Today we have Part 2 of the guest blog from reader Jordan Thompson who we know as Starboard Rower. Let’s now hear the rest of what he has to tell us about the Vz. 35 air rifle.

If you’d like to write a guest post for this blog, please email me at blogger@pyramydair.com.

Over to you, Jordan.

Vz. 35 Training Rifle – Part 2

by Jordan Thompson

Vz.35 with mounted Vz. 24 bayonet. This was the correct bayonet for the training rifle.

This report covers:

- General Impressions

- Main Components

- Minor Parts

- Still a Mystery

- How the rifle works

- What did we learn?

In part I, we dug into the history of the Vz.35.

Now let’s take a look at one example of an early Vz.35, and see what the markings on the rifle can tell us about it’s production.

General Impressions

Close inspection of a Vz.35 indicates a surprising number of markings. We do not typically see this amount of marks on airguns. In this respect the Vz.35 is more like a firearm.

Main Components

Initial impressions focus on the prominent receiver markings, embossed in white and set against richly-blued metal. (This being an airgun, it is properly considered a spring tube, rather than a receiver.)

The double-tailed lion crest is a sovereign symbol, followed by the manufacturer name, the model name, and finally the serial number. These marks are fairly straightforward, and part of the aesthetic appeal of the gun.

1

The Czech coat of arms features prominently on the airgun. Other Czechoslovak rifles of the day had the same crest.

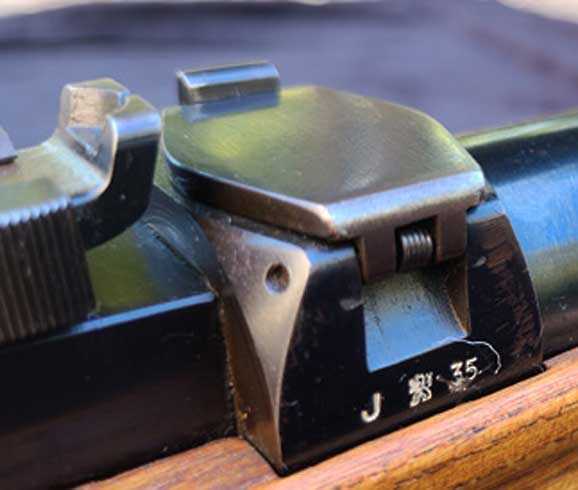

Another major mark is on the side of the hopper, where lead balls are loaded. This is the army acceptance mark.

The Czech army acceptance mark is on the side of the feed hopper. The mark is written as a letter- the Czech lion-and the number. The letter indicates the factory, the lion is the Czechoslovokian national crest and the number indicates the year.

Only two factories are known to have produced the Vz.35 air rifle — Brno (indicated by the letter E) and Strakonice (letter J). Brno was the larger plant, already set up for powder-burning rifle production. Strakonice was the smaller plant, although it is notable that it was the source of the winning air rifle design as discussed in Part I. Interestingly, Strakonice was producing bicycles, motorcycles, and a machine gun for planes at the time they began production of the Vz.35. They did not produce conventional rifles.

In this example we have J, then a lion, followed by 35, indicating acceptance at the Strakonice plant in 1935. This gun is therefore from the first-year of production.

Minor Parts

The story becomes more interesting as we look at smaller parts on the rifle. We can see a pattern where parts were pulled from existing firearm inventory. We can also see that some parts significantly predate the assembled air rifle.

In the rear band we see E lion 34. That would be the Brno arsenal in 1934.

The front band has a similar E lion 34. The crosspin hole has partly obliterated the E, which is common on smaller parts. Both bands indicate Brno manufacture, and 1934 production. Both therefore predate the Vz.35.

The fact that these parts are stamped at all, is interesting. One possible theory is that they are army-accepted Vz.24 rifle parts, pulled from existing depot inventory. The Brno factory could have easily supplied Strakonice with such parts, as they were assembling Vz.24 firearms at the time. This was a common practice at the time and it saved the government money that was not spent on duplicate inventory.

[Editor’s note: The M1 Carbine project mandated parts swapping like this. The government correctly reasoned that if all parts made by different manufacturers for a certain model firearm could interchange, those guns would be far easier to maintain. It is the reason that 1917 Winchester/Enfield rifles were not sent to the European theater in World War I (Winchester’s parts were mot made to the approved specification) and is the reason the Irwin Pederson company was never able to produce an M1 Carbine that was accepted by the Army in World War II.]

Older Still

Looking further, we can see a stylized “ZP” on the bayonet lug. This is a maker’s mark for Zbrojovka Praha, a short-lived company in Prague that went out of business in 1921. This part therefore predates the gun by at least 14 years. Zbrojovka Praha was known for reworking Austrian Mannlicher-pattern bayonet blades.

Note the stylized “ZP” maker mark on the bayonet lug.

The buttplate has two marks. First is an E circle-lion. This is an older-style Czechoslovak Army acceptance mark, which was phased out in 1925 in favor of a different style. It is accompanied by a separate crown – C.

–

Buttplate is German in origin, likely from World War I era production.

By the early 1920s, this part of what became Germany was in Czechoslovak possession. A Czech acceptance stamp has been added to the buttplate, above the original markings.

The crown – C on the buttplate indicates an even older age. It is an imperial inspection mark from Weimar Germany. It is found on MP-18 German submachineguns manufactured by Theodor Bergmann Abteilung Waffenbaul Suhl. These were manufactured from only 1918 to 1920, and have a buttplate and crown – C marking identical to what we see here on the Vz.35 airgun. (The MP-18’s receiver also has this same mark.) It is notable that these were the world’s first submachineguns used in combat.

Still a Mystery

More marks remain. But at this juncture, their significance eludes me. The front sight post has a prominent styled crown – 300 – C.M. The underside of the wood stock is marked with a stylized Z.

This mark on the Vz. 35 stock is unknown at this time.

How the rifle works

The Vz. 35 fires a 4.4mm lead ball that’s gravity-fed through a hopper on top of the action. You saw the closed hopper already, but here is a look at it when it’s open and loaded. When the rifle (yes, the barrel is rifled) is cocked by pulling back on the bolt handle, a long rod on the nose of the piston moves back, allowing one ball to fall from the hopper into the tube just ahead of the rod. The drawing that reader Kevin shared with us last Friday clearly shows this.

The 4.4mm lead balls fall into the action from a hopper by gravity.

A word to the wise, the bolt on this rifle is hard to pull back. The mainspring that occupies a small space inside the action is very powerful. And the rifle fires with a strong jolt.

Rocking the bolt back like this cocks the powerful mainspring.

What did we learn?

The Czechs appear to have made a fine, durable airgun under expedient circumstances. Where they could, they pulled from existing firearm inventory for at least some small parts. A few parts only slightly predate the 1935 airgun, while others go back at least as far as 1920. That is a big gap.

Where did these parts come from? We can speculate on a few sources.

Remember the war reparations Czechoslovakia received from 1918? One possibility is that the oldest parts on the airgun may originate from those stocks, or other parts used to service the WWI rifles. Those included Mannlichers of all patterns from Austria and Hungary. The M95 was the most common. Reparations also included a smaller amount of Mauser 98 patterned rifles and parts from Germany. I would put the buttplate in this category.

Another possibility is that some minor parts are simply obsolete Czechoslovak production of Mauser pattern rifles of the interwar period. They include Mauser-Jelen Short Rifles (1919-1922), the Model 1898/22 (1921-1930), the Model 23 and 23A (1923), the Model 16/33 Carbine (1933), and the Model 12/33 (1933). I would put the bayonet lug in this category.

Or perhaps some minor parts, such as the bands, came from current rifle production lines? That could only be one. The famous Vz.24 itself, produced from 1924 – 1938. The very gun the Vz.35 sought to emulate.

Rarely does an airgun offer such a lesson in history!

Starboard Rower,

What’s the light brown stuff at the forward part of the hopper? Dried grease?

Siraniko

I agree Siraniko, that really looks like dried grease, however, maybe it’s the remains of the deteriorated seal (or both?). Attached is a picture (from vintageairgunsgallery) of a clean lid that shows a circular recess for the seal.

Siranko / hihihi,

That goopy-looking stuff doesn’t seem original to the gun. It is a slightly tacky, rubbery mastic of some sort.

I suspect the original gasket degraded at some point, and a previous owner adding something to help it “reseal”. Whatever they used, it wasn’t great.

I have left it alone since purchasing the gun. Mostly because I didn’t know if it was original. This specimen seems to be in such good condition, I don’t want to “do” anything to it. Just oiling the leather seal when I shoot it, and a good coating of ballistol. Too many historic firearms get reblued… refinished stocks… and the like by well-meaning owners. Not this one!

At this juncture I think I can say with confidence that mastic is not original, and was added. I need to look into how to get a replacement seal and carefully remove the stuff.

StarboardRower

StarboardRower, I would imagine that in 1935 the gasket was made of leather. It may have looked a little like this:

hihihi,

Thank you for that.

Leather would make sense, given the era. Most examples I have seen appear to be a thin dark smooth material (rubber? or similar?), more akin to a gasket. Some have a joint where it looks like a straight strip was cut to length and curled around that recess in the hopper lid.

In the end, I am unsure of the original construction. But I think your suggestion is a good one. Leather could be a good choice for a repair.

StarboardRower

StarboardRower

Lots of information. Nice.

And we going to see it shoot in part 3 and possibly how it was used to train with?

GF1,

Sure! I can do a Part 3. But it will have to be on the performance.

I have found no primary-source information on how they were trained with. Nor a photo of them being used in training. I can only speculate.

The Army Manual I mentioned in the comments of Part I is my best lead. But I have yet to get my hands on a copy!

StarboardRower

StarboardRower

That’s fine. And wonder if the manual actually goes into training or is just a manual of operation.

Guess you need to get that manual so we know.

Probably just a technical manual, with emphasis on maintenance?

I really don’t know. It’s around 30 pages long. So whatever is in it, it sounds like more than just cursory information.

StarboardRower

StarboardRower

Either way you should really be trying to get ahold of that manual.

I bet there has to be a few good things in it. 🙂

Agreed. It is at the top of my wishlist.

I am hoping a reader of the blog will step forward with a copy they are willing to sell.

I have reached out to the publisher in the Czech Republic. They said it is sold out and unavailable. Here is their webpage of recent publications:

http://knihy-brigadyr.cz/vyslo.html

I wonder who bought all the copies? Probably other folks with this same rifle? Perhaps there is a forum or club somewhere in the world devoted to them or a used market where the guns sell along with the reprinted manual? Perhaps there is a copy of the reprint in a museum or library somewhere stateside, as well.

SR,

Below are some google translations from the website. If no picture Is showing, click on blank area. – Don

Description;

Part of sample page 1 translation (publishers comments):

Theory of airgun vz. 35 was implemented as the 4th supplement to the already mentioned regulation D-XIII-1b on the rifle vz. 24. It was a small booklet of 44 pages on not very good fine paper. Thirty text pages were written in a similar form as the “big” regulation of the rifle vz. 24, ie discussed the ways of handling this weapon. The three table pages were a listing of the main parts of the weapon. The remaining pages were a pictorial appendix of variable quality, which included clear important main longitudinal sections, as well as somewhat simplified sketches of individual components. The whole accessory about the airgun vz. 35 was to be glued to regulation D-XIII-1b for all departments. Although the airgun vz. 35 can be considered as an object of rather marginal interest, all the more so we decided for a limited reissue of the original military instructions in the literal form from 1935, in order to conclude a free trilogy about the rifle vz. 24. Although a civilian manual for ČZ 35 air rifles is available today, whether it is a contemporary or a reprint published by a certain publishing house a few years ago, we believe that our modest brochure in the military version will find its “heartbreakers”. – 3 –

Part of sample page2 translation:

Disassembling and folding the air rifle. A. Disassembling the airgun. The air rifle may only be disassembled by an armourer. To disassemble the airgun, you need a screwdriver, two steel punches with a diameter of 2 and 4 mm, a hammer and a wooden mallet. Let’s disassemble the airgun only when it is unavoidable, and do it by removing the air cylinder from the housing. Pull out the trigger pin and remove the trigger. Then we pull out both pins of the guide, slide the guide out of the protrusion of the housing and only then we can pull the air cylinder out of the housing. Pull the nozzle seal, which is pressed against the rear end of the barrel, out of the housing with a wire hook. If the nozzle needs to be replaced, heat it until the tin melts in the turns and then unscrew it with a wrench. (The new nozzle must first be lightly tinned in the threads and screwed onto the cylinder while the tin is melting, which must also be heated to the melting temperature of the tin solder.) As follows: Release the piston spring (it must never be tensioned). Remove the fly protector and unscrew the locking rod, then punch the pin to the upper sleeve with a punch and knock the upper sleeve with a wooden mallet. Use a screwdriver to unscrew the screw to the lower sleeve, loosen the front loop bolt and knock the lower sleeve with a wooden mallet; then we move the butt forward and remove them. Use a screwdriver to unscrew the tension lever shaft and slide it out from the other side with a punch; unscrew the front bolt of the bow and last the connecting bolt. This releases the barrel with the holster in the stock, so we can easily remove it from the stock. After removing the barrel and holster from the stock, we disassemble the other parts of the airgun as follows: Disassembly of the trigger: Disassemble the trigger, which was previously disconnected, by punching out the trigger pin. After disconnecting the trigger lever from the trigger, remove the trigger spring from the trigger. – 13 – – 14 –

Cover:

Don,

Thank you for that. Now I just need to get my hands on the book!

StarboardRower

J.T.

Nice report! Your gun is in remarkable state. None of the blueing has worn off. Seems to be finished to a very high state.

Nice grain on the wood stock, do you know what type of wood was used? I assume that some had stocks from the Vz24?

-Y

Yogi,

I am unsure about the wood type.

One knowledgeable blog commentator from Slovakia has said the vz.35 stock is Oak, and the later vz.47 is Beech. I can’t confirm this. But I have no reason to suspect otherwise.

StarboardRower

Stock is possibly one of the oaks. To my eye it favors an ash or elm. I know when one gets in the lumber trade, species ‘slide’ quite a bit.

Update: I think your guess was a good one. There is a 2005 Strelecky Magazin (Shooting Magazine) article, that describes the 1934 vz.35 development and trials period in significant detail. That source says technical requirements called for “elm or beech, with acceptance for small knots, for the stock and butt.” I believe this is a credible source.

Yogi,

I should add… I am unsure if vz.24 stocks were used. But I wondered about that too. Seems like a way to economize production, right?

The vz.24 receiver dimensions would have required different cuts/inletting in the stock. So at best, there would have to be a split in the production line. Firearms one way, airguns the other. Maybe they did just that, with separate finishing and modification for the airguns. Or perhaps the stocks on vz.35’s were all-together new production. I do not know.

What can we say for sure? We do not see changes in the stocks of the vz.35 over time. That’s interesting. The gun design was not modified during production, as firearms often are. Especially during war production. Photos of others’ vz.35’s indicate that the stock dimensions, wood species, grain, and finishing are consistent across multiple examples, thousands of serial numbers apart. Granted, these were never high-volume guns.

The trainers were made with care. We do not see examples of rushing or economizing as we do with many war-production firearms of the day.

The Czechs seemed to shift to a different pattern to save money (sporter, vs. trainer), rather than press the manufacturer to modify the pattern with cheaper parts, etc. Only after the war did they create a new version of the trainer (vz.47) to save money.

StarboardRower

SR,

This air rifle is in superb condition. The blueing is still so deep and rich. The markings in the wood are still crisp. This air rifle has been very well cared for.

The lead balls in the hopper indicate you do on occasion shoot it. Of course we want to know about the performance of this gem. 😉

P.S. I am sooo thankful I am poor. I would have so many antique air rifles and pistols hanging around my wife would divorce me and make me poor.

All FM will say, RR, he is glad to have gotten hold of what he’s got (1) before meeting Mrs. FM and (2) when prices weren’t crazy and money was actually worth something. In fairness, the Better Half allows FM to have a little fun and vice-versa. After all – you can’t take it with you so you gotta treat yourself once in a while.

FM,

I too am greatly blessed with a fine woman. She actually will encourage me to go out and shoot some on occasion. She knows how much I enjoy it.

RR,

I do shoot it! Yes. Mostly, just for the joy of it. But also, I believe a little oil and working the action on occasion is a way to keep it in good working order.

I can do a report on the performance. If BB agrees… 😉

StarboardRower

StarboardRower,

Yes BB agrees to the performance report. Velocity and accuracy please. And BB also thinks that stuff in the hopper is aged lithium grease. And BB thinks your plunger (the piston in a BB gun) has a leather seal. So oil will bring it back. Maybe 20 drops down the muzzle and a day on it’s butt. Then don’t shoot over the carpet for a long time, as oil will come out the muzzle.

BB

SR,

It is such a joy to shoot these old gals. Many of these are far older than I, yet can shoot with the best of them.

I am looking forward to your performance reports.

Excellent series, Starboard Rower. I think the hallmark of a good series is when you can’t wait to read the next installment, and that’s me. And I love to learn as much from the comments as from the main post. It’s amazing to me that you were able to figure out so many of the markings. I recently came into possession of a customized Mauser Model 98 bolt action firearm in .257 Roberts and would love to unlock the mysteries of all the markings.

P.S. in the caption under the second photo of the butt plate, “German” should be “Germany,” no?

Roamin,

Fixed it. Thanks,

BB

Roamin,

Thank you! I really appreciate the feedback, and am glad to share where others find it interesting.

Enjoy that Mauser 98! Markings really are part of the fun of ownership, and can lead to some real “ah ha!” moments. Clearly, I have gone down that road here!

I have found the gunboards Mauser forum to be useful in research. If you haven’t checked there yet, post some pictures and ask for help. There are many voices that will be quick to help interpret markings. I am grateful to them.

StarboardRower

Could you share a link or two? I was not successful in my earlier attempts. Thank you.

Roamin,

You got it!

https://www.gunboards.com/forums/the-military-mauser-forum.5/

StarboardRower

Jordan,

Roamin Greco said what I was thinking, too. This is a really interesting series and I can’t wait for the next installment, either. When you find such a fine example of a vintage air rifle as this, it’s irresistible to find out as much as you can about its origins and place in history, nice job. You must have deliberated a lot about cleaning out the degraded seal in the hopper. The “mess” is not doing any harm and it is the original, 90-year-old seal material. It may/may not add to the value to the next owner, if that matters to you. The wood, with it’s high contrast grain pattern is beautiful, too!

Will,

Thank you!

Research has been difficult. Especially for an English-speaker. But it sure is fun! Kind of like reading a book… you don’t know where the plot will go.

I was fortunate to get a vz.35 in this condition. I didn’t realize how many markings there were on it, until I had the benefit of time and close inspection. They are all clues.

StarboardRower

Thank you Starboard rower, I am still impressed by even the the quality of a bayonet lug. Nice pictures.

The MP18 is the submachine gun from ww1 that Schmeiser converted from a drum feed design to box magazine at the factory in Suhl. Maybe we could get the military to contract the LCS 19 as a full auto trainer. Those would be great at surplus prices. The British end up taking the wood stock off and call it a sten gun. I like the Sterling. Before 1968, you could just buy one here.

Rob

1stBlue,

Check out these videos of the MP18 here. Both offer some interesting commentary on the magazine. First the (Luger) snail drum. Then the Schmeisser, like you said.

https://www.youtube.com/watch?v=zvxgngDaA4k

https://www.youtube.com/watch?v=7Z7O8SZhdgw

Also – you’ll be able to see that same buttplate and “crown C” stampings we see on the vz.35 here. It seems likely that buttplate would have been used in other guns too. But the 1918-1920 German Bergmann MP18 is the earliest example I can find. Note that the specimens in both videos above have it.

It is also notable that non-Bergmann MP18’s do NOT have this same buttplate/marking. For example, the Swiss produced a “SIG Bergmann” (MP18) under license in 1920. It was contemporary to the German manufacture, but used a different buttplate.

StarboardRower

Truly interesting information/facts on display here; the data about the markings and such can’t have been too easy to find. Seems the designer(s) wanted to make sure the trainees using this air rifle could have as close an experience as possible to firing the powderburner standard-issue rifle. Wonder if you could shoot diabolos with it; guess you would have to load them one-by-one and carefully. Don’t heed FM’s dumb suggestions – you don’t want to damage this very nice and historically-significant air rifle.

FM,

That is a good question.

Diablos are not an option, unfortunately. There is no way to orient the pellet correctly into the barrel.

StarboardRower

SR,

I expect that holds for diabolos, too! 😉

BB

🙂 Ha! Yes…. thank you!

StarboardRower

The devil is always in the details.

B.B. and readership: On B.B.’s advice, I found and purchased a Crosman Mark I pistol. It came to me in relatively good shape, but unfortunately, it appears to have spent too much time in the case and has a few spots of rust here and there. Also the main O ring on the screw-in end cap where the CO² powerlets go, has a visible tear through about half its thickness. I did not have much hope for it, but I read all of B.B.’s blog entries on the gun, and dropped 3 drops of pellgun oil down the chamber where the powerlets go, and three drops around the pin that punctures the powerlets in the end cap. Then I smoothed some more pellgun oil around the torn end cap seal. The gun came with a hollow brass ramrod, so I checked to make sure the barrel was clear. I inserted a new powerlet, tightened down the end cap and flipped the lever to puncture the seal. Nothing. I flipped the lever back and, “sst” I heard a faint hiss for about a half-second and then quiet. SUCCESS! I shot 60 shots, mostly on low power at about 5 yards to get used to the gun and to start practicing B.B.’s lessons on how to shoot one-handed target-style. I left the remaining CO2 in the gun to see if the seals will hold. I still want to get a seal kit. There is a great guest blog that shows in detail how to reseal the entire gun. I will email P.A. to see if they have a seal kit.

Now here’s a question. What is recommended to treat the rusty spots? There are two spots in particular that look challenging: the knurled cylindrical piece peeking out at the breach, and a spot right on the probe that pushes the pellets into the breech.

B.B., will repainting the gun lower it’s value?

Roamin,

Painting won’t hurt the value of the Mark-series airguns, as long as the job is a good one.

BB

RG,

Work some Balistol into those rust spots. It will help some.

Thanks, RidgeRunner. I did and it helped. I put a ballistol dampened clot over a thin screw driver to get into the rusty screw slots. Do I use a toothbrush for the knurled spots? I can’t see any other way to get in there. It’s a nice piece. Heavier than I though it would be.

Roamin Greco,

I’d let it soak up Ballistol for a few days and try brushing it with a toothbrush every week until I’m satisfied.

Siraniko

Thanks, Siraniko. That sounds like a good plan. Now if I can only solve the pellet shortage. Pretty soon, I’ll be shooting cotton swabs…. ;o)

I always have an old toothbrush or two in my tool kits.

SR

A truly wonderful guest blog. I, too, await the third chapter. I was also very impressed with your camera work. It was certainly up to professional standards.

Thank you

Ed

Ed,

Thank you! Let’s hope the third chapter is as good… 😉

StarboardRower

SR, found this on a Czech website; you may have already seen it, but if not, perhaps it is helpful if you ever need to get into the VZ’s mechanism. Couldn’t find anything on how it was used in military training, at least not in English.

http://www.vzduchovka.cz/dokumentace/VZ35_rozkres.jpg

FM,

Thank you! I have seen that diagram before, and it is one of the best ones. I think a lot of readers will be glad you shared it.

“Vzduchovka” factors in to a lot of my keyword searches. It means “airgun” in Czech! The fact that it starts with “Vz” is pure coincidence to the vz.35 name. Apparently the words for “airgun” and “model” both start with VZ in Czech.

StarboardRower

StarboardRower,

Thank you for a very interesting and well done guest blog.

This might be a place for you and the blog readership to learn more about Proof Marks, Gunmakers Marks and lots more:

https://present5.com/proof-marks-and-identification-understanding-firearms-markings-1880/

This is a more general potential initial source also of interest are the research links: http://www.vhu.cz/english-summary/

Now I need to go drink my Pilsner Urquel!

shootski

Shootski,

Thank you for that. I was not aware of Ian’s slide deck there. I will have to look through that.

It appears similar to this book. Image attached. I bought it for my research on the vz.35. But after going through it, there was no relevant info to this training rifle. Emphasis is on other European arsenals. And of course, airguns don’t have firing proofs. But would be a must-have for any firearm collector, I would think!

As for the Military Institute in Prague – that is perhaps my best source! It probably only took me a few months to find them… while you got there in minutes… 🙂

StarboardRower

That is a fine brew. Have heard Budweiser Budvar is good too – not brewed in St. Louis. 😉

Jordan,

The rifle is a beauty, and I am enjoying the level of detail you are presenting with all the pics. I am very much looking forward to the performance report on velocity and accuracy. Thanks for the great job so far. 🙂

Take care,

dave

Do you think the white highlight on the engraving is original? I just bought one this week and it has white highlight as well but only ones I have seen? I assume a collector added it?

,

No, I think the white was added later by an owner.

BB

45flint,

Yes, I believe the white is original manufacture, for the first few years of production. I have seen enough vz.35’s to say that it is common and consistently applied among 4-digit serial number guns.

The amount of white we see today seems dependent on condition. Specimens in good condition tend to have it as a rule. Specimens that have oxidized or lost bluing tend to have less, or none at all.

This appears true of all Czechoslovak produced vz.35’s (1935 – 1938). See attached image for an example of early production, but starting to lose the original white.

I will say that I am less sure of vz.35’s produced under German occupation (late 1938 and later). These tend to have serial numbers above 10,000. I don’t see examples from this era of production with the white engraving, regardless of condition.

As an aside, this era of production began to remove the Lion seals – which was a CS sovereign symbol.

StarboardRower

45flint,

Another image, this time from late production. An example of the factory producing guns without the lion crest.

This one is in poor condition. So it doesn’t hold much meaning for the discussion about white engraving. Still, I will say that models produced under German occupation seem to not have the white engraving, regardless of condition.

StarboardRower

Awesome 2 blogs, cool to read this as I have a VZ35 arriving from a auction in a couple days. It will be so interesting to look at its markings and dates of components. Only thing I find in error is the VZ35 was made to fire 4.45 lead balls not 4.4. But that’s a pretty small error. Lol

Loved your research in this blog must have read it several times. Here are pics of my new rifle. Some interesting acceptance marks as well.

https://imgur.com/a/AzuYi3s

Your gun is in excellent condition. It’s hard to find them for sale at all. Congrats on a great find! Thank you for sharing the photos.

On the hopper… to the top right of the acceptance mark, above “38”… is that another mark/stamp? It looks too uniform to be scratches. Kinda like screw threads?

I do not think this is it. But I have seen one example of an early production Czech army order vz.35, that has another mark: a single German Waffenamt stamp. Very faint. The stamp is located on the back of the spring tube. This particular vz.35 specimen is profiled in a book. If genuine, the stamp would suggest it was confiscated by the occupying forces, and put into the German army depot system. This seems strange, as I have seen no reference to German army usage of airguns for training anywhere. Only export back to Berlin for the RAD. Perhaps a zealous German inspector just began inventorying everything, and putting a stamp on it, before they really began sorting the spoils?