Glock 19 clone.

This report covers:

- What is a break-in?

- Glock 19 clone

- El Gamo

- Do all guns need break-ins?

- Remember the Fire breakbarrel from Crosman?

- So what?

- Summary

Today I want to talk about breaking in an airgun. I’ll touch on firearms, too, because this topic really spans all things that shoot.

What is a break-in?

When I say I’m breaking-in something I mean I’m using it until its mechanical parts become smoother and easier to operate. When things are manufactured they have rough edges that create friction when they slide or rub against other surfaces. Over time these rough edges are smoothed by operation and the item becomes smoother.

A very funny thing happened as I was setting up a possible video for you. Without knowing it, I broke in a firearm until it became so smooth that it was impossible to film the thing I intended filming. That was without firing a shot!

Glock 19 clone

Remember the report Ian McKee wrote on the sub-$200 Glock 19 clone? Well, it convinced me to buy one. Ian bought his directly from the seller who registered it for free, if I’m not mistaken. And since he bought it in the store there was no shipping. Mine was more expensive because of shipping and a fee for the federal firearm license holder to receive and register the pistol for me. Nevertheless it was still a very good deal on a sub-$250 Glock 19 clone.

When I got the pistol I applied some SLIP 2000 EWL to see whether it made things better, because a new pistol is extremely tight and hard to operate. The SLIP worked quite well and I probably mentioned it somewhere but it wasn’t enough for a report. However, something else was.

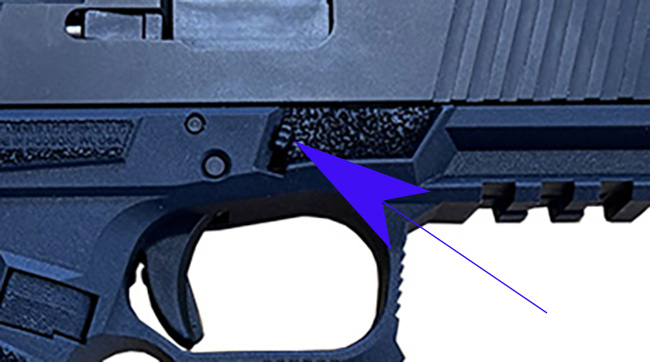

Glock pistols come apart by pulling down on two spring-loaded latches called the slide lock. They are on either side of the frame, just ahead of the trigger guard. They are actually a single piece of metal the runs across the frame and is exposed on both sides.

Glock slide lock. There’s another one on the other side of the pistol.

To field-strip for cleaning Glock tells you to remove the magazine and then remove all ammunition and uncock the pistol. Pull the slide back 3 mm (a quarter-inch for Americans) and grab both slide lock tabs (one on either side of the frame) pull down and release the slide. The slide will then slide forward off the frame and the rest of the disassembly is easy. It sounds quick and it can be—if the pistol is broken in!

My pistol was new and I could not pull both slide lock tabs down simultaneously. It’s not just me, either. There is a video online where a federal agent can’t do it and has to grab a second pistol to demonstrate how it’s done.

But I found a simple way to get past this glitch. I was going to make a video but I practiced with the pistol so much that I actually broke it in! Now it comes apart the way Glock intended and my special way only works about ten percent of the time. No doubt adding the SLIP 2000 EWL also helped. So—what is a break-in, when talking about airguns or firearms?

El Gamo

I remember several decades ago when a reader of my Airgun Letter newsletter came to my airgun range to get me to try his El Gamo breakbarrel. I had criticized Gamo breakbarrels for harsh cocking and heavy triggers. He brought a broken-in Gamo that cocked easily and shot very smooth with a reasonable trigger.

At the same time I was shooting a Beeman C1 that was made by Webley. It was also harsh until about 3,000-4,000 shots had gone through. Then it became smoother to cock and shoot and the trigger became much better. That, my friends, was a break-in!

Do all guns need break-ins?

All guns, be they firearms or airguns, do not need break-ins. I have a Wilson Combat 1911A1 firearm that is as smooth as it’s possible to get and I haven’t shot it much. Every Air Arms TX200 that I have taken out of the box was smooth from shot number one. The HW 97K that I tested in 2024 was similarly smooth. The secret is how well they are machined, finished and fitted at manufacture.

On the other hand a Taurus M1911A1 firearm that I bought for $500 was so rough it didn’t function reliably. I had to swap new parts purchased from Wilson Combat to get it to operate. After that it became ultra-reliable. So the price point is a fairly good indicator of whether or not a gun will need a break-in, but not always.

Remember the Fire breakbarrel from Crosman?

I actually walked you guys through a typical break-in with the Crosman Fire rifle. In that 7-part report series, written in 2022, you got to see how the rifle became smoother to shoot and more accurate the more I shot it. Part of what happened came from me learning the rifle and part came from just using it. The using was the break-in part.

I had hoped to shoot that rifle a LOT more for you to illustrate what a lengthy break-in can do but Crosman abandoned it after just over a year, selling off remaining stocks at fire-sale prices.

So what?

Why did I write today’s report? I wrote it for newer shooters to give their airguns more of a chance to succeed. I will say there are models that have no hope for success and if you have one it probably made that known to you at some point. But many of the harsh-firing airguns that people buy do become smoother with use.

I also wrote it for those veteran shooters who have an airgun they never shoot because it’s rough. I’m probably talking to myself now. You know the airgun I mean. It’s standing in the corner, dusty and unloved. In the back of your mind it will never be loved because it’s too rough for you. My advice would be to read the series I wrote on the Crosman Fire and take it to heart.

A rough direct-sear trigger is never going to morph into a Rekord trigger, but it can become smooth enough to be used. This is one reason why I’m so interested in the new Air Venturi OmniStorm breakbarrel. I don’t expect much at the start but if it will break-in to become a good shooter and if Air Venturi will not abandon it, there is a chance it will be a hit.

Summary

Buying an airgun is just one part of ownership. Using it is another part. Don’t neglect it.

Tom,

So the breaking in process works both ways as that the shooter gets to know the quirks and foibles of the gun he is shooting.

When the those old BSF air rifle triggers become so smooth and worn enough to become dangerous are they considered broken through?

Siraniko

Siraniko,

Good question that needs thought.

BB

At that point, FM would consider it broken, not broken-in and needing repair before using the rifle again.

FawltyM:

I totally agree with you. Totally. Some of my most venerable and well-loved and used air arms have gotten use-polished to the point of being dangerous. In particular, my “Holy Grail” of air guns, my Beeman P-1 pistol, was that way and I was able to retain it by re-reading the aging instruction manual and tightening the tolerances of the trigger mechanism to restore let-off point feeling to a trigger with thousands of individual round cycles that had polished it into an almost mental synapse let of sensitivity.

The SLIPP ELW 50 lubricant, a new favorite air gun addition I’ve added to the arms locker is something that I both really like and respect as a provocateur in this very business; it is so effective as a lubricant that it could easily make things way TOO facile where some “warning friction” is a good thing. Knowing when pieces are reaching release criticality is a good thing to prevent dents in the duct work in the basement ceiling leading to the upstairs living area.

I have sent units back to RWS/Diana in Arkansas for re-builds that decades of faithful and predictable use had rendered too facile and too polished to be reliably used in my basement 10 meter range. Now, that’s NOT usually the case with the chase of friction, of course, but it can and does happen with venerable air arms, bicycle parts and all kinds of things that we can use and habitually take for granted until something untoward happens.

The problem is habituation to a creeping and almost imperceptible change in status. We adapt to the change incrementally and unwittingly until we have a negative result like a dented duct or a BB in the forefinger that one’s GP has to take out and then call you “Roy Rogers” with an earned snicker. (Okay Brian, you got to laugh that time, but you’ll do something that I can retort with eventually!)

One of the things I wrote Tom G about quite a while back was the need, as I see it, for an article on some “hard standards” related to annual maintenance of our air arms that would force us out of our habituation/mindless acceptance of incremental change to actually look hard at how triggers and safeties and such ARE CHANGING and assess for points wherein real work needs to be done to reset the arms to safe operating conditions.

In some peculiar ways, the changing of air arms to malfunctioning may be safer than the changing to hyper-improved functioning when you think about it. When the gun STOPS working, you know to send it in or tear it down. At least unload it and stop using it until fixed.

When the gun works too well, you can get a BB in the forefinger or a dented duct pipe.

Again, is it time to work up an Annual Check Sheet that one would apply to EVERY air arm in the locker and do the tedious work of actually scoring EACH ARM against the standard so that there is a breakthrough against the assumed, the usual, the customary and a realistic evaluation and action plan be taken when needed? I think that the more familiar and favorite the arm (like my RWS/Diana Model 36 in .177 or the Beeman P-1 pistol) are my sterling examples of familiarity breeding potential danger or harm to self, others, or property. Periodically being “jerked back to hard evaluations” is likely necessary with our most treasured and well-used pieces in the arms locker.

BB,

Thank you for today’s chuckle, intentional or not.

Crosman dropped the Fire model “…selling off remaining stocks at fire-sale prices.”

I just about did a spit-take with my drink (what other kind of sale would they have?).

Enjoy your day.

Bill

Bill,

I wondered who would spot that. 😉

BB

Sounds like Crosman abandoned that model before giving airgunners the opportunity to get fired-up about it…

B.B.

So now you need to buy another unbroken in Glock clone and show us your special trick method!

-Y

Yogi,

Why don’t you buy it for me?

BB

Because I only do airguns. You however, have branched out into firearms as well…

-Y

after doing some research i i’m fairly certain it would actually be very straightforward to swap a crosman mtr77np, not only to a steel mainspring but also a .22 barrel. i’m awful tempted to undertake the task since there’s a mtr available 53 miles from me and i could get an optimus from pyramyd to disassemble for it’s internal (and outer) workings. now it’s morphed from my question before of “is it possible?” to the question of “do i actually want or need to?” dilemma, dilemma. all in i’d be give or take 300 dollars deep with the two purchases. or do i just wait until a reasonably priced (600 or under) 46m pops up. they’re both my white whale.

springman,

As to myself, I would search/wait for the 46M. Unless you are a superb 10-meter air pistol shot, it will outshoot you.

Now the MTR77 converted to .22 excites you. Why not do both?

P.S. You might also search for that new fangled clone of the 46M that Air Venturi had out for a bit. It was a 46M disguised as coming from outside of Russia.

realistically i probably should just get the mtr, they show up less often it seems. there’s always a 46m for sale, even if its exorbitantly so. i can always bide my time on the pistol. i may just have to jump on this crosman. i’ve checked schematics and part numbers and i’m almost positive that what i want to do to it is possible. i just really like ssp’s but overlevers aren’t particularly fun or satisfying for me otherwise i’d get a p3 or hw75. i do like my 753s. i haven’t even shot my new “stainless” finish hw30s yet but i think it’s time to buy that old second hand mtr77 and immediately disassemble it. and of course buy a new .22 optimus to use for parts.

I’m curious. Why do you want to change the Crosman to .22 and then also from a gas spring to a conventional spring?

RG,

It is the caliber change that I do not understand. I have changed a sproinger to a gas spring before and then changed it back.

If an HW90 comes my way or this Optimus proves to be worth a diddly, I will be happy to own a gasser again.

To each his or her own.

RidgeRunner,

Of course this serious OVERREACH by the previous administration’s BATF could go away or may already be gone: https://regulations.atf.gov/447-52/2022-08026#447-52

What a joke!

shootski

PS: There appears to be NO REASON for the AVG 46 not to be imported…wakey WAKEY PAir!

Someone didn’t read this correctly! “…that is not one of the models listed below:”

shootski,

They must have just overlooked it in their rush to outlaw everything.

RidgeRunner,

I have done as through of a search on Sanctions that are directed at airgun imports to the USA as i can and find nothing other than this really (perhaps intentionally) POORLY worded BATF instruction, LIMITED TO Firearms, Aand what is and isn’t sanctioned. Note that a number of TARGET FIREARMS are actually listed that are excluded but you could easily think that was the list of guns that are Sanctioned!

shootski

shootski,

As is so often the case, it is not the reality as the perception. In this particular case, customers may have not purchased this as they have perceived it was still made in Russia. AV may have stopped carrying it because of such. Pure speculation on my part.

3mm would be more like 1/8″ iirc.

And it’s going to be interesting to see what the Crosman catalog will look like a couple months from now.

I myself have been guilty of not allowing a good break-in period for many of the sproingers I have shot and reported on for you folks. Of course, that does not refer to the “old gals” around here. There is no telling how many shot cycles some of these have gone through. I can testify that a direct sear trigger can be as nice as even the nicest two stage trigger made if it is properly broken in. Almost all of the “old gals” around here have direct sear triggers and I will take many of them any day over any two stage trigger I have pulled on, and I have pulled on some real nice two stage triggers.

Speaking of break-in, the household Gamo Whisper Fusion is not yet broken in. Just for fun, yesterday bought a can of Lucas Oil tacky red grease in spray form and FM gave a couple to three squirts of the grease to the Gamo mainspring, letting it rest a bit in vertical position to let the grease spread a bit. Then proceeded to put 25 .177 pells through it and while the rifle is by no means “sniper quality” – then again, neither are FM’s eyes – the Gamo was cocking a little easier and the groups appeared to have tightened up about 25% compared to how the hits grouped at the last shooting session with this rifle.

The trigger does not seem to have a “first stage,” but kind of releases crisply and at least for FM, feels “good enough.”

FM.

BB does point out that some airguns will never break in.

I’m curious. Why do you want to change the Crosman to .22 and then also from a gas spring to a conventional spring?

.22 just because the pellets are easier to handle, and conventional spring both out of personal preference and bias, and to lower the power a smidge. if i go through with buying and trying everything the hardest part i think might be the plastic barrel cover if it doesn’t come off easy with a heat gun i might just have to leave it alone and settle for steel spring and .177

Wish I would have read this before selling my C-1.

I loved the style and size of that gun. But the harsh firing turned me off and sold it after only 600 to 700 shots.

May need to look for another:-)

Speakski

A big thing about gun reviews is that few of the reviewers have the time to thoroughly break in and assess the true performance of the gun.

I spend quite a bit of time in a machine shop making things so I’m very familiar with fit, finish and lubrication of assemblies.

As BB mentioned, the “break-in” is the the process of rounding off the rough edges and lapping (fitting) the parts fit together.

Interestingly, a rough finished part in contact with a smooth part will often slide smoother that two rough or two polished parts due to reduced contact/friction. Two polished parts may require quite a bit of force to overcome the initial friction before they start moving. Grease in-between tight fitting parts may make the parts together stick together.

Other than taking base line information, I don’t bother looking for the best pellet, doing any tuning or any serious testing until the airgun is broken in. I expect to shoot 300-500 pellets for the initial break-in and at least a 1000, more likely 2000, shots before the airgun really STARTS to settle in. I think of the first 1000 pellets to be our honeymoon where we really get to know each other. 🙂

I’ll usually remove the excessive amount “long lasting” cheap grease that the factory uses and lubricate with a light machine oil to speed up the initial break-in.

After 500 shots I’ll remove the oil (contaminated with tiny bits of metal), inspect for wear, do some polishing and add shims if needed. Then I’ll re-lubricate with REGULAR grease and oil as required for the second part of break-in.

I don’t use Molybdenum or any of those “super lubricants” until I reach 2000 shots as they will interfere with the break-in process.

Once broken in, and if properly maintained, most decently made airguns will preform well for many decades. Unfortunately, many airguns these days are not designed for long use. 🙁

Just my 2 cents.

Happy Monday!

Hank

Hank,

And THAT may have been my problem with the Glock clone. I probably shouldn’t have lubed it with SLIP2000 EWL at the start.

BB

“Interestingly, a rough finished part in contact with a smooth part will often slide smoother that two rough or two polished parts due to reduced contact/friction.”

Hank,

I found that tidbit most interesting; thank you. 😉

Cheers to you,

dave

Dave,

You’ve probably experienced these things and just not thought of them relative to mechanical parts.

Ever tried to separate two sheets of wet glass? No way in tension, has to be in shear.

Rough surfaces can “engage” to make sliding impossible.

On a rough, textured surface (like one with a lot of tooling marks), only the high spots contact the adjacent surface so the amount of surface area and friction is reduced.

Contrary to where you would expect that polished adjacent surfaces would be used, the cylinders in gasoline engines are often cross-hatched (scored) quit aggressively to provide a surface for oil to cling to.

Some things are just counter intuitive. 🙂

Hank

“You’ve probably experienced these things and just not thought of them relative to mechanical parts.”

Hank, yes, in retrospect, you nailed it! 😉

Ah the varied and interesting study of tribology. Tribology: (Merriam-Webster)”a study that deals with the design, friction, wear, and lubrication of interacting surfaces in relative motion (as in bearings or gears)”.

I once took a graduate level class on tribology, which was an interesting application of high level mathematics.

Mike

Vana2,

I remember when folks would polish their ski (snow) bases (wood and synthetic) and then wax them only to scrape off most of the wax and then polish all over again. Then one day the ski techs were testing their magic on the slide hill and one set of skis were way faster than anyone elses…they had crosshatched the P-Tex base, waxed and then impressed a structure in the wax!

So much for HOW WE ALWAYS DID IT.

The Science of base prep has seen a tremendous amount of progress ever since.

Please note: This REPLY has nothing to do with the ID 10 TANGOS who want to SCREEN/DIMPLE bullets (slugs) to make them fly like golf balls.

shootski

shootski

Mine (golf balls) always slice. But I guess if the dimpled bullets always slice to the same place we can shim the scope to compensate. Ha! ;o)

Roamin Greco,

Slice, Hook, or Crook

The cheaper the scope the more important it becomes to Optically Center.

(I use the mirror technique to center the scope reticle.)

i also prefer adjustable 2D bases ;o)

shootski

FawltyM:

I totally agree with you. Totally. Some of my most venerable and well-loved and used air arms have gotten use-polished to the point of being dangerous. In particular, my “Holy Grail” of air guns, my Beeman P-1 pistol, was that way and I was able to retain it by re-reading the aging instruction manual and tightening the tolerances of the trigger mechanism to restore let-off point feeling to a trigger with thousands of individual round cycles that had polished it into an almost mental synapse let of sensitivity.

The SLIPP ELW 50 lubricant, a new favorite air gun addition I’ve added to the arms locker is something that I both really like and respect as a provocateur in this very business; it is so effective as a lubricant that it could easily make things way TOO facile where some “warning friction” is a good thing. Knowing when pieces are reaching release criticality is a good thing to prevent dents in the duct work in the basement ceiling leading to the upstairs living area.

I have sent units back to RWS/Diana in Arkansas for re-builds that decades of faithful and predictable use had rendered too facile and too polished to be reliably used in my basement 10 meter range. Now, that’s NOT usually the case with the chase of friction, of course, but it can and does happen with venerable air arms, bicycle parts and all kinds of things that we can use and habitually take for granted until something untoward happens.

The problem is habituation to a creeping and almost imperceptible change in status. We adapt to the change incrementally and unwittingly until we have a negative result like a dented duct or a BB in the forefinger that one’s GP has to take out and then call you “Roy Rogers” with an earned snicker. (Okay Brian, you got to laugh that time, but you’ll do something that I can retort with eventually!)

One of the things I wrote Tom G about quite a while back was the need, as I see it, for an article on some “hard standards” related to annual maintenance of our air arms that would force us out of our habituation/mindless acceptance of incremental change to actually look hard at how triggers and safeties and such ARE CHANGING and assess for points wherein real work needs to be done to reset the arms to safe operating conditions.

In some peculiar ways, the changing of air arms to malfunctioning may be safer than the changing to hyper-improved functioning when you think about it. When the gun STOPS working, you know to send it in or tear it down. At least unload it and stop using it until fixed.

When the gun works too well, you can get a BB in the forefinger or a dented duct pipe.

Again, is it time to work up an Annual Check Sheet that one would apply to EVERY air arm in the locker and do the tedious work of actually scoring EACH ARM against the standard so that there is a breakthrough against the assumed, the usual, the customary and a realistic evaluation and action plan be taken when needed? I think that the more familiar and favorite the arm (like my RWS/Diana Model 36 in .177 or the Beeman P-1 pistol) are my sterling examples of familiarity breeding potential danger or harm to self, others, or property. Periodically being “jerked back to hard evaluations” is likely necessary with our most treasured and well-used pieces in the arms locker.

LFranke,

You could start here: https://checklist.gg/templates/law-enforcement-firearms-and-equipment-inspection-checklist

shootski

BB,

So, you’re telling me to man-up, ignore the blister and pain from the trigger guard cutting into my middle finger and put 5000 rounds through one of my China made Pioneer (S2) pistols? I’ll get right to it, soon as I find a Round Toit.

Really just need to reconfigure the shape of the trigger guard first. Might need to find a 55 gal drum to shoot at.

Just kidding. A 5 gal can will do fine ! 😉

Bob M,

That is one of the things that a properly fitted trigger shoe can help you avoid.

Or regular Shooting Gloves not the target shooting type.

shootski

It is interestingly co-incidental Tom published this today. Yesterday, FM decided to field-strip his newly-acquired SIG P365 Nitron 9mm pistol and give it a preliminary cleanup, per the instructions in the well-written and illustrated manual. Taking the slide apart and removing the barrel was “easy peasy.” When it came to re-assembly though, FM started getting pretty anxious at his inability to get the slide repositioned correctly enabling the pistol to operate. Re-reading the instructions several times and making careful note of how to release the slide catch and takedown levers while getting the TINY safety lever out of the way finally did the trick. FM thought he was gonna have to make an embarrassing appointment with a gunsmith to “git ‘er done.”

One thing to be said is, really like this little pistol and believe it will shoot well BUT if you have big paws, the Nitron is probably not your best choice.

I can relate to this report. My first airgun of my “airgun rennaisance” was an Umarex Embark I purchased to teach my kids gun safety and marksmanship. That gun started of pretty rough, especially the creepy and looong trigger pull. But there was a perceptible bump between the second and third stage and a rough spot right before the sear released, so you could find that spot and hold it while you went through your final shooting routine. But then it happened…the trigger smoothed out and that rough spot was gone. After that, it was really hard to find that sweet spot. The second stage became one of those long pulls with a lot of trigger movement and no indication of when the release would occur. So the gun became less accurate due to the break in. The irony is that this propelled my search for other airguns. Now I have a bunch!

BB,

To me it seems that a gun that would break in quickly might also wear out quickly. That idea is based on the notion that the steel that breaks in quickly does not have as good wear resistance as steel that is harder to break in.

It might just be that guns that break in quickly just have smaller burrs.

David Enoch

Shootski,

If you look at the China made Pioneer or S2 spring pistol you will notice the following and why I called it rough.

The barrel is short, and the front sight is too pointed, ouch.

The trigger guard forms a wedge where it attaches to the grip, is not recessed enough where it attaches, and it is thin and somewhat sharp, ouch.

The trigger is thin and edgy, ouch.

The grip is a little too short for all your fingers to grip comfortably and shaped like a tree limb.

The barrel pivot point creates a crunch zone between the barrel and receiver when cocking.

The really good part is, or was, the price. Gloves would help for sure. Same with a trigger shoe.

Well ,well,

Looks like they eventually addressed all the ergonomic issues I mentioned above when they transitioned to a synthetic model and dumped the wood.