by B.B. Pelletier

Happy day after Christmas! I hope your holiday was as happy as mine.

Because I unknowingly repeated a posting last week (Tod brought it to my attention), I reviewed the posts made since the September 30 index. I also looked over your comments and discovered I hadn’t answered some questions. Other readers stepped in for me and I’m grateful, but there was one request that I would like to act on. Bill asked if I would post some close-up photos of some of the technical parts and terms of airguns that get tossed around in the blog. I think that’s a great idea, so I will do it over a series of future posts. I’ll not run them together, to keep from boring the old-timers, but perhaps at the end I will post a mini-index of these things. Or, maybe, I can talk Pyramyd AIR into letting me make all the posts into one article they can put on their site!

Okay, let’s get going with today’s topic: lubricating spring guns. We’ll start with the cocking linkage.

Cocking linkages

There are several types of spring-gun cocking linkages, but they all do the same thing, so they all need the same treatment. A cocking linkage connects the piston and mainspring of an airgun to the hand of the shooter. This varies in only one instance that I know of, and that’s the Rutten rifle, which uses a high-torque electric motor to cock the gun. Cocking linkages need to be lubed with either moly grease or a good-quality petroleum grease. Some people use a lithium-based grease, and that would also work well.

Breakbarrels

The breakbarrel spring gun uses the barrel as a lever for cocking. The barrel rotates on a large bolt that is part of the cocking linkage. On better guns, there are thin washers on either side of what is called the baseblock (the metal slab the barrel rides in), and they keep sideways play to a minimum. The best lube for both these washers and the barrel pivot bolt is moly grease. The moly penetrates the steel surfaces under cocking pressure, and your gun is practically lubricated for life in this area.

When the rifle is cocked, the barrel baseblock pivots on a bolt held between between two action forks. The cocking link connecting the barrel to the piston attaches to the bottom of the baseblock. All these joints need lubrication.

The other place(s) breakbarrel cocking linkages need lubrication is in the movable joints that connect the barrel to the piston. Use moly here, too, if you can. If your gun has a sliding steel connector that rides in the piston and receives the end of the cocking link, like Weihrauchs do, lube all those moving surfaces with moly.

Sidelevers/underlevers

A sidelever or underlever spring gun uses a separate linkage for cocking while the barrel remains still. This mechanism gets lubed the same way the barrel pivot joint and cocking linkage does on the breakbarrel. There will be no large washers in the main pivot joint of this type of cocking linkage, because the linkage is designed specifically for this job – and a little sideways play in the lever doesn’t hurt accuracy.

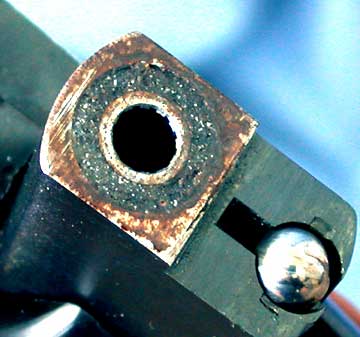

That dark circle around the bore is a leather breech seal! It’s been there for 28 years and still works.

Breech seals

There are two types of barrel breech seals – leather and synthetic. Leather needs to be lubricated often; synthetic seals pretty much take care of themselves. The breech seal keeps the breech tight when the gun is fired. At that moment, there is a small amount of high-pressure air trying to exit the transfer port, but it is blocked by the pellet in the breech. For a tiny fraction of a second, that air is contained by the breech seal! If you put talcum powder on the breech of a breakbarrel rifle, you’ll probably see a tiny puff of powder when the gun fires. More than a tiny puff means the seal leaks, BUT – don’t assume a seal leaks just by its appearance – be certain! Breech seals can look horrible but still work just fine.

Triggers

Some triggers must never be lubricated because they are permanently lubed at the factory. All AirForce rifles have their triggers permanently lubed with a dry moly coating. If you were to put oil or grease on them, you could ruin the trigger’s function and void the limited lifetime warranty.

Other triggers can benefit from a small amount of moly grease at just the right spot. The Rekord trigger, found on Weihrauch and Beeman R-series rifles (except the RX-2), and the close-copy TX 200 trigger benefit from moly grease at the sear contact point.

The Beeman R1 book describes in detail how to disassemble spring-piston air rifles.

Some disassembly required

Some spring guns can be made very smooth through the proper lubrication. I’ve purposely not gone into the disassembly required to get to many of the parts mentioned above. Those who can get to them will find a way, and those who shouldn’t are better off not taking their guns apart. There are a few books that show how to disassemble these guns such as the The Beeman R1 Supermagnum Air Rifle. If this is something you want to do, please get a book first. Otherwise, you’re better off sending your airgun to one of the airgunsmiths who can do the job professionally.

I was directed to a special run of crossman 392 limited ed. I hope factory!

checkerd grip and a changed cocking lever to facilitate the use of the intergated scope rail and included scope.

…a possable collector buds.

Turtle

check the crossman site

What is the trigger used in the RX-2?

The RX-2 trigger is not a Rekord. It has no name that I know of, and it is unique to this model in the Weihrauch line.

B.B.

B.B.

Check this price of a Beeman R1 book on sale.

Please do consider running another reprint or edition of the book.

Manish

Mumbai, India

Oops, forgot to paste the link

https://www.amazon.com/Beeman-R1-supermagnum-air-rifle/dp/B0006F5BXA

Manish

Manish,

My wife thinks the price is a typo. That it’s really supposed to be $64.90. I hope so, because that book isn’t worth $649.

I am seriously considering republishing and updating the book.

B.B.

Hey B.B this site is great, thanks for posting so much good info on here! I ran across this the other day when looking, hopelessly I might add, for some help.

I have an R1 that will not cock, after reading through some of your other posts and checking out various pieces on the gun I have found that either the end of the cylinder is worn slightly or the clip that pushes it is…have you ever heard of such a thing? By placing the tip of a screwdriver in between them the gun cocked fine, I'm hoping you'll have some idea of what to do because I can't see paying beeman $58 an hour to work on it. Thanks.

Andrew,

I have heard of a cocking shoe wearing to the point that the gun would no cock. All it takes is a few thousandths of an inch for that to happen. A new cocking shoe, which is part 30a, Cocking Plate, is what you need.

B.B.