Air Venturi G9 high-pressure hand pump.

This report covers:

- Assembly

- History

- Back to the G9

- Why tighten slightly?

- The test

- More

Today I start looking at the Air Venturi G9 Hand Pump. This is a hands-on report and, reader Elmer Fudd, I still have several of your questions before me to answer:

- Are the more expensive hand pumps worth the difference in price?

- Do the more expensive hand pumps reduce the pumping effort required for higher pressures?

- And I have not told you very much about the AirVenturi G9 hand pump — yet.

Since I’m assembling and testing the pump today, the last question which is actually an area of concern will be addressed in this report. Let’s get started.

Assembly

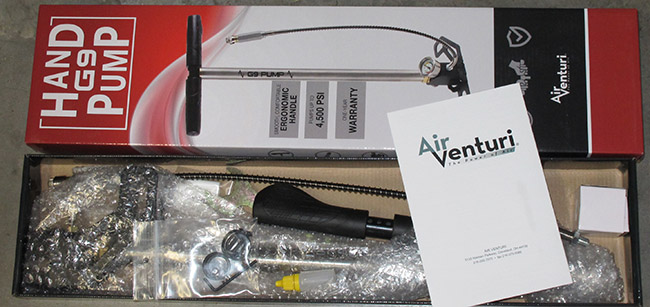

The G9 pump comes to you inside a box that’s too shallow to contain the assembled pump. Some assembly is required. It is EXTREMELY simple to assemble and there are no instructions in the owner’s manual on how to do it. It is so simple that it’s like pouring water out of a boot when the instructions are written on the bottom of the sole.

The Air Venturi GP high-pressure hand pump comes to you in a box.

There are three things to assemble to the pump — the handle, the hose and the gauge. The handle attaches to the top of the pump shaft with two Allen screws. I don’t think this will challenge anyone.

There is the pump, the handle and you can see the two screws that attach the handle in the plastic bag of parts and stuff in the center of this picture. Notice that the base of the pump is attached when you receive it. It’s spring-loaded and each side pushes down and locks when they are deployed.

History

Okay, I’ll pause here to tell everyone that hand pumps did not come this way in the “olden days.” That was 1996, by the way. Fredrik Axelsson, the guy who later would start FXairguns, was also the guy who brought the modern high-pressure hand pump to the market in 1996. In those days we just called it the Swedish hand pump, since it was the only game in town.

I had one of the first ones to come into the United States and it pumped up to a maximum of 3,000 psi. I used it to fill my Career 707, a powerful 10-shot lever-action Korean air rifle that isn’t around anymore — at least not in the US. That pump had a flat baseplate that had to be attached to the base of the pump, but the gauge and hose were on the pump when it came. I can’t remember if the handle was on or not.

The pump that Axelsson designed and built was called the Axsor and is now obsolete. In fact if you do a search on that pump name you’ll find many airgunners tried unsuccessfully to rebuild it — a decade and a half ago. But it was the first.

Back to the G9

Once the handle is on the G9, attach the gauge and the hose. Again there are no directions but all you have to do is look at the picture in the owner’s manual and you’ll know what goes where. Their thread patterns are the same.

This picture from the manual shows where things are supposed to go.

Attaching both the gauge and hose is done hand-tight and then tightened SLIGHTLY more with the combination wrench that comes with the parts. You don’t have to wrap the threads of the hose or the gauge connections with plumber’s tape the way we used to on the early pumps.

Tighten (slightly) both the gauge and the hose with the combination wrench shown here.

Why tighten slightly?

You tighten slightly because both the gauge hole and the hose hole have synthetic seals in their bottoms and you don’t want to crush those seals. And I will show you a trick after assembly to know that you have done it right.

Looking down inside the hole the pump hose screws into we see a synthetic seal. It’s light-colored and difficult to separate from the base of the pump in this photo, but I’ll show another picture that should clarify it for you.

See the small protrusion on the tip of the pump hose connector? That goes down into the open center of the seal in the previous picture. Then the flat spot above the protrusion presses down and squashes the seal against the protrusion and also against itself. It doesn’t take much pressure to make this happen and you have an airtight seal.

The gauge has exactly the same seal and connector and seals in the same way. I’m not showing it to keep this report shorter. If you can change the batteries in a flashlight you can connect the gauge and hose to this pump.

The test

Here’s how to know that you have made these connections correctly. The pump comes to you with a test plug that some call a “deadhead.” It attaches to the spring-loaded female Foster hose connector that attaches to an airgun male Foster inlet, which is why I praise those companies (Crosman, AirForce Airguns, etc) whose reservoirs have male Foster air inlets. I also criticize those companies that do not have this universal air inlet and instead supply a proprietary fill probe.

The pump hose connects to this test plug that some call a “deadhead.” With it connected you can pump the pump and only fill the microbore hose.

So connect the hose to the test plug and pump away. I pumped ten slow strokes, which built the pressure up to 3,000 psi in the hose. Then I left the hose filled for five minutes. After that I photographed the pump gauge.

After five minutes 2,700 psi remained in the air hose.

More

There’s a lot more to come and it’s coming tomorrow. I will attempt to answer both of Elmer Fudd’s questions at that time to the best of my ability. I’ll also have things you didn’t ask about. See you then.

B.B,

“I can’t remember if the handle was on or not.”

It was. I still have my first AXSOR and last time i pulled it out it still worked! I will need to dig it out of deep storage and check/exercise it soon.

Old yes; but is it actually obsolete? My example works and could still fill a few of the current airguns in a pinch.

But i will stick with my 4 Carbon Fiber Tank Cascade with DRY, breathable, and ultra clean Dive Shop air.

Great series so far looking forward to the rest of the series…even if i don’t learn anything new ;^)

This is a great service you are doing for the Dark Side.

shootski

PS: given the very small volume of the Micro Bore hose the pressure loss indicated is about right for the 3,000PSI hot air once it cooled.

shootski,

About the heat/pressure loss — I thought about that, too. I pumped so slow and deliberate that I’m not certain I generated that much heat.

BB

Tom,

Even if you pumped slowly and deliberately the increase in pressure will generate some heat. Maybe a redo with a stroke above 3000 psi as the endpoint and then check if the pressure falls again. Simultaneously spraying some soapy water looking for leaks?

Siraniko

BB,

As Siraniko points out, anytime you compress a fluid, heat will be generated. All the molecules that once had plenty of space to move around in ( and molecules are constantly in motion) now are confined in a smaller space and bump into each other. As they do they release heat energy. and slow down until eventually they move around without bumping into each other. Happens with metals and other materials too, but fluids are what we use to exploit the phenomenon for cryogenics/refrigeration. Pumping fast generates additional heat for sure, through friction in the moving parts of the pump, but slow pumping won’t eliminate it entirely.

I like Siraniko’s proposed test or maybe you could just put in a few pumps to top the air off at 3000 psi, now that it’s cool. The few (may even turn out to be a single stroke) added strokes shouldn’t generate a significant amount of heat that would lower the pressure again after cooling.

Half

Thanks for the well-done report. It is good to know these details. The photo of the seal, and your explanation, would appear to be important to know and assemblers should proceed accordingly. It appears to me to be very simple to assemble (as you indicated). Looking forward to tomorrow’s report!

Awesome report on the G9. I have one on my Wish List. I have purposely waited for your reports to replace the old Hill I gave to my grandson.

Something for Elmer to think about. The new Hill hand pump has a five-year warranty. This G9 has a one-year warranty. The new Crosman hand pump has a ninety-day warranty. Do those real cheap Chinese hand pumps even have a warranty? Perhaps you should read some of the reviews of the Wang Po Industries hand pumps. I did. I am not buying them.

Something else to think about. The Hill hand pump has a “moisture filter” on the input to it. I for one never put much faith in the filter’s ability to take the moisture out of the incoming air, but it is a dandy dust and dirt filter.

I am also considering the purchase of an additional filter that attaches to the foster fitting output of my new hand pump.

https://www.pyramydair.com/product/air-venturi-compact-inline-filter?a=9038

Yes, the G9 has a filter at the output, but I am a firm believer in clean air and no moisture if possible. I personally added another output filter to my AV compressor. Like shootski, I do believe in keeping moisture and dust out of my PCPs.

Thanks RR, the dry-pac system on the Hill pump does look interesting. It appears to use a desiccant to remove the moisture from the air. That should work in my opinion. I wonder if there are some inline filters available that use a desiccant. If not, I think that someone is missing out on a lot of potential sales. The inline filter that you linked to appears to be just another similar filter to what already comes on the G9 hand pump.

To RR and Elmer. If you can get a warranty from the site that sells them, it be a good deal. At least for a backup or starter kit. I have a suspicion that some of the name brand pumps are the same article as the ones you can get on Amazon Prime for about $50. Generally, though, I do believe you get what you pay for, and if you buy something that will just fall apart, by the time you replace it, you end up spending more in money, time, and aggravation than you would if you just purchased the higher quality version in the first place.

Elmer,

I have an output filter I added to my compressor which does indeed have desiccant in it. PAIR sells a similar setup for the Hill compressor. I have considered using such on my next hand pump. It may take a little modification to work and will most definitely use up a few pump strokes to work, but may work in the long run.

If you take your time in pumping, most moisture will be absorbed by the desiccant or will condense in the base of the pump, where it will then be expelled when you bleed off the pressure. My AV compressor does the same thing when I open the bleed valve and it has been my experience over the years that hand pumps will do such.

I live in a high humidity environment. I have never really been troubled by moisture in my PCPs. A little forethought can help. When filling a PCP with a hand pump or even a compressor, always try to have the PCP at a higher level than the pump base. This will encourage any condensed moisture to return to the base. Fill slowly. This will help your hand pump last longer and allow any condensed moisture time to return to the base.

Every once in a while I like to put a couple of drops of silicone oil, NOT PETROLEUM, in the end of my connection hose to inject such into my PCP reservoir. This helps to seal any minor leaks at the o-rings, helps the o-rings to stay fresh longer and I suspect it coats the inside and helps to prevent any rusting. I have heard this may have a negative effect on regulators. You will have to ask BB about that as I have done such for years with the Edge he now has in his possesion.

Thanks RR, that all sounds like good advice!

RR,

I have this “DIANA” handpump. It is made in China, cheap. So far so good, it had one year warranty. I bought it for like 100EUR? Ok it is not working every day but it is now few years without a problem. I oil it of course sometimes. I think the quality control is most important at the end – where it is made does not matter.

tomek,

What many do not realize is most hand pumps as well as scopes are made in China. The increased prices are due to increased warranties and profit markup.

B.B.,

Off-topic, but it appears as though P.A. has left an April Fool’s joke up on the website for too long: https://www.pyramydair.com/product/hatsan-velox-pcp-pistol?m=4078

A good caption might be, “What’s wrong with this picture?” LOL.

Or am I missing something?

Michael

Michael,

I don’t understand your issue. The picture is there and that’s what the pistol looks like. No?

BB

Look at the sight line:

“Wait, where is the front sight? All I can see is the rear sight and the mag! ARGGH!”

;o)

Roamin’,

YEP!

Roamin,

Come on!

BB

B.B., this is the part where you lay out one your trademark similes: “That front sight is about as useless as [Fill in this part].” :o)

P.S., another 2 reasons I love this blog: B.B.’s similes and Tomekisms!

B.B.,

If you held the pistol at arm’s length and tried to align the sights, from what the photos show, would you be able to see the front sight? I know I would not be able to, even with my good eye. You are both expert and experienced shooting pistols, and you are resourceful as well. How would you shoot the Velox as pictured?

Or if the idea is to mount optics on a high mount in order to clear the magazine, then why put sights on it at all?

Michael

Michael,

It’s a dot sight, so presumably it shows a bright dot at its rear. Is it ideal? Not even close.

BB

Maybe the mags have a clear window so you can see the fiber optic insert through it. :o)

We’ll have to wait for B.B.’s test (or a mini guest blog in the comments) to be sure.

Thanks, Michael, I had some fun with this today.

Roamin,

No the mags don’t have a clear window. They are offset to the right. Everybody does it that way.

BB

B.B.,

I am always initially inclined to think you are correct, because, well, you almost always are. But I have studied two photos, which I have cropped to the relevant area to (in effect) zoom for detail. The magazine appears to me to be directly in front of the rear sight, covering the same portions of rail that the sight contacts.

Roamin’ has an excellent idea. If you could review one, you could determine whether or not the photo is real or instead an inaccurate mock-up/artist’s rendering.

If the photo turns out to be accurate, I’ll eat my hat (conveniently fashioned from a slice of Lou Malnati’s pizza)

Michael

One side cropped . . .

This comes to mind….

Is that a glowy fiber thing or an apple? ;^)

Or perhaps Kilroy?

B.B.,

I don’t know what language “velox” is, but I’ll bet it translates to, “D’OH!”

Michael

“Gotcha” in Turkish?

OK, the fun is over. Michael, the answer to your original question is, yes, you are missing something.

Still, that was fun while it lasted.

I’m confessing ignorance and most readers will probably already know this, but why is there a liquid (oil?) covering the pressure gauge?

I also admit that while I have not been interested in a PCP air rifle as I cannot justify (nor afford) an air compressor to fill one, a PCP pistol might be agreeable if it can be filled with a handpump with reasonable effort.

MiTurn

MiTurn,

Good question. The oil isn’t outside the gauge. It fills it. This gauge is a higher quality pressure gauge than what usually comes on a hand pump. Oil-filled pressure gauges are known to be more accurate and less prone to failure.

BB

MiTurn,

It’s a good quality gauge filled with glycerin to dampen the movement of the needle on each pressure stroke of the pump.Glycerin won’t spontaneously combust the way petroleum oil would, should the part of the gauge that holds the actual pressurized air erupt. There are pressure spikes in the air as the pump is forced down and that drives the needle to the right, then it subsides and the needle swings back to the left.The spikes can be very violent in some fluid systems (these gauges aren’t likely to be purpose built, but are rather, adapted to this simpler use as a hand pump gauge) and the inertia of the movement will result in the needle becoming unhinged from the pin that it uses as its axle. It won’t move at that point or, if it just slipped on the pin, you’ll get a false reading.

Half

Half,

Your explanation clarifies the question thoroughly. I’m a newbie, so none of that information was intuitive nor have I come across anything similar in my experiences. Quite a fascinating piece of equipment, disguised as a “bicycle” pump!

Thanks for your help.

MiTurn

MiTurn,

You’re quite welcome. And just for the record, I don’t know those level of details from pursuing the hobby of airgunning. I worked in Industrial Maintenance for 42 years and was actually a Hydraulics and Pneumatics instructor for a number of years in a peer training program for journeymen at my company. It isn’t the kind of detail that you need to know to enjoy the hobby, so don’t sweat it.

Half

Good report, useful to the likes of Caveman FM. Noticed the gauge is liquid filled, and will presume it is glycerin? Have been looking for a replacement gauge for the resident Hatsan pump and while searching read the liquid-filled gauges read more accurately. At least that is the theory. Believe the gauge attachment stem or neck is 10mm but will measure it before ordering the part. “Measure twice, cut once.” Even a Caveman should understand that.

B.B., Siraniko, RidgeRunner, Elmer Fudd, Michael, Roamin Greco, MiTurn…hey actually everyone…

I was just talking to the Dive Shop Fill tech about my appreciation for his FULL 310 BAR fill on my tanks. He said you just need to wait for the molecules to cool since they do a good job of insulating; to about 10% underfilling if not cooled and topped off. Not saying your fill system doesn’t have a very slow leak; just that it fits what the tech said.

First: Siraniko’sleak check advice is a good one, a mechanics stethoscope or a acoustic microphone (with baffle) can also be used to track down leaks.

Second: Ridge Runner and Elmer, the DIRT SPECKS is what i worry about the most for pump, PCP and Regulator valve/piston seats.

Moisture is only an issue if it has salts and biological contamination that then grow crystals or organic gunk in your reservoir. (Ton Jones is knowledgeable about the topic and a very few other folks.)

I need to go to my HIIT workout more when i get back.

shootski

Shootski, what type of system does the dive shop use for dehumidifying the air? I am guessing that it is a refrigeration type dehumidifier system. The dirt specks should be caught by the filter on the fill hose of the G9 hand pump. However, there is nothing stopping them from entering the hand pump. Storing the hand pump in a container of some sort might be a good idea.

Elmer Fudd,

I’ll briefly answer your question(s) directly while i consume my post workout protein shake.

Back from my workout and enjoying my 16 oz of full fat double dark chocolate milk with 25 gram scoop of Dymatize® whey protein isolate along with some other ingredients! The chocolate milk is the part i always anticipate the most!

Actually the Dive Shop uses a molecular sieve downstream of their compressor and before their multi cylinder cascade storage. They have a air/heat exchanger, clean room HEPA filters, and dehumidifiers (so yes they use refrigeration to dry the intake air and more) running in their electronic gas chemistry on a chip monitored Fill room. That ensures the very expensive compressors live in a great preventative environment and the divers trust their gas fills to not kill them. It is one of the most conscientious shops i have ever had the pleasure to deal with. The original owner (RIP Mike!) was one of the original US NAVY UDT Frogmen in WW2!

More details in Part 2 of my reply today.

shootski

Thanks Shootski, I spent a career in commercial HVAC. So, I probably understand more of that explanation than you might have guessed. It makes sense that they would want to insure the quality of the air with such sophisticated measures and equipment. I am looking forward to your continuation.

Elmer Fudd,

Nuff said! ;^)

shootski

shootski,

If I were into hunting or serious target shooting (and therefore PCPs), I’d go to a nearby welding supply place and get a full (of regular air) 330 cubic foot, 6000 psi steel tank and a monster regulator. That would suit me for a few years, I imagine.

Michael

Michael,

You might try that however best i know welding supply doesn’t sell compressed regular air.

I would also try to talk whoever wanted to go that route out of the big steel tank approach since it doesn’t work. Sure 6,000PSI and 330 cu. ft. sounds impressive until you learn that the basic Ideal Gas Laws don’t actually work and air isn’t an Ideal Gas anyhow.

I know, i have seen the airgun forum posts too but have never seen an airgunner using one in the REAL WORLD. But you know what they say about advice on the internet….

shootski

shootski,

My grandmother used to say, “You can’t tell the fly specks from the pepper until you try it.”

Michael

Michael,

I only use whole Black or White pepper corns crushed immediately before use, Red Pepper, or Hungarian Paprika so don’t know what you or your grandmother are talking about.

shootski

Michael

I haven’t heard it that way, but my Granny used to accuse me of “just pickin’ fly sh*t out of the pepper” when I tried to win an argument with her on a tiny technicality. Similar to nit pickin’, if you’re familiar with that old expression concerning lice and hygiene.

B.B.

I was talking to a newbie at the range on Sunday. When he asked about air for PCP’s, I mentioned hand pumps. A PCP shooter who over heard me said, “Yes you can pump up to a 3000 psi fill, but it is a chore. Even pumping to 2,000 psi is a chore.”

-Yogi

Yogi,

I’ll bet that in one of Tom’s future posts on this hand pump topic he could help the guy get past the 3,000PSI Hand Pump Barrier with just a simple technique change, LOL!

shootski

Yogi,

Tomorrow you will find out exactly how hard, and that PCP shooter was off a little. 2000 psi is no chore.

BB

B.B., Siraniko, RidgeRunner, Elmer Fudd, Michael, Roamin Greco, MiTurn…hey actually everyone…

I’m back; great workout!

Part 2 of my reply:

Elmer Fudd ask directly so i briefly answered his direct question.

The Dive Shop i frequent uses Molecular Sieves and Activated Carbon cartridges. The following LINK will explain, IN DETAIL, the difference over other drying media better than i can; especially in the ultra high temperature and pressure environment we deal with in airguns.

https://www.impakcorporation.com/molecular-sieve-is-the-best-desiccant#:~:text=Unfortunately%2C Molecular Sieve is significantly,sorbent used in military applications.

RidgeRunner correctly states “I for one never put much faith in the filter’s ability to take the moisture out of the incoming air, but it is a dandy dust and dirt filter.”

A moisture removing system only works well at pressures typically above 2,000 PSI (140 BAR) so although the pre filter will lower the inlet relative humidity by some small amount…the High pressure in the compressor or pump will wring out far more moisture that needs to be vented and any remaining absorbed.

Michael said: “If you held the pistol at arm’s length and tried to align the sights, from what the photos show, would you be able to see the front sight? I know I would not be able to, even with my good eye. You are both expert and experienced shooting pistols, and you are resourceful as well. How would you shoot the Velox as pictured?”

WHAT! You DON’T have X-RAY vision? That does look pretty bad to me…maybe it is Photo shopped…LOL!

MiTurn if you remove that plug on the gauge you can use the stuff inside to moisturize your dry skin; it is almost always food grade Glycerin. I refill mine with stuff from the pharmacy if it gets contaminated and exposure to direct sunlight doesn’t clear it up.

The primary purpose of the fluid is to keep the Bourdon Tube from vibratiing and getting damaged: https://www.wika.com/en-us/lp_bourdon_tube_pressure_gauge.WIKA

Read the above LINK information if you want to get way smarter about gauges than the average airgunner.

Caveman FM knows more than he lets on!

shootski

shootski,

I feel bourbon relieves pressure! ;^)

Michael

Michael,

You need to take a page out of Caveman FM’s book of life ;^)

That Caveman knows how to live Right!

shootski