by B.B. Pelletier

We’re having some wind here in Texas, so the third report on the Webley Raider 10 has to be postponed. I haven’t forgotten it.

Let’s talk about emplacing field targets and the types of mechanisms they use. You may think you’re done when you buy the targets, but the work has only just begun. You must anchor them to something so each good shot trips their trigger and each bad shot does not. Also, repeatedly pulling on the reset string tends to move the target, so you have to find a good way to anchor it, yet it has to be easily and quickly removable because you don’t want to leave them out in the weather where they can rust. I’ll show you what some people do and what we developed at DIFTA to address this last concern.

Target mechanisms: gravity-type

A field target is supposed to fall when you hit the paddle through the kill zone but remain standing if you hit anywhere else on the target. There are two basic types of target mechanisms that do this. The first is the gravity-based system. In the U.S., Ron Juneau built many of the gravity-type targets we use. In the UK, Nockover built them back in the ’80s.

A gravity system uses the weight of the paddle to drag the field target over center so it falls down. When you emplace a gravity-type target, you have to be very careful to level it so the weight of the paddle will be enough to pull down the target. If the target leans too far forward, the pellet won’t have enough energy to push the paddle over center. If you lean it too far back, the sear may not hold the target upright when you try to reset it. If you lean it to one side or the other, there may be too much friction in the mechanism to allow it to move. For this reason, I always test all targets with an air pistol of about 3 foot-pounds energy. If that will work the target at point-blank range, a 12-foot-pound gun will work it out to 55 yards – the maximum distance allowed.

Target mechanisms – spring-assist types

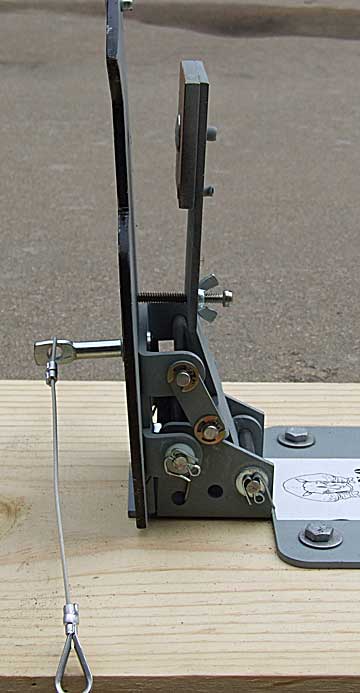

The other common target mechanism is the spring-assist type that uses a spring coupled with a balanced linkage to pull or push down the target. Though more complex than the gravity-type, the spring-assist type is more forgiving of errors in emplacement, and some are made to even be mounted sideways in trees! That doesn’t mean they’re without fault, though. Spring-assist types also need to be somewhat level and their mechanisms need to be clean, lubricated and free from rust to operate properly. But each year that passes sees more reliable spring-type targets on the market.

Emplacing targets

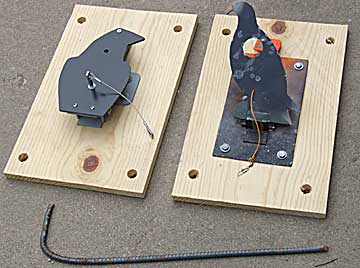

Take another look at the picture of the two targets. Notice that they’re lag-bolted to wood bases. I did this so I could stake them directly to the ground for a quickie field target demonstration. An 18″ rebar stake like the one below the targets is hammered into the ground through each of the four holes in the base so the target will stay put for a while. You can run a match with targets emplaced with rebar stakes, but a club won’t want to use them for long. They’re hard to level and they’re difficult and dirty to pull up when the match is over. Let me tell you a much better way of emplacing targets that we developed at DIFTA.

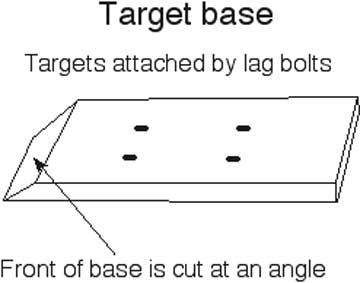

First, all targets were lag-bolted to 2×10 wooden bases. Because the targets come with mounting holes in different locations, this step standardizes them. We made all the 2×10 bases the same length and cut a 45-degree bevel on the front of each base. Let me show you what that looks like.

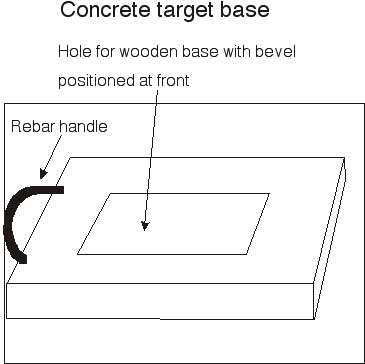

Next, we made custom concrete bases for every target. These were about 18″Lx14″Wx4″D. If I remembered those dimensions incorrectly, maybe Joe McDaniel, who’s the current match director at DIFTA, can revise them for me. We embedded a piece of looped rebar in the front of the concrete base so we could drag it around. After filling the concrete mold with quickset concrete mix, we stuck in a template of the wooden target base we were using. When the quickset was set up but not yet hard, we carefully removed the template and let the form dry. Now we had a heavy platform that the wooden base slipped into tightly. That base was heavy enough to stay put through a lifetime of resets, yet we could drag it around the lane it was on. That lets you reconfigure the course as desired. The concrete base is left out in the weather all the time, but the targets are taken into a storage shed.

That’s one way of having stable, yet movable field targets on a course. There just wasn’t enough room in today’s post for the target hardware, how I repainted them during a match and maintaining them. That’s next.

Hi BB,

I think you have the angled end of the mounting board at the wrong end. The DIFTA Turkey — the only target still using that system at DIFTA — has the angle at the rear. That keeps it from being lifted out of the concrete base with an overly strong pull on the reset cord.

All current DIFTA targets use a 3-point mount very similar to what you show with 4 holes. Actually, one hole in the rear of the board is probably enough although I have see targets get misaligned with the shooting position with only one hole (at the Connecticut Nationals) — another pull on the reset usually will fix that.

Best,

Joe

Mornin’ B.B.,

Thats a pretty neat rig. I have a question on the targets. Do they come with the realy long reset string, or do you have to use your own string?

Thanks,

Brody

B.B.

Thanks,

You know I'm working on this now..your the greatest…this will save time and be very secure…I love it…great idea…easy too!

I thought it would be best to bring them in after a match….now it's easy..also Dick told me about using a cordless drill to wind up the strings…it can't be better..so cool…Dicks target are great..I've been knocking them down in the back yard range, while we decide the layout or the course…they work so fine….

Wayne,

Ashland Air Rifle Range & Rentals

Brody,

Yes, it’s 200# test and about 60 or 65 yrds it looks like…at least 55 yrds..I try one at that distance they pop up so easy with a pull of the string…it’s too cool

Wayne

Thanks Wayne,

I hope your airgun range does well. Your a good man. If im ever out that way, i will have to come by your range, and shoot a bit. lol.

Thanks again,

Brody

Brody,

Please tell us that’s your tractor. It’s really sweet.

Where’s this web site of yours?

Matt61,

Other thread locking tips:

You can also try a couple wraps of plumber’s teflon tape to hold a loose thread. Beeswax is also one of my favorites. Rub it into the thread, or melt it into the threads with a lighter, and the bolt won’t move again until you want it to.

Derrick

Brody,

Some targets do come with a reset string, like the After Hours targets, but most do not include them. I buy bulk 1,000-foot 65-pound test Dacron string at the hardware store and make my own reset strings. I make them about 65 yards long, because they will break and you want some extra. Don’t make them any longer, because at some point, you have to scrap the whole string and start fresh.

B.B.

Wayne,

Hold off on the cordless drill idea. It’s good for two or three targets, but not for 24.

In the next installment I will give you a simple and cheap string-holding mechanism.

B.B.

Joe,

You may be right about the placement of the angle. I dod remember that we had to make a special base for Long Tom because of his size and weight.

Anyway, thanks for responding to this.

B.B.

B.B.,

Off topic question here: I am going to an auction on Aug. 12. In that auction there is a Winchester Model 435 air rifle. I was wondering how much this rifle was worth, and how much I should bid on it.

Thanks,

Jim

Jim,

Condition means a lot with this rifle. It’s one of those that sells better to a Winchester collector than an airgunner.

It’s a German Diana model 35 and you can read my report on that gun here:

/blog/2008/5/diana-35-always-the-contender/

If the rifle looks perfect, pay up to $250. If it’s average, pay no more than $150. A box would add at least 25 percent.

Be very careful about bent barrels! Look at the line of the barrel and receiver, to ensure the barrel doesn’t appear bent up. However, if it is, tell the auctioneer and maybe he’ll be honest enough to mention that.

Then pay $75 and straighten the barrel yourself. Look here:

/blog/2008/7/straightening-barrels/

B.B.

Derrick,

Its not my tractor, although i wish it was. I will have some pics tomorrow of some sweet pullin’ trucks, because im going to the diesel truck pull tonite.

And my website is http://www.freewebs.com/brodman2011

See ya,

Brody

brody,

Thanks for you kind comment..

For some reason, your site didn't come up when I copied and pasted it into google….I must have copied wrong, not getting it all or something, I'll try again later..

But I did go the main site and sign up to build a site for the Ashland Air Rifle Range & Rentals…so that might occupy my time a little for a while…along with the outdoor layout of possibly sites and setup of the range…and building some of the new bases B.B. just described here..whoopee..moving forward!

Wayne

Wayne,

Let me know when it is finished, i will add it to my links. here try this link.

Link

Hope it works,

Brody

B.B.

Very impressive. I’m glad there are folks like Wayne who can do all this. Now, I just have to figure out a way to get up and see him.

I have a question about sights. One thing that swayed me in choosing the standard sights over the National Match for my Garand was a statement in the blog somewhere that it is easier to make a large aperture small than the reverse. You just cover the aperture with cardboard and make a hole of the desired size–a nice alternative to $150 for the NM. The National Match diameter is .052 inches which looks to be about a pinhole. The question is how effective is the cardboard alternative to the original on a scale of 1 to 10 with 10 being as good and 1 being terrible?

On the subject of the Japanese Arisaka mentioned yesterday, I recall that not only was its action unbelievably strong, but it was chambered for a 6.5mm cartridge. This caliber is certainly getting a lot of press now as the ideal balance between the light weight of the 5.56 and the power of the 7.62. I’ve read plenty of WWII memoirs where American soldiers scoffed at captured Japanese rifles as having terrible recoil and the Japanese as being bad shots. But now it seems that like the Russians, they were victims of propaganda and bad press and that their equipment was pretty good.

Derrick, thanks for the thread-locking tips although the line of blue loctite I put on the screw last time is holding firm so far.

Wayne, great news that you’re setting up a website, let us know when it is finished.

Matt61

BB,

Are you planning to tell us how to setup these Field targets up on a tree and on top of a rock?

Joe

brody,

It worked, thanks…that’s a great start…I hope to do as well on my temp site (I thought it best to get something, so I’m not doing business on the blog her too much, like B.B. asked) …check out the site my son Jason built for our cedar raised garden bed kits, we sell online…. http://www.naturalyards.com

He will build me a site when he’s done with the next upgrade.. we want to have a garden blog and keep the info in a data base, like B.B. is doing here..

Along with my interest in air guns… I’m doing research about how blogs interact with a website..

So I’m not going to put much effort into the temp site I signed up for.. just a place to store content and pictures, while I wait for the pro… he’ll probably be pissed at me for not waiting to do it right.. I’m so impulsive, he hates it… but at least it’s smart to grab the domain names, like I did…

But we love each other deeply.. and it feels good…

Your quite a techy for a young person… I saw your video..If you can do so well, I should be able to do something…. but I said that about my son too, when he was 15 and I never even got close to his abilities in the field…

But I’m a better carpenter and field target shooter.. (he’s not interested yet)

Wayne

Ashland Air Rifle Range (now dot com)!!!

hey bb,

sorry, i know i asked you this before but this time its for a friend. cann you reccomend a co2 semi-auto bb pistol that as many shots as possible from 1 co2. i know the crosman c11 only gets about 55 shots. he also want to keep it under $70

criitercontroller

Hi, BB,

I just have a crazy thought – can I load two pellets into the chamber so that my springer will fire two shots at the same time? Not sure why would I want to do that, but can that be done? Thanks.

Alan

B.B.,

Thank you for the info on the Diana 35. I read the other blogs on the 35 and it looks like a great plinking rifle. If you would like to see a picture of the rifle, the website is:

http://kikoauctions.com/listings/auction_listings/2008/081208switzer.htm

Sorry that I don’t really know how to put a web address into a blog comment.

Thanks,

Jim

Matt61,

The aperture conversion will work, and I don’t think for a moment you will do it. After you see what the rifle can do with the installed sight I think you;ll be satisfied.

B.B.

Jim,

That photo is difficult to see, but the rifle looks like a good one.

B.B.

Joe,

Up in a tree I can do, and the rock is simple, just lay a concrete base atop the rock and shim it level.

But maybe I’ll show you a crafty method of hiding a target in plain sight. It’s a trick I learned from Brad Troyer that fools the big boys with their astronomical observatory telescopes!

B.B.

CritterController,

50 shots is about it for a powerful BB pistol (one that shoots 400 + . Look for BB pistols that shoot down around 375 and don’t have blowback. They will sometimes get up to 80 shots per powerlet.

B.B.

Alan,

You can shoot two pellets from a gun but they will not go where you are aiming. And they will be difficult to load. Try it.

B.B.

Alan,

I tried it by accident, they both hit low..

I would only do it in a higher power gun though…. and use two lighter pellets.. I did it by accident in the S410 and it wasn’t any problem, but they were both very low, one 1″ lower than the other..

Wayne

B.B.

Thanks, that vindicates my decision about going with the G.I. sights. Clint Fowler must be used to dealing with elite shooters, so he was pushing hard for the National Match. But, I’ve heard that the originals are very good. They were supposed to be designed to hit targets routinely out to 600 yards and even up to 1100 yards like the Marines did at Belleau Wood. And my Dad said that during his hitch in the army, the sergeants did a demo where they hit every single pop up target out to 700 yards. For a guy who has never shot beyond 50 yards, I’d say that there is plenty of room to grow.

With my weapons acquisition program almost complete, I am now looking at long golden years of running ammo through my guns and improving my shooting skills. I noticed that the only book you recommended on shooting technique was Elmer Keith’s book. I will definitely look at it, but is there another one on rifle shooting? All I could find by a name person was material by G. David Tubb. His instructional DVDs that I’ve seen are okay although I don’t know that I learned much beyond the fact that he is a fantastic shot.

I even have an ideal for what I’m looking for which is a great performer who understands his field and knows how to write about it simply and clearly. This is exactly what I found with Jack Dempsey’s boxing manual, Championship Fighting which I have mentioned. The book begins, “What do you suppose would happen if a baby fell out of a two-story building onto the head of a truck driver below?” It then proceeds to draw out the lesson that you do not have to be big to hit hard; you just need to “put your body weight into fast motion.” And from this foundation, the whole system develops with perfect logic. Incredible. I’ve never seen anything like this. So, I’m wondering if there’s something equivalent in the shooting literature. By the way, the Dempsey book is going for $200 on Amazon, but I read the whole thing for free at the University of Illinois library at Urbana-Champaign, one of the great libraries of the country, and they will glad to send it to any library that requests it.

I have to say that I give you credit for finishing Frank Mann’s book, The Bullet’s Flight, because I stalled out. Undeniably, there is a ton of valuable information, but he is too convoluted. I suspect that amidst his good work that a lot of his activities are those of a backyard crank and to even get to this, there is his stately verbose style which is hinted at by the title and a bizarre choice of subject. Amidst the extensive testimonials at the beginning of the book about what a great guy he is there is one by his daughter talking about how great Frank Mann’s feet were and how vain he was about their high arches and how he could stand and walk on them all day long! And then when I read that he died partly because his book didn’t get a good popular reception, I don’t even know what to think. Maybe the raw data will do more for me at a more advanced stage.

Matt61

Wayne and Alan,

I shot four pellets at once out of the IZH 61 while I was learning about the indexing system. Two went out the barrel, and the crushed remains of the other two fell out of the breech. That cost me many days of misery thinking I had ruined the gun, but there were no ill effects.

Matt61

Matt61,

Of all the book I recommended, the crossbow book and Sixguns by Keith read the easiest.

B.B.

I saw the Japanese Arisaka mentioned in the comments yesterday and today. Weapons used by our enemies often carry a reputation, either over- or under-estimated, that differs from reality.

Of course the quality of rifles coming from the Japanese armories declined in quality over the course of the war as shortages in materials and US bombardments took their toll, but the Arisaka was one heck of a battle rifle in its “prime”.

Crude only in its later production, the Arisaka 99s produced through some point in 1942 show excellent workmanship – I know because my father-in-law (USMC) brought back a beautiful Arisaka Type 99 Short Rifle that he hand selected from thousands, which I own now. Nothing primitive about it, right down to the 1500m anti-aircraft site and other features found in the earlier production. Dust shield is still in place over the chamber (always discareded in combat due to the noise) and the Emperor’s Chrysanthemum on the forward receiver is in perfect condition (most were ground off prior to turning over to US forces to avoid dishonor).

The Arisaka Type 99 battle rifles used in WWII Pacific combat against US forces were chambered for the 7.7x58mm rimless round. The preceding Arisaka Models 1896 through 1911 (also known as Meiji 29th through 44th Year Type; beginning in 1905 commonly referred to as the Type 97) were chambered for the 6.5x50mm semi-rimmed round, which came under criticism during the Sino-Japanese War during the 1930s because they performed poorly against Chinese and mercenary troops armed with 7.9mm rifles.

7.7×58 ammo is available, and I suspect that its a very effective hunting round – there probably isn’t a mammal in the Western Hemisphere you couldn’t take with it. Rigging up a scope would require butchering the receiver, so I shoot it (occasionally) with open sights.

Brian

B.B.

You said that comfort is not considered in the spot the field target shooter shoots from…

But that's in an unofficial contest, the match director can set up what ever with in reason. (or something like that)

I'm so much more accurate when in an anarondack chair with my knee up and the gun on my knee, foot locked in the corner of the chair, elbows locked on the back rest and arm rest…a comfortable tripod…

than in the sitting on a cushion with no backrest… the more I do it the better I get of course, but the comfort level is about 1 out of 5…whereas the chair is 5 out of 5

I'm wondering how many other shooters there are like me, who would like the chairs for an unofficial contest, especially for a 1/2" hole at 50 yards or something…

Also, would the chair just keep us from getting stronger and better at the real contest… why practice at something that you can't do for real…. I'm hoping you'll say the customer's always right, give em what they want… but do they want it anyway.. how about it people?

Maybe it's just me and my bad back…

Wayne,

Ashland Air Rifle Range & Rentals

B.B.

I forgot to tell you, when I got the new high pressure tanks, I took the Air Arms S410 .177 up to 220 bar and just added 15 more shots to the 115 shot string posted a few blogs ago…

Still no “valve lock”…. perfectly on target for about 60 or 65 shots now on 7/8 of full power (982fps with JBS exacts), before having to start aiming high, and still only 1-1/2 mil dots at 90 shots (65 bar)to the end at 50 bar..(729fps)

Should I try for more? The gauge says 250 bar, but you said they are not always accurate.. They forgot to put the instruction book in my box and I keep forgetting to ask PA for one..

Oh, and don’t forget to compare the noise level of the s410 .22 to the Webley Raider 10, when the wind dies…and other head to head comparisons if you can…

I ordered the S410 carbine in .22…I hope the next shipment is on schedule… tomorrow, the 8th, we hope….

Wayne,

Ashland Air Rifle Range

Wayne,

…and you just reinvented Chairgun. Google it.

I also have a bad back, but I learned to compensate. If you are holding an AAFTA match, I’d use their rules. Part of the challenge is the sitting – though it is the most stable position.

From a chair these guns are almost unable to miss.

You can do whatever you want, which means you can run BOTH kinds of matches. Heck, we used to hold couple of Whacky matches every year, just to see how silly we could get. You know – Sheridan Blue Streaks and open sights and stuff like that.

It’s your place, do what you want.

B.B.

Wayne,

Sure! Creep up slowly to discover where valve lock kicks in. That way you’ll get the biggest string of good shots.

B.B.

B.B.

Your right about “these guns” not missing from a chair…

And, from what I read at the high price ($2,000 to $3,500) competitive guns sites about there advertised groups at 50 yards……

My $1,086, S410 .117 could compete…and maybe me too, if I can get that sitting position to be more comfortable..

and practice a “hole” lot more…

sorry FOUR the pun

Wayne

thank you. does blow back take co2?

crittercontroller

crittercontroller,

Yes, that’s what moves the slide.

B.B.

B.B., sounds good. I’m looking forward to the crossbow book.

Brian, that’s quite a treasure you’ve got. Is it accurate? It sounds like the conflict between bullet power and weight will go on forever regardless of the caliber.

Matt61

Yes, my Arisaka is reasonably accurate (probably moreso in the hands of a capable marksman). Sub-4″ groups at 100m aren’t too difficult with the peep sight these come with. Although occasional loud helicopter traffic over the house can be annoying, I haven’t tried out the anti-aircraft sights yet. 😉

Didn’t mention it before, but my 99 came with about the meanest 16″ bayonet I’ve ever seen.

Brian

Crittercontroller, what do you plan to ue the gun for?

Vince,

just plinking really. soda cans and other such targets.

CritterController

Critter Controller

You have been dangling your toes in the water regarding purchasing a pellet pistol for quite a while.

So, how about just taking the plunge and purchase a nice Co2 powered Crosman 357!

It has 10 shots per clip, it is very Inexpensive, it has a very good barrel, it has fully adjustable sights and with the safety on you can “dry-fire” it to practice the trigger pull without using any of the Co2 (the trigger is pretty decent as well). It also comes with a 2nd 10 round clip. I guarantee you could easily resell it if you found you wanted something else for any reason but once you have used it you won’t want to part with it.

It is a perfect “Plinking” gun.

If you have a Dick’s sporting goods nearby, check it out, they are not going to carry them in the future it seems and they are clearing them out at $35.00 each!

Otherwise, mail-order one from Pyramidair to payback all the great advice you are getting for free.

jba

revwarnut,

Thank you. i actually baught the crosman 357 on ur reccomendations, and i am glad i did and i wish i baught it years ago. and i agree with every thing u said it is all that and then some.. however my friend wants a co2 pistol but dont like my crosman 357. and i agree with ordering from pyramyd air kinda pays back for free advice wich i do make many orders from pyramyd. but this is a blog tom gaylord does it out of his own free will and doesnot have to give me any advice if he dont want to.

crittercontroller

Brad Troyer has a plan on making wood and metal field targets for practice.

http://www.airguns.net/ft_woodfieldtarget.php

Hello B.B.:

I am new at airgunning… And I have read a lot about rifle maintenance… BUT… I dont know what people mean by chamber, piston seals, leather, etc etc… Do you know were can I find a Cleaning and Maintenance Manual FOR DUMMIES??? Obviously, with pictures so that I can see clearly were to oil and with what… Thank You… By the way, keep up the good work sir…

New airgunner,

You are approaching this the wrong way. It’s not a homework assignment. There is no test.

Learning about airguns or anything else is a lifelong study. You pick things up gradually through reading. Often, you will learn something through context, but not always. For example, I have recently become interested in radio-controlled helicopters. They are just as jargonized as airguns – perhaps more so.

On the covers of the magazines (they have newsstand magazines!) they have the initials RTF and ARF with no explanation. It took me months to discover what these common acronyms mean, because nowhere in the magazine do they properly give the meanings with the acronym. Ready to fly (RTF) and almost ready to fly (ARF) helicopters are an important sales feature, but those in the business assume everyone who wants to buy their product knows the terms.

As far as cleaning goes you are in luck, because we don’

t clean airgun barrels unless there is a compelling reason to, like sudden inaccuracy. Otherwise, leave them alone. Steel airgun barrels are made from dead-soft steel and will not tolerate the mishandling that occurs during the cleaning of the bore. And they normally don’t need to be cleaned because they don’t get dirty in the conventional sense. There is no combustion when the gun fires, so the bore is free from deposits.

Have you read all the blogs and articles on this website? There are over 900, including everything, so that’s a good year’s reading to start with. Follow the links to other sites and there is an unlimited amount of material to read and eventually comprehend.

B.B.