by B.B. Pelletier

An announcement before we begin. After speaking with the manager of the Firearms Division of the Michigan State Police, Pyramyd AIR has changed their policy regarding sales to addresses in Michigan. Unfortunately, she is the same person who gave out erroneous information 9 months ago! When they spoke to her this time, they quizzed her about the legality of certain airguns, such as the .50-caliber Dragon Slayer, and she replied that the federal government regulates those types of airguns! In fact, she even stated that federal law prohibited felons from owning airguns.

Of course, the federal government does not make specific laws concerning pellet and BB guns. So, Pyramyd AIR has changed their policy for shipping to addresses in Michigan to reflect what they were just told, and that’s how they’ll be handling orders from now on.

On to today’s blog….

A reader asked me about barrel shrouds after reading the Air Arms S410 series. He figured out how they work, but there are subtleties that I thought the rest of you might like to know about, so today I’m looking at shrouds.

Simple shrouds

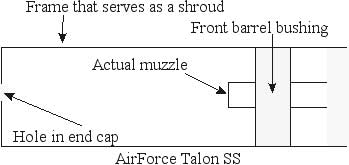

The simplest type of shroud is a jacket that encloses the barrel and contains the violent release of compressed air from the muzzle. It lets the pellet escape but forces the air to use up much of its energy before it leaves the shroud, thus reducing the report. In effect, it acts like the simplest form of silencer, and the only difference is that the shroud covers the entire barrel, while the silencer is just a component added to the barrel. Let’s look at the AirForce Talon SS, which has one of these.

Shroud technology

There can be more to shrouds, however. For one thing, only a few guns have a frame large enough to use as a shroud. Others must install an actual jacket around the barrel. This jacket must be rigid so it doesn’t move and hit the barrel. It must also have its end cap hole aligned precisely with the true muzzle, so the pellets don’t touch the sides of the hole when they exit. And, it must look right on the gun. That drives makers to use a smaller-diameter tube (smaller than the AirForce frame diameter) and to attach it rigidly at the action. But that’s not all.

Holes are the secret

To keep the shroud to an overall length that doesn’t ruin the looks of the gun (and longer barrels are better for PCPs), the wise maker does everything he can to direct the flow of energetic air backwards after it leaves the muzzle, so it has to run the entire length of the barrel and back again before exiting the end cap. That way, the outer shroud diameter can remain small yet still have a lot of space for the air to expand (length instead of width). Some wise person discovered that if they allowed ambient air to exit the shroud at the rear, it wouldn’t build a pressure wave and reflect the compressed air back to the end cap so readily. So, the shrouds on really advanced PCPs will have small holes just in front of where they exit the receiver.

There’s one final consideration for a good shroud – materials. Use the wrong materials and the shroud becomes a gong, amplifying the sound instead of dissipating it. Use the right materials and deaden them further by installing vibration dampers at the right place, and you’ll get a dead-quiet rifle that has nothing you can remove and install on a firearm. Yes, by machining the materials from a removed shroud, you might make an effective silencer for a firearm, but anyone clever enough to do that is better off starting with common PVC pipe from the hardware store.

The wrong material to use would be thin aluminum tubing – something I see a lot of hobbyists using to make shrouds. It’s easy to get, so they use it, without realizing what it does to the outcome of their project. It buzzes and resonates with sound unless you take pains to dampen it.

As you can see, there’s a little more to shrouds than you may have thought. Done well, they are as effective as silencers and can also be quite attractive – like the “barrel” on a TX200 Mark III, which is really an attractive shroud.

Tom I HAVE to believe a company like P.A. has a lawyer on retainer for these questions of law???? One should NEVER rely on an LEO for legal advice. You have a lawyer tell you what’s legal, that way if you wind up in the cross hairs……1.The court knows you were making “reasonable” attempts to stay within the law. 2.If it gets real ugly you hire another lawyer to sue your lawyer for damages. from Savagesam

Hi B.B.,

Can the AA S410 shroud be dis-assembled for maintenance and cleaning?

Same question goes for the TX200 Mark III?

Are the shroud permanetly attached to the barrel because of legality reason so maintenance and cleaning will not be possible?

Thanks!

Cali

Cali,

Let me ask you this – how often do you remove the muffler and tailpipe from your car and maintain and clean it? The S410 and TX200 shrouds are the same.

Don’t even think about them. Just enjoy the gun.

B.B.

B.B.

How do you rate the accuracy of a laser sight compared to red dot and iron sights? I’m assuming there’s no comparison to a scope. I know that the red dot is supposed to be as accurate as the best iron sights and faster to pick up targets. Preliminary tests with my new Deluxe Leapers laser sight mounted on the Walther Nighthawk are pretty good, and it seems like the laser will reduce muzzle flip. You can see where the muzzle is pointing all the time. But I was wondering what the voice of experience has to say about all this.

Matt

att,

In the use of lasers, I don’t have much experience at all. I used to mount them and demonstrate them on AirForce rifles at trade shows, but I don’t use them personally.

Lasers are close-range sighting aids at best. For tactical situations inside buildings they seem to be fine. But out in the wide wonderful world you just can’t find the dot unless it’s dark.

One hunter I know has his scope zeroed for 20-30 yards and the laser sighted for 20 feet. He shoots pigeons in tight spaces and the laser works well for him.

B.B.

BB

I listened to your comments on your weekly show about air guns for youngsters. I totally agree with you on everything you stated. My Dad started me with a Sears Marlin, 22. cal rimfire, which I still have to this day. We did not know anything about spring guns back then. I went out with my 7 year old son the other day, and took my 34 Diana with me. As soon as I took my first shot, he was excited as a young beagle on his first rabbit jump. I let him take a shot while I held the rifle. He was thrilled. He was still game even though the scope kicked him above the eye. Well like you stated, I want to start him off the right way. I am looking for a rifle (he is a (lefty). Either a pellet gun or BB. Some type of single action and iron sights. Can you give me a suggestion. As I mentioned I still have my Marlin, but am hooked on Pellet guns and done with gunpowder.

Thanks

B.B.,

I recently purchased a Baikal MP-514K from Pyramyd. This rifle has an auto safety located just forward of the trigger. When I first got the gun, the safety worked fine. Now, the safety is hard to disengage. In fact, the last time I cocked the gun, I had to hold the safety while simultaneously pulling the trigger in order to fire. That was the last time I fired the rifle.

I emailed Pyramyd with my concerns but they said they had not had any similar complaints about this air rifle.

I also noticed that Pyramyd no longer offers this particular air rifle.

Would it be advisable to attempt to remove or disable the safety?

Thanks,

scottp

JW Burns,

I think an IZH 61 might be nice for him. It’s safer for him to cock than a breakbarrel and he should be able to cock it himself.

If you want something a little larger, a Gamo Delta is nice and will even save you some money.

I would get him started with open sights and hold off on the scope as long as possible. Kids need to learn the fundamentals first.

B.B.

Scott P.,

I haven’t heard of this problem, either, but my test of the 514 was brief. Pyramyd seems to be out of stock, but they indicate they will be restocking this gun.

I would return it to them for repairs, at least once. Let’s hope that’s all it takes.

B.,B.

JW Burns

I’m always glad to make a pitch for the IZH 61 as a fine gun. I’m not a kid, but I may as well be from the standpoint of shooting. It is very gratifying for a beginner to shoot as accurately as you can with this rifle. The artillery hold is a must, but my gun doesn’t seem to require anything in particular beyond a loose hold.

B.B. on the subject of open sights, I am on my third model for the IZH 61: first there was the Daisy, then the Mendoza, and now the Beeman Sport Aperture. The Beeman had a stripped Allen screw which kept it from being held securely, but otherwise, it is the way to go, and I ordered a replacement. It fits the gun perfectly and accuracy is almost the same as the Bug Buster scope at the short ranges I shoot at. But did you say this was an easy sight to attach?! I thought it was an incredible pain in requiring disassembly and then the alternate tightening of three different screws to get it attached. But it certainly works. I’m glad you mentioned it in the blog.

Matt

Are there any hopes that PA will have IZH 60?

They have been moving the date from week to week for several weeks.

I have heard that for fire guns the recoil is felt after the bullet left the barrel?

Is that true for air arms? I guess there could be multiple scenarios using different arms, but what would be a common scenario?

rimugu,

The importer is EAA. Pyramyd AIR changes the due-in date based on what EAA tells them.

As for recoil, yes, it comes long after the bullet leaves the barrel. But in a spring gun, recoil is in motion before the pellet leaves the bore.

B.B.

Thank you, and now with todays post I will be thinking about experimenting with my Benjamin.

Off Topic,

What would be a good distance to sight in a Crosman 1377? I plan on hunting sparrows, starlings, and pigeons out to about 20 yards (realistically more around 10-15).

Also, should I store this gun with a pump or two? It doesn’t mention anything in the owner’s manual.

Thank You,

Marc

BB, I believe Savagesam is correct in saying that law enforcement personnel are a poor source for legal decisions. I believe they are more likely to make policy declarations.

Concerning federal law, the place to go for a legal decision is the U. S. Attorney General. For state law in Texas, it is the Texas Attorney General. I would believe that Michigan would operate on a similar basis.

I hope Pyramid Air will consider consulting the states’ Attorney Generals when ascertaining the legality of airgun sales in those states.

http://www.michigan.gov/ag

fflincher

Marc,

Sight in at the average range you will be shooting. I would guess that’s about 20 yards (10-25 yards).

Yes, store the gun with air in it. One pump is enough if the gun seals well.

B.B.

Matt,

What were the problems with the Daisy and Mendoza aperture sights?

Farmer

For what it’s worth, I live in Michigan. I read your requirements for the purchase of “short” airguns in this state.

There is one other thing, those that hold a Michigan Concealed Pistols License don’t need a purchase permit to purchase handguns. They only need to complete a form to turn in to local law enforcement. Also, no firing tests are done as a part of the “safety check”. It is really just a way to register the handgun.

B.B.,

Do airgun shrouds ever have any sort of complicated (or simple) internal baffles or packing? I know they don’t have to be built to withstand the heat and pressure blowout problems of firearms suppressors.

Thanks,

Pestbgone

Pestbgone,

The TX200 shroud has baffles.

B.B.

Hi Farmer. The Daisy’s hole (for lack of a better term) was too small for me. It was very dark to look through. I tried putting in brighter bulbs and lighting up only the target for contrast, but it wasn’t enough. While I could make out the targets, it felt like eyestrain. The second problem was that I couldn’t get the Daisy secure on the scope rail. It was easy to attach by twisting one large screw, but it wouldn’t stay secure. Within 30 shots or so, the aperture had moved the length of the scope rail and was falling off the end. I didn’t bother trying to tighten it with a wrench or a rubber glove since the small opening disqualified it anyway.

The Mendoza was way too high for the gun. Even when cranked all the way down, it wasn’t close to zeroing. Another problem was that there was no Allen wrench to tighten the two Allen screws which don’t seem to be of a standard size. None of the extensive collection of Allen wrenches I have collected with different equipment would fit. I managed to get it secure with a small screwdriver but don’t think that is very good for the equipment.

Matt

Matt,

Thanks for the info.

My experience with aperture sights on air rifles is with the original sight on the HW55, and it has a screw which fits into the “scope stop” holes, also the sight stop holes, and keeps the sight from moving. I am not surprised the aperture moved without a stop, just like a scope. I expect the same problem would occur with the Mendoza, since I do not think it has a built in stop.

BB–how about the allen screw problem?

Thanks, Matt.

Farmer

Hi Farmer. You’re right about the scope stops generally, but one of the nice things about the IZH 61 for me is that the recoil is so light that a stop isn’t nearly as important as for a magnum. With a little extra umph on the Allen screws, the Bug Buster scope stayed in place for hundreds of rounds. It had moved almost imperceptibly at the end of that time which I can live with. The Daisy sight on the other hand was moving visibly after a couple clips, so something was wrong.

You’re right that to secure the Mendoza you would need the right Allen wrench to avoid stripping the screws very quickly.

Matt

Matt & BB,

As A retired police Officer I can tell you that the reason for autos over wheel guns is the fire power. And yes, revolvers very much less prone to problems then autos.

I retired after 23 years of service and never carried an auto loader. Also, I believe that departments now carry autos. 12 to 15 shots from an auto sure beats the hell otta 5 or 6 from the revolver (;-) My duty piece (S & W model 681 in .357) and my off-duty piece(S & W model 10 .38 Special) Six rounds each. Except for two other male officers and one female officer I could beat the socks off most others whenever we went for our yearly qualifying. I never fired my gun in those 23 years, and only had to pull it out a couple of times.

I still have my two babies, and I also have A Glock which is A very nice gun (for an auto)lol You might also want to know that in NYC, Duty guns Have no adjustable sights.

BB, A question for you. Exactly what is regulated and unregulated as it pertains to PCP’s?

BobC NJ

BB

Just as soon as I clicked the button on the computer asking your opinion on which rifle to get my son for Christmas, I realized that the IZH 61, might be a good choice and wanted to ask you about that rifle. (Actually I wanted it for myself also). Any way, I went ahead and ordered it and am glad to see that you had indeed recommended it. I also order a crony after reading reading your words of why it is a good idea of owning one. I also ordered 4 bins of Crosman Premier’s after your recommendations. I hope you do not mind if I tune you out for a couple of months. At least until the bleeding stops? Thanks

Farmer,

I had the right Allen screw for the Mendoza sight, so I don’t know what the problem is, unless Mendoza has recently switched to using Torx fasteners. Get a magnifying glass and inspect the opening. If it looks like a star, it’s a Torx and no Allen wrench will fit.

B.B.

BobC.,

Thanks for your input. We sure do have a wealth of experience reading this blog!

As for the firepower remark, I agree. I would like to add that I like the .45 ACP for its celebrated effectiveness as a man stopper. Now that there are reliable single-stack 10-round magazines for the 1911, I have good firepower. Remember, my gun is in the drawer of my nightstand, not jammed into my kidneys while I ride in a patrol car.

B.B.

JW,

I understand completely.

Think of me as the complimentary drink girl at the slot macnines who keeps asking if you’d like a drink on the house. I may be plying you with liquor, but I didn’t drive you to the casino.

B.B.

B.B.,

are there any manufacturers who incorporate shroud designs into air pistols?

PW

PW, I don’t think manufacturers use shrouds, but aftermarket tuners like Mac-1 and others sometimes do.

B.B.

My S410 is really loud. I had to remove the insides of the shroud to get a cleaning patch out of it after trying to clean the barrel the wrong way. Is there a specific spot that the cylinder inside needs to sit so that the sound is muffled correctly?