by B.B. Pelletier

More than a decade ago, I saw a curious rifle at the Little Rock Airgun Expo. It looked something like a Beeman R1 but was quite a bit larger. When the seller told me that it was a handmade, one-of-a-kind rifle that was designed to be a more powerful R1, I couldn’t resist buying it. I had just published the R1 book, and here was a great follow-on story that needed to be told.

Steel dreams

The inventor of this rifle, Steve Vissage, had seen the Beeman R1 and wanted a rifle that would put a .22 pellet into the supersonic realm. That was quite a goal for a spring-piston gun of the early 1980s, and it still hasn’t been reached today by any except a few PCPs. Steve thought the best approach was to increase the diameter of the piston and to increase the length of the stroke – some of the same topics we frequently discuss on this blog.

Now I’ll tell you why I am making this report. A number of our new readers are asking the same questions that Steve Vissage asked back in 1981. What does it take to get more power from a spring-piston air rifle? Back in 1982, the R1 was the most powerful spring-piston gun in the world. At 940 f.p.s. in .177, it offered velocity undreamed of 5 years earlier.

When the R1 came out, Robert Beeman wrote in his catalog that it took more than just a powerful mainspring to boost power in a springer. But, because those catalogs are now collector’s items, a lot of newer airgunners haven’t had the opportunity to read them. Many who might have read them don’t believe what Beeman said. What Steve Vissage did is what many of you think should be possible today, and I want to share my observations on that topic.

Steel dreams become real things!

Vissage built three rifles, of which mine was the first. Let me explain what’s so different about talking about airguns and actually building them. When guys start discussing airguns, anything seems possible; but, whenever Vissage made a decision, it got locked into steel…not easily changed. Even if he did make some changes, there was still a cost involved for the original decision that was not followed. Steel dreams cost more and take longer than daydreams. If you don’t understand what I’m driving at, you will by the time this report is finished.

Let’s look at this rifle

A stock R1 weighs 8.9 lbs., give or take. Many new airgunners feel it’s far too heavy, and they’re also impressed by it’s sheer size. The Vissage rifle weighs 11 lbs. It’s also longer than the R1, but I don’t seem to have recorded the length. The barrel came from an Anschutz target rifle; and, since Anschutz doesn’t make target air rifles in .22 caliber, I think that means it’s a .22 rimfire barrel. So, accuracy was out the window, because .22 rimfire bores are several thousandths larger than air rifle bores, and don’t fit pellets very well.

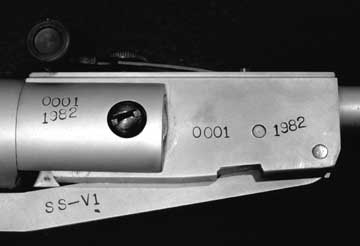

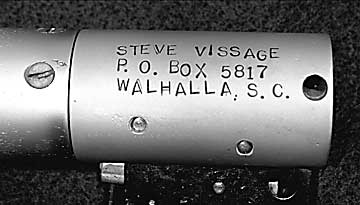

The spring tube, end cap, baseblock and cocking link are all custom-made parts. Steve told me he reckoned he put $600-700 1980’s dollars into making this one rifle. The wood stock came from an HW80. It was opened up to receive the 40-thousandths-larger spring tube. The forward stock screws are very close to the end of the forearm. Look closely at the first photo, and you’ll see they had to be moved forward almost an inch.

The sights are stock Weihrauch items, the same as come on an R1. There is no provision for mounting a scope. The entire rifle is plated with Armaloy, a tough material used on tactical handguns. It is said to resist wear and to be self-lubricating.

The trigger is a Rekord, which was very popular back in the 1980s. Vissage would have been able to get one easily, since they had been on the HW35 for at least 20 years at that time. This is a good place to reflect that he used the factory trigger and sights instead of inventing his own. By this point in the project, he’d sunk a lot of money into this rifle, and inventing a whole new trigger would have cost him more than all he had spent to this point. Don’t forget that all the internal parts – the piston and mainspring, for instance, have to be made from scratch, because the entire rifle has different dimensions than a standard R1.

Speaking of different dimensions, how does Vissage get a stock Rekord trigger to line up with the piston hook if all the internal dimensions are different? Details like that are always overlooked when guys talk about airguns; but, when you actually build one, you want to cock it!

I disassembled this rifle to examine the innards. I also tested it before and after disassembly. Next time, we’ll look deeper into the Vissage SS-1.

This is a very timely post for me: I saw one of these rifles at the Frederick show earlier this month. The vendor had some info on it, but didn’t know much about the condition of the internals.

A very interesting project.

B.B.,

Velocity. Power.

Great article on this attempt to push the air gun velocity barrier even further. The more I read your articles, the clearer it becomes that one of the most common themes in airguns, over a long history, is that faster is better in the consumers mind.

It never ceases to amaze me at how unwilling the American consumer is to become truly informed. We tend to want to simplify our criteria by focusing on one element in any purchase. Since we typically can’t “test drive” every air gun, velocity must be the measure of what is best. If we couldn’t test drive a car would we purchase the fastest without any regard for the quality of the steering?

I thoroughly enjoyed your article in the Shotgun News about The Four Horsemen of Magnum Airguns. A breakthrough in the race to velocity 30 years ago in the airgun world. Unfortunately, the race seems to continue to this day with the typical consumer still primarily focused on velocity and even less concerned about quality and accuracy.

Thanks for your unwavering commitment to the education of the airgunning segment of the populace. We need it now more than ever. A more informed consumer should result in a better overall designed air gun from the manufacturers.

kevin

Phil,

Since I lived in Maryland when I owned and sold this gun, you probably saw this one.

B.B.

Kevin,

Thank you for those kind comments. What I write comes from my own pent-up desire to know things when I was a reader. The authors didn’t seem to notice the things I felt were important, and now that I’m able to write, I’m making up for that omission.

Of course I am overlooking other things in my writings, and that’s going to frustrate the next generation of airgun writers into action.

B.B.

Kevin & B.B.

My thoughts exactly, if power is your goal, go for a PCP, trying to make a springer so powerful, seems to me to be a dead end.. When ever it get's so powerful, it gets too big and has too much recoil for most of us..

Sure we get caught in the marketing hoopla, and buy the damn thing, but then we are unhappy because we can't get groups with it.. and it beats us up to shoot it..

I don't read around a lot, but it seems like very few writers, are like B.B. and tell the truth about what works in an air rifle. In my humble, uninformed opinion, 900fps is as fast as a springer can go and still have an affordable, "shootable" gun.

This fact needs to be promoted more, so the consumer quits buying that high power crap that they end up unhappy with.. it will end up turning more people off to the sport than it brings in..

Wayne,

Ashland Air Rifle Range

BB,in the 80’s was there any knowledge of super-sonic diablo pellet behavior?I can’t wait for the next blog on this topic.this blog,and the adventures of wayne and the gang are something I look foreward to daily…I hope they give you pleasure and a tremendous sense of pride.you are 10 ft tall…frankb

Frank,

There certainly was knowledge of the ballistic performance of a supersonic diabolo pellet in the 1980s, but were airgunners aware of it? Probably not.

B.B.

B.B.

That is my point, why would the manufactures of the "new powerful air gun" want to tell us that the pellet doesn't do well at those speeds, when they just invested in a new model? This leads back the the "Flying Scotsman" issue..

It really is up to us consumers and honest writers like B.B. to lead the way with manufactures. Now is the time we can do it, with the internet and reviews and the like. It may be hard to paddle fast enough to get into the curl of the wave, and lead the way, but we should start paddling…(sorry, I use to be a surfer in Southern Cal as a kid)

Wayne,

AARR&R

Tom:

You wrote a blog, sometime back, about all the idea guys that approach airgun companies (and forums) with the next great idea. Typically they have no idea what it takes to create a product from scratch. You had a great story about what it really takes to get a company to look at a new product. Today’s blog reminded me of that one but I can’t seem to find it with the search. I’d like to re-read it. Any hints on keywords to find that original article would be appreciated. Thanks!

Chris

Chris,

Not a clue.

B.B.

Chris,

Here’s the article B.B. wrote you wanted to re-read.

/blog/2008/9/the-ultra-reliable-air-rifle/

kevin

B.B.,

Great blog. You mentioned that Steve Vissage said he had $600-$700 into this one rifle, but I wonder how many hundreds of hours he had already invested in its development before he ended up with something that actually worked, and worked every time. He probably had boxes of parts that that kind of worked, or worked for a while and then broke, or jammed. Building something from scratch, with your own design, is quite an accomplishment. My hat is off to Mr. Vissage.

Thanks for letting us in on this secret. I am anxious to hear more.

Lloyd

Lloyd,

Who said it worked? My guess is that Mr Vissage’s design was a complete failure in power and accuracy….We’ll see.

kevin

Kevin,

B.B. did describe it as a monster. Could be a pile of negatives. We’ll see.

Lloyd

B.B.

This seems like a quixotic idea from the very beginning. Why get a .22 pellet to shoot supersonic when it will lose accuracy? Was he hoping to use some brand of super-heavy .22s or a .25 caliber which is supposed to be less accurate than .22s anyway? And why the rimfire barrel when there are plenty of .22 air rifle barrels?

I will be interested, though, to hear why a more powerful mainspring will not give you arbitrarily high velocities even though it might cause other problems like increased recoil. I can’t say that I have the answer now.

On another note, I’m trying to figure out where the five .30-30 shells fit in the Winchester 94. From observing the action, it looks like they go nose to tail up into the fore-end. Is that right?

Matt61

Marc,

Sorry, I deleted my first post to you as I re-read your comments and realized it didn’t answer you adequately. First, upgrade your 1377 to the Crosman long steel breech. This gives you a real dovetailed base to mount the scope onto. Then I’d personally look at a Tasco RedDot sight or similar. If you must have scope magnification, you may need an offset (cantilevered) Leapers mount to move the scope far enough rearward. It’s tough to beat a Leapers scope for the money.

Derrick

Lloyd,

I’m sure you are right about the works Steve Vissage put into that gun before it worked. The next part should prove very interesting, indeed.

B.B.

Marc,

The scope you need isn’t going to come in a tiny package. Get a UTG (Leapers) 4X40 Tactedge long eye-relief scope and you will love it. It has a one-inch tube, so get rings for that. Leapers sells them.

B.B.

Matt,

Another reader asked the same question and I answered that back in the ’80s we didn’t know the accuracy would not be there. We had to go supersonic before we found out it didn’t work. And that happened around 1985.

It took another – well heck, most of the shooters in the world still don’t know that supersonic pellets aren’t accurate. That’s why Gamo and Benjamin keep upping the speed.

B.B.

It isn’t called the “School of Hard Knocks” for nutin’!

I have to give Steve Vissage credit. Most of us sit on the sidelines and criticize. He actually built something even if he did some of it wrong.

I’ll agree with anonymous and a little more — why isn’t anybody doing this sort of thing anymore? My guess is because its hard work and you can spend the same amount of money and much less time to get a proven design with cosmetic improvements. My opinions on the reasons for this are innappropriate for a blog of this type:).

bg_farmer, B.B. & All

It's time to tell the Mac1 Airguns story, don't you think..

He's doing it right now. He now owns the boot strap award of the century, as far as I'm concerned…

I only talked with Tim for an hour on the phone, I haven't met him in person.. I'm not up on the particulars, I hope B.B. and others will fill in.. but I'll start….

Tim and his design partner I think it's Les, decided to build the best most accurate Field Target rifle… The USFT, B.B. did a report on it, but not the creator that much..

Tim told me that he mortgaged his condo for $90,000 and they built a prototype that won contests and got attention enough to get orders from those who wanted to have the best chance to win, prepaid orders to the tune of a total $50,000 or so… $1,500 each.. Not knowing if the production models would be as good as the prototype. Tim also worrying that he would have to refund the money.. He had to deal with people that wanted it sooner than he could make them as they started coming out.. Billy lo won the 2005 nationals with the number 6 gun off the line.. (I hope these details aren't too far off). Now he is so back ordered it takes about a year to get one and people on the Gunbroker site are selling their place in line for a profit..

He told me that the price will just keep going up, and he will start to re-coop some investment. The price is $2,200 now, with some improvements, but will be $3,500 in a year, he bets.

I said when are you going to add workers and up production? Tim said, never. It is too hard to teach what he knows, and that isn't what he wants to do..each one his work. He also thinks the Field Target market is tapping out, and the real growth is in the Bench Rest market..

He said the next market is the "bench rest" contests that are springing up at the end of the Cartridge contests, which are becoming way to expensive to do for fun… or sport in some cases..

He is designing a model just for these contests and liked my idea of a video on how to use his rifles and how they preform with a novice to a pro like Billy Lo.. (that is probably why he talked to me for an hour, totally surprised me!) He also might join the Ashland Rifle Range..

He's a super nice guy to talk to, but don't call and bug him about your back order, he said those who do, loose a place in line… (he told me that, and then we talked for another 45 minutes… I felt so honored.. were "bootstrappen buddies"

Wayne,

AARR&R

Wayne,

Let me think about how I could portray Tim’s life. He has done so many things in airgunning over the years.

Maybe hitting some of the highlights would be a good approach?

B.B.

BB,

This blog is really interesting, and will await for part 2, 3, 4 …

I have read in your blog and some other internet sites about the Whiscombe.

you know any site with schematics of the internals?

I am very interested in seeing how Mr. Whiscombe managed to cock two pistons in opposite directions and link them to the trigger and time them to release simultaneously.

I think that as commercial enterprise this rifles were too expensive to compete with PCP’s which would produce more power, less recoil and should be easier to shoot, yet those Whiscombe Rifle must be a beautiful piece of machinery.

Mario J. Garcia-Incera

Mayaguez, P.R.

Mario,

No, I’m not aware of any website that has a schematic of the Whiscombe mechanism. The best I can show you is the photos of the cocking mechanism in the reports I did.

B.B.

Bless you B.B.

I would so love to know more without feeling guilty about keeping Tim off the production line..

Wayne,

AARR&R

Ahhh, springers ….and the love hate relationship we have with them. The pros and cons go on forever.

Anyhow, anyone run across an Air Arms 510? Just wondering.

BB – What’s your take on the issue of heavy pellets in powerful springers? I’ve seen comments by well-respected tuners suggesting it’s a bad idea because of piston bounce, but I’ve gotten the best accuracy with my Gamo Viper using Kodiaks and CP heavies. A couple thousand shots have produced no problems I can discern. It’s when I use lighter pellets that the gun jumps around and vibrates.

Airdog,

I don’t think heavy or light pellets are a problem until the gun tells you they are a problem. If the performance goes from smooth to rough, the gun is telling you to stop using that pellet.

B.B.

Wayne & BB,

Yes, MAC1 sounds like the kind of story I, for one, would like to hear more of. How about a JM story, too…

To Anonymous with the 1377 question:

With your current setup, you have too much eye relief. If you get a BSA 2×20 Pistol Scope [about $50] you can have your eye far away and still see clearly through the scope.

Better is to buy the Crosman steel breech [$30] from their website. The breech has a built-in 11mm dovetail. Your current rings should work OK, since 3/8” is only 2mm larger than 11mm.

–Witt

bg_farmer,

On topic of best low budget springer, under 900fps, someone mentioned a CZ Slavia 634 from the Czech Republic. I got a new one on Gun Broker for $139 or something..

It just came in and I've only run 10 shots across the crony. 760fps avg.

Very nice stock, nice sights, excellent shape and balance, like a quality 10 meter target rifle. and not bad bluing. Cocks at maybe 25 lbs, smooth as silk.. a few plastic parts, trigger & guard, but the important ones seem to be steel. Not bad trigger pull right out of the box, feels as good as the HW-30. (not to be confused with the HW-30s or R-7)

Were anxious to give it a try

Wayne,

AARR&R

Wayne, my recently acquired 634 was able to benefit from a little – and I do mean a little – tweaking.

Mine had a fair bit of friction in the cocking stroke – this was caused by the leaf spring ‘guide’ in the stock being a little too agressive. I flattened it a bit, and the gun cocks more easily now. I was also able to improve my trigger… I removed the blade (the pin slides right out when the action is out of the stock) and lightly dressed the mating faces on the trigger and intermediate lever. This can be done without any further disassembly of the trigger – very easy to do.

Another nice mid-powered shooter (about 30-40fps stronger than the CZ) is the old, discontinued Cometa-built RWS93. I was able to get a NEW one – the gunsmith at Umarex had one lying around – for less than the 634. It’s a large and fairly heavy rifle… but it’s easy to cock and the medium powerplant combined with the over 7lb weight results in a rifle that is extremely easy to shoot well. I also had to dress and lube the trigger mating faces (and mess with the spring guide a bit to de-twang it), but it’s a gun that is just so hard to put down.

The nice thing about both these rifles is that they’ll shoot Gamo Match, Gamo Hunter, Beeman Sportsman (Chinese), Crosman Premier, and RWS Superdomes all reasonably well. And in switching from one pellet to another the POI seems to shift no more than about 2 inches at 60 yards.

Love hate relationship with springers? Only love.

Matt61

Vince,

How cool, I also bought, some RWS93s from Umarex, I got some new RWS94, 93 and 92s and some reconditioned ones as well. unlike you, I don't get inside them at all, so for me without tweaking the trigger, the 93 is my least favorite, but only because of the trigger. The 94 has a different trigger, that is so light maybe 2 lbs. compared to the out of the box 93 maybe, what do you think 5 lbs? The RWS94 is also weighs about 7 lbs but it shoots 7.0 hobby at 1040fps, too fast.. but the 10.6 kodiak at a perfect 850fps. It cocks with about 30 lbs or less. But it has a little too much recoil for me, It's not that much, but after getting spoiled with PCPs, I don't like recoil at all, my groups just aren't as good. The RWS93 and 94 recoil almost the same for me… and there is where I like the 92 much more, the little 92, which is like a poor mans HW-30, shoots the hobby at 700fps…

I think your right the RWS93 with trigger tweaking, would be another great low cost springer… shooting about 750fps with an 8.4 JSB… actually all three of them with a little tweaking would be great for the money..

Why did they pull the three of them off the shelves? Probably to make room for something new from marketing, that was more powerful and cheaper to build..with four color boxes..

Wayne,

AARR&R

BG_Farmer,

How about a series called “Tales of the tuners?” Maccari and McMurray are but two of the guys who shaped our hobby. I have dealt with many of them, and watched some, like Paul Watts, grow up in this business.

B.B.

Thanks B.B.–what you gave us was a wiff of a home cooked apple pie-now that we are all set to eat it you put it on a back burner -talk about leaving your readersin suppense! I was dying to read more and then it ended!–Ever think of becomimg a suspense novel writer? Tell “mom” I can’t wait for a slice of that pie! P.S.–leapers still hasn’t discovered the problem but I should recieving my new scope today!

Lloyd,

This gun even looks like a monster. Look at that spring tube!! I’ll bet it takes two boys and a grown man to cock this thing.

kevin

B.B.

"Tales of the tuners" what a super series! Sounds like it will turn into a book…

Kevin,

I'll call your bet and raise a grown man..

Two boys and two grown men.. and all to stop the recoil

Wayne,

AARR&R

Scott298,

Yes, breaking that story was a dirty trick.

Friday.

B.B.

Wayne,

Always good to hear from you. I’m sure there’s recoil in this monster of a spring gun. Unlikely that his idea of an increased spring size resulted in the increased velocity he had hoped for. B.B. has done several articles about tuning and evolution of velocity wherein the attempt was made to increase velocity with a bigger spring. This isn’t the key but a longer sweep is. His article on the diana’s early on and one of their models (35?) that went to a bigger spring resulted in harder cocking, harsher firing, but no significant increase in velocity. The FWB 124 design figured out increase of velocity with utmost efficiency. I may be way off base but this is my justification for drawing the conclusions. We’ll see though…

kevin

Wayne, it’s weird how the trigger on the 93 went from so icky to so nice with so little work. The trigger is now no worse than my 634, and frankly I think it feels a little better.

I can see why the ’93 went down in the marketplace – the power just wasn’t there for the weight and price (although its velocity is a lot closer to some overrated ‘1000fps’ guns than one might think)… but for the life of me I can’t figure the demise of the ’94. Sure, it is a little heavier than a Gamo, but it does shoot harder and the trigger, construction, and firing behavior are far superior. It really is a delightful rifle. I guess Chinese and Trukish guns have a higher profit margin…

Kevin,

I’ve got a FWB 124 on the way, I’m really looking forward to trying it. I guess it will be a nicer, 634, in size, balance, trigger, and fps… it will be interesting to see how much better..

Vince,

I put a 3-9x50AO leapers on the CZ 634 last night, it sighted in with 4 shots. I love it.. the trigger is better than the HW-30 after only 100 shots… the recoil is just enough, I can deal with it.. it shoots with a real nice “thunk” like it was tuned… Maybe I just lucked out.. you said you tweaked yours.. Just because you can, or did it need it badly? I’m thinking the 634 could be a good one for the range, I wonder how they will hold up..

That is very encouraging about the ease of fixing the RWS93 trigger.. someday maybe, I’ll dive in to one..

Wayne,

Cometa, aren’t those made in Spain? They seem pretty popular in the UK. From what I hera, the Fenix 400 is suppose to be a pretty good good air rifle.

Wayne,

I’m envious. I’ve been “hunting” for a fwb 124 in good shape at a reasonable price. Anxious to hear how it compares to your other springers. The s410 must get boring after awhile. Parcticing technique on the springers keep it interesting don’t you think?

kevin

Kevin,

I was just thinking about that in a way. One of Randy’s friends said he liked to shoot a springer with a lot of recoil, to keep himself in better practice for his center fire rifles.

After shooting the win .270 and New England “Handi Rifle .243”, at the big boys range last weekend, I understand…

It didn’t take long to shoot $50 worth of sighting in rounds. and then another $50 to see if you can group. Meanwhile your ears are ringing even with good plugs, from your shots and your neighbors, a cold line is a serious event, and there is abuse to your body.

So any practice with a monster like the Vissage SS-1 would be a great thing..or a Falcon Hunter..or the like..

HHHMMMMM…..then I came home to my Air Arms s410, filled it, put it on half power and settled in for 130 shots at .03 per shot in my lazyboy….listening to Neil Young..

Wayne,

Ashland Air Rifle Range

B.B.

Nice article sir…. Let’s see how it performs, and if its truly powerful…

Cheers,

Jony

I think the RS94 was the same as the Fenix 400, and in its price range I cannot say enough good about it. It’s true that (at least in my hands) my Gamo’s are just as accurate – but in virtually every other respect it is much superior. My only criticism is the slanted breach (like the Diana breakbarrels) – it makes it harder to seat a tight-fitting pellet properly, and if it doesn’t get seated well the skirt gets mangled when you close the breach. This is really an issue only on the .22, on the smaller .177 it isn’t nearly as prone to this.

My 634 needed nothing badly, but I just wanted to smooth out the rougher edges. It’s entirely possible that I just got one that had a few minor flaws that yours might not have. Even so – all I did was reduce the friction in the cocking and trigger mechanisms. I didn’t open the powerplant at all.

Cool post by Tom, as always!

Tom wrote:

“Back in 1982, the R1 was the most powerful spring-piston gun in the world. At 940 f.p.s. in .177 […]”

Diana Mod. 48 was introduced in 1980. Today, the Mod. 48 shoots 1000 fps in .177 cal, and 870 fps in .22 cal., surpassing the R1 stats quoted above. I reckon this means that early Mod. 48’s were less powerful than today. I wonder what kind of velocities the early 1980’s 48’s achieved?

No doubt already in the early 80’s Weihrauch and Diana were in hot competition in the new Magnum airgun market segment. I’ve heard FWB 124 / 127 was a first here, but didn’t have near the same MV / KE as the HW80 / R1 and Mod. 48.

Continuing with the 80’s Magnum springer theme – when was Webley Patriot launched? I recall seeing ads for these already in the late 80’s. The Patriot snatched the World’s most powerful production springer title, no? It was obviously more powerful than anything Weihrauch or Diana produced, but I don’t think there were other serious contenders in the wider coil-springer realm then, either.

Ilimakko,

Howdy!

I think you’re a couple years early on the Diana 48.

BB

Huh?

Starting from the horse’s mouth:

https://www.diana-airguns.de/en/diana/history

Diana 48 / 52 dates from 1980. This jives with numerous other sources discussing Diana airguns.

Ilimakko,

Thank you, but in this instance I think Diana is mistaken. I was an airgunner at the time and their 48/52 did not come out until around 1983.

The Diana company was sold a few years ago and the new owners may have made a mistake when they created that timeline. Just to be sure, I will check some catalogs, but Diana was imported by RWS USA and I’m pretty sure I’m right about that. I checked it when I wrote the Beeman R1 book. It is the timing that makes all the difference.

BB

Tom,

I contacted Diana. They told me the D48 production started in January 1987, so years after the 1980 in their website timeline, or the 1983 that was suggested. This corresponds to two other lines of evidence I found in these past couple of days.

So, HW80 reigned supreme in the early 1980’s. Still, do you happen to have the date of Webley Patriot emergence?

Ilimakko,

Thank you for checking into that, but I think Diana got it wrong again. However, 1987 is the date the Blue Book says both the 48 and 52 began. I don’t think it’s correct, but I have no proof.

I remember the 48 being brought out much earlier than 1987. The 1983 date I gave was from memory. I remember the R1 came out at 940 f.p.s. in .177. Then it got bumped from 940 to 1,000 f.p.s. the next year. Then a year later the R1 Laser tune came out, bumping the .177 up to as high as 1,100 f.p.s sometimes. Then the 48 hit the streets at 1,100 f.p.s. out of the box and the R1 was knocked out of the running. That was either 1983 or 1984, as close as I can remember.

What I haven’t been able to find is proof of that. Beeman didn’t carry the 48 and Air Rifle Headquarters went out of business around 1980/81. What I need are 1983 and 1984 RWS USA catalogs that I haven’t got.

Then Beeman Kodiak, which is the Webley Patriot, came out in 1993.

BB