Air Venturi Avenge-X classic wood.

Part 12, where all earlier links are

Part 13

This report covers:

- A leak?

- Help!

- What kind of leak?

- Great news

- The work

- Did it heal?

- The secret meeting

- Summary

Yesterday you learned that Tiffany built many of your airguns and that I have a problem with fixing precharged pneumatics (PCP). Today we start putting what we learned into practice. Today we repair a leak in my Avenge-X.

A leak?

Has BB gone mad? Is he actually telling us that his Air Venturi Avenge-X has a problem?

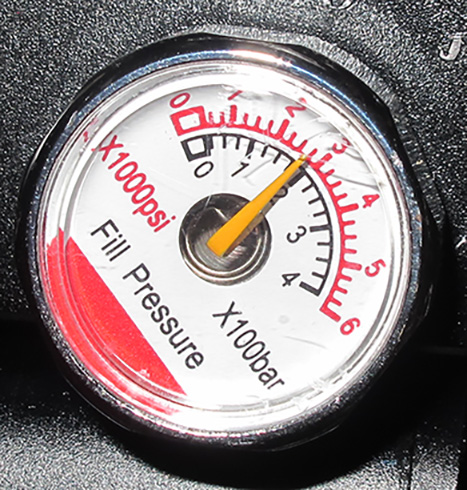

After the last report on the Avenge-X in early July I set it aside for a while to cover other airgun subjects. When I returned to it in late August I saw there was 2800 psi in the reservoir. Since I didn’t remember what I had done in the previous test, I just filled the rifle again to prepare for tuning the powerplant the next morning. But when I looked at the air gauge the next morning I saw the rifle had leaked down from 3500 psi to 2800 psi overnight. So I filled it again and this time I heard air hissing out under the fill pressure gauge.

The fill pressure gauge read 2800 psi, so the rifle held at least that much pressure.

Help!

I called Tyler Patner at Pyramyd AIR and asked him about the leak. I had recently overhauled a Crosman Challenger with all new seals so I knew this job would be easy. I asked Tyler if all I had to do was remove the gauge and rewrap the threads with Teflon tape. Okay, that’s the setup for this report — now I’ll talk you through what happened.

What kind of leak?

There are different kinds of air leaks. Some leak all the way down but not all of them. This one always stopped at 2800 psi, so it wasn’t a broken o-ring. With one of those all the air leaks out.

Teflon tape (plumber’s tape) can sometimes leak part way and then stop. The gauge on the Crosman Challenger I overhauled is sealed with Teflon tape but Tyler told me the Avenge-X gauges are not sealed with Teflon tape, nor are they sealed with o-rings. They each use a dynamic seal that the bottom of the gauge presses against.

The Avenge-X gauges are sealed with a dynamic seal. The rifle comes with a new seal for both gauges — reservoir and regulator.

Great news

This is great news because this kind of seal rarely fails. If there is a leak it’s usually because the parts being sealed aren’t pressed tight against the seal. And the gauges have flats on their outside that an adjustable wrench can grab to tighten.

The work

I removed the barreled action from the wood stock and may I comment that this wood stock fits the Avenge-X action very close. Then I put soapy water around the base of the gauge, where it enters the receiver, because that is where I heard the air leaking out. Since it was holding pressure at 2800 psi I didn’t expect to see any bubbles in the solution and I didn’t, but you never know unless you try.

Water with dish soap makes bubbles where the air leaks.

I then filled the rifle to 3800 psi. Now I would have bubbles to show you!

No, I wouldn’t. There is no air leaking around the fill pressure gauge on my Avenge-X. The next morning it was still holding 3800 psi. I had decided back in July not to fill all the way (4,351 psi), so the rifle is now filled to where I need it for tuning.

Did it heal?

I’ve seen this before but reader shootski commented on it last week.

“I have rediscovered an ancient and simple method to fix leaking PCPs!You all may remember my very early .177 Benjamin Discovery was slowly leaking down to 1/2 charge pressure. I instilled a drop or two of silicone chamber oil in the fill port with no effect. I next replaced the pressure gauge O-Ring but the partial deflation continued. What to do? B.B.s example of ordering parts and installation tools inspired me to order O-Rings/installation protection tool, valves, gauges, and some other parts for both my Discovery and Marauder.As soon as the parts arrived my Discovery STOPPED LEAKING down! It has held a number of 2,000PSI air charges for periods as long as 96 hours with not even a hint of a leak.”

The secret meeting

I think all my PCPs held a secret meeting and decided that — since BB can now disassemble, reseal and assemble his Crosman Challenger that’s still holding air after several weeks — maybe they need to rethink their actions. Maybe they need to behave.

Today I told you how to repair an Avenge-X with a leaking pressure gauge and everything I said will work. The seals come with the gun, so there is nothing to buy. And, if your PCPs hear that you know how to fix them, maybe they won’t act up so much. Tiffany would be proud!

Summary

I said yesterday there will be numerous reports dealing with repairing and modifying airguns. This has been one of them.

Tom,

All machines go to that meeting. The only ones that sit out the meeting are those slated to go to a qualified technician. As long as the owner is “threatening” to do the the repair they usually start working sometimes needing a little percussive maintenance though.

Siraniko

Siraniko,

Yeah? Well, guess what? Last evening I looked at the pressure gauge and saw it had dropped by 400 psi. I did try to tighten the pressure gauge and that may have had an affect. So I guess I will replace that seal after all.

BB

B.B.,

You know it is just a matter of time…pshhh!

The Main O-Ring(s) on a SCUBA regulator are typically replaced every two years as (PM) Preventative Maintenance.

Also don’t know if Tyler told you but for best sealing the seal lip on a dynamic seal needs to point towards the tube pressurized side (higher air pressure side) being contained.

shootski

I purchased DAR gen 3 in .22 from Pyramid. Initially I had some assembly lube seep out in between the plenum and the gauge block but no appreciable air leak until just about one week out of the twelve month warranty period.The Foster fitting failed as a check valve, fixed that using a JTS video showing how to repair same on a Airacuda.Immediately after had a leak at the air gauge block. I found some scratches in two o-ring grooves, one on the regulator housing and another on that part on the plenum side. I have been attempting to hone and polish out the scratches with Swiss files and Scotch Brite. Changed out these o-rings with Buna 70,75,90 and Viton o-rings, no luck.Came closer to sealing it using a .5 mm cross section larger o-ring on the plenum side. I like the rifle too much to relegate it to parts guns status. Last email from DAR stated they may sell me the parts I need , regulator housing or possibly another air tube assembly. We shall see. I tape over threads and use polymer picks to remove/install o-rings especially when they are mounted in aluminum, I wonder if Tiffany does.

..

Now if only we could get AI machines to go to the same meeting!

-Yogi

Yogi,

They ain’t members of the Union yet.

Siraniko

If AI machines unionize, it could mean the end of civilization as we know it. We need to make the dumber, not smarter.

Just for clarification and information, does the one-year limited manufacturer’s warranty that PA advertises for these guns cover the replacement of these types of seals for the first year? The fact that replacement seals are provided with the gun purchase makes me wonder.

Elmer,

I don’t think so. Since they give you the seals why would they include them in the warranty?

BB

BB,

Over the years I’ve often wondered if machines were sentient or if gremlins were real.

I maintained the laser plotter we used to make the photo-tools at the prototype PCB company I worked at. It was a finicky 120v machine and I would occasionally threaten to give it a 220v enema if it didn’t behave. Turned out that the the plotter was very sensitive to line voltage levels and when I checked, I found that the local power company was deliberately reducing the voltage down to 105v to artificially increase power consumption. Threats of going public with the voltage tampering resolved the power problem.

So, lesson learned – if there’s a symptom, there’s cause. Determining the real cause is usually a process of eliminating all the things that are not a problem.

Cheers!

Hank,

That story is going to play well with my story of the Avenge-X “repair.” It’s still in flux, but it should prove interesting.

BB

BB, warranties are typically worded to cover defective materials and/or workmanship for the warranty period. Now, I do understand that these seals do “wear out” over time and might be considered wear and tear items (like for an example: brakes on an automobile) and therefore not covered. But, it seems odd to me that these seals (especially the ones that are not exposed to moving parts) if designed, manufactured, and installed correctly, could be expected to possibly “wear out” within the one-year warranty period. The optional 24-hour leak test service for an extra $10 also seems odd (but perhaps prudent) to me. I spent a career in the commercial HVAC contracting world. And everything, including seals on moving pump shafts, was included in the one-year warranty. The Airgun business appears to be a different situation that just seems odd to me. That’s it in a nutshell.

Believe it or not, but it really is my hope that I Phool Yu in quality control at Wang Po Industries has not been chastised for rejecting some of the components he is looking at.

This is an issue I have seen time and again, not only with companies related to Uncle Xi’s country, but in various countries around the world, including right here in the USA. It most often happens when one company contracts with another company to build their product or components of such. There is often a considerable amount of back and forth “negotiations” concerning the cost of said product and quite often the cost is lower than what the company doing the manufacturing would like.

It is at this point that the manufacturing company decides they need to cut their costs to make what they consider a more decent profit. Sometimes this may involve the substitution of cheaper materials. This may also involve a redesign to reduce costs. This is what happened to General Electric and one of the reasons that company pulled some of their products out of China.

I am also aware there is often a learning period when a new product comes out, a “live and learn” period. TCFKAC is/was famous for that, but far from the only one. This is one of the myriad reasons I am slow to purchase the “new” stuff.

I will admit that sometimes “stuff” happens. Most often it happens during the warranty period. This is why there is often such. There are some instances though that do not raise their ugly heads until much later.

I have received some criticism from some because I do not rush out and buy “the latest and greatest” or the “new and improved”. Is it really?

If something works as intended and gives little or no trouble over a long period, FM will hold on to it until it or FM dies, whichever comes first. Too many people are too easily impressed with bling, bells and whistles, smoke and mirrors. We’ve allowed the bean counters and bottom-line feeders to get their tentacles into too many of our industries and that is one of the reasons, for example, why Boeing planes are going boing-boing all over the place. Oh, FM also forgot about that Starliner capsule thingy. No matter, in a vacuum no one can hear you scream.

FawltyManuel,

Don’t be too quick to blame it all on Boeing or even the sub contractors. Some of the blame for the two crashes seems to fall to choices made by the airlines to not install the complete Angle of Attack System and go for a cheaper version. Some of the blame could also fall on the flight crew(s) that had problems on earlier flights and didn’t do proper maintenance gripes.

Finally the pilot training is suspect since it would take only one circuit breaker being pulled to disable the system that was KNOWN to be causing the altitude/attitude excursions! Fighting the controls of a modern aircraft is almost ALWAYS a lost cause.

One final thought is that Airbus may have a “dirty media tricks department” and some of our media and leadership types are invested in certain companies that stand to benefit from Boeing looking bad.

Boeing certainly should be on the hook for some dumb design/engineering decisions on the blown fuselage plug.

It is a complex situation.

shootski

BB,

I’m pleased that you wrote about this topic because I’d like to ask about how difficult it is to remove a pressure gauge from an air reservoir. My AA200T in .177 (made by CZ, a beautiful air gun) developed a leak at the pressure gauge (overpressurization) and I made this aluminum tool to remove the gauge. I thought I was on easy street. With the tool clamped in a vise, the torque required to unscrew the gauge is more than I can muster with both hands gripping the cylinder and turning it with all I’ve got.

Do I need a strap wrench? Is there a specific torque that I should somehow observe to reinstall the part? Thanks for any assistance with this.

Regards,

Will

Will,

If I were doing this a strap wrench is what I would try first. As for putting it back, I’d try hand-tight and go from there.

Remember Tiffany.

BB

Will S,

I do not own one.

Some generic thoughts.

Is that apparent divot in the Brass matched by another one on the other side? If so it is for a Pin (hook) Spanner.

Is the Brass perhaps just a cover for the actual gauge body?

It might be Left hand threaded.

It could also be riding in twist slot(s) machined into the tube.

PAir sold those some time ago perhaps a call to a tech type there? Or at Champions Choice in Tennessee.

Good luck,

shootski

PS: https://www.gatewaytoairguns.org/GTA/index.php?topic=150497.0

Thank you BB and shootski,

I’ll get a strap wrench and let you know how it worked!

Regards,

Will

PS I did bleed down the pressure first…