This report covers:

- No rebuilds

- Yogi

- Dental picks

- Gunsmith’s screwdrivers

- Lights

- Measuring tools

- Drop cloth

- Cutting board and razor knife

- Electric drill

- Liquids

- Summary

Here we go into Part 2 of the tools that an airgunner needs in his or her kit. Before we continue, I need to explain something.

No rebuilds

I haven’t been talking about rebuilding spring-piston airguns. Reader RidgeRunner asked why I hadn’t put a spring compressor on my list. You won’t find it on today’s list, either. It’s not that I am against airgunners going inside their spring guns, but I don’t think that it’s fair to assume everyone wants to. If you want to then, yes, a mainspring compressor is an essential tool. Either that or just buy a TX200 Mark III and you won’t need one.

My list is those general tools that I think all airgunners will eventually need. Sure, I go inside springers and I have a lot of tools that I will not show you in this series because they are very specific to one or two jobs. But I’m writing about the basic tools I think everyone should own if they own an airgun. Let’s get started.

When I wrote Part One there were tools I didn’t write about, but I knew they would be in Part Two. Then I read all your comments, to see how much agreement there was. And also how many departures there were from my basic list(s). Let’s begin there.

Yogi

Reader Yogi suggested a torque wrench. I haven’t used one of those since I worked for AirForce Airguns in 2003-2005. It’s not on my list and I don’t think it needs to be.

Yogi also recommended zip ties and while I have bags of them to tie the actions of airguns I take to shows (so they can’t be cocked and fired), I don’t consider them to be an essential tool for airguns. Maybe Yogi could elaborate.

However Yogi was the first to recommend a tool that wasn’t on my list but should have been — dental picks.

Dental picks

I used to hoard dental picks because they are so handy for doing so many jobs like removing breech seals and o-rings. Then I found them for sale in an electronics store. In frustration I went online and bought a small assortment of picks that are now in my go-to airgun repair box. Good one, Yogi!

Dental picks are essential if you want to work on airguns.

Gunsmith’s screwdrivers

Another one that wasn’t even on my list but should have been was gunsmith’s screwdrivers. Reader Derrick mentioned hollow-ground screwdrivers and I have a set of them that are so used that I forgot about them entirely. But reader JerryC brought up a whole story about Vessel Phillips screwdrivers from Japan. He got both me and reader sawdust, who is my neighbor, Denny, so excited that I went online and bought a small set for each of us. Sawdust said I should buy some so he could borrow them, but I just eliminated the middle man by buying him a set. They are not that expensive and if there is one screw type I have difficulty with it is the Phillips.

On the other hand, there are Vessel brand screwdrivers with wood handles that are quite expensive. But the Vessel tools that use bits seem to be the most popular today. I sure hope they are as good as JerryC said.

Vessel screwdriver set.

These screwdrivers are for pocket watches and some clocks. I don’t use them for airguns often but when I need them nothing else will work. That thingamabob on the bottom is for taking hands off watches and clocks. I threw it in the picture just for fun.

A proper set of Gunsmith’s screwdrivers.

Lights

Reader Michael mentioned using lights in his guitar work, which, by the way, we all learned is many times more intricate than working on airguns. Well I second that. Lights were on my list for today.

In fact I own lots of lights. Many are for photography but some are for just seeing in wee teeny places where strong room light can’t reach — such as inside the spring tube. The power of LEDs makes battery life last a long time, even with great brilliance.

There are a few of the lights I use when working on airguns.

Measuring tools

I use measuring tools lot, but mostly in my role of writing this blog. That’s for things like measuring group sizes. However, If I want to know how long a collapsed mainspring is, to see if it will fit inside a spring gun, I have to measure the wire size with a caliper and then multiply by the number of coils. When I want to report the length of a barrel, stock pull or overall length I use a tape measure. To give you the weight of guns, parts and so on I use a kitchen scale and for pellets I use an electronic reloading scale.

I use a kitchen scale for things that weigh up to 8 or 9 pounds and a reloading scale for small things. Both scales read in grams and the big one also reads in pounds and ounces while the small one also reads in grains.

I use the digital caliper most of the time, but the dial caliper opens to 8 inches and the micrometer is handy for some things like bullets.

Drop cloth

You need a place to work and even when I was on the kitchen table I had a drop cloth. Leapers gave me a great one that I have used for many years. It rolls up tight when not in use and it protects the gun and work surface from scratches and dents. It’s really more of a pad than a cloth. You have seen mine for years in my pictures while working on airguns.

A UTG drop cloth, which is more of a pad, protects the surface I’m working on.

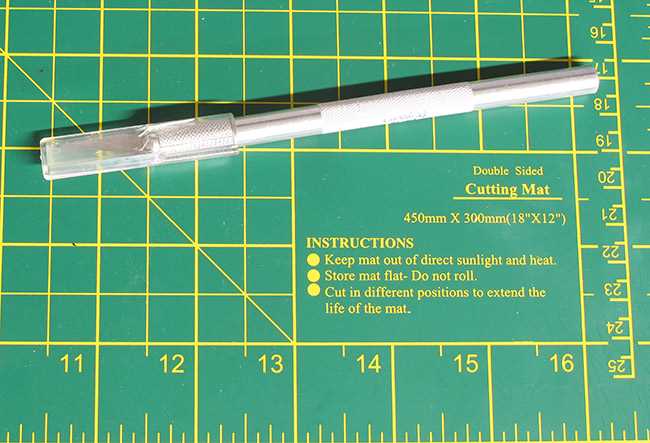

Cutting board and razor knife

I use a razor knife for small work like trimming leather seals. To preserve the surface I work on, I use a cutting board.

When I use a razor knife to trim things I always protect the surface I’m working on with a cutting board.

Electric drill

I can’t say enough about my electric drill. It’s always ready to chuck up a drill bit or a part for some work. I mentioned the Dremel tool in Part One but I use the electric drill just as often. And with that, of course, are the drill bits. I will say this — that good quality drill bits are hard to find. I always seem to get the other kind.

My electric drill comes in very handy many times and not just for drilling.

Liquids

Reader hihihi mentioned lubricants and solvents. That’s probably a whole report of its own. Are they tools? Not really. But they are essential to the airgun repair person. Maybe they will be Part Three.

Summary

In today’s report I have completed the essential tools I believe an airgunner needs to do minor maintenance on his or her airguns. These things take years to acquire unless you’re prepared to spend a bundle. I advise going slow and buying what you need as you need it, if you can.

B.B.,

In these days when everyone seems to slap a scope on a airgun as soon as they get it, perhaps they are not so essential a tool. But one of the most important tools I have, for firearms and for airguns, is a fine set of Swiss files. For any kind of [steel] open sights, they are excellent for adjusting the opening of the rear notch, or slimming down the front sight, in order to get you to see the right balance of light on both sides of the front sight. And on fixed-sighted guns, like my old Hawken, they allowed me to file down the rear sight to raise the point-of-impact to be dead on at 50 yards. They have also tweaked the steel sights on many an old air rifle or pistol…just my 2 cents. I couldn’t live without ’em! 🙂

Great series, take care & God bless,

dave

Dave,

A great set of files are very essential if you know what you are doing with them. I myself have reshaped ramps, removed burrs, rounded edges, smoothed surfaces, etc. Are these for the basic set? I could put in the argument for a good set of wood rasps for reshaping stocks and grips, but some would most definitely freak out.

“I could put in the argument for a good set of wood rasps for reshaping stocks and grips”

RidgeRunner,

I’m with you on that; back in the days when I was doing restoration on old shotguns, many had broken stocks; wood rasps were an essential tool to shape the new ones. 🙂

Those were fun times…and my wife supported me in those efforts…at least till she found out I was only making about $1.50 to $2 per hour (I wanted the guns to be perfect…but that takes a lot of time); then she shut those efforts down to be re-focused on her “honey-do” list. LOL! 🙂

Happy shootin’ to ya,

dave

LOL! My wife would not care as long as the hobby paid for itself and the “honey do” list was done!

I used to rebuild old Mosberg scopes. I enjoyed that very much. I would do that again in a heartbeat, but people want too much for them these days.

“…as long as the hobby paid for itself and the ‘honey do’ list was done!”

You nailed it, man! I was only earning a couple bucks per hour for something that put the “honey do” list on the back burner for many months…that’s the husbandly path to the dog house! Hahaha! =)~

I think all of us husbands find our way there sooner or later.

LOL!!! Sadly, too true! 🙂

B.B.

I grew up with a bunch of guys who thought that bailing wire and duct tape could, at least temporarily, fix just about anything. To me, zip ties are the 21 th Century equivalent.

FWIW-I use zip ties on the end of my zippers on my range bag and gun cases. I zip tie my range ID to the zippers to. I have zip-tied actions in stocks temporarily to check sights or scope placement when I am to lazy to insert the stock screws.

If you ask nicely, many dentists will give you their old picks. They seem to replace them pretty regularly.

B.B.

Maybe you could do a blog on hollow ground screw driver bits? How they are different, how they came to be, and why they are essential.

Thanks,

-Yogi

Yogi,

Good idea about the blog on the screwdrivers. It could save a lot of screw heads.

BB,

You didn’t mention your bathroom scale for measuring the cocking force of springers.

Siraniko

Siraniko,

Ha! 😉

BB

Hi everybody,

so gunsmith’s screwdrivers are a thing… That would explain why it’s sometimes so hard to find a flathead screwdriver or bit that fits.

I sometimes wonder why they don’t use something better on screws that need to be tight like Phillips, hex or Torx screws but that probably has to do with tradition, looks and the fact that qualified technicians have better tools and enough experience so they don’t tend to mess up screw heads 🙂

Stephan

Stephan,

Oh yes! You should not go near an airgun or firearm if you do not have a decent quality set of hollow ground gunsmith’s screwdrivers.

BB,

I cannot overemphasize how important a good quality set of gunsmith’s screwdriver bits is. I have buggered many a screw in my lifetime and have seen even more. This is where you learn the art of repairing screws. Hint. This is when you are most definitely going to need some very small, good quality files. 😉

With these two blogs, you have managed to make a pretty good list of tools. Each of us old geezers can probably add a tool here and there, but your suggestions are spot on for the basic newbie airgunner.

No, you should not go inside a sproinger if you do not know what you are doing. It is really a good idea for most to build their own spring compressor. To do such you really need to have a decent idea of what is going on. I can see where one of these things are not suitable to a newbie.

To Whom It May Concern,

I will take this opportunity to apologize to those who for some strange reason wish to communicate with me and I fail to respond to your comments. My excuse is as many of you have noticed, Word Press has made it much more difficult for anyone to respond to someone else’s comments. Constantly having to login to reply can wear one out pretty quick, but oh no, Word Press is not broken.

Well here I go.

So far no mention of cell phones. It’s probably one of my more important tools for many things. At work we call them our modern day mirror. Turn on the camera or video. Also take pictures as you work on something. Or search for diagrams and such. Don’t know about you all but my smart phone gets used alot.

Used mine yesterday to check if the scope I mounted on the .22 Maximus was level and also measure distance to reposition the target when doing the sight-in and to double-check my math when adjusting elevation and windage.

Agree with you, B.B. – good drill bits seem hard to find. Methinks it’s due to the “build it to Big Box Wally standard” syndrome. Which applies to a lot of other products.

FM

Yes about your cell phone. And yes good drill bits. I have worked at the machine shop for too many years. A good carbide drill will spoil you.

My smartphone is my electronic Swiss Army Knife. Calculator, notepad, camera, document reader, audio recorder/player, flashlight, gps device, web browser, gaming device and probably a dozen other things.

I very rarely use it to make actual phone calls 🙂

CptKlotz

Same with my cell phone. 🙂

I agree CptKlotz and everybody else, all the many functions in one small electronic device are indeed convenient to have available.

However, I wish there were a smartphone that allowed the user complete (!) control. For example over the microphone.

Remember old spy movies, where rooms were first searched for bugs, or loud music played, before beginning to speak privately… 🙂

That is funny. I have never found a use for one of those things yet.

RR

A use for one of what things?

Probably a cellphone

Siraniko

Siraniko

Probably.

I have a cell phone (flip type) so Mrs. RR can get in touch with me when SHE wants. I was referring to the so called “smart” phones.

RR

Try one.

GF1,

Why? I have two laptops and a Kindle. What do I need with a teeny tiny computer that I cannot see what is on the screen just so I can carry it around in my pocket?

The truth is, I have played with them before. They are not worth what they cost or what the “service” costs. I am not one of these who has to have the latest and greatest toy to come along.

RR

Do you carry your laptop and kindle with you? How much did they cost? And if you search you could probably find a smart phone for free or even a hundred bucks if you look hard enough. And probably from the provider you already have.

No, I do not carry them with me. If I am with Mrs. RR, I do not carry my flip phone with me.

My phone company has offered me a free “smart” phone before. I declined. I had to “upgrade” my service. I pay less for service for two flip phones than one “smart” phone would be.

I have yet to invent a reason to justify my having a “smart” phone, most especially since I have something else that does just as well. By the way, one of the laptops is supplied by work. I am working from home and have been for over two years now. They have also supplied me with a nice docking station and two 21 inch monitors. I even brought my very comfortable work chair home. I did buy a wireless ergonomic keyboard and a wireless trackball. I also had a nice cherry desk made. If the company decides I need a “smart” phone for whatever reason, they will provide me with such and pay for the service.

Personally, I just do not need one. I would rather spend that money on the Webley Junior I just picked up. Now that I need. 😉

RR

I guess the different apps available is something I’m talking about with the smart phones. Alot of different things available to allow the phone to do different things.

GF1,

I do understand the attraction of the “smart” phone. Many of the apps, which used to be called software, are available for my laptop or my Kindle. As an example, I use my Caldwell chrony with my Kindle. I have found that I do not need another computer around here.

RR

Yes good example of a app for your Kindle or a smart phone.

And yes if you already have the Kindle why buy a smart phone.

But yep that’s what I was talking about.

Well, here I go. BB, what is you answer now?

The world’s best airgun doesn’t exist…

by Tom Gaylord (B.B. Pelletier) April 6, 2018

RR,

It’s the same.

BB

BB

Has cold blueing been mentioned? I have one that is a pen and it removes the tell tale shine from any screw from that gun I bought second hand. Of course I never make shiny mangled places in screw slots. It is very handy, just repair and smooth area as needed with an appropriate file and press the pen tip against the offending spot and voila. No clean up necessary.

Hoping you follow up with a report on lubricants we all need. There are so many overlapping products and then I hear just get out the 3 in 1 and have a go at it.

Deck

Deck,

I haven’t addressed cold bluing. And I will make lubricants Part 3.

BB

Lubricants are an area where there are so many choices, it is bewildering! I went to a hardware store to buy 3 in 1 oil that B.B. often recommends and found 3 or 4 varieties with that brand name. That’s just one example. But I have 30 tubes of pellgun oil (I got them for a screaming deal), a spray can of Ballistol, a tube of RWS Air Chamber Lube, a tube of Tune in a Tube, and a small container of moly paste, so I think I’m set for a while. What is RWS Spring Cylinder Oil used for?

Roamin,

RWS Spring Cylinder Oil is used to lubricate the piston seals in spring guns.

BB

Hmm. I thought that was what the air chamber lube was for….

Deck,

Those cold bluing pens are pretty good at minimizing the annoying white warning print on blue finish air guns. Just be sure to really press the felt tip hard against the surface. Unfortunately, a pen is therefore only good for about one job. Dennis Adler wrote an excellent tutorial in his blog on how to do this and other “distressing” of air gun replicas of classic firearms. There are also u-toobe videos showing these techniques.

Michael

Michael

I should have mentioned that I store the blueing pen vertically so the tip is always down. Have extended its life at least a couple of years.

Deck

Deck,

I may have to get me one of those pens and try it out. I have done cold blueing on a large scale, but never as a touchup.

RR

It also does a good job on exterior corners or edges that shine.

Deck

I’ll have to remember the shiny edges.

BB-

Great report today, although the pic of Gunsmith screwdrivers is kind of misleading. I would refer to that as more of a general purpose set for household use. Not enough slotted bits in a range of sizes. For interchangeable bits and drivers I would class the Chapman and Brownells at the top for range of sizes and durability. As in I haven’t been able to snap any yet. Next would be the Wheeler, Pachmyer, Weaver sets that are in my tool drawer. Those have (rarely) snapped. Last would be the typical flea market/Harbor Freight sets. Have those in every vehicle, tractor, etc. No big loss if lost, but sure handy to have close. I just don’t trust them for critical work.

Augmenting the interchangeable bit drivers are dedicated hollow ground drivers. Brands I like: Brownells, Forster and Grace. These get pricy. Can’t afford to buy full sets all at once. Bought starter sets and then would add sizes as needed.

Also buy used when I get the chance. I’m not proud. Always looking for good American made brands at sales and flea markets. Take them home, clean em up and touch up the bit and toss em in a bucket. When I need a certain size driver (that I don’t already have) I sort through the bucket for a candidate. Have a decent grinder and a light touch to restore and make the drivers fit the slots. Slot fit is the key to no buggered screw heads. Don’t get in a hurry.

Mention was made of the newer improved bits for driving screws. I refer to most of them as ‘OneWays’. Meaning, their designs are good for going one way- into the workpiece. That’s why manufacturers love them. Easier to use by unskilled labor, they’re cheap and fast. The trouble comes when it’s time to go the other direction. Some tips that can help. Always use the longest driver you have that fits. Make sure the tip is in good condition. Insert the tip into the fastener and then give the driver a good whack on the end of the handle with an appropriate size hammer. This helps seat the bit into the recess and will break the fastener loose from rust and grunge. On tough to budge fasteners, removal becomes an entire body endeavor. The workpiece- gun- gets clamped in a vise or to a table. I press my body weight against the handle. This leaves my hand(s) only providing the turning force. When it works, the world is in proper order, the sun shines fair upon the land and birds sing forth. When it doesn’t work, the skies darken and further measures are employed…

Paco,

I was going to photograph my Chapman sets (both slotted and Phillips, plus those in the box with the handles and extension) but those dark bits don’t photograph well. You are right that what I showed would need to be filed for specific screws to make them right for specific guns. But that’s what gunsmith do.

BB

BB,

This gunsmith is listing his essential tools: https://youtu.be/EYsdidQH5Yo and mentions grinding ordinary screwdrivers into hollow ground to use. This gunsmith made a good illustration of the difference of a hollow ground to a flat ground screwdriver: https://www.youtube.com/watch?v=o7XKmJWQ3aw

Siraniko

Siraniko,

That second video is excellent!

BB

Pacoinohio, on grinding screwdriver bits to size, great “tip”!

paco

This isn’t really a tool but you reminded me of something my dad had in his workshop in the barn when you said you would throw the bits in a bucket then find the one you wanted.

He had 2×4’s above the work bench with adjustable lights on arms and over in one section he bolted the lids of baby food jars to the 2×4’s then he would put things in the jars and screw the jars on the lids. So basically you could see in the glass jars above your head and unscrew the jar and use what you needed and screw the jar back on the lid.

Plus it kept younger Gunfun1 and his brother and our friends from getting into everything. Well until we found where he had the ladder stored. It was a 5 foot ladder I guess. But layed on its side and slid between the work bench and wall with a hinged door. He kept things organized and clean. And if we wanted to use anything it better of got cleaned off and put back where we got it from.

Gunfun1, good idea to recycle glass jars.

Nowadays clear plastic containers provide the same view of the contents but make a less dangerous mess if dropped onto the floor.

Personally, I like the plastic boxes that 16 ferrero rocher chocolates come in, stacked on a small shelf, for nuts’n’bolts etc.

PS chocolate is made from cocoa beans, which are a part of cocoa pods that are the fruit of cocoa trees: I like to remember that eating fruit is supposed to be healthy! 🙂

didn’t know that one can not add a picture when editing one’s comment

hihihi

Nice set up.

hihihi

You know they say dark chocolate is suppose to be good for you. 🙂

chocolate = fruit = good

dark chocolate = more fruit = gooder ! 🙂

hihihi

🙂

B.B., an excellent series. This would have come in handy over the last couple of years as I have become immersed in this hobby.

I would thank JerryC if he could confirm that the Vessel set you pictured is the one he was referring to. Stripping out phillips screws is the bane of my existence! I have seriously considered replacing any phillips screw I come across with a square or hex bit screw.

Roamin,

I guess I am just going to have to test these guys, because Phillips screws are also my bane. JerryC’s screwdrivers have wooden handles. I could have bought some used ones on eBay, but they are more expensive. After all the nice things he said about the Vessel firm I just wanted to see if it is true.

A test is coming!

BB

Don’t know about this brand, but I recently bought a set of Milwaukee drivers that have even worked on the evil Phillips types…so far.

This blog inspired me to do something I should have done many years ago. I ordered a set of torx screws, Pachmayr, to replace all other types when I have to deal with them. Hex not included. This will not be a crusade, just as I have a chance.

Buggered screw heads-R-Us applied for years until I got a set of Outers drivers in the little red box. I still have all of them! But torx rules!!

Gene43,

I have had good experience with Brownell’s Magnatip bits. A little pricy. But good. Got two driver lengths including a stubby.

I’ve still had to piece together additional bits to round out the set. Also a set of fixed her drivers by Wiha in Germany. Worth it. It’s the smaller sizes that will make you get them.

Here’s a pic of my airgun “drawer”. MUCH cleaner than my garage and automotive and carpentry tools!

Also in the pic are my pelletgages and bore cleaning rods. The latter are good for clearing a stuck pellet.

StarboardRower

Trying to attach the pic again…

Also, I would really appreciate an explanation of the difference between hollow ground screw bits and everything else you find at the hardware store.

I would add a recommendation of a good vise to use when working on guns. How do you make things immovable without damaging the item? I have several vices but I need a good vise.

Roamin,

I have several vices, too, but I’m trying to get rid of them. 😉

But good vises we can talk about.

Now, for hollow ground screwdrivers, let’s go back to when we discussed sharpening straight razors. Many of them are also hollow ground.

/blog/2017/10/how-to-sharpen-a-straight-razor-part-5/?swcfpc=1

I don’t actually mention the hollow grind until late in the report, but I show a graphic of it up front. In screwdrivers is keeps the driver from buggering (messing up) the sharp edge of the screw slot.

BB

B.B.,

After I finally bought a used jeweler’s vise, I began to kick myself for not getting one many years ago. I might not ever stop kicking myself for that. A jeweler’s anvil and a small peening hammer are also nice to have if you can pick them up cheap.

B.B.,

Guitar work does involve finesse and trial and error, and guitars, even solidbody electric guitars, are much more delicate than air guns, But guitar work with the instrument’s hardware is not more difficult than air gun work. Below I have a photo of the electronics of a Gibson Les Paul, which is, I’ll admit, intricate. It is also the type of guitar work I am not especially skilled at.

Michael

B.B.,

Guitar amplifiers are much more intricate and involved than are guitars. I am OK at working on them, but that is only for routine things. And a guitar is not likely to kill you. But the capacitors in an amplifier, especially a vacuum tube amplifier, can throw you across the room and stop your heart as it does so. Have to know how to do it safely!

Here is a “gut shot” photo of the inside of a Fender Deluxe Reverb made in 1964. All of the wiring was done by hand in Fullerton, California.

Michael

Michael, I’ve taken several Crosman Mark I and IIs almost completely apart (and managed to put them back together again), but I would not go near electronics with my extra thumbs without a lot of instruction. A man has to know his limitations. Can I send my kids’ broken electronic toys to you? Some cannot be easily replaced.

Roamin,

I know how to do some work on the electronics of guitars and guitar amplifiers, but I know very little about electronics. Huh? Well, I know how to solder and what component is appropriate and how different values will affect the sound. I do not know without reminding myself with a book (and I do have a few) what the difference between watts and current is. Current is measured in amperes and wattage in watts, but beyond that? Nope. But I do know that when it comes to being able to drive complex and demanding (i.e. low ohm) resistance loads, current is what matters. Wattage is a Porsche sports car. Current is a cement truck. But technically the difference beats me. And I’m terrible at math; there’s that

I would simply do a search for electronic toys and vintage toy repairers.

Michael

Thanks, Michael. Now I can stop scratching my head.

Michael,

You fix the guitar, and I will fix the amp. I used to enjoy Heathkit when I was a kid. I built a couple of audio amps. When I was a little older, I repaired radars and communication equipment. Right now I design control systems for manufacturing equipment. I couldn’t tell a Les Paul from a Stratocaster.

B.B.,

Not having a Bore Light or a Bore Scope on the list is forgivable!

NOT having a CHRONOGRAPH on the list isn’t; even if you never open up an airgun you need one to know that something has changed…unless you have a PhD in SPLATOLOGY!

shootski

shootski,

Ah HA! Good on you!

BB

I find a good torque limiting adjustable driver to an essential tool. In my younger days I mounted scopes without a good torque wrench and got lucky most of the time. Mounting rails ,rings and scope caps to the specified torque is the best way to go. For me the most important things to tighten properly and repeatably are scope components and action screws. The torque on your action screws will make the difference between can and can’t. For really quirky drives(mainly odd slotted) ones) I buy cheap harbor freight screw drivers and modify as needed, I have dozens of such in my tool chest with hang tags on them , Off topic, anyone see the new Rossi .22 lever and pump rifles ? Those Phillips head machine screws on the side of the actions are hideous . History Guy video Y’all might enjoy..

https://www.youtube.com/watch?v=R-mDqKtivuII

I use a torque driver similar to this one in rebuilding mechanical seals for pumps in the Petrochem industry as well as in my home workshop.

https://www.amazon.com/dp/B097XXLT39/ref=sspa_dk_detail_4?psc=1&pd_rd_i=B097XXLT39&pd_rd_w=D6HaN&pf_rd_p=df921cda-5343-4253-9b4b-22d7387ad3d4&pd_rd_wg=4dEyn&pf_rd_r=Q14EZX5NPZVBBMV4BDCJ&pd_rd_r=e19a7ed5-103e-4d17-a46c-1a1048dbbbfa&s=hi&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUE2UURXOEFTOUQwTTUmZW5jcnlwdGVkSWQ9QTA2MTEyMDYxMzRNWFg1VURTTEFDJmVuY3J5cHRlZEFkSWQ9QTA5Mzg2MDgxWlBPN0NMSDdPNTU0JndpZGdldE5hbWU9c3BfZGV0YWlsJmFjdGlvbj1jbGlja1JlZGlyZWN0JmRvTm90TG9nQ2xpY2s9dHJ1ZQ==

So many good tools suggested here, FM is getting stressed out deciding what to add to the wish list and determine priorities. Definitely a chrony and torque screwdriver for starters; wouldn’t hurt to have a small air compressor either. Also a good, working brain – used is fine. Have to place an order with Igor for that and hope things don’t get screwed up by supply-chain issues. 🙂

Basil,

Just make sure Igor doesn’t bring you a brain from Abby Normal! Lotsa trouble with that one. 😉

BB