by B.B. Pelletier

You probably know about the three common airgun powerplants – spring-piston, pneumatic and CO2. Actually, there are several types of pneumatics, including multi-pumps such as the Sheridan Silver Streak, single-stroke pneumatics such as the Beeman P3 and precharged pneumatics such as the AR6 by Evanix. Today, we’ll look at a different type of spring gun that uses both the power of the spring directly, such as a catapult gun, and also functions as a spring-piston airgun.

What I’m about to show you is a very common type of mechanism, but it’s not universal. There are some BB guns that have different powerplants, such as the Crosman 350, 3500 and M1 Carbine. But this mechanism is what most collectors think of when they refer to a BB gun powerplant. It’s the same one found in the Red Ryder.

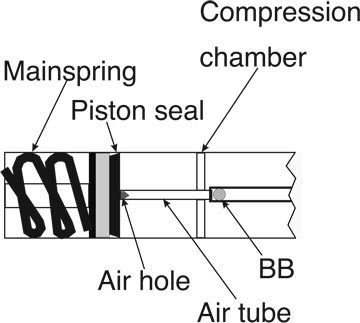

By combining the catapult and the spring-piston, designers got a lot of power from a relatively weak mainspring. The catapult works initially to get the BB off its seat and moving, then a blast of compressed air from the spring-piston kicks the BB in the tail to boost it to maximum velocity.

This is a BB gun mechanism in the cocked state. The air tube moves with the piston as it goes forward. It shoves the BB to an initial velocity before the compressed air rushes through the tube to boost it.

For this type of mechanism to work well, the BB needs to be held fast at the breech end of the barrel, awaiting a shove from the air tube. Initially, manufacturers relied on a slight constriction in barrel diameter to hold the BB. That worked as long as BBs were made of pure lead, but did not work when they switched to steel in the 1920s. A wire spring was then used for many decades to hold the BB in position. It also worked very well, and the spring could be easily pushed out of the way by the air tube when it passed, so it was a good solution for a long time.

When magnet technology improved in the 1960s, small magnets soon replaced the wire spring, and then nothing had to be pushed out of the way. Magnetic shot seats are the standard today.

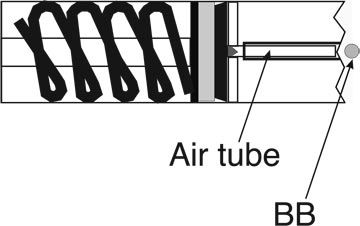

Now the gun has fired. The air tube pushes the BB up to 80-100 f.p.s., while the air is being compressed by the piston seal. The compressed air then rushes through the air hole at the base of the air tube and up the hollow tube to get behind the now-moving BB. It boosts the BB up to its final speed.

This mechanism is one of the reasons I am an airgunner. When I look at the simple design and scant materials that are used to make a BB gun powerplant, I’m overwhelmed by the creativity of the human mind. It takes a lot more ingenuity to propel a steel BB this way than it does to propel a lead bullet using a chemical explosion!

So is a shroud legal? i once made a silencer and then destroyed it after finding out it was illegal. I then made a shroud and it is as effective as the silencer. All your hear is a click of the hammer. It’s on a daisy multi-pump, because i couldn’t mount it on my bengi 392, and there is no point on my springers. All it takes is a pvc pipe and duct tape (no baffles needed.)

I think shrouds are a very contriversial thing. The cops around here all told me mine is legal, and it has baffles. I guess it depends on them. I don’t think they could do anything about one like yours, with no baffles. I mean, you can make one like that by taking a soda bottle and putting it over the end of the barrel. That will quieten the report. If you know some cops (that way you won’t get arrested for asking) you could always ask them. It mosly depends on what they think.

Well mine has a pvc pipe and it just slips over the barrel. I just used black duct tape to seal the back and about 3 layers over the front. This will only work on air guns because the tape in the front will blow out if used on a gun. Its very effective, cheap, and simple. I recommend it. It works on that daisy and that shoots 725fps. Only the hammer goes click.

B.B

With the relative slow speed that air guns produce, are the different types of pellets made like for example “Gamo’s hunter, master point and match” really able to have different impact “harder hits” on target pest. Or is this a racket for producing more sales from the big pellet companies. I have a Benjamin 392 does it shoot fast enough to really make a difference with pellets for hunting?

In my own expiraments I have shot a bar of Dial soap from 35 ft with the Gamo hunters, match, and master point pellets. There has not been any distortion to the pellets and the wound channel didn’t look much different. But you shoot that same pellet/gun combo at a piece of OSB and they flatten out. I was just wondering if the soap was similar to animal flesh? And what I could expect from different types of pellets. I found that they don’t expand and that the only thing I have going for me in hunting situations are the accuracy of the 392 and the heavier weight of the different pellets. But the different types, domed hunter, wad cutter, and pointed master pellets made similar holes. But they heavier master point since it had the point sailed through, while the other two did seem to thump harder on contact.

Nate,

The 392 is a bit slow to show much deformation at any range, but it dies punch a big hole in the target. Dial soap is harder than the Neutrogenia facial bar I used, plus Neutrogena is transparent.

I’d advise you to shoot the most accurate pellet and be thankful for the accuracy.

B.B.

B.B.

Thank you for your response.

I’m glad that I came across this blog. Air Gun’in is a subject that is hard to find information on. Muchless be able to ask questions and get an expert opinion. I appreachiate your knowledge and the fact that you share your opinions to all of us.

I hope you don’t feel like I have ever wasted your time with my novice questions. But I crave information and respect what others have to say.

Thank you B.B

Nate 392

Hi, BB!

Here are(.22) the Crosman Pointed Eun Jin 28.4 grain Wasp(Eley) Magnum (solid)30 grain and the Daystate Varminter Hollow Point 39.5 grain.

[IMG]http://i130.photobucket.com/albums/p245/JHodgeCMI/100_0081.jpg[/IMG]

Did a chrony test and the Daystate Varminter Hollow point came out on top. 55* Day with my Sumatra (.22) 2500 R Carbine at 3000 psi on full power. All shots started at 3000 psi and six shot string with each brand recorded

Varminter 39.5Shot One

813.6 FPS = 58.07 FPE

Shot Two

786.2 FPS = 54.27 FPE

Shot Three

765.5 FPS = 51.41 FPE

Shot Four

757.7 FPS = 50.36 FPE

Shot Five

737.5 FPS = 47.71 FPE

Shot Six

722.2 FPS = 45.75 FPE

[IMG]http://i130.photobucket.com/albums/p245/JHodgeCMI/101_0056.jpg[/IMG]

Wasp (Ely) Magnum solid No. 2 5.5 mm 30 grains (note these slid right out of the rotary magazine since they are 5.50 mm and I felt for field hunting you’d be limited to carrying only one preloaded magazine(the one in the rifle).

Shot One

913.4 FPS = 55.59 FPE

Shot Two

893.2 FPS = 53.15 FPE

Shot Three

882.6 FPS = 51.90 FPE

Shot Four

858.7 FPS = 49.13 FPE

Shot Five

829.7 FPS = 45.86 FPE

Shot Six

805.7 FPS = 43.25 FPE

Eun Jins 28.4 Grains

Shot One

924.7 FPS = 53.93 FPE

Shot Two

902.7 FPS = 51.40 FPE

Shot Three

888.3 FPS = 49.73 FPE

Shot Four

865.5 FPS = 47.25 FPE

Shot Five

845.5 FPS = 45.09 FPE

Shot Six

838.4 FPS = 44.33 FPE

I’d like it if maybe you could put this on your list for future reports. I did not have a chance to do any accuracy tests (just Chrony numbers)as the winds were gusty.

Great Shooting!

Jay (jhodgepiatmsndotcom)

I will note that I took shots at my 22 rimfire spinners and the Daystate Varminters and Wasp Magnums seemed just as accurate as my (perhaps)former Hunting pellet of choice Eun Jin 28.4 grain.

so, in a poppet-valve type system, the valve is held within the airtube? and how come the magnets dont break from the impact? arent they brittle? one last thing, where is the part that the sear catches onto located? its been puzzling me for a while now.

interesting to think a bb smoothbore propelled by spring and tube would be able to get .20 groupings.

dm20,

I would not call a spring piston airgun mechanism, including the BB gun mechanism discussed here, a poppet valve. In fact, I would say there is no apparent valve of any kind. Nothing

The magnet is mounted on the side of the shot seat, away from the movement of the air tube. The force of magnetism holds the BB fast without any mechanical assistance. So when the air tube moves past the shot seat, all it does is break the bonds of magnetic attraction by pushing the BB ahead of it.

The sear is located at the other end of the guide rod inside the mainspring. I didn’t draw that part of the mechanism, but that rod goes all the way back to an anchor. When the gun is cocked, the rear of the mainspring is held fast by a flange on the rear of the guide rod mechanism that is restrained by the anchor, while the sliding rod that the piston head is attached to continues back until it is caught by the sear.

It’s difficult to discuss the design, but when you see it operate you’ll say, oh yeah!

As for the accuracy potential, it gets even better than I reported. Another precision BB gun is the Diana model 30 that shoots shot so smooth they are actually ball bearings. That gun is reported to be even more accurate than a 499, though at $1,000, they are better suited to the shooting galleries (in Europe) that still use them.

B.B.

Hi BB

i have tryed Raptor pellets in my P3

and was very happy with their performance But i also have a HW40 in 22 cal. i shoot Hobby pellets in the

HW40. are there any 22cal PBA pellets out there that are not the plastic jacketed type ie..22cal PBA pellets.

i am trying for a flater trajectory

with my HW40

by the way your blog….excellent.

thanks Norm

Norm,

No PBA pellets have plastic jackets. Gamo will be bringing out a dome and a wadcutter this year.

Don’t look for .22 caliber, though. Wal-Mart has killed that caliber, so Gamo won’t make it, I don’t think.

B.B.

bb

the mechanism seems so simple and it seems like airsoft guns could benifit from it. do you know of any airsoft guns that have this powerplant or are planing to in the future? it seems like a more effective way to propel an airsoft bb concidering the already weak mainspring.

Field Targetier

Field Targetier,

This mechanism is not suited to rapid fire, while the airsoft community seems bent on that direction. I doubt they will embrace it.

B.B.