by B.B. Pelletier

When you think of great airgun triggers, Crosman is probably not the first company that comes to mind. But, are you aware that they designed a trigger that for many years was one of the top target triggers around? Probably not, because this trigger was found on their model 160/167 target rifle that came out during the period CO2 powerlets were suffering. All the CO2 guns made from 1955 through the late 1960s suffered from leaks, so CO2 got a bad rap and CO2 guns were largely ignored. Which is why in the 1990s airgunners everywhere began discovering what wonderful guns they had ignored, and none more than the 160.

The 160 trigger is adjustable

I addressed the Crosman 160 when I reported on the QB 78, so read that report to catch up on the rifle. Today, I want to look at just the trigger. It’s adjustable for pull weight, sear engagement and has a trigger stop.

Do NOT disassemble any part of your gun unless you are 100% positive that you can put it back together again!

It came from a crossbow!

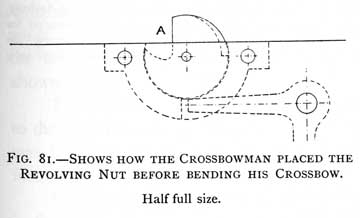

When I read Sir Ralph Payne-Gallwey’s excellent book, The Crossbow, first published in 1903, I was stunned to see the ancestor of the Crosman 160 trigger in a military crossbow of the 1400s. The trigger is based on a rotating sear called a nut. Back then the nut was made from animal horn, and hundreds, if not thousands, have survived to this day. Crosman used steel or sintered iron – I can’t tell which.

From Payne-Gallwey’s famous crossbow book, this illustration of the trigger nut illustrates how a vintage crossbow trigger works.

Getting to the trigger requires disassembly

To get to the trigger, you must first remove the action from the stock. The safety switch has to be taken out and the single-action nut removed and then the action and stock separate easily.

Once the rifle’s action is out of the stock, two trigger sideplate screws can be removed. This exposes the internals of the trigger. If you have an original Crosman trigger, there will probably be iron filings inside the trigger box. Brush them out before proceeding. The QB triggers don’t seem to have this problem.

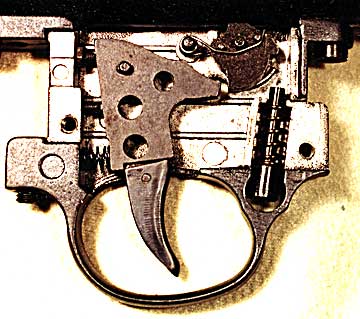

Crosman’s 160 trigger (a QB 79 target trigger clone is shown) has the same rotating sear as the crossbow trigger. The dark half-round part at the upper right holds the hammer until the trigger releases it to rotate out of the way.

All adjustments appear in the picture

Pay attention to that trigger picture. See the two small screws coming in from the upper left side? The top one adjusts the amount of sear contact area. The bottom one is the trigger overtravel stop. The spring at the bottom is the trigger-return-spring adjustment that also regulates the weight of the trigger pull. The trigger shown is a modern copy of a 160 trigger from a QB 79 target rifle, and the first stage is built into the trigger blade, which is spring-loaded to move back and then stop as your trigger finger tightens.

The large pin with a spring around it at the right is the safety mechanism. The safety lever had to be removed to get the action out of the stock. Even with the sideplate off and the internals exposed like this, the trigger can still be cocked and adjusted, which makes your job much easier. However, it is not necessary to remove the sideplate to adjust the trigger.

Adjusting the 160’s trigger

I adjust the sear contact first, leaving plenty of contact area. The sear responds well to lubrication, so you can have a good amount of sear contact for safety’s sake. After adjusting the sear, I set the overtravel stop. It’s possible to adjust this trigger so it will not cock and also so it cannot be fired after being cocked, so keep testing it as you go. The trigger-return spring is adjusted last, then the trigger is lubricated.

I lube the sear contact area with Beeman M-2-M moly grease. People used to warn that moly is too slippery for trigger lubrication, but that warning has faded today. After that, a drop of FP-10 goes on the sear pins on both sides of the sear so it can turn freely. The job is now done, and you can put the gun back together.

With lubrication and proper adjustment, you can get a safe trigger-pull in the 1-lb. range. It will go even lighter, but I think that’s flirting with disaster.

If you own a 160/167 or a 180/187 with this trigger and you’ve never adjusted it, give it a try! You might be pleasantly surprised.

B.B.

Does the new 1760/2260 have the same adjustable trigger as you describe?

Michael in Florida

Michael,

No.

B.B.

BB,

Have I said something in the past to offend you? You seem really short with your answers. If I have, I sincerely apologize.

I’ve answered my own question regarding the 2260 trigger.

http://www.spiralsol.com/airgunmod/1005.pdf

Regards

Michael in Florida

Michael,

I answer 30-80 messages a day. They are posted to nearly 700 postings in this blog. So when the answer is a simple yes or no, I give myself a break.

No offense taken.

B.B.

B.B. In the past have you done a article on the Rekord (sp?) trigger? I own a Weirauch (sp?) (Beeman import) RX-1 with a rekord trigger. I’m looking to learn more about this trigger.

Savagesam,

Sorry to report that the RX-1 doesn’t have the Rekord trigger – at least not the same one we talk about. As far as I know it has a pretty good trigger, but it is different than the Rekord.

B.B.

BB

with your many years of airgun and firearm experience you must have had or seen countless funny and interesting things. Have you ever shot yourself? Seen someone do so? While that may sound gory, these kind of stories told in the right fashion can help others avoid such situations. It would be great to hear a few of your funny/sad/careless moments that only experience gives. Maybe a blog…..?

Paul

Paul,

Let me give it some thought. Perhaps I can put something together.

B.B.

BB,

Do you know of any quality airguns with electronic triggers? I know that’s probably a taboo word since batteries don’t tend to mix well with anything but childrens’ toys. I’m aware of plinking CO2 guns like the Drozd, but that’s not meant for accuracy.

I’ve been thinking about some “what ifs,” like a quality PCP air rifle used an electronic trigger. Theoretically it could be far more adjustable than a mechanical one, no? Imagine a 1 ounce trigger pull.

-Alan D.

alan,

i have an airwolf that i love!

I dont think bb needs his imagination to feel a 1 ounce trigger, he would need his finger to feel a 1 ounce trigger. Maybe his feet to walk and get one of his match guns! There is much more that goes into a trigger that makes it good. I would say that some 2lb triggers are better than some 1 pound triggers!

-sumo

Alan D.

There are several target airguns with electronic triggers and, no, they are not better. While air pistols have to have a 500 gram trigger, and they are the ones with the electronic triggers, one ounce is HEAVY for a target trigger on an air rifle. They can get down to 20 grams or less.

B.B.

what target airguns have electric triggers?

-sumo

Sumo,

Off the top of my head, the FWB P90 and the Pardini 161E. I know there are others, but those come to mind. The Pardini might actually be a Morini.

B.B.

I can’t debate the question of whether or not other triggers may be better, but the trigger on my FWB90 is pretty darned good. Certainly the best trigger in my collection, air or powder.

my airwolf trigger could not be better. Then again some of my traditional triggers are as good.

-sumo

Enjoying reading past posts, saw a mention of using old blue Beeman laser seal in an R1 with a lighter weight mainspring to get 200 fps more .177. Could you elaborate on that a bit, and comment on accuracy etc? And where is this done?

Also, saw a mention of a Venom Mag80 Laza tune, same question?

THANKS

BB,

do you know something about the field target world championship in Tennessee?

Markus

R1 Laser tune,

Beeman used to offer a Laser tune as an option for the R1. It involved a different mainspring that was less powerful (had less spring rate) than the factory spring but more coils (of thinner wire, I believe). As a result, it pushed the piston faster than the factory spring. A special blue piston seal that had to be fitted to the rifle by hand gave superior sealing, and special Laser Lube was used on it.

The Venomacx Mag80 Laza kit tune was different. It had a stroked piston (shorter, so it could go back farther) a larger, more powerful mainspring, covered with a black substance Tom Gaylord called “black tar” (hence the name many use today, six synthetic buttons around the piston to relieve friction and a special piston seal. That kit was really remarkable, in that the rifle went from 17.5 foot-pounds up to about 23 foot-pounds, yet it felt like a smooth R7 when it fired. It was the smoothest R1 tune ever. Also now long gone, I believe.

B.B.

Markus,

I know a little. What is your question?

B.B.

Wow, that sounds great, wish somebody still did it.

Did Beeman ever make a 2-7×32 AO air rifle scope? I think I might have on e on an air rifle I purchased, a BSA Supersport. No marks on exterior of scope of any kind, but saw an ad for the Beeman SS1000 that appears to have a scope very much like this.

[IMG]http://i5.photobucket.com/albums/y174/jrguerra/Air%20Firearms/WebleySupersportright.jpg[/IMG]

Thanks in advance for the help.

All the Beeman scopes I know about are marked with their name, but they are buying heavily from China now, so nothing is impossible.

B.B.

http://www.airguns.net/general_rekord_trigger.php I keep having trouble signing in as savagesam. I found this on the weihrauch/Rekord trigger.

savagesam,

I don’t know what your sign-in problem could be, but I do know Google is squirrley. And they host Blogger.

I like the American Airguns website – especially the classifieds.

B.B.

My point was/is, how do I go about confirming if I do or do not have a rekord trigger? I believe it is. But now you’ve given me reason to wonder. From, savagesam

Savagesam,

That’s easy. A Rekord has a large aluminum screw that hangs down behind the trigger blade. If your trigger has that screw, it’s a Rekord. If not, it’s something else.

Look at the drawing you sent to me and you’ll see the screw I mean. Then look at every Weihreuch rifle and you will see it – except on the HW 90 (gas spring) and certail smaller rifles like some of the 30s.

B.B.

Nope. Mine has it. I always knew it was. I just couldn’t/can’t remember WHY I knew it was. I can take a pic. if you like?

Sorry, above post is from savagesam

Savagesam,

No pic necessary. As long as you know what you have, everyone is happy.

B.B.