks.

All JSBs are diabolos.

B.B.

B.B.,

The likelihood that Smooth Twist rifled barrels favor domed pellets shouldn’t surprise people. Domed pellets usually end up being more accurate than wadcutters, pointed and hollow point pellets at 50 feet or more with ALL barrels, right?

Question: Are FX’s smooth twist barrels also choked?

Michael

Michael,

I found nothing about the choke, so I don’t know.

B.B.

Michael

Seems to me that the rifling IS the choke in a ST barrel .

twotalon.

B.B.,

I’m interested in the .177 Discovery. I’ve read your review and contacted Crosman but couldn’t get an answer:

If I shot the same weight pellet using PCP and then using CO2, how much slower would the CO2 be?

Very respectfully,

Larry

Larry, if it’s a cold day, the air will be much better than the CO2. If it’s blazing hot, my guess would be less than one might think. But because the Discovery is so easy to pump up (hey, only 1950 PSI or so), if I had one, I’d stick with PCP for it.

CO2 guns do work very well in the Philippines because it’s so hot most of the time.

Michael

Larry,

At least 200 f.p.s. slower.

B.B.

Thank you B.B.

B.B.,

Your mention of people often asking you how many lands or grooves are in the rifling of a barrel reminds me of an oldie but goodie:

On average, how many grooves are there on an LP record?

TWO.

(Monty Python did have a “three sided” record with one side that had two grooves. My friends and I figured out that the best way to go from one groove to the other was to lightly bump the turntable on the side.)

Michael

If one of you guys want to buy the Walther lgv with the competition ultra stock with adjustable cheekpiece, dont wait too long. My gunsmith said Umarex decided to stop selling the most expensive comp ultra stock. The challenger and the master will be the only versions available.

B.B.

A question that’s actually on topic:

“The pellet doesn’t “spin up” to its rotational speed as it travels down the barrel. It’s spinning just as fast at one inch down the bore as it will be when it leaves the muzzle.” But, for smooth twist: the “bore is smooth until the final few inches, then the pellet reaches the rifled portion and the rifling takes over.”

Thus, in a smooth twist barrel the pellet is approaching muzzle velocity when it first engages the rifling. Might this create a problem with lead deposits and, possibly, more barrel wear?

Very respectfully,

Larry

Larry,

Doesn’t seem to. People report the Smooth Twist barre4ls are cleaner than conventional rifling.

B.B.

A question on that same statement but external ballistic, the projectile doesnt increase rotation, but how does time spent rotating in the barrel affect the deceleration as it flies over distance? Can longer times engaged with rifling create more momentum or retained spin through flight? Or is the decrease of spin decided by usual resistance factors, pellet weight, head shape and aerodynamics. Those seem obvious, but what else can affect the lose of spin in flight?

RDNA,

Rotational speed seems to have little or no effect on velocity in the atmosphere. A faster twist does slow the bullet or pellet in the barrel, bit that’s all. And a bullet spun to speed in a 7 inch barrel has the same velocity over distance as a bullet exiting a 20-inch barrel at the same velocity. Spin doesn’t affect speed that much.

B.B.

Not about lose of speed, but lose of spin, drag and bc are extremely finicky things to calculate, so my question is about losing spin. Does a pellet/bullet fired from a 6″ barrel with 1:16 twist have the same spin at 100 yards as a pellet from 20″ of barrel same twist same distance. If the velocity is the same then it will slow its spinning the same right?

Hm, I was wondering about the same statement. The physics principle of inertia, the first law of motion, seems to say that once a projectile achieves a rate of rotation in a barrel it acquires the corresponding momentum. How long it is spun at that same rate does not affect the momentum. This quantity does not accumulate when it is sustained over time; it just keeps the same value. So barrel length should have no effect on how long the spin is retained once the projectile leaves the barrel.

However, I don’t believe that projectiles retain the same speed in the barrel. They are always accelerating because of the pressure of gas. So, the time a projectile travels in a barrel will increase its momentum and retain its spin in flight, not because of the length of the barrel but because of the higher speed that this length makes possible.

Matt61

So velocity at a given twist produces a flight spin concretely, internal ballistics dont change that. How bout external? Pellet shape and drag causing spin to decrease differently? Certain spin stabilize certain shape better, but do those shapes promote sustained spin? Does a pointed retain spin better then a wadcutter and if a long pointed needs faster spin will its shape help keep the spin high? Its probably affected further out then needn’t worry about for pellets but spin and stability really interest me and I think it applies to accuracy enough for pellets to think about it.

Let’s look at the rotational speed of a bullet. The formula for computing the rotational speed of a bullet is:R = (12/T) × VwhereT = TwistV = Velocity in f/sR = Rotations per secondNow consider a bullet chronographed at about 2750 f/s muzzle velocity fired from a rifle with a 10″ twist. It is rotating at around 198,000 rpm. Let the flight velocity decay to 2000 f/s. Now what is the bullet rotational speed? Well, it doesn’t fall off much because the only things slowing it down are inertia and skin friction drag (which is pretty low). With the M80 ball bullet it has been measured about 90 percent of the original rpm (or in this case about 178,00 rpm), depending on the bullet. Then chronograph an identical bullet from the same rifle, this time with a muzzle velocity of 2000 f/s. Its rotational velocity will be 144,000 rpm. Its stability will be different from the bullet fired at 3000 f/s and allowed to slow down to 2000 f/s. It will not have the same drag at 2000 f/s although the bullets are identical.

So a bullet loses velocity faster then it loses spin, and different spin at the same speeds makes different drag… sooo… is the spin affected by dwell time, ie varying momentums, drag, anything? by being spun longer or less in a barrel?

B.B.

Wonderful article! When I clean my break barrel air gun, the last inch or two is much harder to push through.

Does this mean that the barrel is choked? It has a glued on/pressure fit (?) plastic shroud/front finer optic the last two inches.

Thanks,

-Yogi

Yogi,

That’s the test for a choked barrel.

Tom

Gunfun1, in searching for green lasers, I had to remember to get one for a pistol, not a rifle. That cuts down what is already a small pool. Why are there so few green lasers and why are they so darned expensive? They are supposed to be more visible, so maybe that impacts the technology and the expense. Anyway, if we are living in the age of optics, I may as well take advantage.

That is an interesting question of why you don’t need to use holdover with a green laser. It seems to defy geometry. Your sightline should intersect with the bullet trajectory at just one point. All I can guess is that the laser is a continuous medium unlike a mark on a reticle. And lasers are not the most precise instruments. So maybe these two factors fudge things enough so that you look like you are still on the same aimpoint when maybe you are not. I don’t know.

scott80, with the various blowback designs, I completely missed the CZ 75. Yes, this would be cheaper and more convenient than the firearm. But I have something even cheaper than that which is dry firing! Apparently, elite shooters spend a good fraction of their time dry firing. That’s not something I can do with my spring guns or even CO2 without wasting money, so the firearms are a good reminder for this kind of practice. Besides, apparently the CZ 75 SP-01 has somehow managed to eliminate almost all recoil in 9mm, so I want to try that out for myself.

Matt61

Matt61

The one I got is pretty good. I can easily see it out to 150 in the daylight. If its cloudy or dark even farther.

And Ed explained the other day pretty well what is happening when it seemed like I didn’t need hold over or under for the laser. I guess the main reason that it was working was I was shooting at a 12oz breaverage can. And not trying to hit a 1″ target at the 15-60 yards I was shooting at.

What Ed was saying that if I zeroed the lazer at 50 yards which I did. The bullets trajectory still should of hit the can at those distances I shot at if I aimed at center mass of the can. Which I did also. So depending on the distance I shot at the bullet would hit either high or low or dead on in the middle of the can.

All and all it makes for a pretty quick acquisition of the target. Just point and shoot. Pretty much just that quick. So the bigger the target the easier it will be to hit. I like it.

I was going to try a green laser on my 1077 next. But they are awful expensive to just throw on a plinking gun. But on the other hand works real nice on that Savage .22 bolt action rimfire rifle I have it on now. That gun has a purpose. I use it for pesting when I feel the air gun might not have enough power to take the pest.

Is the fact that lasers are usually mounted at the same height as the barrel relevant? Extending the point blank range by starting at the same height so it rides along further before drop kicks in?

RDNA

How is a laser mounted at the same height of the barrel?

It has to be mounted above or below or to the side of the barrel.

I’m not talking a laser bore sighter that you put in the barrel for zeroing a scope. I’m using the laser to aim with.

And there is hold over or under needed at different distances even with a laser. If I was trying to hit a 1″ circle at 15-60 yards and always aiming for the center of the circle there would be different distances that I would miss the 1″ circle. I would hit above or below the circle. Then also there would be distances that I hit the 1″ circle. Of course if I do my part shooting the gun.

I was thinking with side mounting you have them closer to the same height. With most airguns the bottom doesnt usually supply many mounting possibilities and the top has some kind of sight or scope so that left the side. How do zero for different ranges though with the laser crossing side to side? Seems like the bottom might be the best place if a good spot is there for a rail.

RDNA

I would rather have a elevation error rather than a windage error.

Elevation is a normal thing a shooter is use to compensating for with hold over or under do to the trajectory of the projectile.

Windage or the side to side error that would happen at some point of the projectiles flight by mounting the laser on the side of a barrel would be something I wouldn’t like to compensate for at different distances. Plus you would have the trajectory of the projectile messing with elevation also. That would really throw your POI off in relation to POA. You would have elevation and windage messing with you at different distances that you shoot at.

I myself would stay with mounting a laser as close as possible to the barrel. But definitely only above or below the barrel. Not on the side of the barrel.

Did a little digging on my 2200 today after I got my physical done, although it’s a 2200A it has a black powder coat with a silkscreen of a flying ashcan pellet on the receiver and the blue book says that’s the second variant mfd 82-83.

Don’t really matter to me because I’m not letting it go for nearly book value.

It was jammed up inside the receiver by a couple plastic pieces that broke off the sliding bolt, I shook it for a long time before admitting to myself it required complete disassembly. I guess a pellet got back inside the receiver somehow and made a mess when someone forced the bolt too hard. Seems like it was pumping air I was just concerned about not being able to cock and air it out.

OUCH I’d say it’s pumping air alright!

I put my finger over the transfer port so not to lose the seal, slid one of my drifts in place and gave it a little tap, feels like the time I shot myself in the handle with an airsoft pistol to see what it felt like and I don’t see the seal anywhere.

Pretty sure it’s no Canadian neutered model it was at least as loud as my 392 @ 10 pumps

Went to put 2 pumps in it for overnight storage and found the seal, I probably won’t get much sleep tonight but I’m gonna try to save it for tomorrow’s #1 priority after the inspection on my apartment

“The pellet doesn’t “spin up” to its rotational speed as it travels down the barrel. It’s spinning just as fast at one inch down the bore as it will be when it leaves the muzzle. The length of the barrel has very little to do with how fast the pellet spins. All it can do is increase the pellet’s velocity, which does make it spin faster. But it is the rate of rifling’s twist that determines how fast the pellet spins.”

This statement is completely wrong. There is actually a formula for calculating the revolutions per minute of a projectile based on it velocity and twist rate. This is the formula, RPM = MV X 720/Twist Rate (in inches). A projectile does in fact “spin up” as it is accelerates to its maximum velocity before leaving the barrel. The length of the barrel to an extent determines the muzzle velocity therefore any increase in velocity will also increase the RPM of the projectile. Here is a great article on this if you’re interested.

http://bulletin.accurateshooter.com/2008/06/calculating-bullet-rpm-spin-rates-and-stability/

LDD,

Welcome to the blog.

Where, in that formula, does the length of the barrel get plugged in? Nowhere.

The inches refers to the twist rate, which is a constant throughout the length of the barrel unless there is a gain twist.

My statement is correct.

B.B.

I apologize for the harsh wording of my comment. I should have proof read it better before posting it . I also miss read part of the article that I referred to earlier. The issue I have with your statement, “The pellet doesn’t “spin up” to its rotational speed as it travels down the barrel. It’s spinning just as fast at one inch down the bore as it will be when it leaves the muzzle”, is that it is similar to the “bowling ball vs feather in a vacuum experiment”. I agree that both statements are true if very specific requirements are met. I admit that your statement is true, as long as the power plant has sufficient energy to repel the projectile to its maximum velocity within 1″. I also agree that a projectile propelled to 900 fps from a 12 inch barrel is spinning at the same rpm as a projectile propelled to the same velocity from a 24 inch barrel at a given twist rate, say 1 in 16. The problem is that although both projectiles are spinning at 40,500 RPM, one had to do it in 12 inches for an average of 3,375rpm per inch, and the other in 24 inches for an average of 1,687 per inch. The 24″ barrel is, most likely, running at a much higher efficiency therefore a smaller amount of air and much slower acceleration. That means it requires longer to “spin up” to its final RPM. I know the velocity gain is not linear throughout the acceleration in the barrel, but I think it still applies. I just think it is important to understand that as long a projectile is accelerating, it is also increasing how fast it is spinning. For that reason it is possible, in some cases, to overcome marginally stabilized projectile by increasing its velocity.

I want to say thank you for all you do for our industry. I wish there was more people that would invest as much time and energy to promote and write about our hobby as you do. I enjoy your articles very much. I was also very sorry to hear about the passing of your dear wife.

First air gun rifling I know of was Harry Pope in 1873-1874. Working in his uncles shop he made himself a “ringer” air pistol!